Abstract

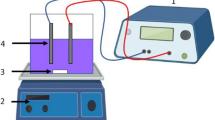

In this study, Taguchi experimental design was used to the optimize operating parameters for the degradation of paper mill effluent using electrochemical (EC) process with two-dimensional concentric aluminum tube electrodes (CATE). For this purpose, four significant experimental factors were used in four levels pH (6–9), electrolysis time (10–40 min), voltage (6–12 V) and surface area (357–624 cm2). The process parameters were optimized, through performing L16 orthogonal array of Taguchi technique, for the removal of chemical oxygen demand (COD) and turbidity. The percent COD and turbidity reductions were transferred into an accurate S/N ratio for a larger value is the better (LBT) response. The study presents a unique method of finding optimum combination of process parameters to illustrate their effect on the turbidity and COD reduction. The treatment conditions for the maximum elimination of the pollutants were second level of pH (7), third level of ET (30 min), fourth level of voltage (12 V) and second level of surface area (446 cm2). The confirmation experiment results were within the confidence intervals (CI) indicating an acceptable agreement between predicted and observed values. Based on the p-values, the electrolysis time and voltages were found to be the most significant factors for both COD and turbidity reduction. The findings of research indicated, that the Taguchi method can be used successfully for the treatment of paper industry effluent by electrochemical technique.

Similar content being viewed by others

References

Ashrafi O, Yerushalmi L, Haghighat F. Wastewater treatment in the pulp-and-paper industry: a review of treatment processes and the associated greenhouse gas emission. J. Environ. Manag. 2015;158:146–57.

Adeogun, AI, Bhagawati P, Shivayogimath C. Pollutants removals and energy consumption in electrochemical cell for pulping processes wastewater treatment: Artificial neural network, response surface methodology and kinetic studies. Journal of Environmental Management. 2021;281:1–12.

Ali M, Sreekrishnan T. Aquatic toxicity from pulp and paper mill effluents: a review. Adv. Environ. Res. 2001;5(2):175–96.

Hubbe MA, Metts JR, Hermosilla D, Blanco MA, Yerushalmi L, Haghighat F, et al. Wastewater treatment and reclamation: A review of pulp and paper industry practices and opportunities. Bio. Res. 2016;11(3):7953–8091.

Sridhar R, Sivakumar V, Prince Immanuel V, Prakash MJ. Treatment of pulp and paper industry bleaching effluent by electrocoagulant process. J. Hazard. Mater. 2011;186(2–3):1495–502.

Farooqi IH, Basheer F. Treatment of Adsorbable Organic Halide (AOX) from pulp and paper industry wastewater using aerobic granules in pilot scale SBR. J. Water Process Eng. 2017;19:60–6.

Kumar D, Sharma C. Remediation of Pulp and Paper Industry Effluent Using Electrocoagulation Process. J. Water Resour. Prot. 2019;11(3):296–310.

Karrasch B, Parra O, Cid H, Mehrens M, Pacheco P, Urrutia R, et al. Effects of pulp and paper mill effluents on the microplankton and microbial self-purification capabilities of the Biobío River. Chile Sci. Total Environ. 2006;359(1–3):194–208.

Kamali M, Khodaparast Z. Review on recent developments on pulp and paper mill wastewater treatment. Ecotoxicol. Environ. Saf. 2015;114:326–42.

Pokhrel D, Viraraghavan T. Treatment of pulp and paper mill wastewater - A review. Sci. Total Environ. 2004;333(1–3):37–58.

Mandal TN, Bandana TN. Studies on physicochemical and biological characteristics of pulp and paper mill effluents and its impact on human beings. J. Freshw. Biol. 1996;8(4):191–6.

Kamali M, Alavi-Borazjani SA, Khodaparast Z, Khalaj M, Jahanshahi A, Costa E, et al. Additive and additive-free treatment technologies for pulp and paper mill effluents: Advances challenges and opportunities. Water Res. Ind. 2019;21:100–9.

Tahreen A, Jami M, Ali F. Role of electrocoagulation in wastewater treatment: A developmental review. J. Water Process Eng. 2020;37:1–11.

Khan NA, Khan SU, Islam DT, Ahmed S, Farooqi IH, Isa MH. Performance evaluation of column-SBR in paper and pulp wastewater treatment: Optimization and bio-kinetics. Desalin. Water Treat. 2019;156:204–219.

Azadi Aghdam M, Kariminia HR, Safari S. Removal of lignin, COD, and color from pulp and paper wastewater using electrocoagulation. Desalin. Water Treat. 2016;57(21):9698–704.

AlJaberi FY, Abdulmajeed BA, Hassan AA, Ghadban ML. Assessment of an Electrocoagulation Reactor for the Removal of Oil Content and Turbidity from Real Oily Wastewater Using Response Surface Method. Recent Innov. Chem. Eng. 2020;13(1):55–71.

Apshankar KR, Goel S. Nitrate removal from drinking water using direct current or solar powered electrocoagulation. SN Appl. Sci. 2020;2(2):1–11.

Kobya M, Can OT, Bayramoglu M. Treatment of textile wastewaters by electrocoagulation using iron and aluminum electrodes. J. Hazard. Mater. 2003;100(1–3):163–78.

Mollah MYA, Schennach R, Parga JR, Cocke DL. Electrocoagulation (EC)—science and applications. J. Hazard. Mater. 2001;84(1):29–41.

Mollah MYA, Morkovsky P, Gomes JAG, Kesmez M, Parga J, Cocke DL. Fundamentals, present and future perspectives of electro coagulation. J. Hazard. Mater. 2004;114(1):199–210.

Vik EA, Carlson DA, Eikum AS, Gjessing ET. Electrocoagulation of potable water. Water Res. 1984;18(11):1355–60.

Chen G. Electrochemical technologies in wastewater treatment. Sep. Purif. Technol. 2004;38(1):11–41.

Mahvi AH, Ebrahimi SJ, Mesdaghinia A, Gharibi H, Sowlat MH. Performance evaluation of a continuous bipolar electrocoagulation/electrooxidation–electroflotation (ECEO–EF) reactor designed for simultaneous removal of ammonia and phosphate from wastewater effluent. J. Hazard. Mater. 2011;192(3):1267–74.

Daneshvar N, Oladegaragoz A, Djafarzadeh N. Decolorization of basic dye solutions by electrocoagulation: An investigation of the effect of operational parameters. J. Hazard. Mater. 2006;129(1–3):116–22.

Mechelhoff M, Kelsall GH, Graham NJD. Electrochemical behaviour of aluminium in electrocoagulation processes. Chem. Eng. Sci. 2013;95:301–12.

Bhagawati PB, Shivayogimath CB. Separation of pollutants from pulp mill wastewater by electrocoagulation. In Int. J. Energ. Technol. Policy. 2017;13(1–2):166–76.

Zodi S, Louvet JN, Michon C, Potier O, Pons MN, Lapicque F. Electrocoagulation as a tertiary treatment for paper mill wastewater: removal of non-biodegradable organic pollution and arsenic. Sep. Purif. Technol. 2011;81(1):62–8.

Gönder ZB, Arayici S, Barlas H. Treatment of pulp and paper mill wastewater using utrafiltration process: Optimization of the fouling and rejections. In Ind. Eng. Chem. Res. 2011;51(17):6184–95.

Amani Ghadim AR, Aber S, Olad A, Ashassi-Sorkhabi H. Optimization of electrocoagulation process for removal of an azo dye using response surface methodology and investigation on the occurrence of destructive side reactions. Chem. Eng. Process. Process Intensif. 2013;64:68–78.

Coimbra EC, Mounteer AH, Do Carmo AL, Michielsen MJ, Tótola LA, Guerino JP, et al. Electrocoagulation of Kraft pulp bleaching filtrates to improve biotreatability. Process. Saf. Environ. Prot. 2021;147:346–55.

Wagle D, Lin CJ, Nawaz T, Shipley HJ. Evaluation and optimization of electrocoagulation for treating Kraft paper mill wastewater. J. Environ. Chem. Eng. 2020;8(1):103595.

Pandey N, Thakur C. Statistical Comparison of Response Surface Methodology-Based Central Composite Design and Hybrid Central Composite Design for Paper Mill Wastewater Treatment by Electrocoagulation. Process Integration and Optim. Sustain. 2020;4(4):343–59.

Wan J, Huang M, Ma Y, Guo W, Wang Y, Zhang H. Prediction of effluent quality of a paper mill wastewater treatment using an adaptive network-based fuzzy inference system. Appl. Soft Comput. J. 2011;11:3238–46.

Zolgharnein J, Bagtash M, Asanjarani N. Hybrid central composite design approach for simultaneous optimization of removal of alizarin red S and indigo carmine dyes using cetyltrimethylammonium bromide-modified TiO2 nanoparticles. J. Environ. Chem. Eng. 2014;2(2):988–1000.

Davis R, John P. Application of taguchi-based design of experiments for industrial chemical processes. Statistical Approaches With Emphasis on Design of Experiments Applied to Chemical Processes 2018. https://doi.org/10.5772/intechopen.69501

Barrado E, Vega M, Pardo R, Grande P, Del Valle JL. Optimisation of a purification method for metal-containing wastewater by use of a Taguchi experimental design. Water Res. 1996;30(10):2309–14.

Hasani G, Maleki A, Daraei H, Ghanbari R, Safari M, McKay G. A comparative optimization and performance analysis of four different electrocoagulation-flotation processes for humic acid removal from aqueous solutions. Process. Saf. Environ. Prot. 2019;121:103–17.

Syam Babu D, Anantha Singh TS, Nidheesh PV, Suresh KM. Industrial wastewater treatment by electrocoagulation process. Sep. Sci. Technol. 2019:1–33.

Vepsäläinen M, Sillanpää M. Electrocoagulation in the treatment of industrial waters and wastewaters. Advanced Water Treatment 2020. https://doi.org/10.1016/B978-0-12-819227-6.00001-2

Kumar D, Sharma C. Reduction of chlorophenols and sludge management from paper industry wastewater using electrocoagulation process. Sep. Sci. Technol. (Philadelphia). 2020;55(15):2844–54.

Izadi A, Hosseini M, Najafpour Darzi G, Nabi Bidhendi G, Pajoum SF. Treatment of paper-recycling wastewater by electrocoagulation using aluminum and iron electrodes. J. Environ. Health Sci. Eng. 2018;16(2):257–64.

Camcioglu S, Ozyurt B, Hapoglu H. Effect of process control on optimization of pulp and paper mill wastewater treatment by electrocoagulation. Process. Saf. Environ. Prot. 2017;111:300–19.

Bhagawati PB, Shivayogimath CB. Studies on Electrochemical Treatment of Paper mill Effluent International Journal of Science, Technology, Engineering and Management - A VTU Publication 2020; 2(3) 24–32.

Kumar D, Gaurav VK, Sharma C. Ecofriendly Remediation of Pulp and Paper Industry Wastewater by Electrocoagulation and Its Application in Agriculture. Am. J. Plant Sci. 2018;9:2462–79.

Ozyonar F. Optimization of operational parameters of electrocoagulation process for real textile wastewater treatment using Taguchi experimental design method. Desalin. Water Treat. 2016;57(6):2389–99.

Deghles A, Kurt U. Treatment of raw tannery wastewater by electrocoagulation technique: optimization of effective parameters using Taguchi method. Desalin. Water Treat. 2016;57(32):14798–809.

Gönder ZB, Balcıoğlu G, Kaya Y, Vergili I. Treatment of carwash wastewater by electrocoagulation using Ti electrode: optimization of the operating parameters. Int. J. Environ. Sci. Technol. 2019;16(12):8041–52.

Apaydin O, Ozkan E. Landfill leachate treatment with electrocoagulation Optimization by using taguchi method. Desalin. Water Treat. 2020;173:65–76.

Thirugnanasambandham K, Sivakumar V, Shine K. Optimization of reverse osmosis treatment process to reuse the distillery wastewater using Taguchi design. Desalin. Water Treat. 2016;57(51):24222–30.

Oden MK, Sari EH. Treatment of metal plating wastewater using iron electrode by electrocoagulation process: Optimization and process performance. Process. Saf. Environ. Prot. 2018;119:207–17.

Yousefi Z, Zafarzadeh A, Ghezel A. Application of Taguchi’s experimental design method for optimization of Acid Red 18 removal by electrochemical oxidation process. Environ. Health Eng. Manag. 2018;5(4):241–8.

Asghari A, Kamalabadi M, Farzinia H. Electrochemical removal of methylene blue from aqueous solutions using taguchi experimental design. Chem. Biochem. Eng. Q. 2012;26(2):145–54.

Mukherjee T, Das P, Ghosh SK, Rahaman M. Removal of Alizarin red S from wastewater: Optimizing the process parameters for electrocoagulation using taguchi method. In: Ghosh S, editor. Wastewater Recycling and Management Singapore: Springer; 2019. p. 239–249.

Mengelizadeh N, Pourzamani H, Saloot MK, Hajizadeh Y, Parseh I, Parastar S. Electrochemical Degradation of Reactive Black 5 Using Three-Dimensional Electrochemical System Based on Multiwalled Carbon Nanotubes. J. Environ. Eng. 2019;145(5):04019021.

Dargahi A, Nematollahi D, Asgari G, Shokoohi R, Ansari A, Samarghandi MR. Electrodegradation of 2,4-dichlorophenoxyacetic acid herbicide from aqueous solution using three-dimensional electrode reactor with G/β-pbo2 anode: Taguchi optimization and degradation mechanism determination. RSC Adv. 2018;8(69):39256–68.

Khandegar V, Saroha AK. Effect of electrode shape and current source on performance of electrocoagulation. J. Hazar. Toxic, and Radioact. Waste. 2016; 20(1):1–4.

Kobya M, Ozyonar F, Demirbas E, Sik E, Oncel MS. Arsenic removal from groundwater of Sivas-Şarkişla Plain, Turkey by electrocoagulation process: Comparing with iron plate and ball electrodes. J. Environ. Chem. Eng. 2015;3(2):1096–106.

Hamdan SS, El-Naas MH. Characterization of the removal of Chromium(VI) from groundwater by electrocoagulation. J. Ind. Eng. Chem. 2015;20(5):2775–81.

AlJaberi FY. Operating cost analysis of a concentric aluminum tubes electrodes electrocoagulation reactor. Heliyon. 2019;5(8):e02307.

Mehdipoor MA, Moosavirad SM. Effect of Holed Ferrum electrodes (HFE) on the efficiency of the electrocoagulation process for copper recovery and optimization of parameters, using RSM. Hydrometallurgy. 2020;194:105313.

Khandegar V, Acharya S, Jain AK. Data on treatment of sewage wastewater by electrocoagulation using punched aluminum electrode and characterization of generated sludge. Data in Brief. 2018;18:1229–38.

Abbar AH, Salman RH, Abbas AS. Studies of mass transfer at a spiral wound woven wire mesh rotating cylinder electrode. Chem. Eng. Process. Process Intensif. 2018;127:10–6.

Hawari A H, Alkhatib AM, Das P, Thaher M, Benamor A. Effect of the induced dielectrophoretic force on harvesting of marine microalgae (Tetraselmis sp.) in electrocoagulation. J. Environ. Manag. 2020; 260: 1–7.

Gabe DR, Wilcox GD, Garcia JG, Walsh FC. The rotating cylinder electrode: Its continued development and application. J. Appl. Electrochem. 1998;28:759–80.

Salman HR. Removal of Manganese Ions (Mn2+) from a Simulated Wastewater by Electrocoagulation/ Electroflotation Technologies with Stainless Steel Mesh Electrodes: Process Optimization Based on Taguchi Approach. Iraqi J. Chem. Pet. Eng. 2019;20(1):39–48.

APHA, AWWA, WEF. Standard Methods for the examination of water and wastewater. Washington DC: American public health association; 1995.

Ross PJ. Taguchi techniques for quality engineering, 2nd edn. New York: McGraw-Hill; 1996.

Pardeshi PM, Mungray AA, Mungray AK. Determination of optimum conditions in forward osmosis using a combined Taguchi-neural approach. Chem. Eng. Res. Des. 2016;109:215–25.

Phadke MS. Quality engineering using robust design. Prentice Hall. Pignatello: Englewood Cliffs, NJ; 1989.

Overbeek JTG. Recent developments in the understanding of colloid stability. J. Colloid Interface Sci. 1977;58(2):408–22.

Lyklema J. Fundamentals of interface and colloid science: Particulate colloids. Amsterdam: Elsevier; 2005.

Aoudj S, Khelifa A, Drouiche N, Hecini M, Hamitouche H. Electrocoagulation process applied to wastewater containing dyes from textile industry. Chem. Eng. Process. Process Intensif. 2010;49(11):1176–82.

Shamaei L, Khorshidi B, Perdicakis B, Sadrzadeh M. Treatment of oil sands produced water using combined electrocoagulation and chemical coagulation techniques. Sci. Total Environ. 2018;645:560–72.

Chen X, Chen G, Yue PL. Investigation on the electrolysis voltage of electrocoagulation. Chem. Eng. Sci. 2002;57(13):2449–55.

Mongomery DC. Design and Analysis of Experiments. 9th edition. New York: John Wiley and Sons Inc; 2017.

Barman G, Kumar A, Khare P. Removal of congo red by carbonized low-cost adsorbents: Process parameter optimization using a Taguchi experimental design. J. Chem. Eng. Data. 2011;56(11):4102–8.

Salman R H, Hassan HA, Abed KM, Al-Alawy AF, Tuama DA, Hussein KM, Jabir HA. Removal of chromium ions from a real wastewater of leather industry using electrocoagulation and reverse osmosis processes. In AIP Conference Proceedings. 2020: 0201861–12.

Mani N, Suchithra B, Saravana Thamizhan, R, Prakash DG. Optimization of parameters for dye removal by electrooxidation using Taguchi Design. J. Electrochem. Sci. Eng. 2014; 4(4)4): 227–34.

Silva MB, Carneiro LM, Silva JPA. dos Santos Oliveira, I, Filho H JI, de Oliveira Almeida C R. An Application of the Taguchi Method (Robust Design) to Environmental Engineering: Evaluating Advanced Oxidative Processes in Polyester-Resin Wastewater Treatment. Am. J. Anal. Chem. 2014;5(13):828–37.

Yildiz YŞ, Şenyiǧit E, Irdemez Ş. Optimization of specific energy consumption for Bomaplex Red CR-L dye removal from aqueous solution by electrocoagulation using Taguchi-neural method. Neural Comput. & Applic. 2013;23(3–4):1061–9.

Acknowledgements

We gratefully thank Visvesvaraya Technology University, Jnana Sangama, Belagavi for support extended to this research work. The authors would also like to thank Basaveshwar Engineering College, Bagalkot, Karnataka for providing research facilities and encouragement.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors would like to declare that there is no conflicts of interest regarding the publication of this paper.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bhagawati, P.B., Shivayogimath, C.B. Electrochemical technique for paper mill effluent degradation using concentric aluminum tube electrodes (CATE). J Environ Health Sci Engineer 19, 553–564 (2021). https://doi.org/10.1007/s40201-021-00627-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40201-021-00627-8