Abstract

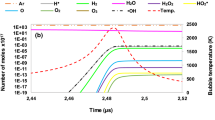

The bubbles of water jet cavitation and of multifunction cavitation (MFC) generated by nozzles with diameters of 0.1, 0.2 and 0.8 mm were investigated for the collapse pressure of microjets, the nozzle-specimen distance, the degree of processing, the photocatalyst characteristics for titanium oxide particles, and the multi-bubble sonoluminescence. The dependence of these characteristics on the nozzle diameter was clarified. The nozzle-specimen distance became shorter as the nozzle diameter decreased. The titanium oxide powder was processed with MFC using 0.8, 0.2 and 0.1 mm water jet nozzles. More hydrogen was generated with a nozzle diameter of 0.8 mm than with a 0.1 mm nozzle. A 0.2 mm nozzle generated less hydrogen than a 0.1 mm nozzle because the water jet pressure from a 0.2 mm nozzle was lower. A 0.1 mm nozzle produced the same luminous intensity from cavitation bubbles as a 0.8 mm nozzle. These results mean that the bubble temperature attained by 0.1 and 0.8 mm nozzles is relatively high. The smaller the nozzle diameter becomes, the smaller the bubble diameter and the lower the collapse pressure of the microjet, which leads to a lower degree of processing and reduced influence on photocatalytic properties.

Similar content being viewed by others

REFERENCES

Engel, O.G., A Model for Multiple-Drop-Impact Erosion of Brittle Solid: NASA Contractor Report No. CR-1943, Washington, DC: Natl. Aeronaut. Space Admin., 1971, p. 1.

Summers, D.A., Waterjetting Technology, London: E&FN Spon, 1995. ISBN 9780419196600

Miller, R.K., Waterjet Cutting: Technology and Industrial Applications Paperback, Lilburn: Fairmont, 1991. ISBN-10: 0881730688, ISBN-13: 978-0881730685.

Hashish, M., Characteristics of surfaces machined with abrasive-waterjets, J. Eng. Mater. Technol., 1991, vol. 113, p. 354.

Hashish, M., A modeling study of metal cutting with abrasive waterjets, J. Eng. Mater. Technol., 1984, vol. 106, p. 88.

Mayuet, P.F., Girot, F., Lamíkiz, A., Fernández-Vidal, S.R., et al., SOM/SEM based characterization of internal delaminations of CFRP samples machined by AWJM, Procedia Eng., 2015, vol. 132, p. 693.

Saitou, N., Enomoto, K., Kurosawa, K., Morinaka, R., Hayashi, R., Ishikawa, T., and Yoshimura, T., Development of water jet peening technique for reactor internal components of nuclear power plant, J. Jet Flow Eng., 2003, vol. 20, no. 1, p. 4.

Ijiri, M., Shimonishi, D., Nakagawa, D., and Yoshimura, T., Evolution of microstructure from the surface to the interior of Cr–Mo steel by water jet peening, Mater. Sci. Appl., 2017, vol. 8, no. 10, p. 708.

Yoshimura, T., Tanaka, K., and Yoshinaga, N., Development of mechanical-electrochemical cavitation technology, J. Jet Flow Eng., 2016, vol. 32, no. 1, p. 10.

Yoshimura, T., Tanaka, K., and Yoshinaga, N., Material processing by mechanical-electrochemical cavitation, Proc. 23rd Int. Conf. on Water Jetting, Washington, 2016, p. 223.

Yoshimura, T., Tanaka, K., and Yoshinaga, N., Nano-level material processing by multifunction cavitation, Nanosci. Nanotechnol. Asia, 2018, vol. 8, no. 1, p. 41.

Yoshimura, T., Maeda, D., Ogi, T., Kato, F., and Ijiri, M., Sonoluminescence from ultra-high-temperature and high-pressure cavitation and its effect on surface modification of Cr-Mo steel, Global J. Technol. Optim., 2020, vol. 11, no. 2. https://doi.org/10.4172/gjto.2020.11.240

Kling, C.L., A High Speed Photographic Study of Cavitation Bubble Collapse: Cavitation and Multiphase Flow Laboratory Report No. 03371-2-T, Ann Arbor, MI: Univ. Michigan, 1970.

Summers, D.A., et al., Consideration in the design of a waterjet device for reclamation of missile casings, Proc. Fourth U.S. Water Jet Conf., Berkeley: Univ. Calif., 1987. p. 82.

Yoshimura, T., Tanaka, K., and Ijiri, M., Nanolevel surface processing of fine particles by waterjet cavitation and multifunction cavitation to improve the photocatalytic properties of titanium oxide, in Cavitation—Selected Issues, London: InTech Open, 2018. https://doi.org/10.5772/intechopen.79530

Yoshimura, T., Ijiri, M., Shimonishi, D., and Tanaka, K., Micro-forging and peening aging produced by ultra-high-temperature and pressure cavitation, Int. J. Adv. Technol., 2019, vol. 10, no. 1, p. 1, https://doi.org/10.24105/0976-4860.10.227

Ijiri, M. and Yoshimura, T., Evolution of surface to interior microstructure of SCM435 steel after ultra-high-temperature and ultra-high-pressure cavitation processing, J. Mater. Process. Technol., 2018, vol. 251, p. 160.

Sadighi-Bonabi, R., Rezaee, N., Ebrahimi, H., and Mirheydari, M., Interaction of two oscillating sonoluminescence bubbles in sulfuric acid, Phys. Rev. E, 2010, vol. 82, p. 016316-1.

Didenko, Y.T., McNamara, W.B., and Suslick, K.S., Effect of noble gases on sonoluminescence temperatures during multibubble cavitation, Phys. Rev. Lett., 2000, vol. 84, no. 4, p. 777.

Sivalingam, G., Agarwal, N., and Madras, G., Distributed midpoint chain scission in ultrasonic degradation of polymers, AIChE J., 2004, vol. 50, no. 9, p. 2258.

Basedow, A.M. and Ebert, K.H., Ultrasonic degradation of polymers in solution, Adv. Polym. Sci., 1977, vol. 22, p. 83.

Rayleigh, L., On the pressure developed in a liquid during the collapse of a spherical cavity, Philos. Mag., 1917, vol. 34, no. 200, p. 94.

Plesset, M.W., The dynamics of cavitation bubbles, J. Appl. Mech., 1949, vol. 16, no. 3, p. 277.

William, B., McNamara, W.B. III, Didenko, Y.T., and Suslick, K.S., Sonoluminescence temperatures during multi-bubble cavitation, Nature, 1999, vol. 401, p. 772.

Sehgal, C., Steer, R.P., Sutherland, R.G., and Verrall, R.E., Sonoluminescence of argon saturated alkali metal salt solutions as a probe of acoustic cavitation, J. Chem. Phys., 1979, vol. 70, p. 2242.

Didenko, Y.T. and Pugach, S.P., Spectra of water sonoluminescence, J. Phys. Chem., 1994, vol. 98, p. 9742.

Matula, T.J., Roy, R.A., Mourad, P.D., McNamara, W.B. III, and Suslick, K.S., Comparison of multibubble and single-bubble sonoluminescence spectra, Phys. Rev. Lett., 1995, vol. 75, p. 2602.

Yasui, K., Fundamentals of acoustic cavitation and sonochemistry, in Theoretical and Experimental Sonochemistry Involving Inorganic Systems, Pankaj and Ashokkumar, M., Eds., New York: Springer-Verlag, 2011, chap. 1, pp. 1–29.

Gompf, B., Gunther, R., Nick, G., Pecha, R., and Eisenmenger, W., Resolving sonoluminescence pulse width with time-correlated single photon counting, Phys. Rev. Lett., 1997, vol. 79, p. 1405.

Gaitan, D.F., Crum, L.A., Church, C.C., and Roy, R.A., Sonoluminescence and bubble dynamics for a single, stable, cavitation bubble, J. Acoust. Soc. Am., 1992, vol. 91, no. 6, p. 3166.

Brenner, M.P., Hilgenfeldt, S., and Lohse, D., Single-bubble sonoluminescence, Rev. Mod. Phys., 2002, vol. 74, p. 425.

Ijiri, M. and Yoshimura, T., Sustainability of compressive residual stress on the processing time of water jet peening using ultrasonic power, Heliyon, 2018, vol. 4, p. e00747. https://doi.org/10.1016/j.heliyon.2018

Niishiro, R. and Kudo, A., Development of visible-light-driven TiO2 and SrTiO3 photocatalysts doped with metal cations for H2 or O2 evolution, Solid State Phenom., 2010, vol. 162, p. 29.

Liu, H., Yuan, J., Shangguan, W., and Teraoka, Y., Visible-light-responding BiYWO6 solid solution for stoichiometric photocatalytic water splitting, J. Phys. Chem. C, 2008, vol. 112, no. 23, p. 8521.

Yoshimura, T., Komura, M., and Sato, K., Study on improved photocatalytic properties of titanium oxide by ejector method, J. Jet Flow Eng., 2014, vol. 30 no. 2, p. 4.

Minnaert, M., On musical air-bubbles and the sound of running water, Philos. Mag., 1993, vol. 16, no. 104, p. 235. https://doi.org/10.1080/14786443309462277

Atchley, A., The Blake threshold of cavitation nucleus having a radius-dependent surface tension, J. Acoust. Soc. Am., 1988, vol. 85, no. 1, p. 152.

Peng, G., Oguma, Y., and Shimizu, S., Numerical simulation of unsteady cavitating jet by a compressible bubbly mixture flow method, IOP Conf. Ser.: Earth Environ. Sci., 2018, vol. 163, art. ID 012037. https://doi.org/10.1088/1755-1315/163/1/012037

Peng, G., Tryggvason, G., and Shimizu, S., Two-dimensional direct numerical simulation of bubble cloud cavitation by front-tracking method, IOP Conf. Ser.: Mater. Sci. Eng., 2015, vol. 72, art. ID 012001. https://doi.org/10.1088/1757-899X/72/1/012001

Ijiri, M., Shimonishi, D., Tani, S., Okada, N., Yamamoto, M., Nakagawa, D., Tanaka, K., and Yoshimura, T., Multifunction cavitation technology to improve the surface function of Al-Cu alloy, Int. J. Lightweight Mater. Manuf., 2019, vol. 2, p. 50.

Funding

This research was supported in part by the Japan Society for the Promotion of Science, Grant-in-Aid for Scientific Research C, Grant no. 16K06029, and by the Light Metal Educational Foundation, Inc.

Author information

Authors and Affiliations

Corresponding authors

About this article

Cite this article

Toshihiko Yoshimura, Shimonishi, D., Hashimoto, D. et al. Effect of Processing Degree and Nozzle Diameter on Multifunction Cavitation. Surf. Engin. Appl.Electrochem. 57, 106–116 (2021). https://doi.org/10.3103/S1068375521010154

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068375521010154