Abstract

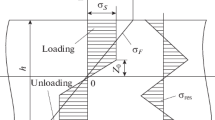

The final stage in the production of hot rolled steel is leveling on roller levelers under cyclic alternating deformation. When laser cuts a sheet, it may bend due to the release of residual stresses that are unevenly distributed over the volume. The majority of roller leveler models for calculating the process under cyclic alternating deformation does not provide an adequate assessment and prediction of residual stresses in a steel sheet. On the basis of finite element analysis, formation of residual stresses due to roller leveling of hot rolled strip is disclosed. The implementation of a leveling process model was performed in SIMULIA Abaqus. Models are verified by comparing forces under the rollers. We have experimentally confirmed the convergence of the simulation results with the measurements of the strip flatness obtained after sheets plasma cutting. It was found that after leveling, tensile longitudinal residual stresses remain on the upper surface of the sheet, compressive ones remain on the lower surface, stresses are zero in the middle in thickness, and the stress values are opposite in sign in the remaining parts of the section. It was established that the same parameters of the leveling process of different strength categories lead to different deviations of stresses. An increase in yield strength of the strip leads to an increase in the deviation of residual stresses along the strip thickness. The proposed method of simulation of roller leveling process should be used to study the stress-strain state of hot-rolled steel and to design improved strip leveling setting modes with minimal residual stress deviations.

Similar content being viewed by others

REFERENCES

Garber, E.A., Bolobanova, N.L., and Trusov, K.A., Application of the finite element method to reveal the causes of loss of planeness of hot-rolled steel sheets during laser cutting, Russ. Metall. (Engl. Transl.), 2018, vol. 2018, no. 1, pp. 103–108.

Tselikov, A.I., Polukhin, P.I., and Grebenik, V.M., Mashiny i agregaty metallurgicheskikh zavodov. Tom 3. Mashiny i agregaty dlya proizvodstva i otdelki prokata (Machines and Units of Metallurgical Plants, Vol. 3: Machines and Units for Production and Finishing of Rolled Products), Moscow: Metallurgiya, 1988.

Slonim, A.Z. and Sonin, L.A., Mashiny dlya pravki listovogo i sortovogo prokata (Machines for Leveling of Sheet and Long Products), Moscow: Metallurgiya, 1987.

Nedorezov, I.V., Modelirovanie protsessov pravki prokata na rolikovykh mashinakh (Modeling of Leveling Processes on Roller Machines), Yekaterinburg: AKVA-press, 2003.

Shinkin, V.N., Approximate methods for calculating a (2n + 1)-regular sheet leveling machine. Part 1: First approximation, Aktual. Probl. Gumanit. Estestv. Nauk, 2017, no. 2, pp. 40–44.

Shelest, A.E., Yusupov, V.S., Perkas, M.M., Sheftel’, E.N., Prosvirnin, V.V., and Akopyan, K.E., Development of a method for determining the geometric and deformation parameters of metal sheets levelling on roller machines, Proizvod. Prokata, 2016, no. 7, pp. 2–8.

Salganik, V.M. and Zaitsev, D.A., Mathematical description of the process of cold levelling of thick sheets, Aktual. Probl. Sovrem. Nauki, Tekh. Obraz., 2016, vol. 1, no. 1, pp. 56–59.

Maksimov, E.A., Shatalov, R.L., and Vasil’ev, Yu.S., Refinement of the methodology for calculating the parameters of levelling thick sheets on a roller machine, Stal’, 2017, no. 1, pp. 35–38.

Gruber, M., Oligschläger, M., and Hirt, G., Adjusting of roller levellers by finite element simulations including a closed-loop control, Adv. Mater. Res., 2014, vol. 1018, pp. 207–214.

Behrens, B.-A., El Nadi, T., and Krimm, R., Development of an analytical 3D-simulation model of the levelling process, J. Mater. Process. Technol., 2011, vol. 211, no. 6, pp. 1060–1068.

Madej, L., Muszka, K., Perzynski, K., Majta, J., and Pietrzyk, M., Computer aided development of the levelling technology for flat products, CIRP Ann., 2011, vol. 60, no. 1, pp. 291–294.

Liu, Z., A new curvature analytical method in plate levelling process, ISIJ Int., 2018, vol. 58, no. 6, pp. 1094–1101.

Chen, W., A 2.5-dimensional analytical model of cold leveling for plates with transverse wave defects, J. Iron Steel Res. Int., 2015, vol. 22, no. 8, pp. 664–671.

Doege, E., Menz, R., and Huinink, S., Analysis of the leveling process based upon an analytic forming model, CIRP Ann., 2002, vol. 51, no. 1, pp. 191–194.

Silvestre, E., Sáenz de Argandoña, E., Galdos, L., and Mendiguren, J., Testing and modeling of roll levelling process, Key Eng. Mater., 2014, vols. 611–612, pp. 1753–1762.

Gruber, M. and Hirt, G., Numerical investigation of a process control for the roller leveling process based on a force measurement, Mater. Sci. Forum, 2015, vol. 854, pp. 249–254.

Gruber, M., Oligschläger, M., and Hirt, G., The effect of the initial stress and strain state in sheet metals on the roller levelling process, Key Eng. Mater., 2015, vol. 651, pp. 1023–1028.

Gruber, M. and Hirt, G., A strategy for the controlled setting of flatness and residual stress distribution in sheet metals via roller levelling, Procedia Eng., 2017, vol. 207, pp. 1332–1337.

Garber, E.A., Bolobanova, N.L., and Trusov, K.A., Detection and elimination of reasons of flatness loss in hot-rolled steel sheets during laser-beam cutting, Proizvod. Prokata, 2017, no. 6, pp. 11–15.

Garber, E.A., Bolobanova, N.L., and Trusov, K.A., Simulation of stresses and deformations in plane steel strip during its straightening in roller leveler, Chern. Metall., Byull. Nauchno-Tekh. Ekon. Inf., 2018, no. 1, pp. 68–73.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by S. Avodkova

About this article

Cite this article

Kotov, K.A., Bolobanova, N.L. & Nushtaev, D.V. Modeling the Stress State of a Steel Strip with a Roller Leveling Machine under Cyclic Alternating Deformations. Steel Transl. 50, 750–755 (2020). https://doi.org/10.3103/S0967091220110091

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091220110091