Abstract

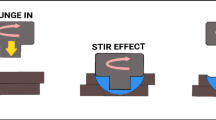

Synergetic double-sided probeless friction stir spot welding is a novel process proposed in this study, which is used to solve the contradiction between the improvement of metallurgical bonding and deterioration of hook defect. The effect of the coordinated movement of the tools on the joint formation was evaluated based on the coupled Eulerian-Lagrangian technique. By flexibly adjusting the welding parameters on both sides, the mechanical interlock caused by hook defect could be effectively regulated while significantly improving the metallurgical bonding, due to the enhancement of thermo-mechanical cycle along the thickness direction. According to the microstructure analysis, the interfacial evolution was ascribed to the combined effects of plastic deformation, material flow, atom diffusion, and recrystallization, as well as local abrasion. In addition, the microhardness profile exhibited a uniform distribution. Based on the above characteristics, the technology is expected to obtain higher strength joints, which will promote its applications in the manufacture fields.

Similar content being viewed by others

References

Wang FF, Li WY, Shen J, Zhang ZH, Santos JFD (2016) Global and local mechanical properties and microstructure of bobbin tool friction-stir-welded Al-Li alloy. Sci Technol Weld Join 21(6):479–483. https://doi.org/10.1080/13621718.2015.1132128

Chu Q, Li WY, Yang XW, Shen JJ, Li YB, Wang WB (2017) Study of process/structure/property relationships in probeless friction stir spot welded AA2198 Al-Li alloy. Weld World 61(2):291–298. https://doi.org/10.1007/s40194-017-0423-3

Xiao RS, Zhang XY (2014) Problems and issues in laser beam welding of aluminum-lithium alloys. J Manuf Process 16(2):166–175. https://doi.org/10.1016/j.jmapro.2013.10.005

Ji SD, Meng XC, Huang RF, Ma L, Gao SS (2016) Microstructures and mechanical properties of 7 N01-T4 aluminum alloy joints by active-passive filling friction stir repairing. Mater Sci Eng A 664:94–102. https://doi.org/10.1016/j.msea.2016.03.131

Xu RZ, Ni DR, Yang Q, Liu CZ, Ma ZY (2017) Influence of Zn coating on friction stir spot welded magnesium-aluminium joint. Sci Technol Weld Join 22(7):512–519. https://doi.org/10.1080/13621718.2016.1266735

Xu ZW, Li ZW, Ji SD, Zhang LG (2018) Refill friction stir spot welding of 5083-O aluminum alloy. J Mater Sci Technol 34(5):878–885. https://doi.org/10.1016/j.jmst.2017.02.011

Schmal C, Meschut G, Buhl N (2019) Joining of high strength aluminum alloys by refill friction stir spot welding. Weld World 63:541–550. https://doi.org/10.1007/s40194-018-00690-0

Tozaki Y, Uematsu Y, Tokaji K (2010) A newly developed tool without probe for friction stir spot welding and its performance. J Mater Process Technol 210(6-7):844–851. https://doi.org/10.1016/j.jmatprotec.2010.01.015

Badarinarayan H, Shi Y, Li X, Okamoto K (2009) Effect of tool geometry on hook formation and static strength of friction stir spot welded aluminum 5754-O sheets. Int J Mach Tool Manu 49(11):814–823. https://doi.org/10.1016/j.ijmachtools.2009.06.001

Cao JY, Wang M, Kong L, Guo LJ (2016) Hook formation and mechanical properties of friction spot welding in alloy 6061-T6. J Mater Process Technol 230:254–262. https://doi.org/10.1016/j.jmatprotec.2015.11.026

Chu Q, Li WY, Yang XW, Shen JJ, Vairis A, Feng WY, Wang WB (2018) Microstructure and mechanical optimization of probeless friction stir spot welded joint of an Al-Li alloy. J Mater Sci Technol 34(10):1739–1746. https://doi.org/10.1016/j.jmst.2018.03.009

Cox CD, Gibson BT, Delapp DR, Strauss AM, Cook GE (2014) A method for double-sided friction stir spot welding. J Manuf Process 16(2):241–247. https://doi.org/10.1016/j.jmapro.2013.10.006

Evans WT, Cox C, Gibson BT, Strauss AM, Cook GE (2016) Two-sided friction stir riveting by extrusion: a process for joining dissimilar materials. J Manuf Process 23:115–121. https://doi.org/10.1016/j.jmapro.2016.06.001

Yang XW, Feng WY, Li WY, Xu YX, Chu Q, Ma TJ, Wang WB (2018) Numerical modelling and experimental investigation of thermal and material flow in probeless friction stir spot welding process of Al 2198-T8. Sci Technol Weld Join 23:704–714. https://doi.org/10.1080/13621718.2018.1469832

Yazdi SR, Beidokhti B, Sabzevar MH (2019) Pinless tool for FSSW of AA 6061-T6 aluminum alloy. J Mater Process Technol 267:44–51. https://doi.org/10.1016/j.jmatprotec.2018.12.005

Chu Q, Yang XW, Li WY, Zhang Y, Lu T, Vairis A, Wang WB (2018) On visualizing material flow and precipitate evolution during probeless friction stir spot welding of an Al-Li alloy. Mater Charact 144:336–344. https://doi.org/10.1016/j.matchar.2018.07.026

Wang FL, Han L, Zhong J (2009) Stress-induced atom diffusion at thermosonic flip chip bonding interface. Sensor Actuat A-Phys 149(1):100–105

Zhang C, Li H, Li MQ (2016) Detailed evolution mechanism of interfacial void morphology in diffusion bonding. J Mater Sci Technol 32:259–264. https://doi.org/10.1016/j.sna.2008.11.006

Zhang C, Li H, Li MQ (2017) Role of surface finish on interface grain boundary migration in vacuum diffusion bonding. Vacuum 137:49–55. https://doi.org/10.1016/j.vacuum.2016.12.021

Chu Q, Li WY, Hou HL, Yang XW, Vairis A, Wang C, Wang WB (2019) On the double-side probeless friction stir spot welding of AA2198 Al-Li alloy. J Mater Sci Technol 35:784–789. https://doi.org/10.1016/j.jmst.2018.10.027

Wang FF, Li WY, Shen J, Wen Q, Santos JFD (2018) Improving weld formability by a novel dual-rotation bobbin tool friction stir welding. J Mater Sci Technol 34(1):135–139. https://doi.org/10.1016/j.jmst.2017.11.001

Yuan W, Mishra RS, Carlson B, Verma R, Mishra RK (2012) Material flow and microstructural evolution during friction stir spot welding of AZ31 magnesium alloy. Mater Sci Eng A 543:200–209. https://doi.org/10.1016/j.msea.2012.02.075

Zhang C, Li H, Li MQ (2016) Detailed analysis of surface asperity deformation mechanism in diffusion bonding of steel hollow structural components. Appl Surf Sci 371:407–414. https://doi.org/10.1016/j.apsusc.2016.03.039

Malard B, Geuser FD, Deschamps A (2015) Microstructure distribution in an AA2050 T34 friction stir weld and its evolution during post-welding heat treatment. Acta Mater 101:90–100. https://doi.org/10.1016/j.actamat.2015.08.068

Funding

The authors would like to gratefully acknowledge the financial support of the State Key Laboratory of Solidification Processing [2019-QZ-01] and the National Natural Science Foundation of China [51875470].

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

About this article

Cite this article

Chu, Q., Li, W.Y., Zou, Y.F. et al. Preliminary investigation of a novel process: synergetic double-sided probeless friction stir spot welding. Weld World 65, 1441–1449 (2021). https://doi.org/10.1007/s40194-021-01106-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-021-01106-2