Abstract

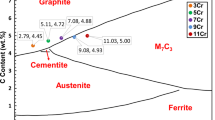

Fast removal of soft phases (e.g., pearlite and ferrite) in the iron matrix limits the wear life of high-Cr white irons. To address this shortcoming, the authors successfully produced fine networks of M6C carbide in a high-Cr white iron through extensive thermodynamic calculations. Fishbone-like networks of M6C carbides were observed with an optical microscope. It was experimentally determined that such carbide networks protected the soft matrix and increased the overall hardness. Additionally, electron backscattered diffraction was conducted, which showed that the alloy contained phases of M7C3, M6C, ferrite, and retained austenite. Solidification sequence was determined by correlating the thermodynamic equilibrium calculation results with the size and distribution of each phase. A dry sand/rubber wheel apparatus following ASTM standard G65 Procedure A was utilized to assess the abrasive wear performance of the developed alloy. Results showed that the volume loss of the developed material was 25 pct less than that of conventional high-Cr white irons. Wear scars were investigated using a scanning electron microscope, and the improved wear resistance was attributed to the “buffer” effect and plastic deformation of the introduced M6C carbide networks.

Similar content being viewed by others

References

J. Wan, J. Qing and M. Xu: MS&T18, Columbus, 2018, pp. 430–37.

J. Wan, P. W. Habecker, J. Qing and M. Xu: AFS Transaction, 2019, vol. 127, pp.19-31.

J. Wan, J. Qing, and M. Xu: AISTech, Pittsburgh, 2019, pp. 1041–52.

M. F. Buchely, J. C. Gutierrez, L. M. Leon and A. Toro: Wear, 2005, vol. 259, pp. 52-61.

A. Bedolla-Jacuinde, M. W. Rainforth and I. Mejia: Metall. Trans. A, 2013, vol. 44, pp. 856-72.

J.-Y. Su, Q.-D. Zhou, and Y.-D. Jia: in ASME, New York, 1987.

O. F. Higuera-Cobos, F. D. Dumitru & D. H. Mesa-Grajales: Fac. Ing., 2016, vol. 25, no. 41, pp. 93-103.

K. Hokkirigawa, K. Kato and Z. Z. Li: Wear, 1988, vol. 123, pp. 241-51.

J. A. Hawk, R. D. Wilson, J. H. Tylczak and O. N. Dogan: Wear, 1999, vol. 225, pp. 1031-42.

J. H. Tylczak, J. A. Hawk and R. D. Wilson: Wear, 1999, vol. 225, pp. 1029-69.

D. Tolfree: Thesis, “Investigation of the Gouging Abrasion Resistance of Materials in the Mining Industry” McGill University, 2000.

Annual Book of ASTM Standards, “ASTM Designation G81-97A,” ASTM, 2018.

J. Wan, D. C. Van Aken, J. Qing, T. J. Yaniak, T. C. Clements, and M. Xu: Wear, 2019, Vol. 436-37, p. 202967.

J. Wan, J. Qing and M. Xu: Metall. Trans. A, 2019, vol. 50, no. 3, pp. 1162-74.

P. Nurthen, O. Bergman, and I. Hauer: Carbide Design in Wear Resistant Powder Materials, in PM2008 World Congress, Washington, 2008.

W. Shen, L. Yu, Z. Li, Y. He, Q. Zhang, H. Zhang, Y. Jiang, and N. Lin: Met. Mater. Int., 2017, vol. 23, pp. 1150-57.

A. S. Chaus: Mater. Sci. Technol., 2014, vol. 30, pp. 1105-15.

X. Zhou, X. Yin, F. Fang, J. Jiang, and W. Zhu: J. Rare Earths, 2012, vol. 30, pp. 1075-78.

19. K. Frisk, J. Bratberg, A. Markström (2005) CALPHAD Comput. Coupling Phase Diagrams Thermochem. 29:91-96

ASTM: Annual Book of ASTM Standards, “ASTM Designation G65-16,” ASTM,, West Conshohocke, 2016.

S. Liu, Y. Zhou, X. Xing, J. Wang, X. Ren, and Q. Yang: Sci. Rep., 2016, vol. 6, pp. 32941-46.

J.J. Penagos, F. Ono, E. Albertin, and A. Sinatora: Wear, 2015, Vols. 340-341, pp. 19-24.

M. W. Hyttel, D. D. Olsson, G. Reisel, and J. Bøttiger: Wear, 2013, vol. 307, pp. 134-41.

T. Prucha (2020) Int. J. Metalcast. doi:10.1007/s40962-020-00502-6

P. A. Ramosa, P. P. Brito, C. E. Santos, C. Vieira, and E. R. Silva: Int. J.Refract. Met. Hard Mater., 2020, vol. 86, p. 105119.

27. J. Wan, D. C. VanAken, J. Qing, M. Xu (2020) Int. J. Metalcast. 1:20. doi:10.1007/s40962-020-00502-6

D. Casellas, J. Caro, S. Molas, J. M. Prado, and I. Valls: Acta Materialia, 2007, vol. 55, pp. 4277-86.

A. Bedolla-Jacuinde, F. Guerra, I. Mejia, and U. Vera: Metals, 2019, vol. 9, p. 1321.

Acknowledgements

The authors would like to thank Dr. David C. Van Aken for his technical guidance. James Liggett is acknowledged for his help on English editing. The FEI Helios NanoLab dual beam FIB was obtained with a Major Research Instrumentation grant from the National Science Foundation under contract DMR-0723128.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted on September 4, 2021; accepted February 13, 2021.

Rights and permissions

About this article

Cite this article

Wan, J., Lu, Y., Qing, J. et al. Developing a M6C-Reinforced High-Cr White Iron for Abrasive Wear Application. Metall Mater Trans A 52, 1976–1984 (2021). https://doi.org/10.1007/s11661-021-06207-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06207-7