Abstract

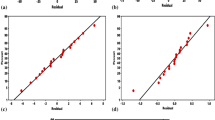

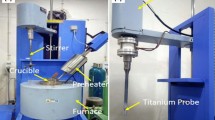

In the present study, the effect of electromagnetic stirring parameters, including stirring time, pouring temperature and stirring frequency, on the morphology of the AM60 alloys was investigated using Taguchi-based grey relational analysis (TGRA). Each parameter of the process was analyzed at three levels. To accommodate all parameters, an orthogonal array L9 based on the Taguchi approach was used. The optimum parameters were chosen, using different microstructural responses such as shape factor, roundness, average grain size, average grain density and average aspect ratio. The optimal processing parameters were found to be 240 s, 30 Hz and 610 °C for stirring time, stirring frequency and pouring temperature, respectively. Results showed that the shape factor, roundness and average grain density were improved by 33%, 12.8% and 5.5%, respectively. Moreover, the average grain size and the aspect ratio decreased compared to those related to the preliminary set of experimental parameters, which represents the refining of the primary α-Mg phases. In addition, optimal experiment shows a dramatic improvement in tensile strength, uniform elongation and hardness compared to the initial conditions. Besides, the overall grey relational grade was compared to an initial set of experimental parameters, showing an improvement of 64%.

Similar content being viewed by others

References

M.K. Kulekci, Magnesium and its alloys applications in automotive industry. The International Journal of Advanced Manufacturing Technology 39(9–10), 851–865 (2008)

M. Pekguleryuz, M. Celikin, Creep resistance in magnesium alloys. Int. Mater. Rev. 55(4), 197–217 (2010)

F. Pan, M. Yang, X. Chen, A review on casting magnesium alloys: modification of commercial alloys and development of new alloys. J. Mater. Sci. Technol. 32(12), 1211–1221 (2016)

A. Luo, A. Sachdev, Microstructure and mechanical properties of magnesium-aluminum-manganese cast alloys. Int. J. Metalcast. 4(4), 51–59 (2010)

J. Wannasin, R. Canyook, S. Wisutmethangoon, M. Flemings, Grain refinement behavior of an aluminum alloy by inoculation and dynamic nucleation. Acta Mater. 61(10), 3897–3903 (2013)

Y. Zhang, G. Wu, W. Liu, L. Zhang, S. Pang, W. Ding, Microstructure and mechanical properties of rheo-squeeze casting AZ91-Ca magnesium alloy prepared by gas bubbling process. Mater. Des. 67, 1–8 (2015)

L. Zhang, G.-H. Wu, S.-H. Wang, W.-J. Ding, Effect of cooling condition on microstructure of semi-solid AZ91 slurry produced via ultrasonic vibration process. Transactions of Nonferrous Metals Society of China 22(10), 2357–2363 (2012)

M.A. Easton, M. Qian, D. StJohn (2009) Grain refinement in alloys: novel approaches.

C. Wang, A. Chen, L. Zhang, W. Liu, G. Wu, W. Ding, Preparation of an Mg–Gd–Zn alloy semisolid slurry by low frequency electro-magnetic stirring. Mater. Des. 84, 53–63 (2015)

M.S. Chang, Use of Taguchi method to develop a robust design for the magnesium alloy die casting process. Mater. Sci. Eng., A 379(1–2), 366–371 (2004)

K.C. Apparao, A.K. Birru, Optimization of Die casting process based on Taguchi approach. Materials Today: Proceedings 4(2), 1852–1859 (2017)

I. Dumanić, S. Jozić, D. Bajić, J. Krolo, Optimization of semi-solid high-pressure die casting process by computer simulation, Taguchi method and Grey relational analysis. Int. J. Metalcast. 15, 108–118 (2021). https://doi.org/10.1007/s40962-020-00422-5

M.A. Easton, H. Wang, J. Grandfield, C.J. Davidson, D.H. StJohn, L.D. Sweet, M.J. Couper, Observation and prediction of the hot tear susceptibility of ternary Al-Si-Mg alloys. Metallurgical and Materials Transactions A 43(9), 3227–3238 (2012)

Y. Chen, L. Zhang, W. Liu, G. Wu, W. Ding, Preparation of Mg–Nd–Zn–(Zr) alloys semisolid slurry by electromagnetic stirring. Mater. Des. 95, 398–409 (2016)

S.-F. Liu, L.-G. Kang, H. Han, L.-Y. Liu, X.-Q. Zou, H.-H. Guo, Influence of electromagnetic stirring on microstructure of AZ91-0 8% Ce magnesium alloy. Journal of central south university of technology. 13(6), 613–617 (2006)

X.-L. Zhang, T.-J. Li, H.-T. Teng, S.-S. Xie, J.-Z. Jin, Semisolid processing AZ91 magnesium alloy by electromagnetic stirring after near-liquidus isothermal heat treatment. Mater. Sci. Eng., A 475(1–2), 194–201 (2008)

L.K. Pan, C.C. Wang, Y.C. Hsiao, K.C. Ho, Optimization of Nd: YAG laser welding onto magnesium alloy via Taguchi analysis. Opt. Laser Technol. 37(1), 33–42 (2005)

C. Lin, Use of the Taguchi method and grey relational analysis to optimize turning operations with multiple performance characteristics. Mater. Manuf. Processes 19(2), 209–220 (2004)

J. Lin, C. Lin, The use of the orthogonal array with grey relational analysis to optimize the electrical discharge machining process with multiple performance characteristics. Int. J. Mach. Tools Manuf 42(2), 237–244 (2002)

M.-J. Tsai, C.-H. Li, The use of grey relational analysis to determine laser cutting parameters for QFN packages with multiple performance characteristics. Opt. Laser Technol. 41(8), 914–921 (2009)

R. Rao, V. Yadava, Multi-objective optimization of Nd: YAG laser cutting of thin superalloy sheet using grey relational analysis with entropy measurement. Opt. Laser Technol. 41(8), 922–930 (2009)

W. Wei, G.-H. Wu, Q.-D. Wang, Y.-G. Huang, S. Ming, W.-J. Ding, Investigation of flux containing GdCl3 on recycling Mg-Gd-Y-Zr scraps. Transactions of Nonferrous Metals Society of China 18, s292–s298 (2008)

G.-H. Wu, W. Wei, S. Ming, Q.-D. Wang, W.-J. Ding, Influence of GdCl3 addition on purifying effectiveness and properties of Mg-10Gd-3Y-0 5 Zr alloy. Transactions of Nonferrous Metals Society of China. 20(7), 1177–1183 (2010)

O. Lunder, T.K. Aune, K. Nisancioglu, Effect of Mn additions on the corrosion behavior of mould-cast magnesium ASTM AZ91. Corrosion 43(5), 291–295 (1987)

Y.-J. Li, T.-J. Luo, Y.-S. Yang, Effects of trace element and purification on properties of AZ80 magnesium alloy. Transactions of Nonferrous Metals Society of China 20, s407–s410 (2010)

H. Matsubara, Y. Ichige, K. Fujita, H. Nishiyama, K. Hodouchi, Effect of impurity Fe on corrosion behavior of AM50 and AM60 magnesium alloys. Corros. Sci. 66, 203–210 (2013)

D. Brabazon (2014) 5.07 Routes to Spheroidal Starting Material for Semisolid Metal Processing.

C.-Y. Kung, K.-L. Wen, Applying grey relational analysis and grey decision-making to evaluate the relationship between company attributes and its financial performance—a case study of venture capital enterprises in Taiwan. Decis. Support Syst. 43(3), 842–852 (2007)

N. Tosun, Determination of optimum parameters for multi-performance characteristics in drilling by using grey relational analysis. The International Journal of Advanced Manufacturing Technology 28(5–6), 450–455 (2006)

P.K. Sahu, S. Pal, Multi-response optimization of process parameters in friction stir welded AM20 magnesium alloy by Taguchi grey relational analysis. Journal of Magnesium and Alloys 3(1), 36–46 (2015)

M. Yousefieh, M. Shamanian, A. Saatchi, Optimization of the pulsed current gas tungsten arc welding (PCGTAW) parameters for corrosion resistance of super duplex stainless steel (UNS S32760) welds using the Taguchi method. J. Alloy. Compd. 509(3), 782–788 (2011)

A. Musfirah, A. Jaharah, Magnesium and aluminum alloys in automotive industry. J. Appl. Sci. Res. 8(9), 4865–4875 (2012)

A.H. Jabbari, M. Sedighi, Investigation of electromagnetic and mechanical stirring sequence effects on production of magnesium matrix nanocomposite. Int. J. Metalcast. 14, 489–504 (2020). https://doi.org/10.1007/s40962-019-00374-5

Y. Lei, H. Hai, S.-W. Gu, H.-W. Dong, X.-G. Zhang, Effects of electromagnetic stirring on microstructure and mechanical properties of super light Mg-Li-Al-Zn alloy. Transactions of nonferrous metals society of China 20, s388–s392 (2010)

R. Kesharwani, S. Panda, S. Pal, Multi objective optimization of friction stir welding parameters for joining of two dissimilar thin aluminum sheets. Procedia Materials Science 6, 178–187 (2014)

S. Khalilpourazary, N. Payam, Optimization of the injection molding process of Derlin 500 composite using ANOVA and grey relational analysis. Journal of Computational & Applied Research in Mechanical Engineering (JCARME) 6(1), 39–50 (2016)

N.F. Mehr, H. Aashuri, The effects of annular electromagnetic stirring parameters on microstructure evolution of rheocast AZ91 magnesium alloy. Journal of Materials Research and Technology 8(2), 2300–2308 (2019)

C. Limmaneevichitr, S. Pongananpanya, J. Kajornchaiyakul, Metallurgical structure of A356 aluminum alloy solidified under mechanical vibration: An investigation of alternative semi-solid casting routes. Mater. Des. 30(9), 3925–3930 (2009)

H.-I. Chen, J.-C. Chen, J.-J. Liao, The influence of shearing conditions on the rheology of semi-solid magnesium alloy. Mater. Sci. Eng., A 487(1–2), 114–119 (2008)

D. Min, J. Shen, S. Lai, J. Chen, Effect of heat input on the microstructure and mechanical properties of tungsten inert gas arc butt-welded AZ61 magnesium alloy plates. Mater. Charact. 60(12), 1583–1590 (2009)

Y.-F. Wang, S.-D. Zhao, C.-Y. Zhang, Microstructures and mechanical properties of semi-solid squeeze casting ZL104 connecting rod. Transactions of Nonferrous Metals Society of China 28(2), 235–243 (2018)

M.K. Aghayani, B. Niroumand, Effects of ultrasonic treatment on microstructure and tensile strength of AZ91 magnesium alloy. J. Alloy. Compd. 509(1), 114–122 (2011)

Acknowledgement

Financial support provided by Shahid Chamran University of Ahvaz (Ahvaz, Iran) through Grant No. SCU.EM98.788 is gratefully appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Eftekhar, A.H., Sadrossadat, S.M. & Reihanian, M. Statistical Optimization of Electromagnetic Stirring Parameters for Semisolid AM60 Slurry Using Taguchi-Based Grey Relational Analysis. Inter Metalcast 16, 212–222 (2022). https://doi.org/10.1007/s40962-021-00586-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-021-00586-8