Abstract

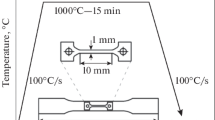

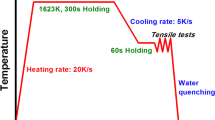

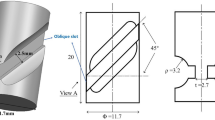

The intrinsic factor of crack defect in continuous casting slab is determined by the high-temperature mechanical properties of slab itself. At present, the measurement for the thermal mechanical properties is mostly achieved by Gleeble Hot-Tensile test. However, the uneven temperature distribution in the specimen during the test will definitely affect the accuracy of the measured mechanical properties. To acquire accurate high-temperature mechanical properties, studies of the temperature distribution in the tensile specimen and its effect on mechanical properties is significant. In this paper, A three-dimensional electromagnetic model and a three-dimensional Joule thermal model for the as-cast steel specimen in Hot-Tensile test were built to study current density and temperature distribution in the specimen. It was found that temperature difference between surface and center of steel specimen reaches 62 °C, when the test temperature is 1300 °C. An average absolute difference method was used to calibrate the inhomogeneous distribution of temperature. Compared with the original test, the difference of the tensile strength between the calibrated and original test decreased from 26 to 10 MPa with test temperature increasing from 800 °C to 1300 °C.

Similar content being viewed by others

References

J. Brimacombe and K. Sorimachi: Metall. Trans. B., 1977, vol. 8, pp. 489-505.

B. Böttger, M. Apel, B. Santillana, and D. Eskin: Metall. Mater. Trans. A., 2013, vol. 44, pp. 3765-77.

A.H. Bui and V.H. Nguyen: J. Met. Mater. Miner., 2020, vol. 30, pp. 80–85.

M. Merklein and J. Lechler: J. Mater. Process. Technol., 2006, vol. 177, pp. 452-55.

X. Qiang, F. Bijlaard, and H. Kolstein: Steel Construction, 2012, vol. 30, pp. 73-79.

A.A. Kuril, G.J. Ram, and S.R. Bakshi: Metall. Mater. Trans. B., 2019, vol. 50B, pp. 2029–36.

V. Euser, D. Williamson, K. Clarke, K. Findley, J. Speer, and A. Clarke: Metall. Mater. Trans. B., 2019, vol. 50, pp. 3654-62.

Z. Chen, P. Nash, and Y. Zhang: Metall. Mater. Trans. B., 2019, vol. 50, pp. 1718-28.

D.J. Seol, Y.M. Won, T. Yeo, K.H. Oh, J.K. Park, and C.H. Yim: ISIJ Int., 1999, vol. 39, pp. 91-98.

C. Zhang, M. Bellet, M. Bobadilla, H. Shen, and B. Liu: Metall. Mater. Trans. A., 2010, vol. 41, pp. 2304-17.

S. Brown, J. James, and J. Spittle: Modell. Simul. Mater. Sci. Eng., 1997, vol. 5, pp. 539-48.

J. Spittle, S. Brown, J. James, and R. Evans: Proc. 7th Int. Symposium on Physical Simulation of Casting, 1997, pp. 93–99.

S. Semiatin, D. Mahaffey, N. Levkulich, and O. Senkov: Metall. Mater. Trans. A., 2017, vol. 48, pp. 5357-67.

H. Ye, C. Basaran, and D. Hopkins: Appl. Phys. Lett., 2003, vol. 82, pp. 1045-47.

J. Martins, J. Alves, D. Neto, M. Oliveira, and L. Menezes: Int. J. Adv. Manuf. Tech., 2016, vol. 83, pp. 897-909.

D. Mattis and J. Bardeen: Phys. Rev., 1958, vol. 111, pp. 412-17.

M. van Rooyen and T.H. Becker: J. Strain Anal. Eng. Des., 2018, vol. 53, pp. 117-29.

L. Zheng, T. Lee, N. Liu, Z. Li, G. Zhang, J. Mi, and P. Grant: Mater. Des., 2017, vol. 117, pp. 157-17.

C. Zhang, M. Bellet, M. Bobadilla, H. Shen, and B. Liu: Inverse Probl. Sci. Eng., 2011, vol. 19, pp. 485-508.

M. Hojny: Modeling Steel Deformation in the Semi-Solid State, 2nd ed., Springer International Publishing AG, Switzerland, 2018, pp. 103-16.

D.J. Seol, Y.M. Won, K.H. Oh, Y.C. Shin, and C.H. Yim: ISIJ Int., 2000, vol. 40, pp. 356-63.

M.N. Ãzisik, M.N. Özısık, and M.N. Özışık: Heat Conduction, Wiley, New York, 1993, p. 145.

M. Greconici, G. Madescu, and M. Mot: Skin effect analysis in a free space conductor, Facta Univ. Ser. Electron. Energet., 2010, vol. 23, pp. 207–15.

H.A. Wheeler: Proc. IRE, 1942, vol. 30, pp. 412–24.

D. Clarke and J. Hemp: Flow Meas. Instrum., 2009, vol. 20, pp. 22-37.

Z. Nie, Y. Hou, J. Deng, P.A. Ramachandran, S. Wen, and W. Ma: Appl. Therm. Eng., 2017, vol. 125, pp. 856-69.

C. Yan, W. Li, X. Di, Z. Xue, S. Bai, and F. Liu: J. Cent. South Univ. Technol., 2007, vol. 14, pp. 319-23.

X. Li: Numerical Simulation and Experimental Verification of JOULE Effect in Gleeble Thermo-Mechanical Simulating Test (Thesis), Shanghai Jiao Tong University, Shanghai, 2012, pp. 31–33.

Y. Zhou, Y. Yang, G. Yang, D. Yin, Y. Qin, and J. Liu: Manuf. Rev., 2015, vol. 2, pp. 18.

X. Xie, S. Yu, M. Long, D. Chen, H. Duan, H. Chen, H. Fan, and T. Liu: Numer. Heat Transfer, Part A, 2017, vol. 72, pp. 642-56.

M. Peet, H. Hasan, and H. Bhadeshia: Int. J. Heat Mass Transfer, 2011, vol. 54, pp. 2602-08.

G. Chester and A. Thellung: Proceedings of the Physical Society, 1961, vol. 77, pp. 1005-13.

E. Kardoulaki, J. Lin, D. Balint, and D. Farrugia: J. Strain Anal. Eng. Des., 2014, vol. 49, pp. 521-32.

M. Faisal, E. El-Shenawy, and M.A. Taha: Mater. Sci. Appl., 2017, vol. 8, pp. 273-280.

E. Gorkunov, S.Y. Mitropolskaya, D. Vichuzhanin, and E. Tueva: Physical Mesomechanics, 2011, vol. 14, pp. 85-93.

N. Takahashi, M. Morishita, D. Miyagi, and M. Nakano: IEEE Trans. Magn., 2010, vol. 46, pp. 548-51.

M. Ouadah, O. Touhami, R. Ibtiouen, A. Bouzida, S. Bouyegh, D. Allou, and A. Haddad: Proceedings of Engineering and Technology, 2017, vol. 17, pp. 97-101.

Acknowledgments

The authors would like to thank the National Natural Science Foundation of China (NSFC) for financial support (Project Nos. 51874059, 51874060).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted September 1, 2020; accepted January 1, 2021.

Rights and permissions

About this article

Cite this article

Jiang, W., Long, M., Chen, D. et al. Temperature Distribution in the As-Cast Steel Specimen During Gleeble Hot-Tensile Test and Its Effect on High-Temperature Mechanical Properties. Metall Mater Trans B 52, 1228–1242 (2021). https://doi.org/10.1007/s11663-021-02071-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02071-3