Abstract

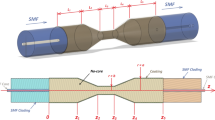

In our previous works, we presented a theoretical approach to describe the behavior of a single-mode step-index optical fiber or polymer optical fiber such as poly (methyl methacrylate) or PMMA fiber coated by moisture-sensitive polymers (MSPs) and moisture-insensitive polymers periodically. The periodic structure is surrounded by a high young's modulus material such as stainless steel mesh. Absorption of the moisture by the MSPs causes to deform the optical fiber, such that the optical fiber gratings are induced. Induced fiber gratings are the basis of the proposed relative moisture sensor. Due to the low Young's modulus of polymers, the polymer fiber sensors are more sensitive relative to the glass optical fiber sensors. The difference between the coefficient of thermal expansion of different polymers is the origin of errors in the sensor's outputs. In this paper, a theoretical approximate method is employed to optimize the moisture density in the presence of temperature variation and as a result, the error due to temperature change is investigated, and finally, a structure for temperature-compensated distributed optical fiber moisture sensor is proposed. By the development of this numerical approach, it is shown that the proposed sensor can be employed for moisture and temperature measurement simultaneously. The optimal design of a long length distributed optical fiber moisture sensor makes it a good candidate for application in the agriculture fields and gardens’ smart irrigation.

Similar content being viewed by others

Abbreviations

- a :

-

The outer radius of the optical fiber (core and cladding)

- b :

-

The outer radius of the coating polymers

- c :

-

The outer radius of the high Young's modulus material

- \(a_{1}\) :

-

Amplitude of the fundamental harmonic of normal stress

- \(b_{l}\) :

-

lTh Fourier amplitude of induced refractive index

- A :

-

Cross-sectional area

- E :

-

Young's modulus

- E(r):

-

Core mode normalized electronic field

- G :

-

Shear modulus

- K :

-

Coupling coefficient

- \(l\) :

-

Fourier components

- \(L_{1}\) :

-

Length of moisture-sensitive polymer in one structural period

- \(L_{2}\) :

-

Length of moisture-insensitive polymer in one structural period

- \(L\) :

-

One structural period of the sensor

- \(M\) :

-

Mode amplitude

- n :

-

Refractive index

- P :

-

Photo-elastic tensor

- Q :

-

Thermo-hygroscopic strain

- r :

-

Moisture concentration

- S :

-

Strain tensor

- t :

-

Temperature

- u :

-

Displacement vector

- α :

-

Coefficient of thermal expansion

- β :

-

Coefficient of hygroscopic swelling

- γ :

-

Shear-lag parameter

- \(\gamma^{ - 1}\) :

-

Spatial constant

- δ :

-

Propagation constant

- ε :

-

The error of the numerical calculations

- \(\varepsilon_{{\text{o}}}\) :

-

Vacuum permittivity

- λ :

-

Lame's constant

- μ :

-

Modulus of rigidity

- \(\nu\) :

-

Poisson's ratio

- σ :

-

Stress tensor

- ω :

-

Laser frequency

- Г :

-

Attenuation

References

Ali TA, Shehata MI, Mohamed NA (2015) Design and performance investigation of a highly accurate apodized fiber Bragg grating-based strain sensor in single and quasi-distributed systems. Appl Opt 54:5243–5251

Arregui FJ, Liu Y, Matias IR, Claus RO (1999) Optical fiber humidity sensor using a nano Fabry–Perot cavity formed by the ionic self-assembly method. Sens Actuators B Chem 59(1):54–59. https://doi.org/10.1016/S0925-4005(99)00232-4

Berruti G, Consales M, Giordano M, Sansone L, Petagna P, Buontempo S, Breglio G, Cusano A (2013) Radiation hard humidity sensors for high energy physics applications using polyimide-coated fiber Bragg gratings sensors. Sens Actuators B Chem 177:94–102

Bertholds A, Dandliker R (1987) Deformation of single-mode optical fibers under static longitudinal stress. J Lightw Technol 5:895–900

Botsis J, Humbert L, Colpo F, Giaccari P (2005) Embedded fiber Bragg grating sensor for internal strain measurements in polymeric materials. Opt Laser Eng 43(3–5):491–510. https://doi.org/10.1016/j.optlaseng.2004.04.009

Chen Z, Li XX, Du G, Chen N, Suen AYM (2011) A sol-gel method for preparing ZnO quantum dots with strong blue emission. J Luminesc 131(10):2072. https://doi.org/10.1016/j.jlumin.2011.05.009

Chen Q, Lu P (2008) Fiber Bragg gratings and their applications as temperature and humidity sensors. J Mol Opt Phys 235–260

Corres JM, Arregui FJ, Matias IR (2006) Design of humidity sensors based on tapered optical fibers. J Lightw Technol 24(11):4329–4336

Cox LH (1952) The elasticity and strength of paper and other fibrous materials Br. J Appl Phys 3:72–79

Dana HR, Casari P, El Abdi R, Fréour S, Jacquemin F (2017) Characterisation of the hygro-thermo-mechanical behaviour of organic matrix composites instrumented with optical fibres: a study of interfacial bonding. Int J Adhes Adhes 77:63–71. https://doi.org/10.1016/j.ijadhadh.2017.04.001

Dana HR, Jacquemin F, Freour S, Perronnet A, Casari P, Lupi C (2014) Numerical and experimental investigation of hygro mechanical states of glass fiber reinforced polyester composites experienced by FBG sensors. Comp Struct 116:38–47

Dimitrakopoulos G, Demestichas P (2010) Intelligent transportation systems. IEEE Veh Technol Mag 5(1):77–84. https://doi.org/10.1109/MVT.2009.935537

Feng X, Sun C, Zhang X, Ansari F (2010) Determination of the coefficient of thermal expansion with embedded long-gauge fiber optic sensors. Meas Sci Technol 21(6):065302

Fu MY, Lin GR, Liu WF, Wu CW (2011) Fiber-optic humidity sensor based on an air-gap long-period fiber grating. Opt Rev 18(1):93–95. https://doi.org/10.1007/s10043-011-0038-7

Her SC, Huang CY (2011) Effect of coating on the strain transfer of optical fiber sensors. Sensors 11:6926–6941

Hromadka J, Hazlan NNM, Hernandez FU, Correia R, Norris A, Morgan SP, Korposh S (2019) Simultaneous in situ temperature and relative humidity monitoring in mechanical ventilators using an array of functionalised optical fibre long period grating sensors. Sens Actuators B Chem 286:306–314. https://doi.org/10.1016/j.snb.2019.01.124

Joe H-E, Yun H, Jo S-H, Jun MBG, Min B-K (2018) A review on optical fiber sensors for environmental monitoring. Int J Precis Eng Manuf Green Technol 5(1):173–191

Karalekas D, Cugnoni J, Botsis J (2008) Monitoring of process induced strains in a single fibre composite using FBG sensor: A methodological study. Compos Part A Appl S 39(7):1118–1127. https://doi.org/10.1016/j.compositesa.2008.04.010

Karalekas D, Cugnoni J, Botsis J (2009) Monitoring of hygrothermal ageing effects in an epoxy resin using FBG sensor: a methodological study. Compos Sci Technol 69(3–4):507–514. https://doi.org/10.1016/j.compscitech.2008.11.028

Kronenberg P, Rastogi PK, Giaccari P, Limberger HG (2002) Relative humidity sensor with optical fiber Bragg gratings. Opt lett 27(16):1385–1387

Landau LD, Lifshitz EM (1986) Theory of Elasticity, 3rd edn. Pergamon Press, Oxford

Liehr S, Breithaupt M, Krebber K (2017) Distributed humidity sensing in PMMA optical fibers at 500 nm and 650 nm wavelengths. Sensors 17(4):738. https://doi.org/10.3390/s17040738

Lin MR, Ritter JE, Rosenfeld L, Lardner TJ (1990) Measuring the interfacial shear strength of thin polymer coatings on glass. J Mater Res 5:1110–1117

MacLean A, Moran C, Johnstone W, Culshaw B, Marsh D, Parker P (2003) Detection of hydrocarbon fuel spills using a distributed fibre optic sensor. Sens Actuators A Phys 109(1–2):60–67. https://doi.org/10.1016/j.sna.2003.09.007

Ramezani-Dana H, Casari P, Perronnet A, Fréour S, Jacquemin F, Lupi C (2014) Hygroscopic strain measurement by fibre Bragg gratings sensors in organic matrix composites—application to monitoring of a composite structure. Compos Part B-Eng 58:76–82. https://doi.org/10.1016/j.compositesb.2013.10.014

Sadd MH (2009) Elasticity: theory, applications, and numeric. Academic Press, London

Sanij MD, Noghani FE, Bahrampour A, Bahrampour AR (2019) A proposal for distributed humidity sensor based on the induced LPFG in a periodic polymer coated fiber structure. Opt Laser Technol 17:126–133. https://doi.org/10.1016/j.optlastec.2019.04.019

Sanij MD, Rooholamininejad H, Bahrampour AR (2020) Analytical solution of an induced fiber grating relative humidity sensor. Iran J Sci Technol Trans A Sci. https://doi.org/10.1007/s40995-020-00838-y

Snyder AW (1972) Coupled-mode theory for optical fibers. JOSA 62(11):1267–1277

Stajanca P, Hicke K, Krebber K (2019) Distributed fiberoptic sensor for simultaneous humidity and temperature monitoring based on polyimide-coated optical fibers. Sensors 19(23):5279. https://doi.org/10.3390/s19235279

Yariv A (1973) Coupled-mode theory for guided-wave optics. IEEE J Quantum Electr 9(9):919–933

Yariv A (1989) Quantum electronics, 3rd edn. Wiely, New York

Yeo TL, Sun T, Grattan KTV (2008) Fibre-optic sensor technologies for humidity and moisture measurement. Sens Actuators A Phys 144(2):280–295. https://doi.org/10.1016/j.sna.2008.01.017

Yost WT, Cantrell JH, Gates TS, Whitley KS (1998) Effects of molecular weight on mechanical properties of the polyimide Larc-SI™. In: Review of progress in quantitative nondestructive evaluation. Springer, Boston, pp 1411–1417

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bahrampour, A., Dehghani Sanij, M., Rooholamininejad, H. et al. The Theoretical Study of an Optimal Distributed Fiber Moisture Sensor Based on the Periodic Polymer Coating. Iran J Sci Technol Trans Sci 45, 1097–1104 (2021). https://doi.org/10.1007/s40995-021-01087-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40995-021-01087-3