Abstract

Background

The internal strain distribution developing during plastic deformation is important for understanding the mechanical properties of polycrystalline materials. Such distributions may be determined by the microstructural feature tracking method. However, the strain accuracy and the sources of uncertainty of this method are not well quantified yet.

Objective

Evaluate the accuracy of local strain determination based on laboratory-based multimodal X-ray tomography measurements.

Methods

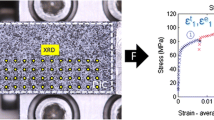

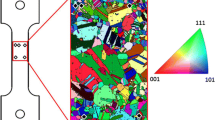

The plastic deformation behavior of a particle-contained fully recrystallized Al-4mass%Cu alloy was characterized during in-situ tensile testing using absorption contrast tomography to reveal marker particles and diffraction contrast tomography to reveal the grain structure.

Results

It was found that the accuracy in strain measurement is inversely proportional to the particle distance, whereas it is independent of the particle size, and the accuracy is not biased by grain boundaries. As an illustrative example, the preliminary analysis of the microstructure-strain relationships reveals significant strain differences both between and within individual grains.

Conclusions

The results document the validity and limitations of the microstructural feature tracking method for local strain measurements using a laboratory X-ray source, are of importance for local strain analysis in general and may be considered as an alternative to other methods, e.g. digital image correlation. The measurements allow evaluation of effects of the grain microstructure on the local strain development during plastic deformation. By a preliminary analysis of the strain difference between two selected grains, it is suggested that the grain shape and crystallographic relationships between neighboring grains are of importance for the development of local strains.

Similar content being viewed by others

References

Kocks UF, Canova GR (1981) How many slip systems, and which? In: Hansen N, Horsewell A (eds) Deformation of Polycrystals: Mechanisms and Microstructures, Proc 2nd Risø Int Symp on Metallurgy and Materials Science. T. Leffers and H. Lilholt, Risø Denmark, p 35–44

Maire E, Withers PJ (2014) Quantitative X-ray tomography. Inter Mater Rev 59:1–43. https://doi.org/10.1179/1743280413Y.0000000023

Poulsen HF (2004) Three-Dimensional X-Ray Diffraction Microscopy, Mapping Polycrystals and their Dynamics, Springer-Verlag Berlin Heidelberg, pp. 1–149. https://doi.org/10.1007/b97884

Lienert U et al (2011) High-energy diffraction microscopy at the advanced photon source. JOM 63:70–77. https://doi.org/10.1007/s11837-011-0116-0

Johnson G, King A, Honnicke MG, Marrow J, Ludwig W (2008) X-ray diffraction contrast tomography: a novel technique for three-dimensional grain mapping of polycrystals. II. The combined case, J Appl Cryst 41:310–318. https://doi.org/10.1107/S0021889808001726

King A, Reischig P, Adrien J, Ludwig W (2013) First laboratory X-ray diffraction contrast tomography for grain mapping of polycrystals. J Appl Cryst 46:1734–1740. https://doi.org/10.1107/S0021889813022553

McDonald SA et al (2015) Non-destructive mapping of grain orientations in 3D by laboratory X-ray microscopy. Sci Rep 5:14665. https://doi.org/10.1038/srep14665

Holzner C et al (2016) Diffraction Contrast Tomography in the Laboratory - Applications and Future Directions. Micros Today 24(4):34–43. https://doi.org/10.1017/S1551929516000584

Bachmann F et al (2019) 3D grain reconstruction from laboratory diffraction contrast tomography. J Appl Cryst 52:643–651. https://doi.org/10.1107/S1600576719005442

Sun J, Zhang Y, Lyckegaard A, Bachmann F, Juul Jensen D (2019) Grain boundary wetting correlated to the grain boundary properties: A laboratory-based multimodal X-ray tomography investigation. Scripta Mater 163:77–81. https://doi.org/10.1016/j.scriptamat.2019.01.007

Bay BK, Smith TS, Fyhrie DP, Saad M (1999) Digital volume correlation: three-dimensional strain mapping using X-ray tomography. Exp Mech 39:217–226. https://doi.org/10.1007/BF02323555

Naimpas N et al. (2014) Rich tomography techniques for the analysis of microstracture and deformation. Int J Comput Methods 3:1343006–1–18. https://doi.org/10.1142/S0219876213430068

Palanca M et al (2015) Three-dimensional Local Measurement of Bone Strain and Displacement: Comparison of Three Digital Volume Correlation Approaches. J Biomech Eng 137:071006. https://doi.org/10.1115/1.4030174

Marrow TJ et al (2014) A quantitative three-dimensional in situ study of a short fatigue crack in a magnesium alloy. Int J Fatigue 66:183–193. https://doi.org/10.1016/j.ijfatigue.2014.04.003

Cai B et al (2014) In situ synchrotron tomographic quantification of granular and intragranular deformation during semi-solid compression of an equiaxed dendritic Al-Cu alloy. Acta Mater 76:371–380. https://doi.org/10.1016/j.actamat.2014.05.035

Mostafavi M et al (2015) Yield behavior beneath hardness indentations in ductile metals, measured by three-dimensional computed X-ray tomography and digital volume correlation. Acta Matar 82:468–482. https://doi.org/10.1016/j.actamat.2014.08.046

Mostafavi M et al (2016) Quantifying yield behaviour in metals by X-ray nanotomography. Sci Rep 6:34346. https://doi.org/10.1038/srep34346

Buljac A et al (2018) Digital Volume Correlation: Review of Progress and Challenges. Exp Mech 58:661–708. https://doi.org/10.1007/s11340-018-0390-7

Vertyagina Y et al (2014) In situ quanitative three-dimensional characterisation of sub-indentation cracking in polycrystalline alumina. J Eur Ceram Soc 34:3127–3132. https://doi.org/10.1016/j.jeurceramsoc.2014.04.022

Haldrup K, Nielsen SF, Wert JA (2008) A General Methodology for Full-Field Plastic Strain Measurements Using X-ray Absorption Tomography and Internal Markers. Exp Mech 48:199–211. https://doi.org/10.1007/s11340-007-9079-z

Kobayashi M et al (2008) High-density three-dimensional mapping of internal strain by tracking microstructural features. Acta Mater 56:2167–8211. https://doi.org/10.1016/j.actamat.2007.12.058

Kobayashi M, Miura H (2020) 3D/4D characterization of strain distribution evolving within the microstructure during plastic deformation. Curr Opin Solid State Mat Sci 24:100835. https://doi.org/10.1016/j.cossms.2020.100835

Toda H et al (2016) Diffraction-amalgamated grain boundary tracking for mapping 3D crystallographic orientation and strain fields during plastic deformation. Acta Mater 107:310–324. https://doi.org/10.1016/j.actamat.2016.01.072

Li N et al (2016) Strain Measurements Through Optimized Particle Tracking in Volumetric Images: Methodology and Error Assessment. Exp Mech 56:1281–1291. https://doi.org/10.1007/s11340-016-0146-1

Toda H et al (2006) Three-dimensional observation of nanoscopic precipitates in an aluminum alloy by microtomography with Fresnel zone plate optics. Appl Phys Lett 89:143112. https://doi.org/10.1063/1.2359288

Furuta S et al (2017) Investigation of three-dimensional morphology changes of the eutectic Si particles affected by trace P and Sr in Al-7%Si cast alloys by means of synchrotron nano-tomography. Mater Charact 130:237–242. https://doi.org/10.1016/j.matchar.2017.06.009

Patterson BM et al (2016) In Situ Laboratory-Based Transmission X-Ray Microscopy and Tomography of Material Deformation at the Nanoscale. Exp Mech 56:1585–1597. https://doi.org/10.1007/s11340-016-0197-3

Lindkvist A, Fang H, Juul Jensen D, Zhang Y (2020) Optimizing laboratory X-ray diffraction contrast tomography for grain structure characterization of pure iron. J Appl Cryst accepted

Lorensen WE, Cline HE (1987) Marching Cubes: A High Resolution 3D Surface Construction Algorithm. Comput Graph (ACM) 21:163–169. https://doi.org/10.1145/37401.37422

Barber CB, Dobkin DP, Huhdanpaa HT (1996) The Quickhull Algorithm for Convex Hulls. ACM Trans Math Software 22:469–483. https://doi.org/10.1145/235815.235821

Randle V, Hansen N, Juul Jensen D (1996) The deformation behavior of grain boundary regions in polycrystalline aluminium. Phil Mag A 73:265–282. https://doi.org/10.1080/01418619608244382

Thorning C, Somers MAJ, Wert JA (2005) Grain interaction effects in polycrystalline Cu. Mater Sci Eng A 397:215–228. https://doi.org/10.1016/j.msea.2005.02.043

Pokharel R et al (2015) In-situ observation of bulk 3D grain evolution during plastic deformation in polycrystalline Cu. Int J Plast 67:217–234. https://doi.org/10.1016/j.ijplas.2014.10.013

Chatterjee K et al (2016) Study of grain-level deformation and residual stresses in Ti-7Al under combined bending and tension using high energy diffraction microscopy (HEDM). Int J Solids Struct 94–95:35–49. https://doi.org/10.1016/j.ijsolstr.2016.05.010

Juul NY, Oddershede J, Winther G (2020) Analysis of Grain-Resolved Data from Three-Dimensional X-Ray Diffraction Microscopy in the Elastic and Plastic Regimes. JOM 72:83–90. https://doi.org/10.1007/s11837-019-03829-6

Acknowledgments

This work was supported by Japan Society for the Promotion of Science KAKENHI, Grant-in-Aid for Scientific Research (B), Grant Number 19H02456. The authors gratefully thank the Cooperative Research Facility Centre in TUT for supporting specimen preparation. DJJ and YZ further acknowledge the support from the European Research Council (ERC grant agreement No 788567 M4D) for part of this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kobayashi, M., Zhang, Y., Ishikawa, H. et al. Investigation of Relationships between Grain Structure and Inhomogeneous Deformation by Means of Laboratory-Based Multimodal X-Ray Tomography: Strain Accuracy Analysis. Exp Mech 61, 817–828 (2021). https://doi.org/10.1007/s11340-021-00701-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-021-00701-0