Abstract

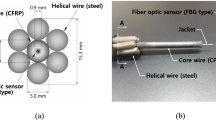

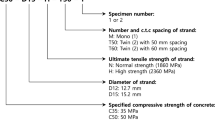

The present study involves the smart precast box culvert, which can sense the strain and stress achieved based on the fiber optic sensor embedded into the fiber-reinforced polymer. These culverts (2.00 × 2.00 × 2.00 m) was investigated experimentally with different seven trial load tests subject to join the dual box culvert using two steel strand and two smart steel strand (CH2&CH3) which is connected to fiber-reinforced polymer strain sensor for analyzing deformation sensor, line load strain, stress region, and stress–strain self-sensing of the culverts. From the monitored results in this self-sensing static load test, the maximum deformation sensor was 131.75 µɛ at the lower smart steel strand (CH3) and the cracks (0.10 mm) initiated on the roof slab of the culverts for a specimen due to bending moment in the culvert not exceeded its moment capacity because the applied load was smaller than the ultimate load. This paper proposes a series of fiber-reinforced polymer strain sensors to connect to the smart strand to completely meet the culvert’s requirements, and their sensing performance is come out. This study, therefore, implied that the experimental finding of the fiber-reinforced polymer strain sensors has the potential to monitor the structural health over time.

Similar content being viewed by others

References

Zhou Z, Wang Z, Shao L (2016) Fiber-reinforced polymer-packaged optical fiber Bragg grating strain sensors for infrastructures under harsh environment. J Sensors 2016:1–18

Leung CKY, Wan KT, Inaudi D, Bao X, Habel W, Zhou Z et al (2015) Review: optical fiber sensors for civil engineering applications. Mater Struct 48:871–906

Housner LABGW, Caughey TK et al (1997) Structural control: past, present, and future. J Eng Mech 123:897–971

Meltz G, Morey WW, Glenn WH (1989) Formation of Bragg gratings in optical fibers by a transverse holographic method. Opt Lett 14:823–825

Mufti AA (2003) FRPs and FOSs lead to innovation in Canadian civil engineering structures. Constr Building Mater 17:379–387

Zhou Z, Liu J, Li H, Ou J (2005) A new kind of high durable traffic weighbridge based on FBG sensors, vol. 5855: SPIE, 2005.

Zhou Z, Lan C, Lin T, Ou J (2005) A novel ice-pressure sensor based on dual FBGs, vol. 5765: SPIE, 2005.

Huang L, Zhao L, Yan L (2018) Flexural performance of RC beams strengthened with polyester FRP composites. Int J Civil Eng 16:715–724

Zou L, Ravet F, Bao X, Chen L, Huang R, Khoo H (2004) In-line inspection of pipeline buckling by distributed Brillouin scattering sensor. In 2nd Int. Workshop on SHM of Innovative Civil Engineering Structures, Winnipeg, Canada, 2004, pp. 183–192.

Murayama H, Wada D, Igawa H (2013) Structural health monitoring by using fiber-optic distributed strain sensors with high spatial resolution. Photon Sens 2013:355–376

Gu X, Chen Z, Ansari F (2000) Embedded fiber optic crack sensor for reinforced concrete structures. ACI Struct J 97:468–476

Wu Z, Xu B (2002) Infrastructural health monitoring with BOTDR optic fiber sensing technique.

Zhao Y, Ansari F (2002) Embedded fiber optic sensor for characterization of interface strains in FRP composite. Sens Actuators A: Phys 100:247–251

Sun C, Liang Y, Ansari F (2004) Serially multiplexed dual point fiber optic acoustic emission sensor. J Lightwave Technol 22:14–24

Liang Y, Tennant A, Jia H, Xiong X, Ansari F (2005) Implementation of long gauge fiber optic sensor arrays in civil structures. In Sensing Issues in Civil Structural Health Monitoring, Dordrecht, 2005, pp. 403–412.

Haddad RH, Marji CS (2019) Composite strips with U-shaped CFRP wrap anchor systems for strengthening reinforced concrete beams. Int J Civil Eng 17:1799–1811

Pandey PK, Singh KK, Gaurav A (2019) Effect of span-to-depth ratio on the flexural properties of woven neat epoxy/glass fiber-reinforced polymer symmetric laminates. Springer, Singapore, pp 59–65

Kim YHPHY, You YJ, Moon CK (2008) Short-term durability test for GFRP rods under various environmental conditions. Compos Struct 83:37–47

Habel WR, Krebber K (2011) Fiber-optic sensor applications in civil and geotechnical engineering. Photon Sens 1:268–280

Liu D, Sun Q, Lu P, Xia L, Sima C (2016) Research progress in the key device and technology for fiber optic sensor network. Photon Sens 6:1–25

Merzbacher CI, Kersey AD, Friebele EJ (1999) Fiber-optic sensors in concrete structures: a review. In: Grattan KTV, Meggitt BT (eds) Optical fiber sensor technology: applications and systems. Springer, US, Boston, pp 1–24

Zhao F, Bao H, Xue S, Xu Q (2019) Multi-objective particle swarm optimization of sensor distribution scheme with consideration of the accuracy and the robustness for deformation reconstruction. Sensors (Basel, Switzerland) 19:1306

Zhao Y, Du J, Bao H, Xu Q (2018) Optimal sensor placement based on eigenvalues analysis for sensing deformation of wing frame using iFEM. Sensors (Basel, Switzerland) 18:2424

Mendez A, Morse TF (1992) Overview of optical fiber sensors embedded in concrete. Fiber Opt Smart Struct Skins V 1798:205–216

R. Measures (1992) Smart structures—a revolution in civil engineering. In Advanced Composite Materials in Bridges and Structures, Montreal, pp. 31–59.

Zhang W (2018) Prediction of the bond-slip law between externally bonded concrete substrates and CFRP plates under fatigue loading. Int J Civil Eng 16:1085–1096

Kulchin YN, Vitrik OB, Dyshlyuk AV, Shalagin AM, Babin SA, Vlasov AA (2008) An interrogation technique for fiber Bragg grating sensors based on optical time-domain reflectometry. Optoelectron Instrument Data Process 44:178

Chen TZJ, Guo Y (2014) Application research on distributed optical fiber monitoring technology in static load test of large diameter and post-grouting filling pile. Appl Mech Mater 580:572–578

Kang M-K, Park D-J, Lee S-S (2012) Strain measurements on a cantilever beam with fiber Bragg grating sensors using a pair of collimators. Int J Precis Eng Manuf 13:455–458

Prasad ASG, Asokan S (2015) Fiber Bragg grating sensor package for submicron level displacement measurements. Exp Tech 39:19–24

Xu D-S, Borana L, Yin J-H (2014) Measurement of small strain behavior of a local soil by fiber Bragg grating-based local displacement transducers. Acta Geotech 9:935–943

I. F. R. N. Co (2019) Self-sensing prestressed anchorage system and cable and its engineering application. Publishing House of building Industry in China, Beijing, China (in Chinese)

Acknowledgements

The authors are grateful for the financial support of the National Key Research and Development Program of China (Project No.: 2017YFC0703410, 2018YFC0809400), the Special Fund for the Innovative Talents in the Field of Science and Technology in Harbin (Project No.: RC2014QN012014), the Fundamental Research Funds for the Central Universities (Project No.: HIT.BRET III.2012 33), and the Fund of China Railway Major Bridge Engineering Group Co. (Project No.: MH20170232). At last but not least, I would like to acknowledge the Zhongda Road and Bridge Material Limited Company.

Funding

The National Key Basic Research Program of China (Project No.: 2017YFC0703410, 2018YFC0809400), the Special Fund for the Innovative Talents in the Field of Science and Technology in Harbin (Project No.: RC2014QN012014), the Fundamental Research Funds for the Central Universities (Project No.: HIT.BRET III.2012 33), and the Fund of China Railway Major Bridge Engineering Group Co. (Project No.: MH20170232). At last but not least, I would like to acknowledge to Zhongda Road and Bridge Material Limited Company.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Gebremedhn, Z., Qiao, G., Sun, L. et al. Strain/Stress Self-Sensing Precast-Box Culvert: Smart Element Design, and Experimental Verification. Int J Civ Eng 19, 851–859 (2021). https://doi.org/10.1007/s40999-020-00569-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40999-020-00569-6