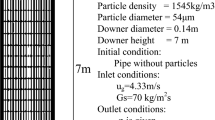

Abstract—This study focuses on turbulent convection of molten magnesium in a titanium reduction reactor. The reactor retort is a cylindrical vessel with a radius of 0.75 m and a height of 4 m, which contains liquid magnesium at a temperature of 850°C. During a process that lasts for more than 2 days, significant temperature gradients occur in the reduction apparatus due to an exothermic chemical reaction on the metal surface and simultaneous cooling of the side wall of the retort and heating of its bottom. Temperature gradients cause convective flows inside the reactor, which in turn significantly affect the formation of the titanium block. The mathematical model of convective flows in the reactor is based on the equations of thermogravitational convection for a single-phase medium in the Boussinesq approximation. We consider the possibility of modeling turbulent convective flows in a titanium reduction reactor using RANS (Reynolds-averaged Navier–Stokes equations) k–ε and k–ω SST (Shear Stress Transport) models. The results of simulations performed with the k–ω SST model on relatively coarse grids (0.825 million finite volumes) are shown to qualitatively and quantitatively agree with the results of LES simulations on fine grids (3.7 million finite volumes). However, the k–ε model does not always produce acceptable results. RANS simulations produce average velocity and temperature fields with averaging times much longer than those possible in LES simulations. Several different configurations of heating and cooling of the apparatus were examined, including those that were previously unstudied. It has been found that using the k–ω SST model allows simulation of flow dynamics taking into account changes in the heating and cooling conditions of the apparatus during the entire process and identification of single- and double-vortex large-scale flows in the retort, as well as the transition between them, so the degree of convection influence on the reaction can be assessed.

Similar content being viewed by others

REFERENCES

Frick, P., Khalilov, R., Kolesnichenko, I., Mamykin, A., Pakholkov, V., Pavlinov, A., and Rogozhkin, S., Turbulent convective heat transfer in a long cylinder with liquid sodium, Europhys. Lett., 2015, vol. 109, p. 14002. https://doi.org/10.1209/0295-5075/109/14002

Khalilov, R., Kolesnichenko, I., Pavlinov, A., Mamykin, A., Shestakov, A., and Frick, P., Thermal convection of liquid sodium in inclined cylinders, Phys. Rev. Fluids, 2018, vol. 3, p. 043503. https://doi.org/10.1103/PhysRevFluids.3.043503

Teimurazov, A. and Frick, P., Thermal convection of liquid metal in a long inclined cylinder, Phys. Rev. Fluids, 2017, vol. 2, p. 113501. https://doi.org/10.1103/physrevfluids.2.113501

Zwirner, L. and Shishkina, O., Confined inclined thermal convection in low-Prandtl-number fluids, J. Fluid Mech., 2018, vol. 850, pp. 984–1008. https://doi.org/10.1017/jfm.2018.477

Mandrykin, S.D. and Teimurazov, A.S., Turbulent convection of liquid sodium in an inclined cylinder of unit aspect ratio, Vychisl. Mekh. Splosh. Sred, 2018, vol. 11, no. 4, pp. 417–428. https://doi.org/10.7242/1999-6691/2018.11.4.32

Ahlers, G., Grossmann, S., and Lohse, D., Heat transfer and large scale dynamics in turbulent Rayleigh–Benard convection, Rev. Mod. Phys., 2009, vol. 81, pp. 503–537. https://doi.org/10.1103/revmodphys.81.503

Rogozhkin, S.A., Aksenov, A.A., Zhluktov, S.V., Osipov, S.L., Sazonova, M.L., Fadeev, I.D., Shepelev, S.F., and Shmelev, V.V., Development and verification of a turbulent heat transport model for sodium-based liquid metal coolants, Vychisl. Mekh. Splosh. Sred, 2014, vol. 7, no. 3, pp. 306–316. https://doi.org/10.7242/1999-6691/2014.7.3.30

Belyaev, I.A., Genin, L.G., Listratov, Ya.I., Melnikov, I.A., Sviridov, V.G., Sviridov, E.V., Ivochkin, Yu.P., Razuvanov, N.G., and Shpansky, Yu.S., Specific features of liquid metal heat transfer in a tokamak reactor, Magnetohydrodynamics, 2013, vol. 49, nos. 1–2, pp. 177–190.

Garmata, V.A., Guoyanitskiy, B.S., Kramnik, V.Yu., Lipkes, Ya.M., Seryakov, G.V., Suchkov, A.B., and Khomyakov, P.P., Metallurgiya titana (Metallurgy of Titanium), Moscow: Metallurgiya, 1968.

Garmata, V.A., Petrun’ko, A.N., Galitskiy, N.V., Olesov, Yu.G., and Sandler, R.A., Titan (Titanium), Moscow: Metallurgiya, 1983.

Sergeyev, V.V., Galitskiy, N.V., Kiselev, V.P., and Kozlov, V.M., Metallurgiya titana (Metallurgy of Titanium), Moscow: Metallurgiya, 1971.

Mal’shin, V.M., Zavadovskaya, V.N., and Pampushko, N.A., Metallurgiya titana (Metallurgy of Titanium), Moscow: Metallurgiya, 1991.

Khalilov, R.I., Khripchenko, S.Yu., Frik, P.G., and Stepanov, R.A., Electromagnetic measurements of the level of a liquid metal in closed volumes, Meas. Tech., 2007, vol. 50, pp. 861–866. https://doi.org/10.1007/s11018-007-0163-7

Krauter, N., Eckert, S., Gundrum, T., Stefani, F., Wondrak, T., Frick, P., Khalilov, R., and Teimurazov, A., Inductive system for reliable magnesium level detection in a titanium reduction reactor, Metall. Mater. Trans. B, 2018, vol. 49, pp. 2089–2096. https://doi.org/10.1007/s11663-018-1291-y

Tarunin, E.L., Shikhov, V.M., and Yurkov, Yu.S., Free convection in a cylindrical vessel for a given heat flux at the upper boundary, in Gidrodinamika (Hydrodynamics), Perm, 1975, no. 6, pp. 85–98.

Tsaplin, A.I. and Nechaev, V.N., Numerical modeling of non-equilibrium heat and mass transfer processes in a reactor for the production of porous titanium, Vychisl. Mekh. Splosh. Sred, 2013, vol. 6, no. 3, pp. 483–490. https://doi.org/10.7242/1999-6691/2013.6.4.53

Teimurazov, A.S. and Frick, P.G., Numerical study of molten magnesium convection in a titanium reduction apparatus, J. Appl. Mech. Tech. Phys., 2016, vol. 57, pp. 1264–1275. https://doi.org/10.1134/S0021894416070129

Teimurazov, A., Frick, P., and Stefani, F., Thermal convection of liquid metal in the titanium reduction reactor, IOP Conf. Ser.: Mater. Sci. Eng., 2017, vol. 208, p. 012041. https://doi.org/10.1088/1757-899X/208/1/012041

Teimurazov, A., Frick, P., Weber, N., and Stefani, F., Numerical simulations of convection in the titanium reduction reactor, J. Phys.: Conf. Ser., 2017, vol. 891, p. 012076. https://doi.org/10.1088/1742-6596/891/1/012076

Khalilov, R., Kolesnichenko, I., Teimurazov, A., Mamykin, A., and Frick, P., Natural convection in a liquid metal locally heated from above, IOP Conf. Ser.: Mater. Sci. Eng., 2017, vol. 208, p. 012044. https://doi.org/10.1088/1757-899X/208/1/012044

Pope, S.B., Turbulent Flows, Cambridge: Cambridge Univ. Press, 2000. https://doi.org/10.1017/CBO9780511840531

Deardorff, J.W., A numerical study of three-dimensional turbulent channel flow at large Reynolds numbers, J. Fluid Mech., 1970, vol. 41, pp. 453–480. https://doi.org/10.1017/S0022112070000691

Issa, R.I., Solution of the implicitly discretized fluid flow equations by operator-splitting, J. Comput. Phys., 1986, vol. 62, pp. 40–65. https://doi.org/10.1016/0021-9991(86)90099-9

Chen, F., Huai, X., Cai, J., Li, X., and Ruixue, M., Investigation on the applicability of turbulent-Prandtl-number models for liquid lead-bismuth eutectic, Nucl. Eng. Des., 2013, vol. 257, pp. 128–133. https://doi.org/10.1016/j.nucengdes.2013.01.005

Cebeci, T., Model for eddy conductivity and turbulent Prandtl number, J. Heat Transf., 1973, vol. 95, pp. 227–234. https://doi.org/10.1115/1.3450031

ACKNOWLEDGMENTS

The simulations were carried out on the Triton supercomputer at the Institute of Continuous Media Mechanics in Perm, Russia.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by L. Trubitsyna

Rights and permissions

About this article

Cite this article

Karasev, T.O., Teimurazov, A.S. Modeling of Liquid Magnesium Turbulent Convection in a Titanium Reduction Apparatus Using the RANS and LES Approaches. J Appl Mech Tech Phy 61, 1203–1215 (2020). https://doi.org/10.1134/S0021894420070044

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0021894420070044