Abstract

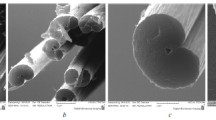

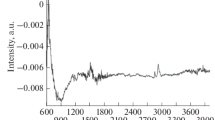

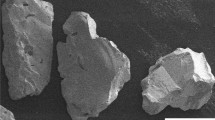

Argon ion sputter etching of AISI type 420 stainless steels was carried out at a power of 250 W for 14.4 ks to form cone-shaped protrusions with bottom diameters of 10–20 µm by using a radio-frequency magnetron sputter apparatus. The sputter etching was also applied to AISI type 316 stainless steel at 250 W for 10.8 ks, and fine column-shaped protrusions with diameters smaller than 500 nm were formed. In addition, plasma-nitriding was applied to the protrusions of type 420 steel using nitrogen gas of 0.53 Pa mixed with argon gas of 0.67 Pa at a power of 50 W for 1.8 ks. The gripping ability of protrusions was measured by friction tests for three types of fiber sheets. For a cotton cloth, the friction coefficients of the as-sputter-etched and plasma-nitrided type 420 steel specimens were 1.3 and 1.7 at a nominal compressive stress of 0.8 kPa, and that of the as-sputter-etched type 316 steel specimen was 1.0. These are much larger than 0.8 and 0.5 of the specimens polished with #100 emery paper and buff-polished with alumina powders. Also for microfiber and polyester fiber sheets, the specimen with protrusions showed a higher gripping ability than those of the mechanically polished specimens. The reason for the large gripping ability of protrusion specimens is due to piercing of the protrusions between and into weaving yarns.

Similar content being viewed by others

References

Wehner, G. K., & Hajicek, D. J. (1971). Cone formation on metal targets during sputtering. Journal of Applied Physics, 42(3), 1145–1149.

Witcomb, M. J. (1974). The development of ion-bombardment surface structures on stainless steel. Journal of Materials Science, 9, 551–563.

Auciello, O., & Kelly, R. (1984). Ion bombardment modification of surfaces. Amsterdam, The Netherlands: Elsevier.

Zhang, Q., Wang, R., Kato, M., & Nakasa, K. (2005). Formation of conical carbides on the surface of stainless and alloy steels by sputter-etching. Journal of Japan Institute of Metals, 69(3), 312–319.

Nakasa, K., Yamamoto, A., Kubo, T., Wang, R., & Sumomogi, T. (2014). Formation of fine protrusions by sputter etching of martensitic stainless steel. Tetsu-to Hagané, 100(5), 647–655.

Wang, R., Zhang, Q., Kato, M., & Nakasa, K. (2006). Formation of fine and dense conical carbides on tool steel surface by sputter etching. Materials Transactions, 47(7), 1798–1804.

Nakasa, K., Yamamoto, A., Kubo, T., Wang, R., & Sumomogi, T. (2017). Formation of fine protrusions by sputter etching of commercially pure titanium. Journal of Japan Institute of Metals and Materials, 81(4), 211–220.

Nakasa, K., Yamamoto, A., Kubo, T., Wang, R., & Sumomogi, T. (2018). Formation of multiscale protrusions on commercially pure titanium and stainless steel by two-stage sputter etching using different cathode disks. Materials Transactions, 59(7), 1198–1205.

Nakasa, K., Yan, X., Yoshida, M., & Sumomogi, T. (2010). Deformation characteristics of fine protrusions formed by sputter-etching of stainless steels. Journal of Solid Mechanics and Materials Engineering, 4(7), 1103–1110.

Nakasa, K., Yamamoto, A., Wang, R., & Sumomogi, T. (2015). Effect of plasma nitriding on the strength of fine protrusions formed by sputter etching of AISI type 420 stainless steel. Surface and Coating Technology, 272, 298–308.

Nakasa, K., Yamamoto, A., Wang, R., & Sumomogi, T. (2016). Effect of plasma nitriding on the compressive strength of multi-functional fine protrusions formed by sputter-etching of stainless steels. Transactions of the JSME. https://doi.org/10.1299/transjsme.16-00059

Nakasa, K., Gao, S., Yamamoto, A., & Sumomogi, T. (2019). Plasma nitriding of cone-shaped protrusions formed by sputter etching of AISI 420 stainless steel and their application to impression punch to form micro-holes on polymer sheets. Surface and Coating Technology, 358, 891–899.

Nakasa, K., Yamamoto, A., & Sumomogi, T. (2018). Gripping and frictional-conveying characteristics of fine protrusions formed by sputter-etching of stainless steels. Transactions of the JSME. https://doi.org/10.1299/transjsme.17-00360

Chyou, S. D., & Shih, H. C. (1991). The effect of nitrogen on the corrosion of plasma-nitrided 4140 steel. Corrosion, 47(1), 31–34.

Pinedo, C. E., & Monteiro, W. A. (2004). On the kinetics of plasma nitriding a martensitic stainless steel type AISI 420. Surface and Coatings Technology, 179, 119–123.

Corengia, P., Ybarra, G., Moina, C., & Broitman, E. (2004). Microstructure and corrosion behavior of DC-pulsed plasma nitrided AISI 410 martensitic stainless steel. Surface and Coatings Technology, 187, 63–69.

Figueroa, C. A., Alvarez, F., Zhang, Z., Collins, G. A., & Short, K. T. (2005). Structural modifications and corrosion behavior of martensitic stainless steel nitrided by plasma immersion ion implantation. Journal of Vacuum Science & Technology, A, 23(4), 693–698.

Zinkle, S. J. (2012). Radiation-induced effects on microstructure. In R. J. M. Konings (Ed.), Comprehensive nuclear materials (Vol. 1, pp. 65–98). Amsterdam, The Netherland: Elsevier.

Acknowledgment

This work was partly supported by JSPS KAKENHI Grant Number JP20K04246. We greatly appreciate the guidance provided by Mr. Y. Ishimoto and Mr. N. Fuyama of Hiroshima Prefectural Technology Research Center regarding the use of SEM and of the EDX apparatus. We also express our gratitude to Mr. Y. Yoshikawa and Mr. Y. Mikami of Hiroshima Kokusai Gakuin University for their assistance in preparing the samples.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This paper was presented at ASPEN 2019.

Rights and permissions

About this article

Cite this article

Nakamura, M., Nakasa, K., Kitamika, Y. et al. Formation of Fine Protrusions by Sputter Etching of Stainless Steels and Evaluation of Gripping Ability of Fiber Sheets. Int. J. Precis. Eng. Manuf. 22, 689–696 (2021). https://doi.org/10.1007/s12541-021-00495-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-021-00495-0