Abstract

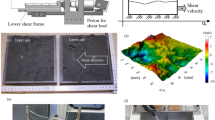

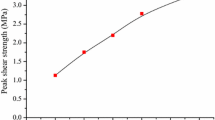

Changes in shear velocity can strengthen or weaken the frictional resistance of joints/faults in natural systems, but the mechanism remains unclear. We investigated the shear behavior of a rough basalt fracture in well-controlled, repeatable shear tests under constant and dynamic normal load conditions at different shear velocities. Normal load vibrations, simulating a dynamic normal load, were applied to the upper block of a fractured basalt sample. Simultaneously, a shear load was applied to the bottom block, providing a constant shear velocity. The peak shear strength increased with increasing shear velocity under constant normal load conditions. The peak shear strength decreased at a lower shear velocity under normal load vibrations. When the shear velocity exceeded the critical value, vc, the peak shear strength increased. The apparent coefficient of friction reduced under normal load vibrations. The reduction in the dynamic coefficient of friction increased with increasing shear velocity. We identified a phase shift between the peak normal load and peak shear load with peak shear load delay (D1) and a phase shift between peak normal load and the peak coefficient of friction with the peak coefficient of friction delay (D2). D1 and D2 were dependent on the quasi-static coefficient of friction and shear velocity, and both decreased with increasing shear velocity. D1 decreased with the increasing quasi-static coefficient of friction, while D2 was almost constant with changes in the quasi-static coefficient of friction. A new shear strength criterion was proposed for a rough joint under a constant shear velocity and normal load vibrations.

Similar content being viewed by others

Abbreviations

- F s :

-

Quasi-static normal force (kN)

- F d :

-

Dynamic normal force amplitude (kN)

- F s d :

-

Dynamic normal force (kN)

- F shear :

-

Shear force (kN)

- σ n :

-

Initial normal stress (MPa)

- σ :

-

Final normal stress (MPa)

- τ :

-

Shear stress (MPa)

- S :

-

Nominal area of the shear plane (m2)

- f :

-

Frequency (Hz)

- t :

-

Time (s)

- v :

-

Shear velocity (mm/min)

- v c :

-

Critical shear velocity (mm/min)

- f static :

-

Coefficient of quasi-static friction, i.e., initial coefficient of friction (–)

- f dynamic :

-

Coefficient of dynamic friction (–)

- ΔF N :

-

Changes of normal force (kN)

- ΔF s :

-

Changes of shear force (kN)

- ΔF N1 :

-

Changes of normal force in the loading stage (kN)

- ΔF N2 :

-

Changes of normal force in the unloading stage (kN)

- ΔF s1 :

-

Changes of shear force in the loading stage (kN)

- ΔF s2 :

-

Changes of shear force in the unloading stage (kN)

- Δf s1 :

-

Changes of coefficient of friction in the loading stage (–)

- Δf s2 :

-

Changes of coefficient of friction in the unloading stage (–)

- Δd 1 :

-

Changes of normal displacement in the loading stage (mm)

- Δd 2 :

-

Changes of normal displacement in the unloading stage (mm)

- ΔFyield :

-

Difference of Fshear between steady-state peak and initial level prior to vibration (kN)

- Δτ :

-

Transient change in shear stress (MPa)

- Δt :

-

Time shift (s)

- D1:

-

Phase shift between peak normal force and peak shear force (–)

- D2:

-

Phase shift between peak normal force and peak friction coefficient (–)

- a :

-

Factor 1 (–)

- b :

-

Factor 2 (–)

- α :

-

Parameter 1 (–)

- β :

-

Parameter 2 (–)

- \({\rho }_{\tau }\) :

-

Modulus of the normalized shear stress change (–)

- \({\gamma }_{\tau }\) :

-

Phase shift (°)

- E :

-

Energy consumption (J)

- d :

-

Shear displacement (mm)

- Ψ:

-

State of the asperity contacts (–)

References

Li Y, Sun S, Tang C (2019) Analytical prediction of the shear behaviour of rock joints with quantified waviness and unevenness through wavelet analysis. Rock Mech Rock Eng 52:1–13

Shang J, West LJ, Hencher SR (2018) Tensile strength of large-scale incipient rock joints: a laboratory investigation. Acta Geotech 13:869–886

Dang W, Konietzky H, Frühwirt T (2016) Rotation and stress changes of a plane joint during direct shear tests. Int J Rock Mech Min Sci 89:129–135

Stein RS (1999) The role of stress transfer in earthquake occurrence. Nature 402:605–609

Du HB, Dai F, Xu Y, Wei MD (2020) Mechanical responses and failure mechanism of hydrostatically pressurized rocks under combined compression-shear impacting. Int J Mech Sci 165:105219

Adam C, Adam D, Kopf F, Paulmichl I (2009) Computational validation of static and dynamic plate load testing. Acta Geotech 4(1):35–55

Candela T, Brodsky EE, Marone C, Elsworth D (2014) Laboratory evidence for particle mobilization as a mechanism for permeability enhancement via dynamic stressing. Earth Planet Sci Lett 392:279–291

Julian BR (2000) Period doubling and other nonlinear phenomena in volcanic earthquakes and tremor. J Volcanol Geothermal Res 101(1):19–26

Eshiet KI, Sheng Y (2017) The role of rock joint frictional strength in the containment of fracture propagation. Acta Geotech 12:897–920

Huang D, Song Y, Cen D (2016) Numerical modeling of earthquake-induced landslide using an improved discontinuous deformation analysis considering dynamic friction degradation of joints. Rock Mech Rock Eng 49(12):1–20

Huang D, Li Y, Song Y, Xu Q, Pei X (2019) Insights into the catastrophic Xinmo rock avalanche in Maoxian county, China: combined effects of historical earthquakes and landslide amplification. Eng Geol 258:105158

Wu H, Zhao G, Liang W (2019) Investigation of cracking behavior and mechanism of sandstone specimens with a hole under compression. Int J Mech Sci 163:105084

Cao W, Li X, Tao M (2016) Vibrations induced by high initial stress release during underground excavations. Tunn Undergr Space Technol 53:78–95

Hobbs BE, Brady BHG (1985) Normal stress changes and the constitutive law for rock friction (abstract). Eos Trans AGU 66:385

Olsson WA (1988) The effects of normal stress history on rock friction, key questions in rock mechanics, in Proceedings of the 29th U.S. Symposium, edited by P. A. Cundall, R. L. Sterling, and A. M. Starfield, 111–117, Univ. of Minnesota, Balkema.

Konietzky H, Frühwirt T, Luge H (2012) A new large dynamic rock mechanical direct shear box device. Rock Mech Rock Eng 45(3):427–432

Linker MF, Dieterich JH (1999) Effects of variable normal stress on rock friction: Observations and constitutive equations. J Geophys Res 97:4923–4940

Richardson E, Marone C (1999) Effects of normal force vibrations on frictional healing. J Geophys Res 28:859–878

Dang W, Konietzky H, Frühwirt T, Herbst M (2020) Cyclic frictional responses of planar joints under cyclic normal load conditions: Laboratory tests and numerical simulations. Rock Mech Rock Eng 53:337–364

Dang W, Konietzky H, Frühwirt T (2016) Shear behaviour of a plane joint under dynamic normal load (DNL) conditions. Eng Geol 213:133–141

Dang W, Konietzky H, Chang L, Frühwirt T (2018) Velocity-frequency-amplitude-dependent frictional resistance of planar joints under dynamic normal load (DNL) conditions. Tunn Undergr Space Technol 79:27–34

Dang W, Konietzky H, Frühwirt T (2017) Direct shear behavior of planar joints under cyclic normal load conditions: effect of different cyclic normal force amplitudes. Rock Mech Rock Eng 50(4):1–7

Hong T, Marone C (2005) Effects of normal stress perturbations on the frictional properties of simulated faults. Geochem Geophys Geosyst 6:Q03012

Kilgore B, Beeler N, Lozos JD (2017) Rock friction under variable normal stress. J Geophys Res Solid Earth 122:1–34

Kilgore B, Lozos J, Beeler N, Oglesby D (2012) Laboratory observations of fault strength in response to changes in normal stress. J Appl Mech 791007.

Prakash V, Clifton RJ (1993) Time resolved dynamic friction measurements in pressure-shear, in Experimental Techniques in the Dynamics of Deformable Solids. Appl Mech Div ASME 165:33–48

Prakash V (1998) Frictional response of sliding interfaces subjected to time varying normal pressures. J Tribol 120:97–102

Bureau L, Baumberger T, Caroli C (2000) Shear response of a frictional interface to a normal load modulation. Phys Rev E Stat Phys Plasmas Fluids Relat Interdiscip Topics 62(5):6810–6820

Perfettini H, Schmittbuhl J, Rice JR, Cocco M (2001) Frictional response induced by time dependent fluctuations of the normal loading. The analysis of international relations. Prentice Hall J Geophys Res 106:455–472

Cochard A, Bureau L, Baumberger T (2003) Stabilization of frictional sliding by normal load vibrations. J Appl Mech 70:220–226

Boettcher MS, Marone C (2004) Effects of normal stress variation on the strength and stability of creeping faults. J Geophys Res Solid Earth 109(B3).

Tang ZC, Wong LNY (2016) Influences of normal loading rate and shear velocity on the shear behavior of artificial rock joints. Rock Mech Rock Eng 49(6):1–8

Beeler NM, McLaskey G, Lockner D, Kilgore B (2019) Near‐fault velocity spectra from laboratory failures and their relation to natural ground motion. J Geophys Res Solid Earth JB017638.

Crawford AM, Curran JH (1981) The influence of shear velocity on the frictional resistance of rock discontinuities. Int J Rock Mech Min Sci Geomech Abstracts 18(6):505–515

Cochard A, Rice JR (2000) Fault rupture between dissimilar materials: Ill-posedness, regularization, and slip-pulse response. J Geophys Res 105:891–925

Tse R (1979) Cruden DM (1979) Estimating joint roughness coefficients. Int J Rock Mech Min Sci Geomech Abstr 16(5):303–307

Barton NR, Choubey V (1977) The shear strength of rock joints in theory and practice. Rock Mech 10:1–54

Wang G, Zhang X, Jiang Y, Wu X, Wang S (2016) Rate-dependent mechanical behavior of rough rock joints. Int J Rock Mech Min Sci 83:231–240

Rice JR, Lapusta N, Ranjith K (2001) Rate and state dependent friction and the stability of sliding between elastically deformable solids. J Mech Phy Solid 49:1865–1898

Song Y, Huang D, Cen D (2016) Numerical modelling of the 2008 Wenchuan earthquake-triggered Daguangbao landslide using a velocity and displacement dependent friction law. Eng Geol 215:50–68

Dang W, Wu W, Konietzky H, Qian J (2019) Effect of shear-induced aperture evolution on fluid flow in rock fractures. Comp Geotech 114:103152

Song Z, Konietzky H, Herbst M (2018) Bonded-particle model-based simulation of artificial rock subjected to cyclic loading. Acta Geotech 14:955–971

Cai X, Zhou Z, Du X (2020) Water-induced variations in dynamic behavior and failure characteristics of sandstone subjected to simulated geo-stress. Int J Rock Mech Min Sci 130:104339

Acknowledgements

This work was supported by the National Nature Science Foundation of China (51678578 , 51904359 & 51978677), Natural Science Foundation of Guangdong Province of China (2020A151501528), Fundamental Research Funds for the Central Universities (19lgzd41), Natural Science Foundation of Shenzhen (JCYJ20190807162401662), and the Open Research Fund of the State Key Laboratory of Coal Resources and Safe Mining, CUMT (SKLCRSM20KF002). Special thanks to Prof. Heinz Konietzky, Dr. Thomas Frühwirt, Mr. Tom Weichmann, Mrs. Beatrice Tauch and Mr. Gerd Münzberger for help during laboratory testing.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The author declres that thay have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dang, W., Chen, J. & Huang, L. Experimental study on the velocity-dependent frictional resistance of a rough rock fracture exposed to normal load vibrations. Acta Geotech. 16, 2189–2202 (2021). https://doi.org/10.1007/s11440-021-01168-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-021-01168-y