Abstract

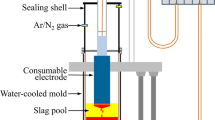

Pressurized electroslag remelting (PESR) has been widely used for preparation of high-quality high nitrogen steels. However, desulfurization might be limited by the pressurized-nitrogen atmosphere in the process. In this paper, the desulfurization behaviors of electroslag remelting in air and nitrogen pressure were investigated and further an appropriate method to improve the sulfur removal in PESR was explored. The results show that the ESR in air maintained relatively high and stable desulfurization ability, but the PESR provided worse sulfur removal owing to the lack of sulfur gasifying oxidation under N2 pressure. With the decline of sulfur distribution coefficient (LS) and the enrichment of sulfur in slag during the remelting, the desulfurization in PESR was gradually weakened. The level of gas pressure had little effect on sulfur removal. The Na2O addition in conventional CaO-Al2O3-CaF2 slags significantly increased the activity of desulfurizers and LS, and slightly improved sulfur mass transfer in slags, then alleviated the negative effect brought by the reduction of desulfurization ability in PESR and achieved higher desulfurization degree. In addition, desulfurization in the remelting was mainly achieved at the liquid metal film of electrode tips, which was benefited from the great reaction specific surface area and high initial sulfur content.

Similar content being viewed by others

REFERENCES

1. G. Stein, and J. Menzel: Int. J. Mater. Prod. Tec., 1995, vol. 10, pp. 478–88.

2. J. Yu, F.B. Liu, H.B. Li, Z.H. Jiang, Y. Li, C.P. Kang, A. Wang, W.C. Zhang, and H. Feng: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 3112–24.

3. H.C. Zhu, Z.H. Jiang, H.B. Li, H. Feng, W.C. Jiao, S.C. Zhang, P.B. Wang, and J.H. Zhu: ISIJ Int., 2018, vol. 58, pp. 1267–74.

4. Z.H. Jiang, H.C. Zhu, H.B. Li, G.H. Liu, P.B. Wang, J.H. Zhu, S.C. Zhang, and H. Feng: ISIJ Int., 2018, vol. 58, pp. 107–13.

5. T. Mattar, K. El Fawakhry, H. Halfa, and M. El Demerdash: Metall. Mater. Trans. B, 2006, vol. 36B, pp. 987–95.

6. J. Yu, F.B. Liu, Z.H. Jiang, H.B. Li, C.P. Kang, W.C. Zhang, A. Wang, and X. Geng: ISIJ Int., 2020, vol. 60, pp. 1684–92.

7. H. Feng, H.B. Li, W.C. Jiao, Z.H. Jiang, M.H. Cai, H.C. Zhu, and Z.G. Chen: Metall. Mater. Trans. A, 2019, vol. 50A, pp. 4987–99.

8. C.B. Shi, Y. Huang, J.X. Zhang, J. Li, and X. Zheng: Int. J. Miner. Metall. Mater., 2020, https://doi.org/10.1007/s12613-020-2075-3.

9. Y. Liu, Z. Zhang, G.Q. Li, Q. Wang, L. Wang, and B.K. Li: Steel Res. Int., 2017, vol. 88, pp. 1700058.

10. K. Narita, T. Onoye, T. Ishii, and T. Kusamichi: Tetsu-to-Hagané, 1978, vol. 64, pp. 1568–77 (in Japanese).

11. M. Kato, K. Hasegawa, S. Nomura, and M. Inouye: Trans. ISIJ, 1983, vol. 23, pp. 618–27.

12. R.S.E. Schneider, M. Molnar, S. Gelder, G. Reiter, and C. Martinez: Steel Res. Int., 2018, vol. 89, pp. 1800161.

T. Mattar, Kamal EI-Fawakhry, H. Haifa, and M. Eissa: Steel Res. Int., 2008, vol. 79, pp. 691–97.

M. Eissa, and A. EI-Mohammadi: Steel Res., 1998, vol. 69, pp. 413–17.

15. C.B. Shi, X.C. Chen, H.J. Guo, Z.J. Zhu, and H. Ren: Steel Res. Int., 2012, vol. 83, pp. 472–86.

16. L.Z. Chang, X.F. Shi, and J.Q. Cong: Ironmak. Steelmak., 2014, vol. 41, pp. 182–86.

17. X.C. Chen, C.B. Shi, F. Wang, H. Ren, and H.J. Guo: J. Mater. Metall., 2013, vol. 12, pp. 27–32 (in Chinese).

18. S.C. Duan, X. Shi, M.C. Zhang, B. Li, W.S. Yang, F. Wang, H.J. Guo, and J. Guo: Metall. Mater. Trans. B, 2019, vol. 51B, pp. 353–64.

19. K. Mineura, I. Takahashi, and K. Tanaka: ISIJ Int., 1990, vol. 30, pp. 192–98.

20. C.B. Shi, W.T. Yu, H. Wang, J. Li, and M. Jiang: Metall. Mater. Trans. B, 2016, vol. 48B, pp. 146–61.

21. E. Moosavi-Khoonsari, and I.H. Jung: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 2875–88.

22. Y.H. Gao, Q.C. Liu, and L.T. Bian: Metall. Mater. Trans. B, 2011, vol. 43B, pp. 229–32.

23. M.K. Cho, J. Cheng, J.H. Park, and D.J. Min: ISIJ Int., 2010, vol. 50, pp. 215–21.

24. A. Hernandez, A. Romero, F. Chavez, M. Angeles, and R.D. Morales: ISIJ Int., 1998, vol. 38, pp. 126–31.

25. W.H.V. Niekerk, and R.J. Dippenaar: ISIJ Int., 1993, vol. 33, pp. 59–65.

26. J.Y. Choi, D.J. Kim, and H.G. Lee: ISIJ Int., 2001, vol. 41, pp. 216–24.

27. Q. Stein, I. Huchlenbroich, and M. Wagner: Mater. Sci. Forum, 1999, vol. 318-320, pp. 167–74.

28. T. Rashev: Mater. Manuf. Process., 2004, vol. 19, pp. 31–40.

29. S.C. Liu, T. Hashida, H. Takahashi, H. Kuwano, and Y. Hamaguchi: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 791–98.

30. Q. Stein, and I. Huchlenbroich: Mater. Manuf. Process., 2006, vol. 19, pp. 7–17.

31. P. Saravanan, and V.S. Raja: Int. J. Mater. Chem. Phys., 2015, vol. 1, pp. 141–45.

32. P. Saravanan, and V.S. Raja: Int. J. Mater. Chem. Phys., 2015, vol. 1, pp. 212–19.

33. D.E. Williams, M.R. Kilburn, J. Cliff, and G.I. Waterhouse: Corros. Sci., 2010, vol. 52, pp. 3702–16.

34. P. Roffey, and E.H. Davies: Eng. Fail. Anal., 2014, vol. 44, pp. 148–57.

35. A. Matsui, Y. Uchida, N. Kikuchi, and Y. Miki: ISIJ Int., 2017, vol. 57, pp. 1012–18.

36. S.H. Lee, and D.J. Min: Materials, 2020, vol. 13, pp. 2478.

37. J.H. Wei, and A. Mitchell: Acta Metall. Sin., 1984, vol. 5, pp. 261–79 (in Chinese).

38. D. Hou, Z.H. Jiang, Y.W. Dong, Y. Li, W. Gong, and F.B. Liu: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 1885–97.

39. D. Hou, D.Y. Wang, T.P. Qu, J. Tian, and H.H. Wang: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 3088–102.

40. Q. Wang, Y. Liu, F. Wang, G.Q. Li, B.K. Li, and W.W. Qiao: Metall. Mater. Trans. B, 2017, vol. 48B, pp. 2649–63.

41. K.H. Zhang, Y.L. Zhang, and T. Wu: J. Iron Steel Res. Int., 2019, vol. 26, pp. 1041–51.

42. H. Iwai, and K. Kunisada: ISIJ Int., 1989, vol. 29, pp. 135–39.

43. K.H. Zhang, Y.L. Zhang, F.S. Li, and T. Wu: J. Iron Steel Res., 2018, vol. 4, pp. 265–72 (in Chinese).

44. Z.H. Jiang, D. Hou, Y.W. Dong, Y.L. Cao, H.B. Cao, and W. Gong: Metall. Mater. Trans. B, 2016, vol. 47B, pp. 1465–74.

45. J.Y. Li, and G.G. Cheng: ISIJ Int., 2019, vol. 59, pp. 2013–23.

46. C.B. Shi, X.M. Yang, J.S. Jiao, C. Li, and H.J. Guo: ISIJ Int., 2010, vol. 50, pp. 1362–72.

47. X.M. Yang, C.B. Shi, M. Zhang, G.M. Chai, and F. Wang: Metall. Mater. Trans. B, 2011, vol. 42B, pp. 1150–80.

48. W.M. Li, Y.L. Sun, S.P. Wu, and X.M. Zang: High Temp. Mat. PR-ISR, 2020, vol. 39, pp. 405–16.

49. C.B. Shi, D.L. Zheng, B.S. Guo, J. Li, and F. Jiang: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 3390–3402.

50. C.B. Shi: ISIJ Int., 2020, https://doi.org/10.2355/isijinternational.ISIJINT-2019-661.

51. Z.H. Jiang, G. Xu, Y. Li, H.B. Li, J.B. Lv, and Q. Wang: ISIJ Int., 2018, vol. 59, pp. 1234–41.

52. H. Wang, J. Li, C.B. Shi, Y.F. Qi, and Y.X. Dai: ISIJ Int., 2019, vol. 59, pp. 828–38.

53. T.S. Zhang, D.Y. Wang, C.W. Liu, M.F. Jiang, M. Lu, B. Wang, and S.X. Zhang: J. Iron Steel Res. Int., 2014, vol. 21, pp. 99–103.

54. M.A. Swetnam, R.V. Kumar, and D.J. Fray: Metall. Mater. Trans. B, 2006, vol. 37B, pp. 381–88.

55. Y.N. Wang, J. Yang, and Y.P. Bao: Metall. Mater. Trans. B, 2014, vol. 45B, pp. 2669–78.

56. J.M. Su, Z.H. Dou, T.A. Zhang, and Y. Liu: J. Iron Steel Res. Int., 2020, vol. 27, pp. 392–401.

57. X.M. Li, M. Lv, W.D. Yin, J.X. Zhao, and Y.R. Cui: J. Iron Steel Res. Int., 2018, vol. 26, pp. 519–28.

58. K.H. Zhang, Y.L. Zhang, and T. Wu: Metals, 2018, vol. 8, pp. 1068.

59. J.J. Pak, K. Ito, and F.J. Fruehan: ISIJ Int., 1989, vol. 29, pp. 318–23.

60. R. Inoue, and H. Suito: Trans. ISIJ, 1982, vol. 22, pp. 514–23.

61. Z.F. Tong, J.L. Qiao, and X.Y. Jiang: ISIJ Int., 2017, vol. 57, pp. 245–53.

62. M. Li, T. Utigard, and M. Barati: Metall. Mater. Trans. B, 2014, vol. 46B, pp. 74–82.

63. H. van Limpt, R. Beerkens, and O. Verheijen: J. Am. Ceram. Soc., 2006, vol. 89, pp. 3446–55.

64. J.J. Pak, and R.J. Fruehan: Metall. Trans. B, 1991, vol. 22B, pp. 39–46.

ACKNOWLEDGMENT

This research was sponsored by the National Natural Science Foundation of China [Grant Nos. U1960203/51774074/52004060], China National Postdoctoral Program for Innovative Talents [Grant No. BX20200076], China Postdoctoral Science Foundation [Grant No. 2020M670775], Talent Project of Revitalizing Liaoning [Grant No. XLYC1902046], Shanxi Municipal Major Science & Technology Project [Grant No. 20181101014], and Transformation Project of Scientific and Technological Achievements in Jiangsu Province (Grant No. BA2017135).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 24, 2020; accepted January 20, 2021.

Rights and permissions

About this article

Cite this article

Yang, SX., Li, HB., Feng, H. et al. Desulfurization Behavior of Fe-18Cr-18Mn Alloy during the Pressurized Electroslag Remelting with Different Atmospheres and Na2O-containing Slags. Metall Mater Trans B 52, 1294–1308 (2021). https://doi.org/10.1007/s11663-021-02092-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02092-y