Abstract

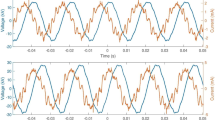

Drying has been used to preserve food for ages. Various techniques have been applied to obtain a final product that is reduced in terms of both volume and weight. This research was performed to specify the influences of convective drying (50 and 75 °C), microwave drying (90 and 160 W) and combination of microwave and convective drying (for 90 W both 50 °C and 75 °C, for 160 W both 50 °C and 75 °C) operations on drying kinetics, energy and specific energy consumption, color, activation energy, and effective moisture diffusivity of pepinos. To select the most appropriate pattern of drying curves, experimental data was utilized in ten different mathematical models. Based on the statistical tests applied to make an assessment, for all drying conditions models of Midilli et al. and Wang and Singh were found to satisfactorily explain drying kinetics of pepino. The results indicated that total energy consumption lowered with the rise of microwave power and air temperature owing to the decline of drying period with the rise of air temperature and microwave power. From the color of dried samples, the lightness value decreased from with increasing drying temperature compared with the fresh product. Offering high-quality final product with low economic cost in food industry leads to the proliferation of the research topics on the development of drying methods.

Similar content being viewed by others

References

Aghbashlo M, Samimi-Akhijahani H (2008) Influence of drying conditions on the effective moisture diffusivity, energy of activation and energy consumption during the thin-layer drying of berberis fruit (Berberidaceae). Energ Convers Manag 49(10):2865–2871

Amiri Chayjan R, Kaveh M, Khayati S (2015) Modeling drying characteristics of hawthorn fruit under microwave-convective conditions. J Food Process Preserv 39(3):239–253

An K, Zhao D, Wang Z, Wu J, Xu Y, Xiao G (2016) Comparison of different drying methods on Chinese ginger (Zingiber officinale Roscoe): Changes in volatiles, chemical profile, antioxidant properties, and microstructure. Food Chem 197:1292–1300

Arumuganathan T, Manikantan MR, Rai RD, Anandakumar S, Khare V (2009) Mathematical modeling of drying kinetics of milky mushroom in a fluidized bed dryer. Int Agrophys 23(1):1–7

Bhattacharya M, Srivastav PP, Mishra HN (2015) Thin-layer modeling of convective and microwave-convective drying of oyster mushroom (Pleurotus ostreatus). J Food Sci Technol 52(4):2013–2022

Calín-Sanchez Á, Figiel A, Szarycz M, Lech K, Nuncio-Jáuregui N, Carbonell-Barrachina ÁA (2014) Drying kinetics and energy consumption in the dehydration of pomegranate (Punica granatum L.) arils and rind. Food Bioprocess Tech 7(7):2071–2083

Celen S, Kahveci K (2013) Microwave drying behaviour of apple slices. Proc Inst Mech Eng P 227(4):264–272

Crank J (1975) The mathematics of diffusion, 2nd edn. Oxford University Press, Oxford, pp 104–106

Doymaz İ (2007) Influence of pretreatment solution on the drying of sour cherry. J Food Eng 78(2):591–596

Doymaz İ (2011) Drying of Pomegranate arils and selection of a suitable drying model. Food Biophys 6(4):461–467

Doymaz İ (2012) Infrared drying of sweet potato (Ipomoea batatas L.) slices. J Food Sci Technol 49(6):760–766

Doymaz İ, İsmail O (2011) Drying characteristics of sweet cherry. Food Bioprod Process 89(1):31–38

Doymaz İ, Kipcak AS, Piskin S (2015) Microwave drying of green bean slices: Drying kinetics and physical quality. Czech J Food Sci 33(4):367–376

Evin D (2011) Microwave drying and moisture diffusivity of white mulberry: experimental and mathematical modeling. J Mech Sci Technol 25(10):2711–2718

Francke A (2010) The effect of magnesium fertilization on the macronutrient content of pepino dulce (Solanum muricatum Ait.) fruit. J Elementol 15(3):467–475

Giri SK, Prasad S (2007) Drying kinetics and rehydration characteristics of microwave-vacuum and convective hot-air dried mushrooms. J Food Eng 78(2):512–521

Gowen AA, Abu-Ghannam N, Frias JM, Barat JM, Andres AM, Oliveira JC (2006) Comparative study of quality changes occurring on dehydration and rehydration of cooked chickpeas (Cicer arietinum L.) subjected to combined microwave–convective and convective hot air dehydration. J Food Sci 71(6):282–289

Herraiz FJ, Raigón MD, Vilanova S, García-Martínez MD, Gramazio P, Plazas M, Garcia-Martinez MD, Prohens J (2016) Fruit composition diversity in land races and modern pepino (Solanum muricatum) varieties and wild related species. Food Chem 203:49–58

Horuz E, Maskan M (2015) Hot air and microwave drying of pomegranate (Punica granatum L.) arils. J Food Sci Technol 52(1):285–293

Horuz E, Bozkurt H, Karataş H, Maskan M (2018) Simultaneous application of microwave energy and hot air to whole drying process of apple slices: drying kinetics, modeling, temperature profile and energy aspect. Heat Mass Transfer 54(2):425–436

Kadam DM, Dhingra D (2011) Mass transfer kinetics of banana slices during osmo-convective drying. J Food Process Eng 34(2):511–532

Kassem AS, Shokr AZ, El-Mahdy AR, Aboukarima AM, Hamed EY (2011) Comparison of drying characteristics of Thompson seedless grapes using combined microwave oven and hot air drying. J Saudi Soc Agric Sci 10(1):33–40

Kouchakzadeh A, Shafeei S (2010) Modeling of microwave-convective drying of pistachios. Energ Convers Manage 51(10):2012–2015

Kowalski SJ, Pawłowski A (2011) Energy consumption and quality aspect by intermittent drying. Chem Eng Process 50(4):384–390

Li L, Wang Z, Hu X, Wu J, Liao X, Chen F, Zhao G (2010) Drying effects of two air-drying shelters in a pilot test on sultana grapes. J Food Process Eng 33(1):162–178

Maheshwari RK, Malhotra J, Mohan L, Upadhyay B (2014) Exotic Pepino: a shrub for prophylactic consequence and nutritional regime. Int J Pharma Res Health Sci 2(1):42–48

Malafronte L, Lamberti G, Barba AA, Raaholt B, Holtz E, Ahrné L (2012) Combined convective and microwave assisted drying: experiments and modeling. J Food Eng 112:304–312

Martinez-Romero D, Serrano M, Valero D (2003) Physiological changes in pepino (Solanum muricatum Ait.) fruit stored at chilling and non-chilling temperatures. Postharvest Biol Technol 30:177–186

Midilli A, Kucuk H, Yapar Z (2002) A new model for single layer drying. Dry Technol 20(7):1503–1513

Minaei S, Motevali A, Najafi G, Mousavi Seyedi SR (2011) Influence of drying methods on activation energy, effective moisture diffusion and drying rate of pomegranate arils (‘Punica granatum’). Aust J Crop Sci 6(4):584–591

Motevali A, Abbaszadeh A, Minaei S, Khoshtaghaza MH, Ghobadian B (2012) Effective moisture diffusivity, activation energy and energy consumption in thin-layer drying of Jujube (Zizyphus jujube Mill). J Agric Sci Tech 14(3):523–532

Murthy TPK, Manohar B (2014) Hot air drying characteristics of mango ginger: prediction of drying kinetics by mathematical modeling and artificial neural network. J Food Sci Technol 51(12):3712–3721

Omolola AO, Jideani AIO, Kapila PF (2014) Modeling microwave drying kinetics and moisture diffusivity of Mabonde banana variety. Int J Agric Biol Eng 7(6):107–113

Orhan N, Deliorman Orhan D, Aslan M, Ergun F (2014) Effect of exotic fruit “Pepino” (Solanum muricatum Aiton.) on blood glucose level. Turkish. J Pharm Sci 11(2):195–202

Özbek B, Dadali G (2007) Thin-layer drying characteristics and modelling of mint leaves undergoing microwave treatment. J Food Eng 83(4):541–549

Rayaguru K, Routray W (2011) Microwave drying kinetics and quality characteristics of aromatic Pandanus amaryllifolius leaves. Int Food Res J 18(3):1035–1042

Sadeghi M, Mirzabeigi Kesbi O, Mireei SA (2013) Mass transfer characteristics during convective, microwave and combined microwave–convective drying of lemon slices. J Sci Food Agric 93(3):471–478

Saxena J, Dash KK (2015) Drying kinetics and moisture diffusivity study of ripe jackfruit. Int Food Res J 22(1):414–420

Scala DK, Vega-Galvez A, Uribe E, Oyanadel R, Miranda M, Vergara J, Quispe I, Lemus-Mondaca R (2011) Changes of quality characteristics of pepino fruit (Solanum muricatum Ait) during convective drying. Int J Food Sci Technol 46:746–753

Di Scala K, Vega-Gálvez A, Uribe E, Oyanadel R, Miranda M, Vergara J, Lemus-Mondaca R (2011) Changes of quality characteristics of pepino fruit (Solanum muricatum Ait) during convective drying. Int J Food Sci Technol 46(4):746–753

Tham TC, Ng MX, Ong SP, Hii CL, Law CL (2018) Application of microwave-assisted drying on specific energy consumption, effective diffusion coefficient and topological changes of crumb natural rubber (Cis‑1, 4‑polyisoprene). Chem Eng Process 128:19–35

Unal HG, Sacilik K (2011) Drying characteristics of hawthorn fruits in a convective hot-air dryer. J Food Process Preserv 35(2):272–279

Uribe E, Vega-Galvez A, Scala DK, Oyanadel R, Torrico JS, Miranda M (2011) Characteristics of convective drying of pepino fruit (Solanum muricatum Ait.): application of weibull distribution. Food Bioprocess Technol 4:1349–1356

Valadez-Carmona L, Cortez-García RM, Plazola-Jacinto CP, Necoechea-Mondragón H, Ortiz-Moreno A (2016) Effect of microwave drying and oven drying on the water activity, color, phenolic compounds content and antioxidant activity of coconut husk (Cocos nucifera L.). J Food Sci Technol 53(9):3495–3501

Vega-Gálvez A, Di Scala K, Rodríguez K, Lemus-Mondaca R, Miranda M, López J, Perez-Won M (2009) Effect of air-drying temperature on physico-chemical properties, antioxidant capacity, colour and total phenolic content of red pepper (Capsicum annuum, L. var. Hungarian). Food Chem 117(4):647–653

Wang ZF, Fang SZ, Hu XS (2009) Effective diffusivities and energy consumption of whole fruit Chinese jujube (Zizyphus jujuba Miller) in microwave drying. Dry Technol 27(10):1097–1104

Xie L, Mujumdar AS, Zhang Q, Wang J, Liu S, Deng L, Gao ZJ (2017) Pulsed vacuum drying of wolfberry: Effects of infrared radiation heating and electronic panel contact heating methods on drying kinetics, color profile, and volatile compounds. Dry Technol 35(11):1312–1326

Łechtańska JM, Szadzińska J, Kowalski SJ (2015) Microwave-and infrared-assisted convective drying of green pepper: quality and energy considerations. Chem Eng Process 98:155–164

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

G. Izli, O. Taskin and N. Izli declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Izli, G., Taskin, O. & Izli, N. Convective, Microwave and Combined Microwave-Convective Drying of Pepino. Erwerbs-Obstbau 63, 175–184 (2021). https://doi.org/10.1007/s10341-021-00555-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10341-021-00555-9