Abstract

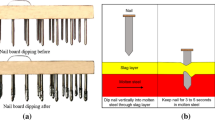

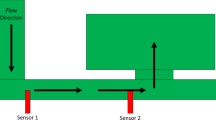

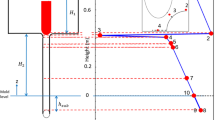

In the current study, the transient fluid flow pattern in steel continuous casting molds with varied dimensions was evaluated using nail board measurement and onsite top flux observation. Effects of steel throughput, argon flow rate, submergence depth of the submerged entry nozzle, and mold dimension on the flow pattern inside the mold were investigated. The top flux under lower steel throughput, higher gas flow rate, and shallower submergence depth of the submerged entry nozzle were easily swept away by argon bubbles so that the molten steel was exposed to the air, called exposed eyes. Linear fitting equations between the steel throughput and the gas volume percentage for the transient flow pattern were performed. The critical linear relationships of the double roll flow pattern transformed to the complex flow, and the complex flow transformed to the single roll flow pattern. Flow pattern regimes were plotted with the results of the industrial measurements. The present work aimed at providing an operating interval of the steel throughput and the gas volume percentage to maintain the double roll flow pattern inside the mold for the regular casting practice.

Similar content being viewed by others

References

H. Nakato, M. Ozawa, K. Kinoshita, Y. Habu, T. Emi, Trans. Iron Steel Inst. Jpn. 24, 957–965 (1984)

W.H. Emling, T.A. Waugaman, S.L. Feldbauer, and A.W. Cramb: Steelmaking Conf. Proc., 1994, pp. 371–79.

J. Knoepke, M. Hubbard, J. Kelly, R. Kittridge, and J. Lucas: Steelmaking Conf. Proc., Chicago, IL, 1994, pp. 381–88.

R. McDavid, B. Thomas, Metall. Mater. Trans. B 27, 672–685 (1996)

N. Kasai, H. Mizukami, A. Mutou, Tetsu-to-Hagané 89, 1120–1127 (2003)

X. Zhang, Y. Ren, L. Zhang, Metall. Mater. Trans. A 49, 5469–5477 (2018)

L. Zhang: Non-metallic Inclusions in Steels: Industrial Practice (in Chinese), Metallurgical Industry Press, 2019, pp. 63–70.

P. Andrzejewski, K.U. Kohler, W. Pluschkell, Steel Res. 63, 242–246 (1992)

T. Teshima, J. Kubota, M. Suzuki, K. Ozawa, T. Masaoka, S. Miyahara, Tetsu-to-Hagane 79, 576–582 (1993)

P.H. Dauby, M.B. Assar, and G.D. Lawson: La Rev. Metall.-CIT, 2001, vol. 98, pp. 353–66.

P.H. Dauby, S. Kunstreich, ISSTech2003 (Warrendale, PA, ISS, 2003), pp. 491–503

L. Zhang, S. Yang, K. Cai, J. Li, X. Wan, B.G. Thomas, Metall. Mater. Trans. B 38, 63–83 (2007)

Z. Liu, B. Li, M. Jiang, F. Tsukihashi, ISIJ Int. 53, 484–492 (2013)

I.C. Ramos, R.D. Morales, S. Garcia-Hernandez, A. Ceballos-Huerta, ISIJ Int. 54, 1797–1806 (2014)

M.M. Salazar-Campoy, R.D. Morales, A. Nájera-Bastida, V. Cedillo-Hernández, J.C. Delgado-Pureco, Metall. Mater. Trans. B 48, 1376–1389 (2017)

N. Bessho, R. Yoda, H. Yamasaki, Iron Steelmaker 18, 39–44 (1991)

B.G. Thomas, X. Huang, R.C. Sussman, Metall. Mater. Trans. B 25, 527–547 (1994)

R. Liu, B.G. Thomas, J. Sengupta, S.D. Chung, M.K. Trinh, ISIJ Int. 54, 2314–2323 (2014)

W. Chen, Y. Ren, L. Zhang, P.R. Scheller, JOM 71, 1158–1168 (2019)

K. Kohler, P. Andrzejewski, E. Julius, and H. Haubrich: Steelmaking Conf. Proc., 1995, pp. 445–49.

S. Kunstreich, P. Dauby, Ironmaking Steelmaking 32, 80–86 (2005)

J. Zheng, R. Liu, X. Wang, G. Xu, Z. Lyu, Y. Kolesnikov, X. Na, Metall. Mater. Trans. B 51, 558–569 (2020)

H.H. Visser, W. Van Der Knoop, W.F.M. Damen, T.G. Van Essen, J. Van Oord, D. Bal, S.R. Higson, J.P.T.M. Brockhoff, Metall. Ital. 101, 61–67 (2009)

T. Zhang, J. Yang, P. Jiang, Metals 9, 36 (2019)

P.H. Dauby, Iron Steel Technol. 8, 152–160 (2011)

X. Deng, C. Ji, Y. Cui, L. Li, X. Yin, Y. Yang, A. McLean, Ironmaking Steelmaking 44, 461–471 (2017)

R.M. Mcdavid, B.G. Thomas, Metall. Trans. B 27, 672–685 (1996)

B. Rietow, B.G. Thomas, AISTech 2008 Steelmaking Conference Proc (Pittsburgh, PA, 2008).

K. Cukierski, B.G. Thomas, Metall. Mater. Trans. B 39, 94–107 (2008)

K. Timmel, N. Shevchenko, M. Röder, M. Anderhuber, P. Gardin, S. Eckert, G. Gerbeth, Metall. Mater. Trans. B 46, 700–710 (2015)

H. Bai, B.G. Thomas, Metall. Mater. Trans. B 32, 1143–1159 (2001)

R. Liu, B.G. Thomas, Metall. Mater. Trans. B 46, 388–405 (2015)

L. Zhang, B.G. Thomas, ISIJ Int. 43, 271–291 (2003)

Q. He, ISIJ Int. 33, 343–345 (1993)

B. Li, F. Tsukihashi, Trans. Iron Steel Inst. Jpn. 45, 30–36 (2005)

G. Kastner, W. Brandstätter, B. Kaufmann, C. Wassermayr, M. Javurek, Steel Res. Int. 77, 404–408 (2006)

L. Zhang, S. Taniguchi, K. Cai, Metall. Mater. Trans. B 31, 253–266 (2000)

L. Zhang, S. Taniguchi, Int. Mater. Rev. 45, 59–82 (2000)

L. Zhang, S. Taniguchi, and K. Matsumoto: Ironmak.ing Steelmak., 2002, vol. 29, pp. 326–36.

L. Zhang, Y. Wang, X. Zuo, Metall. Mater. Trans. B 39, 534–550 (2008)

S. Yamashita, M. Iguchi, ISIJ Int. 41, 1529–1531 (2001)

L.C. Hibbeler, B.G. Thomas, Iron Steel Technol. 10, 121–136 (2013)

X. Zhang, Y. Ren, L. Zhang, W. Yang, Metall. Mater. Trans. B 49, 3186–3199 (2018)

Z.Q. Liu, F.S. Qi, B.K. Li, S.C.P. Cheung, Int. J. Multiphase Flow 79, 190–201 (2016)

Acknowledgments

The authors are grateful for support from the National Science Foundation China (Grant No. U1860206, No. 51725402), S&T Program of Hebei (Grant No. 20311004D), the High Steel Center (HSC) at Yanshan University, and the High Quality Steel Consortium (HQSC) at University of Science and Technology Beijing (USTB), China.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted November 4, 2020; accepted January 14, 2021.

Rights and permissions

About this article

Cite this article

Zhou, H., Zhang, L., Chen, W. et al. Determination of Transient Flow Pattern in Steel Continuous Casting Molds Using Nail Board Measurement and Onsite Top Flux Observation. Metall Mater Trans B 52, 1106–1117 (2021). https://doi.org/10.1007/s11663-021-02083-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02083-z