Abstract

Neodymium is one the most widely used rare-earth metals, the main quantity of which is used in manufacturing permanent magnets. Experimental data on the physicochemical properties of neodymium and the Fe–30% Nd–1% B–1% Co–1% Dy alloy in the liquid state are reported. Initially, in manufacturing NdFeB magnets, an Fe–30% Nd–1% B–1% Co–1% Dy ingot is prepared. The kinematic viscosity and electrical resistivity of liquid Nd (99.85% purity) and the kinematic viscosity of the Fe–30% Nd–1% B–1% Co–1% Dy alloy are measured. The temperature dependence of the kinematic viscosity of the neodymium melt is described by the Arrhenius–Frenkel–Eyring equation and agrees with the results of theoretical calculation. The temperature of the kinematic viscosity of the Fe–30% Nd–1% B–1% Co–1% Dy melt exhibits anomalous behavior in a temperature range of 1320–1550°C: the viscosity increases with the temperature. The increase in the viscosity with the temperature, i.e., so-called “quasi-gas” behavior of the melt is described in terms of physical chemistry concepts using the molar viscosity concept. The temperature dependence of the electrical resistivity of liquid neodymium is described by a linear function. The measured values of the electrical resistivity of the neodymium melt are 30% higher than the experimental values obtained by other investigators. The measured results are recommended to optimize the metallurgical production conditions of the sintered permanent NdFeB magnets in Ural Strip Casting.

Similar content being viewed by others

REFERENCES

M. E. Drits, Properties of Elements: Handbook (ID Ruda Metally, Moscow, 2003).

E. M. Savitskii, V. F. Terekhova, and O. P. Naumkin, “Physicochemical properties of rare-earth metals, scandium, and yttrium,” Usp. Fiz. Nauk LXXIX (2), 263–293 (1963).

A. I. Kiselev and V. I. Kononenko, Thermophysical Properties of Rare-Earth Metals Melts: Numerical Estimates (UrO RAN, Ekaterinburg, 2003).

V. I. Kononenko, A. L. Sukhman, S. L. Gruverman, and V. V. Torokin, “Density and surface tension of liquid rare earth metals, scandium and yttrium,” Phys. Stat. Sol. (a). 84, 423–432 (1984).

S. I. Popel’, Surface Phenomena in Melts (Metallurgiya, Moscow, 1994).

R. A. Khairulin and S. V. Stankus, “Change in the praseodymium and neodymium density at crystallization from liquid state,” in Thermal Physics of Crystallization of Substances and Materials (Inst. Teor. Fiz., Sib. Otd. Akad. Nauk SSSR, Novosibirsk, 1987), pp. 143–154.

W. G. Rohr, “The liquid densities of cerium and neodymium metals,” J. Less-Comm. Met. 10 (6), 389–391 (1966).

L. L. Bezukladnikova and V. N. Kononenko, “Surface and volume properties of lanthanides,” Metally, No. 5, 117–120 (1994).

V. E. Zinov’ev, Thermal Properties of Metals at High Temperatures. Handbook (Metallurgiya, Moscow, 1989).

V. I. Kononenko, A. I. Kiselev, and I. N. Latosh, “Calculation of kinetic characteristics of liquid rare-earth metals,” Metallofiz. 8 (2), 2–23 (1986).

V. G. Postovalov, E. P. Romanov, V. P. Kondrat’ev, and V. I. Kononenko, “Theory of transport in liquid metals: Calculation of dynamic viscosity,” High Temp. 41 (6), 762–770 (2003).

V. P. Kondrat’ev, E. P. Romanov, and V. G. Postovalov, “Kinetic properties of light lanthanide melts,” J. Phys.: Conference Series 98, art. 062020 (2008).

S. N. Banchilla and L. N. Filippov, “Study of electrical conductivity of liquid metals,” Teplofiz. Vys. Temp. 11 (6), 1301–1305 (1973).

V. G. Postovalov, E. P. Romanov, and V. P. Kondrat’ev, “Structural characteristics and the temperature derivative of the electrical resistivity of liquid lanthanides,” Phys. Met. Metallogr. 103 (3), 234–245 (2007).

C. Hiemstra, P. Keegstra, W. I. Masselink, and J. B. Van Zytveld, “Electrical resistivity of solid and liquid Pr, Nd and Sm,” J. Phys. F: Met. Phys. 14 (8), 1867–1875 (1984).

H. I. Güntherodt, E. Hauser, and H. U. Künzi, “Electrical resistivity of liquid rare-earth metals and their alloys,” in Proceedings of Third International Conference on Liquid Metals (Bristol, 1976), pp. 324–336.

S. Ozawa, T. Saito, J. Yu, et al. “Solidification behavior in undercooled Nd–Fe–B alloys,” J. Alloys Compd., 322 (1–2), 276–280 (2001).

M. J. Kramer, L. H. Lewis, L. M. Fabietti, Y. Tang, W. Miller, K. W. Dennis, and R. W. Mc Callum, “Solidification, microstructural refinement and magnetism in Nd2Fe14B,” J. Magn. Magn. Mater. 241 (1), 144–155 (2002).

T. Hattori, N. Fukamachi, R. Goto, N. Tezuka, and S. Sugimoto, “Microstructural evaluation of Nd–Fe–B strip cast alloys,” Mater. Trans. 50 (3), 479–482 (2009).

D. Yu. Vasilenko, A. V. Shitov, A. V. Vlasyuga, A. G. Popov, N. V. Kudrevatykh, and N. V. Pechishcheva, “Microstructure and properties of Nd–Fe–B alloys produced by strip casting and of permanent magnets fabricated from them,” Met. Sci. Heat Treat. 56 (11–12), 585–590 (2015).

O. A. Esin, B. R. Gel’chinskii, N. A. Vatolin, et al., “On the correlation between the viscosity and surface tension in simple liquids,” Zh. Fiz. Khim. 49 (11), 2955–2957 (1975).

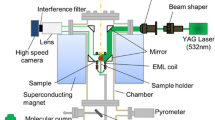

G. V. Tyagunov, V. S. Tsepelev, M. N. Kushnir, and G. N. Yakovlev, “Installation for measuring the kinematic viscosity of metallic melts,” Zavodsk. Labor., No. 10, 919–920 (1980).

A. V. Ryabina, V. I. Kononenko, and A. A. Razhabov, “Electrode-less method for measuring electrical resistivity of solid and liquid metals and installation for realization of the method,” Rasplavy, No. 1, 34–42 (2009).

G. V. Tuagunov, B. A. Baum, V. S. Tsepelev, A. G. Tyagunov, and A. N. Vlokh, “Measuring the electrical resistivity by rotating magnetic field method,” Zavodsk. Labor. 69 (2), 36–38 (2003).

O. I. Ostrovskii, V. A. Grigoryan, and A. F. Vishkarev, Properties of Metallic Melts (Metallurgiya, Moscow, 1988).

E. R. Andrievskaya, “Phase equilibria in the refractory oxide of zirconia, hafnia and yttria with rare-earth oxides,” J. Europ. Ceram. Soc. 28, 2363–2388 (2008).

A. Rouanet, Rev. Int. Hautes Temp. Refract. 8, 161 (1971).

M. P. Van Dijk, K. J. de Vries, and A. J. Burgraaf, “Oxygen ion and mixed conductivity in compounds with the fluorite and pyrochlore structure,” Solid State Ionics 9–10, 913–920 (1983).

Y. Matsuura, “Phase diagram of the Nd–Fe–B ternary system,” Jpn. J. Appl. Phys. 24 (8), 635–637 (1985).

E. Yu. Tyunina, “Molar viscosity of liquid metals in a range of 300–4000 K,” Zh. Fiz. Khim. 88 (4), 557–563 (2014).

S. R. Nagel and J. Tauc, “Nearly-free-electron approach to the theory of metallic glass alloys,” Phys. Rev. Lett. 35 (6), 380–383 (1975).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by N. Kolchugina

Rights and permissions

About this article

Cite this article

Slinkin, I.V., Chikova, O.A. & V’yukhin, V.V. Viscosities of the Nd and Fe–30% Nd–1% B–1% Co–1% Dy Melts. Russ. Metall. 2021, 109–113 (2021). https://doi.org/10.1134/S0036029521020257

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029521020257