The Alloy Phase Diagram International Commission (APDIC) promotes the effective dissemination of data on phase diagrams and thermodynamics of phases in accordance with the required quality standards and furthers the application of phase diagrams in research and industry. The annual report of the Ukrainian Commission on Phase Diagrams and Thermodynamics, which is a member of APDIC as one of the national participants, presents information on the findings of Ukrainian scientists in this field in 2017–2019. Information on the research findings is presented in a table, collecting data on the systems studied and results obtained and listing references to the published papers.

Similar content being viewed by others

References

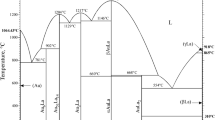

V.T. Witusiewicz, A.A. Bondar, U. Hecht, O.M. Stryzhyboroda, N.I. Tsyganenko, V.M. Voblikov, V.M. Petyukh, and T.Ya. Velikanova, “Thermodynamic remodeling of the ternary Al–Mo–Ti system based on novel experimental data,” J. Alloys Compd., 749, 1071–1091 (2018), https://doi.org/10.1016/j.jallcom.2018.03.283.

O.V. Zaikina, V.G. Khoruzha, K.E. Kornienko, and T.Ya. Velikanova, “Phase equilibria in the aluminum corner of the Al–Ti–Pt system,” Powder Metall. Met. Ceram., 57, No. 1–2, 114–126 (2018), https://doi.org/10.1007/s11106-018-9959-z.

V.G. Khoruzhaya and K.Ye. Korniyenko, “Phase equilibria in the ternary Al–Ti–Pt system. IV. Vertical sections in the ternary Al–Ti–Pt system in the composition range 0–50 at.% Pt.,” Powder Metall. Met. Ceram., 58, No. 5–6, 323–328 (2019), https://doi.org/10.1007/s11106-019-00081-0.

O.V. Zaikina, V.G. Khoruzhaya, K.Ye. Korniyenko, K.A. Meleshevich, D.V. Pavlyuchkov, and T.Ya. Velikanova, “Phase equilibria in the ternary Al–Ti–Pt system. I. Solidus surface of the Al–Ti–Pt system in the range 0–50 at.% Pt,” Powder Metall. Met. Ceram., 57, No. 9–10, 587–595 (2019), https://doi.org/10.1007/s11106-019-00020-z.

O.V. Zaikina, V.G. Khoruzhaya, K.Ye. Korniyenko, D.V. Pavlyuchkov, K.A. Meleshevich, and T.Ya. Velikanova, “Phase equilibria in the ternary Al–Ti–Pt system. II. Liquidus surface of the Al–Ti–Pt system in the compositions range 0–50 at.% Pt,” Powder Metall. Met. Ceram., 57, No. 11–12, 709–715 (2019), https://doi.org/10.1007/s11106-019-00035-6.

O.V. Zaikina, V.G. Khoruzhaya, K.Ye. Korniyenko, and T.Ya. Velikanova, “Phase equilibria in the ternary Al–Ti–Pt system. III. The Al–Ti–Pt melting diagram in the composition range 0–50 at.% Pt,” Powder Metall. Met. Ceram., 58, No. 1–2, 81–88 (2019), https://doi.org/10.1007/s11106-019-00050-7.

V.T. Witusiewicz, A.A. Bondar, U. Hecht, A. Theofilatos, N.I. Tsyganenko, S.V. Utkin, and I.B. Tikhonova, “Experimental study and thermodynamic re-modelling of the constituent binaries and ternary B–Fe–Ti system,” J. Alloys Compd., 800, 419–449 (2019), https://doi.org/10.1016/j.jallcom.2019.05.341.

S.V. Utkin, V.Z. Kublii, S.V. Sleptsov, A.A. Bondar, P.P. Levchenko, G.A. Osokin, and T.Ya. Velikanova, “Solidus surface of the Mo–Ni–B system,” J. Superhard Mater., 41, No. 5, 287–301 (2019), https://doi.org/10.3103/S1063457619050010.

A.M. Storchak-Fedyuk, L.V. Artyukh, L.A. Duma, T.Ya. Velikanova, P.G. Agraval, and M.A. Turchanin, “Phase equilibria in the Cu–Ti–Zr system at 750°C. I. The isothermal section with copper content from 0 to 50 at.%,” Powder Metall. Met. Ceram., 56, No. 1–2, 78–87 (2017), https://doi.org/10.1007/s11106-017-9874-8.

A.M. Storchak-Fedyuk, L.V. Artyukh, A.V. Grytsiv, P.G. Agraval, M.A. Turchanin, and T. Ya. Velikanova, “Phase equilibria in the Cu–Ti–Zr system at 750°C. I. The isothermal section with copper content from 50 to 100 at.%,” Powder Metall. Met. Ceram., 56, No. 3–4, 220–230 (2017), https://doi.org/10.1007/s11106-017-9889-1.

A.M. Storchak, T.Ya. Velikanova, L.V. Artyukh, A.V. Grytsiv, M.A. Turchanin, P.G. Agraval, and V.M. Petyukh, “Phase equilibria and phase transformations at high temperatures in ternary alloys of the Ni–Ti–Zr system at 50–100 at.% Ni,” Powder Metall. Met. Ceram., 58, Nos. 3–4, 210–221 (2019), https://doi.org/10.1007/s11106-019-00066-z.

O.L. Semenova, V.M. Petyukh, and O.S. Fomichev, “The quasibinary ZrCo–ZrNi phase diagram,” Powder Metall. Met. Ceram., 56, No. 3–4, 210–219 (2017), https://doi.org/10.1007/s11106-017-9888-2.

O.L. Semenova, V.M. Petyukh, and O.S. Fomichov, “The Ni–Zr phase diagram in the range 25–60 at.% Ni,” Powder Metall. Met. Ceram., 58, No. 7–8, 474–484 (2019), https://doi.org/10.1007/s11106-019-00098-5.

M. Bulanova, J.C. Tedenac, I. Fartushna, K. Meleshevich, and K. Darmostuk, “Phase equilibria in the Cr–Si–Ti system below 40 at.% Si,” J. Alloys Compd., 785, 897–910 (2019), https://doi.org/10.1016/j.jallcom.2019.01.222.

M.O. Shevchenko, V.S. Sudavtsova, V.G. Kudin, L.O. Romanova, and M.I. Ivanov, “Thermodynamic properties of binary Al–Nd alloys,” Powder Metall. Met. Ceram., 56, No. 5–6, 333–354 (2017), https://doi.org/10.1007/s11106-017-9901-9.

M.O. Shevchenko, V.G. Kudin, M.I. Ivanov, V.V. Berezutskii, and V.S. Sudavtsova, “Thermochemical properties of binary Ba–In alloy,” Powder Metall. Met. Ceram., 56, Nos. 9–10, 88–100 (2018), https://doi.org/10.1007/s11106-018-9928-6.

V.S. Sudavtsova, K.Yu. Pastushenko, M.O. Shevchenko, M.I. Ivanov, and V.G. Kudin, “The thermodynamic properties and phase equilibria in Ce–Sn alloys,” Powder Metall. Met. Ceram., 57, No. 7–8, 473–479 (2018), https://doi.org/10.1007/s11106-018-0006-x.

V.S. Sudavtsova, M.O. Shevchenko, V.G. Kudin, L.O. Romanova, and M.I. Ivanov, “Thermodynamic properties of Co–Pr alloys,” Powder Metall. Met. Ceram., 56, No. 1–2, 94–101 (2017), https://doi.org/10.1007/s11106-017-9876-6.

V.S. Sudavtsova, M.O. Shevchenko, M.I. Ivanov, V.V. Berezutskii, and V.G. Kudin, “Thermodynamic properties of liquid copper–lanthanum alloys,” Russ. J. Phys. Chem. A, 91, No. 6, 990–997 (2017), https://doi.org/10.1134/S0036024417060231.

M.O. Shevchenko, V.G. Kudin, V.S. Sudavtsova, M.I. Ivanov, and V.V. Berezutskii, “Thermodynamic characteristics and phase equilibria in the alloys of the Ge–La system,” Russ. J. Phys. Chem. A, 91, No. 8, 1380–1387 (2017), https://doi.org/10.1134/S0036024417080313.

P.M. Subotenko, V.G. Kudin, M.O. Shevchenko, M.I. Ivanov, V.V. Berezutskii, and V. S. Sudavtsova, “Thermodynamic properties of La–Ni alloys,” Powder Metall. Met. Ceram., 55, No. 9–10, 717–725 (2017), https://doi.org/10.1007/s11106-017-9859-7.

V. S. Sudavtsova, M. O. Shevchenko, M. I. Ivanov, V. G. Kudin, and N. V. Podopryhora, “Thermodynamic properties and phase equilibria of Nd–Ni alloys,” Powder Metall. Met. Ceram., 58, No. 9–10, 581–590 (2020), https://doi.org/10.1007/s11106-020-00115-y.

K.Yu. Pastushenko, V.S. Sudavtsova, P.P. Levchenko, M.O. Shevchenko, and M.I. Ivanov, “Thermodynamic properties of Ni–Sb alloys,” Powder Metall. Met. Ceram., 58, No. 3–4, 222–229 (2019), https://doi.org/10.1007/s11106-019-00067-y.

V.S. Sudavtsova, M.O. Shevchenko, M.I. Ivanov, V.V. Berezutskii, V.G. Kudin, and K.Yu. Pastushenko, “Thermodynamic properties of alloys of the binary Sb–Yb system,” Russ. J. Phys. Chem. A, 91, No. 7, 1174–1182 (2017), https://doi.org/10.1134/S0036024417070287.

V.S. Sudavtsovap, M.O. Shevchenko, M.I. Ivanov, A.S. Kozorezov, and V.G. Kudin, “Thermodynamic properties of alloys of the Sn–Yb system,” Russ. J. Phys. Chem. A, 92, No. 4, 630–639 (2018), https://doi.org/10.1134/S0036024418040295.

V.G. Kudin, M.O. Shevchenko, M.I. Ivanov, V.V. Berezutskii, P.M. Subotenko, and V.S. Sudavtsova, “Thermodynamic properties of Al–La–Ni melts,” Powder Metall. Met. Ceram., 55, No. 9–10, 603–611 (2017), https://doi.org/10.1007/s11106-017-9845-0.

A.R. Kopan, N.P. Gorbachuk, S.M. Lakiza, Ya.S. Tishchenko, and D.S. Korablov, “Low-temperature thermodynamic functions of gadolinium hafnate (Gd2Hf2O7),” Powder Metall. Met. Ceram., 57, No. 5–6, 336–343 (2018), https://doi.org/10.1007/s11106-018-9988-7.

A.R. Kopan, N.P. Gorbachuk, S.M. Lakiza, and Ya.S. Tishchenko, “High-temperature enthalpy of La2Hf2O7 in the temperature range 490–2120 K,” Powder Metall. Met. Ceram., 56, No. 11–12, 697–706 (2018), https://doi.org/10.1007/s11106-018-9945-5.

Ya.S. Tishchenko, S.M. Lakiza, V.P. Red’ko, and O.V. Dudnik, “Isothermal section of the Al2O3–TiO2–Er2O3 phase diagram at 1400°C,” Powder Metall. Met. Ceram., 56, No. 7–8, 456–462 (2017), https://doi.org/10.1007/s11106-017-9916-2.

Ya.S. Tishchenko, S.M. Lakiza, V.P. Red’ko, and O.V. Dudnik, “Isothermal section of the Al2O3–TiO2–Gd2O3 phase diagram at 1400°C,” Powder Metall. Met. Ceram., 56, No. 1–2, 88–93 (2017), https://doi.org/10.1007/s11106-017-9875-7.

Ya.S. Tishchenko, S M. Lakiza, V.P. Red’ko, and O.V. Dudnik, “Isothermal sections of the Al2O3–TiO2–Y2O3 phase diagram at 1550 and 1400 °C,” Powder Metall. Met. Ceram., 55, No. 11–12, 698–706 (2017), https://doi.org/10.1007/s11106-017-9857-9.

O.A. Kornienko, O.V. Chudinovych, A.I. Bykov, A.V. Samelyuk, and E.R. Andrievskaya, “Phase equilibria in the La2O3–Er2O3 system in the temperature range 1100–1500°C,” Powder Metall. Met. Ceram., 58, No. 1–2, 89–98 (2019), https://doi.org/10.1007/s11106-019-00051-6.

O.A. Kornienko, “Interaction of lanthanum and samarium oxides at 1250°C,” Ukr.Khim. Zh., 84, No. 3, 28–33 (2018).

O.V. Chudinovych, S.F. Korichev, and E.R. Andrievskaya, “Interaction of yttrium, lanthanum, and samarium oxides at 1600°C,” Powder Metall. Met. Ceram., 58, No. 9–10, 599–607 (2020), https://doi.org/10.1007/s11106-020-00113-0.

O. M. Yakovenko, O. S. Roik, V. P. Kazimirov, V. E. Sokol’skii, N. V. Golovataya, G. M. Zelinskaya, and T. M. Mika, “Structure of the Al–Ge–Fe alloys in the liquid and solid state,” J. Non-Cryst. Solids, 455, 75–82 (2017), https://doi.org/10.1016/j.jnoncrysol.2016.10.026.

O.S. Roik, V.P. Kazimirov, O.M. Yakovenko, V.E. Sokolskii, N.V. Golovataya, T.M. Mika, and G.M. Zelinskaya, “Structure of liquid Al–Ge–Ni melts in a wide composition range.,” J. Mol. Liq., 293, 111458 (2019), https://doi.org/10.1016/j.molliq.2019.111458.

V.E. Sokol’skii, D.V. Pruttskov, V.M. Busko, V.P. Kazimirov, O.S. Roik, A.D. Chyrkin, V.I. Galinich, and I.A. Goncharov, “Investigation of the structure of CaO–Al2O3–SiO2 melts as a basis for the development of new agglomerated welding fluxes and industrial refractories,” J. Min. Met. Sect. B: Metall., 54B, No. 2, 133–141 (2018), https://doi.org/10.2298/JMMB170908001S.

M. Ivanov, V. Berezutski, N. Usenko, and N. Kotova, “Enthalpies of mixing in binary liquid alloys of lutetium with 3d metals,” Int. J. Mater. Res., 108, No. 1, 29–35 (2017), https://doi.org/10.3139/146.111445.

M. Ivanov, N. Usenko, and N. Kotova, “Enthalpies of mixing in binary Mn–In and ternary Mn–In–Gd liquid alloys,” Int. J. Mater. Res., 109, No. 4, 291–300 (2018), https://doi.org/10.3139/146.111611.

M. Ivanov, N. Usenko, N. Kotova, and N. Golovataya, “Enthalpies of mixing in ternary Ce–Cu–Sb liquid alloys,” Int. J. Mater. Res., 110, No. 11, 1058–1065 (2019), https://doi.org/10.3139/146.111833.

P.G. Agraval, L.A. Dreval, and M.A. Turchanin, “Thermodynamic properties of iron melts with titanium, zirconium, and hafnium,” Powder Metall. Met. Ceram., 55, No. 11–12, 707–716 (2017), https://doi.org/10.1007/s11106-017-9858-8.

P.G. Agraval, L.A. Dreval, and M.A. Turchanin, “Interaction of components in Cu–Fe glass-forming melts with titanium, zirconium, and hafnium. I. Calorimetric study of mixing enthalpies,” Powder Metall. Met. Ceram., 56, No. 3–4, 231–238 (2017), https://doi.org/10.1007/s11106-017-9890-8.

P. Agraval, M. Turchanin, L. Dreval, and A. Vodopyanova, “Mixing enthalpy of liquid Cu–Hf–Ni alloys at 1873 K,” J. Therm. Anal. Calorim., 128, No. 3, 1753–1763 (2017), https://doi.org/10.1007/s10973-016-6060-z.

P. Agraval, L. Dreval, M. Turchanin, A. Storchak-Fedyuk, L. Artyukh, and T. Velikanova, “Enthalpy of mixing of liquid Ni–Ti–Zr alloys at 1873 K,” J. Chem. Thermodyn., 106, 309–316 (2017), https://doi.org/10.1016/j.jct.2016.11.008.

L.A. Dreval, P.G. Agraval, and M.A. Turchanin, “Calorimetric investigation of the mixing enthalpy of liquid Co–Cu–Ti alloys at 1873 K,” Phys. Chem. Liq., 56, No. 5, 674–684 (2018), https://doi.org/10.1080/00319104.2017.1376058.

P.G. Agraval, M.A. Turchanin, A.A. Vodopyanova, and L.A. Dreval, “Mixing enthalpies of liquid Cu–Hf–Ti alloys by high-temperature calorimetry,” Powder Metall. Met. Ceram., 57, No. 5–6, 344–348 (2018), https://doi.org/10.1007/s11106-018-9989-6.

P.G. Agraval, L.A. Dreval, and M.A. Turchanin, “Interaction of components in Cu–Fe glass-forming melts with titanium, zirconium, and hafnium. II. Temperature–concentration dependence of thermodynamic mixing functions,” Powder Metall. Met. Ceram., 56, No. 5–6, 323–332 (2017), https://doi.org/10.1007/s11106-017-9900-x.

P.G. Agraval, L.A. Dreval, and M.A. Turchanin, “Interaction of components in Cu–Fe glass-forming melts with titanium, zirconium, and hafnium. III. Modeling of metastable phase transformations with participation of liquid phase,” Powder Metall. Met. Ceram., 56, No. 7–8, 463–472 (2017), https://doi.org/10.1007/s11106-017-9917-1.

M.A. Turchanin, P.G. Agraval, T.Ya. Velikanova, and A.A. Vodopyanova, “Predicting the composition ranges of amorphization for multicomponent melts in the framework of the CALPHAD method,” Powder Metall. Met. Ceram., 57, No. 1–2, 57–70 (2018), https://doi.org/10.1007/s11106-018-9955-3.

L.A. Dreval, M.A. Turchanin, P.G. Agraval, and Y. Du, “Cu–Fe–Co system: Verification of the hightemperature phase equilibria and thermodynamic modeling of the low-temperature phase relations involving ordered phase,” Powder Metall. Met. Ceram., 56, No. 9–10, 546–555 (2018), https://doi.org/10.1007/s11106-018-9927-7.

A. Bondar and K. Korniyenko, “Al–Co–Cr ternary phase diagram evaluation,” [Web resource], MSI Eureka, MSI, Mater. Sci. Int., Stuttgart (2018), Document ID: 10.10906.2.2.

R. Ferro, A. Saccone, S. Delfino, and K. Korniyenko, “Al–Co–V ternary phase diagram evaluation,” [Web resource], MSI Eureka, MSI, Mater. Sci. Int., Stuttgart (2017), Document ID: 10.19103.2.4.

K. Korniyenko, “Al–Cr–Mo ternary phase diagram evaluation,” [Web resource], MSI Eureka, MSI, Mater. Sci. Int., Stuttgart (2017), Document ID: 10.18613.2.2.

I. Tyshchenko and K. Korniyenko, “Al–Er–Hf–O ternary phase diagram evaluation,” [Web resource], MSI Eureka, MSI, Mater. Sci. Int., Stuttgart (2017), Document ID: 10.68290.1.4.

I. Tyshchenko and K. Korniyenko, “Al–Gd–Hf–O ternary phase diagram evaluation,” [Web resource], MSI Eureka, MSI, Mater. Sci. Int., Stuttgart (2017), Document ID: 10.52997.1.4.

I. Tyshchenko and K. Korniyenko, “Al–Hf–La–O ternary phase diagram evaluation,” [Web resource], MSI Eureka, MSI, Mater. Sci. Int., Stuttgart (2017), Document ID: 10.56384.1.8.

I. Tyshchenko and K. Korniyenko, “Al–Hf–O–Y ternary phase diagram evaluation,” [Web resource], MSI Eureka, MSI, Mater. Sci. Int., Stuttgart (2017), Document ID: 10.50692.1.0.

A. Watson and K. Korniyenko, “Al–Mn–Ti ternary phase diagram evaluation,” [Web resource], MSI Eureka, MSI, Mater. Sci. Int., Stuttgart (2019), Document ID: 10.15074.3.2.

K. Korniyenko and I. Tyshchenko, “Al–O–Y ternary phase diagram evaluation,” [Web resource], MSI Eureka, MSI, Mater. Sci. Int., Stuttgart (2019), Document ID: 10.10925.1.8.

K. Korniyenko, “Al–Pd–Ti ternary phase diagram evaluation,” [Web resource], MSI Eureka, MSI, Mater. Sci. Int., Stuttgart (2017), Document ID: 10.21189.2.9.

E. Semenova, “Co–Ni–Zr ternary phase diagram evaluation,” [Web resource], MSI Eureka, MSI, Mater. Sci. Int., Stuttgart (2017), Document ID: 10.14030.2.4.

I. Tyshchenko, K. Korniyenko, and M. Glabay, “Co–O–Zr ternary phase diagram evaluation,” [Web resource], MSI Eureka, MSI, Mater. Sci. Int., Stuttgart (2017), Document ID: 10.20987.1.5.

K. Korniyenko, “Gd–O binary phase diagram evaluation,” [Web resource], MSI Eureka, MSI, Mater. Sci. Int., Stuttgart (2017), Document ID: 20.27481.1.2.

I. Tyshchenko and K. Korniyenko, “Hf–O–Ta ternary phase diagram evaluation,” [Web resource], MSI Eureka, MSI, Mater. Sci. Int., Stuttgart (2017), Document ID: 10.11425.1.7.

K. Korniyenko, “Hf–Pd–Pt ternary phase diagram evaluation,” [Web resource], MSI Eureka, MSI, Mater. Sci. Int., Stuttgart (2018), Document ID: 10.15360.1.4.

I. Tyshchenko and K. Korniyenko, “La–O–Zr ternary phase diagram evaluation,” [Web resource], MSI Eureka, MSI, Mater. Sci. Int., Stuttgart (2018), Document ID: 10.10316.1.2.

I. Tyshchenko and K. Korniyenko, “O–Sm–Zr ternary phase diagram evaluation,” [Web resource], MSI Eureka, MSI, Mater. Sci. Int., Stuttgart (2018), Document ID: 10.11200.1.5.

K. Korniyenko, “Rh–Ti binary phase diagram evaluation,” [Web resource], MSI Eureka, MSI, Mater. Sci. Int., Stuttgart (2017), Document ID: 20.32761.1.3.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 59, Nos. 9–10 (535), pp. 148–159, 2020.

Rights and permissions

About this article

Cite this article

Turchanin, M., Velikanova, T., Korniyenko, K. et al. Information on the Annual Report of the Ukrainian Commission on Phase Diagrams and Thermodynamics. Powder Metall Met Ceram 59, 601–609 (2021). https://doi.org/10.1007/s11106-021-00182-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-021-00182-9