Abstract

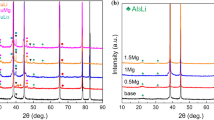

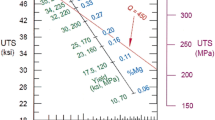

The present work was undertaken with the aim of studying the microstructural changes and intermetallic phases in Al-Si base 413.0 alloys as well as variations in tensile properties, including ultimate stress, yield strength and elongation at rupture, resulting from the addition of alloyed elements: strontium (Sr), magnesium (Mg), copper (Cu), silver (Ag), zinc (Zn) and nickel (Ni), to the base alloy 413.0, under different conditions of heat treatments, i.e., solutionizing and artificial aging (in the temperature range of 155 °C–240 °C). The results obtained in relation to microstructural observations and tensile tests reveal that the addition of alloying elements, in particular Mg, Cu, Ag, Ni, Zn and Sr, leads to an increase in the ultimate stress and yield strength values with a decrease in the strain levels of the base alloy 413.0, following hardening during artificial aging. Both Ag and Zn do not form specific phases during solidification at a slow rate of ~ 0.8 °C/s but only segregate to the α-aluminum cell boundaries. Addition of 0.73% Ag improves the values of yield strength at all aging temperatures. Also, it enhances the alloy resistance to softening during aging in the temperature range 200–240 °C. Similar behavior was exhibited by the addition of 2.5% Zn.

Similar content being viewed by others

References

M. Zeren, Effect of copper and silicon content on mechanical properties in Al–Cu–Si–Mg alloys. J. Mater. Process. Technol. 169(2), 292–298 (2005)

E. Sjölander, S. Seifeddine, The heat treatment of Al–Si–Cu–Mg casting alloys. J. Mater. Process. Technol. 210(10), 1249–1259 (2010)

C.H. Caceres, I.L. Svensson, J.A. Taylor, Strength-ductility behaviour of Al–Si–Cu–Mg casting alloys in T6 temper. Int. J. Cast Met. Res. 15(5), 531–543 (2003)

P.S. Wang, S.L. Lee, J.C. Lin, M.T. John, Effects of solution temperature on mechanical properties of 319.0 aluminum casting alloys containing trace beryllium. J. Mater. Res. 15(09), 2027–2035 (2000)

S.P. Ringer, K. Hono, Microstructural evolution and age hardening in aluminium alloys: atom probe field-ion microscopy and transmission electron microscopy studies. Mater. Charact. 44(1), 101–131 (2000)

R. Molina, P. Amalberto, M. Rosso, Mechanical characterization of aluminium alloys for high temperature applications Part1: Al-Si-Cu alloys. Metall. Sci. Technol. 29(1), 5–11 (2011)

H.R. Ammar, C. Moreau, A.M. Samuel, F.H. Samuel, H.W. Doty, Influences of alloying elements, solution treatment time and quenching media on quality indices of 413-type Al–Si casting alloys. Mater. Sci. Eng., A 489(1), 426–438 (2008)

F.J. Tavitas-Medrano, J.E. Gruzleski, F.H. Samuel, S. Valtierra, H.W. Doty, Effect of Mg and Sr-modification on the mechanical properties of 319-type aluminum cast alloys subjected to artificial aging. Mater. Sci. Eng. A 480(1), 356–364 (2008)

D.G. Eskin, Decomposition of supersaturated solid solutions in Al–Cu-Mg–Si Alloys. J. Mater. Sci. 38, 279–290 (2003)

S.K. Son, M. Takeda, M. Mitome, Y. Bando, T. Endo, Precipitation behaviour of an Al–Cu alloy during isothermal aging at low temperatures. Mater. Lett. 75, 629–632 (2005)

S.P. Ringer, K. Hono, Microstructural evolution and age hardening in aluminum alloys: Atom Probe Field-Ion microscopy and transmission electron microscopy studies. Mater. Charact. 44, 101–131 (2000)

C.R. Hutchinson, S.P. Ringer, Precipitation processes in Al–Cu–Mg alloys microalloyed with Si. Metall. Mater. Trans. A 31A, 2721–2733 (2000)

S. Abis, M. Massazza, P. Mengucci, G. Tiontino, Early Ageing Mechanisms in a High-Copper AlCuMg Alloy. Scripta Mater. 45, 685–691 (2001)

D. Emadi, L.V. Whiting, M. Sahoo, J.H. Sokolowski, P. Burke, M. Hart, Optimal heat treatment of A356.2 Alloy, in Light Metals. (The Minerals, Metals, and Materials Society, Warrendale, 2003), pp. 983–989

N.R. Andrade González, Aging Effects in 319-Type Alloys, PhD. Thesis, McGill University (2006).

D. Apelian, S. Shivkumar, G. Sigworth, Fundamental aspects of heat treatment of cast Al–Si–Mg Alloys. AFS Trans. 97, 727–742 (1989)

F.H. Samuel, A.M. Samuel, H. Liu, Effect of Magnesium Content on the Aging Behaviour of Water-Chilled Al-Si-Cu-Mg-Fe-Mn (380) Alloy Castings. J. Mater. Sci. 30, 1–10 (1995)

R.R. Hultgren, P.D. Desai, D.T. Hawkins, M. Gleiser, K.K. Kelley, Selected Values of the Thermodynamic Properties of Binary Alloys (American Society for Metals Park, Ohio, 1973).

A.J. McAlister, The Ag−Al (Silver-Aluminum) system. Bull. Alloy Phase Diagr. 8, 526 (1987)

H. Okamoto (ed.), Desk Handbook: Phase Diagrams for Binary Alloys (ASM International, Materials Park, 2000)

N.A. Zarkevich, D.D. Johnson, Predicted hcp Ag-Al metastable phase diagram, equilibrium ground states, and precipitate structure. Phys. Rev. B, 67(6), 1-7 (2003). id. 064104

S.S. Lim, P.L. Rossiter, J.E. Tibballs, Assessment of the Al–Ag binary phase diagram. Calphad 19, 131–141 (1995)

M. Demirtas, G. Purcek, H. Yanar, Z.J. Zhang, Z.F. Zhang, Effect of chemical composition and grain size on RT superplasticity of Zn-Al alloys processed by ECAP. Lett. Mater. 5(3), 328–334 (2015)

L. Li, S. Ji, Q. Zhu, Y. Wang, X. Dong, W. Yang, S. Midson, Y. Kang, Effect of Zn concentration on the microstructure and mechanical properties of Al-Mg-Si-Zn alloys processed by gravity die casting. Metall. Mater. Trans. A 49A, 3247–3256 (2018)

T. Saitoa, S. Wenner, E. Osmundsen, C.D. Marioarab, S.J. Andersen, J. Røyset, W. Lefebvre, R. Holmestad, The effect of Zn on precipitation in Al–Mg–Si alloys. Phil. Mag. 94(21), 2410–2425 (2014)

M.H. Abdelaziz, A.M. Samuel, H.W. Doty, S. Valtierra, F.H. Samuel, Effect of additives on the microstructure and tensile properties of Al–Si alloys. J. Mater. Technol. 8, 2255–2268 (2019)

A. Mohamed and F. H. Samuel, A Review on the Heat Treatment of Al-Si-Cu/Mg Casting Alloys, in Heat Treatment - Conventional and Novel Applications, F. Czerwinski, Editor. 2012: InTech Open Access, Chapter 4, pp. 55-69. https://doi.org/10.5772/50282

W.D. Callister, Fundamentals of Materials Science and Engineering: An Interactive E, vol. 5 (Wiley, New York, 2001).

D. Eskin, Decomposition of supersaturated solid solutions in Al–Cu–Mg–Si alloys. J. Mater. Sci. 38(2), 279–290 (2003)

A.M. Samuel, F.H. Samuel, Modification of iron intermetallics by magnesium and strontium in Al–Si alloys. Int. J. Cast Met. Res. 10(3), 147–157 (1997)

E.A. Elsharkawi, M.H. Abdelaziz, H.W. Doty, S. Valtierra, F.H. Samuel, Effect of β-Al5FeSi and π-Al8Mg3FeSi6 phases on the impact toughness and fractography of Al–Si–Mg-based alloys. Int. J. Metalcast. 12(1), 148–163 (2018). https://doi.org/10.1007/s40962-017-0153-8

E.A. Elsharkawi, A.M. Samuel, F.H. Samuel, E. Simielli and G.K. Sigworth, Influence of solutionizing time, modification, and cooling rate on the decomposition of Mg-containing iron intermetallic phase in 357 alloys. Transactions of the American Foundry Society, 120, pp. 55-65; 116th Metalcasting Congress, April 17-20, 2012, Columbus, Ohio.

M.F. Ibrahim, E.M. Elgallad, S. Valtierra, H.W. Doty, F.H. Samuel, Metallurgical parameters controlling the eutectic silicon characteristics in Be-treated Al–Si–Mg alloys. Materials 9, 78 (2016). https://doi.org/10.3390/ma9020078

J.M. Rosalie, L. Bourgeois, Silver segregation to θ′ (Al2Cu)–Al interfaces in Al–Cu–Ag alloys. Acta Mater. 60, 6033–6041 (2012)

G.A. Zaki, A.M. Samuel, H.W. Doty, F.H. Samuel, Effect of metallrgical parameters on the performance of Al–2%Cu-based alloys. Int. J. Metalcast. 11(3), 581–597 (2017). https://doi.org/10.1007/s40962-016-0113-8

G.A. Zaki, A.M. Samuel, H.W. Doty, F.H. Samuel, Effect of metallurgical parameters on the performance of Al–Cu based alloys. Int. J. Metall. Mater. Sci. Eng. 6(1), 35–56 (2016)

Y. Yan, X. Zhang, F. Li, F. Li, H. Wang, H. Liu, B. Xiong, Effect of Zn addition on microstructure and mechanical properties of an Al–Mg–Si alloy. Mater. Int. 24, 97–100 (2014)

G.F.V. Voort, J. Asensio-Lozano, The Al-Si phase diagram. Microsc. Microanal. 15(2), 60–61 (2009). https://doi.org/10.1017/S1431927609092642

L. Liu, A.M. Samuel, F.H. Samuel, H.W. Doty, S. Valtierra, Influence of oxides on porosity formation in Sr-treated Al-Si casting alloys. J. Mater. Sci. 38(6), 1255–1267 (2003)

A.M. Samuel, F.H. Samuel, Effect of Mg and Sr Addition on the Formation of Iron Based Intermetallics in Al-Si-Fe DC Alloys, in International Symposium on Light Metals 1997 Métaux Légers as held at the 36th Annual Conference of Metallurgists of CIM., L.M. 1997, Editor. 1997: Sudbury, On., Canada. pp. 425-437

F.H. Samuel, G. Pucella, C. Villeneuve, A.M. Samuel, H.W. Doty, S. Valtierra, Microstructural observations on Fe-intermetallics in unmodified and Sr-modified Al-Si-Cu (A3801) die casting alloy. Int. J. Cast Metals Res. 12(3), 197–210 (1999)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Samuel, A.M., Samuel, F.H., Abdelaziz, M.H. et al. Hardening of Al–Si–Cu–Mg Cast Alloys: Role of Ag and Zn addition. Inter Metalcast 16, 3–19 (2022). https://doi.org/10.1007/s40962-021-00573-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-021-00573-z