Abstract

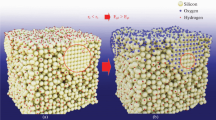

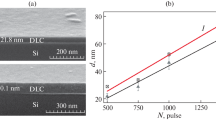

Hydrogenized carbon films 0.5–7.0 μm thick doped with silicon (11.9 ± 0.4 at %) and oxygen (1.7 ± 0.1 at %) have been grown on VT-6 titanium and silicon substrates in an externally heated arc discharge plasma. The hardness, internal stresses, surface morphology, wettability, and surface potential of the films against their thickness have been studied. It has been found that as the film gets thicker, the allowable load on the material and its hardness grow. It has been shown that the films have low internal stresses (below 600 MPa) and the water contact angle is 75°–80°. It have turned out that an increase in film thickness raises the negative surface potential from 50 to 670 mV.

Similar content being viewed by others

REFERENCES

X. An, Zh. Wu, L. Liu, T. Shao, S. Xiao, S. Cui, H. Lin, R. K. Y. Fu, X. Tian, P. K. Chu, and F. Pan, Surf. Coat. Technol. 365, 152 (2019). https://doi.org/10.1016/j.surfcoat.2018.08.099

C. W. Zou, H. J. Wang, L. Feng, and S. W. Xue, Appl. Surf. Sci. 286, 137 (2013). https://doi.org/10.1016/j.apsusc.2013.09.036

D. C. Sutton, G. Limbert, D. Stewart, and R. J. K. Wood, Friction 1 (3), 210 (2013). https://doi.org/10.1007/s40544-013-0023-1

R. Paul, S. Bhattacharyya, R. Bhar, and A. Pal, Appl. Surf. Sci. 257, 10451 (2011). https://doi.org/10.1016/j.apsusc.2011.06.144

W. Yue, X. Gao, C. Wang, Z. Fu, X. Yu, and J. Liu, Mater. Lett. 73, 202 (2012). https://doi.org/10.1016/j.matlet.2012.01.044

X. Li, P. Ke, and A. Wang, AIP Adv. 5 (1), 017111 (2015). https://doi.org/10.1063/1.4905788

H. W. Choi, R. H. Dauskardt, S.-C. Lee, K.-R. Lee, and K. H. Oh, Diamond Relat. Mater. 17, 252 (2008). https://doi.org/10.1016/j.diamond.2007.12.034

K.-R. Lee, K. Y. Eun, I. Kim, and J. Kim, Thin Solid Films 377–378, 261 (2000). https://doi.org/10.1016/S0040-6090(00)01429-2

Abdul Wasy Zia, Zhifeng Zhou, Po Wan Shum, and Lawrence Kwok Yan Li, Surf. Coat. Technol. 320, 118 (2017). https://doi.org/10.1016/j.surfcoat.2017.01.089

P. A. Karaseov, O. A. Podsvirov, K. V. Karabeshkin, A. Ya. Vinogradov, A. Azarov, A. I. Titov, and A. S. Smirnov, Nucl. Instrum. Methods Phys. Res., Sect. B 268, 3107 (2010). https://doi.org/10.1016/j.nimb.2010.05.063

M. Shiureviciute, J. Laurikaitiene, D. Adliene, L. Augulis, Z. Rutkuniene, and A. Jotautis, Vacuum 83, s159 (2009). https://doi.org/10.1016/j.vacuum.2009.01.052

K. Koshigan, F. Mangolini, J. B. McClimon, B. Vacher, S. Bec, R. W. Carpick, and J. Fontaine, Carbon 93, 851 (2015). https://doi.org/10.1016/j.carbon.2015.06.004

D. Bociaga, A. Sobczyk-Guzenda, W. Szymanski, A. Jedrzejczak, A. Jastrzebska, A. Olejnik, and K. Jastrzebski, Appl. Surf. Sci. 417, 23 (2017). https://doi.org/10.1016/j.apsusc.2017.03.223

D. Bociaga, M. Kaminska, A. Sobczyk-Guzenda, K. Jastrzebska, L. Swiatek, and A. Olejnik, Diamond Relat. Mater. 67, 41 (2016). https://doi.org/10.1016/j.diamond.2016.01.025

A. Bendavid, P. J. Martin, C. Comte, E. W. Preston, A. J. Haq, F. S. Magdon Ismail, and R. K. Singh, Diamond Relat. Mater. 16, 1616 (2007). https://doi.org/10.1016/j.diamond.2007.02.006

N. Kumar, S. A. Barve, S. S. Chopade, K. Rajib, N. Chand, D. Sitaram, A. K. Tyagi, and D. S. Patil, Tribol. Int. 84, 124 (2015). https://doi.org/10.1016/j.triboint.2014.12.001

D. Batory, A. Jedrzejczak, W. Szymanski, P. Niedzielski, M. Fijalkowski, P. Louda, I. Kotela, M. Hromadka, and J. Musil, Thin Solid Films 590, 299 (2015). https://doi.org/10.1016/j.tsf.2015.08.017

A. S. Grenadyorov, K. V. Oskomov, N. F. Kovsharov, and A. A. Solovyev, J. Phys.: Conf. Ser. 1115, 042046 (2018). https://doi.org/10.1088/1742-6596/1115/4/042046

A. S. Grenadyorov, A. A. Solovyev, K. V. Oskomov, and V. O. Oskirko, J. Vac. Sci. Technol., A 37 (6), 061512 (2019). https://doi.org/10.1116/1.5118852

F. F. Conde, J. A. Á. Diaz, G. F. da Silva, and A. P. Tschiptschin, Mater. Res. 22 (2), e20180499 (2019). https://doi.org/10.1590/1980-5373-mr-2018-0499

S. Meškinis, S. Tamulevičius, V. Kopustinskas, M. Andrulevičius, A. Guobienė, R. Gudaitis, and I. Liutvinienė, Thin Solid Films 515 (19), 7615 (2007). https://doi.org/10.1016/j.tsf.2006.11.089

E. V. Zavedeev, O. S. Zilova, A. D. Barinov, M. L. Shupegin, N. R. Arutyunyan, B. Jaeggi, B. Neuenschwander, and S. M. Pimenov, Diamond Relat. Mater. 74, 45 (2017). https://doi.org/10.1016/j.diamond.2017.02.003

I. A. Khlusov, V. F. Pichugin, E. A. Gostischev, Yu. P. Sharkeyev, R. A. Surmenev, M. A. Surmeneva, Y. V. Legostayeva, M. V. Chaikina, M. V. Dvornichenko, and N. S. Morozova, Byull. Sibir. Med. 10 (3), 72 (2011). https://doi.org/10.20538/1682-0363-2011-3-72-81

M. Zhao, B. Song, J. Pu, T. Wada, B. Reid, G. Tai, F. Wang, A. Guo, P. Walczysko, Yu Gu, T. Sasaki, A. Suzuki, J. V. Forrester, H. R. Bourne, P. Devreotes, C. Mccaig, and J. M. Penninger, Nature 442 (7101), 457 (2006). https://doi.org/10.1038/nature04925

O. V. Bondar, D. V. Saifullina, I. I. Shakhmaeva, I. I. Mavlyutova, and T. I. Abdullin, Acta Nat. 4 (1), 78 (2012). https://doi.org/10.32607/20758251-2012-4-1-78-81

V.P. Rotstein, R. Gyuntsel, A.B. Markov, D.I. Proskurovsky, M.T. Fam, E. Rikhter, and V.A. Shulov, Fiz. Khim. Obr. Mater. 1, 62 (2006).

J. B. Cai, X. L. Wang, W. Q. Bai, X. Y. Zhao, T. Q. Wang, and J. P. Tu, Appl. Surf. Sci. 279, 450 (2013). https://doi.org/10.1016/j.apsusc.2013.04.136

W. C. Oliver and G. M. Pharr. J. Mater. Res. 19 (1), 3 (2004). https://doi.org/10.1557/jmr.2004.19.1.3

V. A. Novikov, D. V. Grigoryev, A. V. Voitsekhovskii, S. A. Dvoretsky, and N. N. Mikhailov, J. Surf. Invest.: X-Ray, Synchrotron Neutron Tech. 10 (5), 1096 (2016). https://doi.org/10.1134/S1027451016050372

X. L. Peng, Z. H. Barber, and T. W. Clyne, Surf. Coat. Technol. 138, 23 (2001). https://doi.org/10.1016/S0257-8972(00)01139-7

A. S. Grenadyorov, A. A. Solovyev, K. V. Oskomov, S. A. Onischenko, A. M. Chernyavskiy, M. O. Zhulkov, and V. V. Kaichev, Surf. Coat. Technol. 381, 125113 (2020). https://doi.org/10.1016/j.surfcoat.2019.125113

A. S. Grenadyorov, A. A. Solovyev, K. V. Oskomov, and V. S. Sypchenko, Surf. Coat. Technol. 349, 547 (2018). https://doi.org/10.1016/j.surfcoat.2018.06.019

A. A. Ogwu, T. I. T. Okpalugo, and J. A. D. McLaughlin, AIP Adv. 2 (3), 032128 (2012). https://doi.org/10.1063/1.4742852

A. R. Shugurov, A. V. Panin, and K. V. Oskomov, Phys. Solid State 50 (6), 1050 (2008). https://doi.org/10.1134/S1063783408060097

ACKNOWLEDGMENTS

The authors thank the administration of the Tomsk Regional Research Center for Collective Use center (Siberian Branch, Russian Academy of Sciences) for the submission of the NanoTest 600 nanoindenter.

Funding

This study was supported by grant no. MK-1234.2020.8 of the President of the Russian Federation. Surface potential measurements were supported by the Russian Science Foundation, grant no. 19-19-00186.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by V. Isaakyan

Rights and permissions

About this article

Cite this article

Grenadyorov, A.S., Solov’ev, A.A. & Oskomov, K.V. The Influence of the Thickness of Silicon- and Oxygen-Doped Hydrogenized Carbon Films on Their Surface Properties. Tech. Phys. 66, 139–144 (2021). https://doi.org/10.1134/S1063784221010096

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063784221010096