Abstract

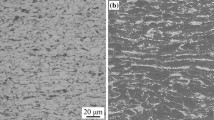

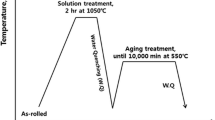

Plain medium carbon steel with multiscale ferrite (α) + cementite (θ) lamellar structure was produced by warm rolling and subsequently annealing. The effect of annealing time on microstructural evolution was studied via scanning electron microscope and electron backscatter diffraction. The obtained results showed that the feature of multiscale lamellar microstructure remained virtually the same with annealing times from 10 to 60 minutes, while the increase of annealing time destabilizes the stability of the microstructure. The specimen annealed for 30 minutes demonstrated good combination of strength and ductility because of the improvement of strain strengthening ability. The strain hardening behavior was described by instantaneous strain hardening exponent (\( n_{i} \)) and modified Crussard–Jaoul (C–J) model. Furthermore, the respective strengthening contribution of grain refinement, sub-grain strengthening and cementite particles to the yield strength was investigated in detail.

Similar content being viewed by others

References

H.B. Li, L.F. Fan, L.S. Chen and L.Y. Jia: Ironmak. Steelmak, 2019, 2019, pp. 1-7.

[2]M. Jung, M. Kang and Y.K. Lee: Acta Mater., 2012, vol. 60, pp. 525-36.

[3]Jansto S G: Metall. Mater. Trans. B, 2014, vol. 45(2), pp. 438-44.

[4]Q.T. Zhu, J. Li, J. Zhang, C.B. Shi, J.H. Li and J. Huang: Metall. Mater. Trans. B, 2019, vol. 50, pp. 1365-77.

[5]K. Lu: Acta Metall. Sin. (in Chinese), 2015, vol. 51, pp. 1-10.

[6]Y. Wang, M. Chen, F. Zhou and E. Ma: Nature, 2002, vol.419, pp.912-15.

[7]Z.S. You, L. Lu and K. Lu: Acta Mater., 2011, vol. 59, pp. 6927-37.

[8]J.L. Ning, Y.T. Zhang, L. Huang and Y.L. Feng: Mater. Des, 2017, vol. 120, pp. 280-90.

[9]M.H. Zhang, L.F. Li, J. Ding, Q.B. Wu, Y.D. Wang, J. Almer, F.M. Guo and Y. Ren: Acta Mater., 2017, vol. 141, pp. 294-303.

[10]M.H. Zhang, Q. Tan, J. Ding, H.Y. Chen, F.M. Guo, Y. Ren and Y.D. Wang: Mater. Sci. Eng. A, 2018, vol. 729, pp. 444-51.

[11]S. Ahmad, L.F. Lv, L.M. Fu, H.R. Wang, W. Wang and A.D. Shan: Iron Steel Res. Int. 2019, vol. 32, pp. 361-71.

[12]J.J. Sun, T. Jiang, Y.J. Wang, S.W. Guo and Y.N. Liu: Mater. Sci. Eng. A, 2018, vol. 734, pp. 311-17.

[13]W.L. Li, N.R. Tao and K. Lu: Scr. Mater., 2008, vol. 59, pp. 546-49.

[14]P.F. Wang, Z. Han and K. Lu: Wear, 2018, vol. 402, pp. 100-108.

[15]J. Ning, B. Xu, M.S. Sun, C.Y. Zhao, Y.L. Feng and W.P. Tong: Mater. Sci. Eng. A, 2018, vol. 735, pp. 275-87.

[16]C.S. Zheng, L.F. Li: Mater. Sci. Eng. A, 2018, vol. 713, pp. 35-42.

[17]X.L. Wu, M.X. Yang, F.P. Yuan, G.L. Wu, Y.J. Wei, X.X. Huang and Y.T. Zhu: Proc. Natl. Acad. Sci. U. S. A., 2015, vol. 112, pp.14501-05.

[18]X.L. Wu, Y.T. Zhu: Mater. Res. Lett., 2017, vol. 5, pp. 527-32.

[19]L. Zhang, Z. Chen, Y.H. Wang, G.Q. Ma, T.L. Huang, G.L. Wu and D.J. Jensen: Scr. Mater., 2017, vol. 141, pp. 111-14.

[20]J.J. Sun, T. Jiang, Y.J. Wang, S.W. Guo and Y.N. Liu: Mater. Sci. Eng. A, 2020, vol. 785, p. 139339. https://doi.org/10.1016/j.msea.2020.139339.

[21]M. Huang, G.H. Fan, L. Geng, G.J. Cao, Y. Du, H. Wu, T.T. Zhang, H.J. Kang, T.M. Wang, G.H. Du and H.L. Xie: Sci Rep, 2016, vol. 6, pp. 1-10.

[22]R. Song, D. Ponge and D. Raabe: Scr. Mater., 2005, vol. 52, pp. 1075-80.

[23]L. Storojeva, D. Ponge, R. Kaspar and D. Raabe: Acta Mater., 2004, vol. 52, pp. 2209-20.

[24]C. Prasad, P. Bhuyan, C. Kaithwas, R. Saha and S. Mandal: Mater. Des., 2018, vol. 139, pp. 324-35.

[25]A. Ohmori, S. Torizuka and K. Nagai: ISIJ Int., 2004, vol. 44, pp. 1063-71.

R. Ding, Y.J. Yao, B.H. Sun, G. Liu, J.G. He, T. Li, X.H. Wan, Z.B. Dai, D. Ponge, D. Raabe, C. Zhang, A. Godfrey, G. Miyamoto, T. Furuhara, Z.G. Yang, S. van der Zwaag and H. Chen: Sci. Adv, 2020, vol. 6, p. 1430.

[27]M. Jafari, C. Bang, J.C. Han, K Kim, S Na, C. G. Park and B. Lee: J. Mater. Sci. Technol., 2020, vol. 1, pp. 1-11.

[28]X. Zhou, X.Y. Li and K. Lu: Science, 2018, vol. 360, pp. 526-30.

[29]X.L. Liang, H. Wang, Q.F. Pan, J.Y. Zheng, H.Q. Liu, R.Q. Zhang, Y.Xu and Q.Y. Dan: J. Iron Steel Res. Int., 2020, vol. 27, pp. 549-65.

[30]J.H. Hollomon: Trans. Aime, 1945, vol. 162, pp. 223-49.

[31]M.F. Ashby: Philos. Mag, 1970, vol. 21, pp. 399-424.

Y. Estrin, H. Mecking: Acta Metall, 1984, vol. 32: 57-70.

[33]C. Crussard, J. Mech: Phys. Solids, 1957, vol. 5, pp. 95-114.

[34]S.A. Etesami, M.H. EnayatibAli, Ghatei Kalashami: Mater. Sci. Eng. A, 2017, vol. 682, pp. 296-303.

[35]H.W. Swift, J. Mech: Phys. Solids, 1952, vol. 1, pp. 1-18.

[36]M.X. Yang, R.G. Li, P. Jiang, F.P. Yuan, Y.D. Wang, Y.T. Zhu and X.L. Wu: Mater. Res. Lett., 2019, vol. 7, pp. 433-38.

[37]X.L. Wu, P. Jiang, L. Chen, J.F. Zhang, F.P. Yuan and Y.T. Zhu: Mater. Res. Lett., 2014, vol. 2, pp. 185-91.

[38]C.S. Zheng, L.F. Li and Y.D. Wang: Mater. Sci. Eng A, 2015, vol. 631, pp. 181-88.

[39]K.K. Ray and D. Mondal, Acta Metall. Mater., 1991, vol. 39, pp. 2201-08.

[40]C.S. Zheng, L.F. Li, W. Yang, W.Y. Yang and Z.Q. Sun, Mater. Sci. Eng. A, 2014, vol. 617, pp. 31-8.

Acknowledgments

The authors gratefully acknowledge financial supports from the National Natural Science Foundation of China (NSFC) (Grant Nos. 51974134); The Defense Industrial Technology Development Program (No. JCKY2018407C008); Natural Science Foundation of Hebei Province of China (No. E2017209237).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted September 19, 2020; accepted January 8, 2021.

Rights and permissions

About this article

Cite this article

Zhang, D., Zhang, M., Cao, K. et al. Effect of Annealing Time on Microstructure Stability and Mechanical Behavior of Ferrite-Cementite Steel with Multiscale Lamellar Structure. Metall Mater Trans B 52, 1023–1033 (2021). https://doi.org/10.1007/s11663-021-02075-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-021-02075-z