Abstract

Dynamic behavior of a material is essential in applications such as collision, explosion, ballistic impact, high-speed machining, and metal forming. As impact loadings, as well as accidental or malicious explosions, may impose high loading rates to engineering structures, estimating the dynamic response of a material accurately is crucial. Therefore, an analytical strain rate-dependent criterion on ductile fracture initiation is developed at the continuum scale by further developing the energy balance concept. The criterion is based on continuum modeling of energy release rates, and the critical state is reached when the rate of energy change of fractured and unfractured states becomes equal. The formulation introduces a material length scale and a material property that is a function of strain rate and temperature. The developed ductile fracture criterion is implemented into two example applications, an aluminum alloy and a titanium alloy, whose experimental data are obtained from the open literature. Fracture loci of these alloys at various strain rates and the critical energy release rates as a function of strain rate are determined. The results of the example applications agree well with the experimental results reported in the literature.

Similar content being viewed by others

Abbreviations

- A :

-

Area of the fracture plane

- \(A_{1}, A_{2}, A_{3}\) :

-

Material constants

- \(c_\mathrm{{V}}\) :

-

Specific heat capacity at constant volume

- \(\mathrm {C}_\mathrm{{I}}\) :

-

Specific surface energy density

- du :

-

Plastic work increment per unit volume

- dk :

-

Kinetic energy increment per unit volume

- dw :

-

Mechanical work increment per unit volume (of the unfractured medium)

- dW :

-

Mechanical work increment of the unfractured medium

- d\(W^{*}\) :

-

Mechanical work increment of the fractured medium

- d\(\varepsilon _{ij}\) :

-

Components of (plastic) strain increment tensor (of the unfractured medium)

- d\(\varepsilon _\mathrm{{I}}, \hbox {d}\varepsilon _\mathrm{{II}}, \hbox {d}\varepsilon _\mathrm{{III}}\) :

-

Strain increments of the unfractured medium in principal directions

- d\(\varepsilon _\mathrm{{I}}^{*}, \hbox {d}\varepsilon _\mathrm{{II}}^{*}, \hbox {d}\varepsilon _\mathrm{{III}}^{*}\) :

-

Strain increments of the fractured medium in principal directions

- d\(\varepsilon _\mathrm{{eff}}\) :

-

Equivalent (plastic) strain increment

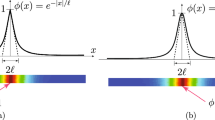

- \(l_{\mathrm{{I}},0}\) :

-

Characteristic length (relevant to ductile fracture)

- \(l_\mathrm{{I}}, l_\mathrm{{II}}, l_\mathrm{{III}}\) :

-

Current dimensions of the volume element

- m, n :

-

Material constants

- T :

-

Actual material temperature

- \(T_\mathrm{{melt}}\) :

-

Melting temperature of the material

- \(T_\mathrm{{room}}\) :

-

Room temperature

- \(v_\mathrm{{I}}, v_\mathrm{{II}}, v_\mathrm{{III}}\) :

-

Components of velocity vector (in principal directions)

- \(x_\mathrm{{I}}, x_\mathrm{{II}}, x_\mathrm{{IIII}}\) :

-

Principal directions

- \(\beta \) :

-

Fraction of the plastic work contributing to temperature increase

- \(\varepsilon _{ij}\) :

-

Components of true strain

- \(\dot{\varepsilon _{0}}\) :

-

Reference strain rate

- \(\dot{\varepsilon _\mathrm{{I}}}, \dot{\varepsilon _\mathrm{{II}}}, \dot{\varepsilon _\mathrm{{III}}}\) :

-

True strain rates in principal directions

- \(\varepsilon _\mathrm{{eff}}\) :

-

Equivalent (plastic) strain

- \(\bar{\varepsilon _{f}}\) :

-

Equivalent (plastic) strain at fracture

- \(\lambda \) :

-

Nonnegative scalar factor

- \(\rho \) :

-

Mass density of the material

- \(\sigma _{ij}\) :

-

Components of true stress tensor

- \(\sigma _\mathrm{{I}}, \sigma _\mathrm{{II}}, \sigma _\mathrm{{III}}\) :

-

Principal stresses of the unfractured medium

- \(\sigma _\mathrm{{I}}^{*}, \sigma _\mathrm{{II}}^{*}, \sigma _\mathrm{{III}}^{*}\) :

-

Principal stresses of the fractured medium

- \(\sigma _\mathrm{{eff}}\) :

-

Equivalent stress

- \({\Gamma }_\mathrm{{I}}\) :

-

Critical effective energy release rate (of tensile mode fracture)

- \({\Delta }T\) :

-

Increase in temperature

References

Amini, M.R., Nemat-Nasser, S.: Micromechanisms of ductile fracturing of DH-36 steel plates under impulsive loads and influence of polyurea reinforcing. Int. J. Fract. 162, 205–217 (2010)

Anderson, D., Winkler, S., Bardelcik, A., Worswick, M.J.: Influence of stress triaxiality and strain rate on the failure behavior of a dual-phase DP780 steel. Mater. Des. 60, 198–207 (2014)

Andreaus, U., Baragatti, P.: Experimental damage detection of cracked beams by using nonlinear characteristics of forced response. Mech. Syst. Signal Process. 31, 382–404 (2012)

Andreaus, U., Baragatti, P., Casini, P., Iacoviello, D.: Experimental damage evaluation of open and fatigue cracks of multi-cracked beams by using wavelet transform of static response via image analysis. Struct. Control Health Monit. 24, e1902 (2017)

Asim, U.B., Siddiq, M.A., McMeeking, R.M., Kartal, M.E.: A multiscale constitutive model for metal forming of dual phase titanium alloys by incorporating inherent deformation and failure mechanisms. arXiv preprint arXiv: 2002.04459 (2020)

ASM Handbook Committee: Properties of wrought aluminum and aluminum alloys. ASM Handbook. Volume 2: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, pp. 62–122. ASM International, Materials Park (2010)

Austin, R.A., McDowell, D.L.: A dislocation-based constitutive model for viscoplastic deformation of fcc metals at very high strain rates. Int. J. Plast. 27, 1–24 (2011)

Avriel, E., Lovinger, Z., Nemirovsky, R., Rittel, D.: Investigating the strength of materials at very high strain rates using electromagnetically driven expanding cylinders. Mech. Mater. 117, 165–180 (2018)

Bai, Y., Wierzbicki, T.: Application of extended Mohr-Coulomb criterion to ductile fracture. Int. J. Fract. 161, 1–20 (2010)

Barsoum, I., Faleskog, J.: Rupture mechanisms in combined tension and shear-experiments. Int. J. Solids Struct. 44, 1768–1786 (2007)

Benzerga, A.A., Leblond, J.B., Needleman, A., Tvergaard, V.: Ductile failure modeling. Int. J. Fract. 201, 29–80 (2016)

Bobbili, R., Madhu, V.: Effect of strain rate and stress triaxiality on tensile behavior of Titanium alloy Ti-10-2-3 at elevated temperatures. Mater. Sci. Eng. A 667, 33–41 (2016)

Bobbili, R., Paman, A., Madhu, V.: High strain rate tensile behavior of Al-4.8Cu-1.2Mg alloy. Mater. Sci. Eng. A 651, 753–762 (2016)

Børvik, T., Dey, S., Clausen, A.H.: Perforation resistance of five different high-strength steel plates subjected to small-arms projectiles. Int. J. Impact Eng. 36, 948–964 (2009)

Børvik, T., Hopperstad, O.S., Berstad, T., Langseth, M.: A computational model of viscoplasticity and ductile damage for impact and penetration. Eur. J. Mech. A/Solids 20, 685–712 (2001)

Børvik, T., Hopperstad, O.S., Dey, S., Pizzinato, E.V., Langseth, M., Albertini, C.: Strength and ductility of Weldox 460 E steel at high strain rates, elevated temperatures and various stress triaxialities. Eng. Fract. Mech. 72, 1071–1087 (2005)

Boyer, R., Welsch, G., Collings, E.W.: Materials Properties Handbook: Titanium alloys. ASM International, Materials Park (1998)

Carlioz, T., Dormieux, L., Lemarchand, E.: Thermodynamics of crack nucleation. Contin. Mech. Thermodyn. 32, 1515–1531 (2020)

Cayless, R.B.C.: Alloy and temper designation systems for aluminum and aluminum alloys. ASM Handbook. Volume 2: Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, pp. 15–28. ASM International, Materials Park (2010)

Charoensuk, K., Panich, S., Uthaisangsuk, V.: Damage initiation and fracture loci for advanced high strength steel sheets taking into account anisotropic behaviour. J. Mater. Process. Technol. 248, 218–235 (2017)

Chen, Y., Clausen, A.H., Hopperstad, O.S., Langseth, M.: Stress-strain behaviour of aluminium alloys at a wide range of strain rates. Int. J. Solids Struct. 46, 3825–3835 (2009)

Clausen, A.H., Børvik, T., Hopperstad, O.S., Benallal, A.: Flow and fracture characteristics of aluminium alloy AA5083-H116 as function of strain rate, temperature and triaxiality. Mater. Sci. Eng. A 364, 260–272 (2004)

Chiyatan, T., Uthaisangsuk, V.: Mechanical and fracture behavior of high strength steels under high strain rate deformation: experiments and modelling. Mater. Sci. Eng. A 779, 139125 (2020)

De Angelo, M., Spagnuolo, M., D’Annibale, F., Pfaff, A., Hoschke, K., Misra, A., Dupuy, C., Peyre, P., Dirrenberger, J., Pawlikowski, M.: The macroscopic behavior of pantographic sheets depends mainly on their microstructure: experimental evidence and qualitative analysis of damage in metallic specimens. Contin. Mech. Thermodyn. 31(4), 1181–1203 (2019)

Desai, C.S., Siriwardane, H.J.: Constitutive laws for engineering materials with emphasis on geologic materials. Prentice-Hall, Upper Saddle River (1984)

Dieter, G.E.: Mechanical Metallurgy. McGraw-Hill, New York (1986)

Dorogoy, A., Rittel, D.: Dynamic large strain characterization of tantalum using shear-compression and shear-tension testing. Mech. Mater. 112, 143–153 (2017)

El-Magd, E., Abouridouane, M.: Characterization, modelling and simulation of deformation and fracture behaviour of the light-weight wrought alloys under high strain rate loading. Int. J. Impact Eng. 32, 741–758 (2006)

Erice, B., Gálvez, F.: A coupled elastoplastic-damage constitutive model with Lode angle dependent failure criterion. Int. J. Solids Struct. 51, 93–110 (2014)

Erice, B., Gálvez, F., Cendón, D.A., Sánchez-Gálvez, V.: Flow and fracture behaviour of FV535 steel at different triaxialities, strain rates and temperatures. Eng. Fract. Mech. 79, 1–17 (2012)

Eringen, A.C.: Mechanics of Continua. Robert E. Krieger Publishing Company, Melbourne (1980)

Fu, J., Xie, W., Zhou, J., Qi, L.: A method for the simultaneous identification of anisotropic yield and hardening constitutive parameters for sheet metal forming. Int. J. Mech. Sci. 181, 105756 (2020)

Gambirasio, L., Rizzi, E.: On the calibration strategies of the Johnson-Cook strength model: discussion and applications to experimental data. Mater. Sci. Eng. A 610, 370–413 (2014)

Gao, C.Y., Zhang, L.C.: Constitutive modelling of plasticity of fcc metals under extremely high strain rates. Int. J. Plast. 32, 121–133 (2012)

Grimsmo, E.L., Clausen, A.H., Aalberg, A., Langseth, M.: Fillet welds subjected to impact loading: an experimental study. Int. J. Impact Eng. 108, 101–113 (2017)

Grimsmo, E.L., Clausen, A.H., Langseth, M., Aalberg, A.: An experimental study of static and dynamic behaviour of bolted end-plate joints of steel. Int. J. Impact Eng. 85, 132–145 (2015)

Gurson, A.L.: Continuum theory of ductile rupture by void nucleation and growth: part I-yield criteria and flow rules for porous ductile media. J. Eng. Mater. Technol. 99, 2–15 (1977)

Hahn, G.T., Kanninen, M.F., Rosenfield, A.R.: Fracture toughness of materials. Annu. Rev. Mater. Sci. 2, 381–404 (1972)

Hahn, G.T., Rosenfield, A.R.: Metallurgical factors affecting fracture toughness of aluminum alloys. Metall. Trans. A 6, 653–668 (1975)

Hancock, J.W., Mackenzie, A.C.: On the mechanisms of ductile failure in high-strength steels subjected to multi-axial stress-states. J. Mech. Phys. Solids 24, 147–160 (1976)

Huang, J., Guo, Y., Qin, D., Zhou, Z., Li, D., Li, Y.: Influence of stress triaxiality on the failure behavior of Ti-6Al-4V alloy under a broad range of strain rates. Theor. Appl. Fract. Mech. 97, 48–61 (2018)

Huh, H., Ahn, K., Lim, J.H., Kim, H.W., Park, L.J.: Evaluation of dynamic hardening models for BCC, FCC, and HCP metals at a wide range of strain rates. J. Mater. Process. Technol. 214, 1326–1340 (2014)

Johnson, GR., Cook, WH.: A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In: Proceedings of the 7th International Symposium on Ballistics, Hague, pp. 541–547 (1983)

Johnson, G.R., Cook, W.H.: Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 21, 31–48 (1985)

Kabirian, F., Khan, A.S., Pandey, A.: Negative to positive strain rate sensitivity in 5xxx series aluminum alloys: Experiment and constitutive modeling. Int. J. Plast. 55, 232–246 (2014)

Kapoor, R., Nemat-Nasser, S.: Determination of temperature rise during high strain rate deformation. Mech. Mater. 27, 1–12 (1998)

Karr, D.G., Akçay, F.A.: A criterion for ductile fracture based on continuum modeling of energy release rates. Int. J. Fract. 197, 201–212 (2016)

Khan, A.S., Liang, R.: Behaviors of three BCC metal over a wide range of strain rates and temperatures: experiments and modeling. Int. J. Plast 15, 1089–1109 (1999)

Khan, A.S., Liu, H.: A new approach for ductile fracture prediction on Al 2024–T351 alloy. Int. J. Plast. 35, 1–12 (2012a)

Khan, A.S., Liu, H.: Variable strain rate sensitivity in an aluminum alloy: response and constitutive modeling. Int. J. Plast. 36, 1–14 (2012b)

Khan, A.S., Liu, H.: Strain rate and temperature dependent fracture criteria for isotropic and anisotropic metals. Int. J. Plast. 37, 1–15 (2012c)

Khan, A.S., Liu, J., Yoon, J.W., Nambori, R.: Strain rate effect of high purity aluminum single crystals: experiments and simulations. Int. J. Plast. 67, 39–52 (2015)

Kim, J.H., Kim, D., Han, H.N., Barlat, F., Lee, M.G.: Strain rate dependent tensile behavior of advanced high strength steels: Experiment and constitutive modeling. Mater. Sci. Eng. A 559, 222–231 (2013)

Kim, W.J., Kim, H.K., Kim, W.Y., Han, S.W.: Temperature and strain rate effect incorporated failure criteria for sheet forming of magnesium alloys. Mater. Sci. Eng. A 488, 468–474 (2008)

Landau, P., Osovski, S., Venkert, A., Gärtnerová, V., Rittel, D.: The genesis of adiabatic shear bands. Sci. Rep. 6, 37226 (2016)

Larsson, R., Razanica, S., Josefson, B.L.: Mesh objective continuum damage models for ductile fracture. Int. J. Numer. Methods Eng. 106, 840–860 (2016)

Lee, W.S., Lin, C.F., Liu, T.J.: Impact and fracture response of sintered 316L stainless steel subjected to high strain rate loading. Mater. Charact. 58, 363–370 (2007)

Liao, D., Zhu, S.P., Correia, J.A., De Jesus, A.M., Berto, F.: Recent advances on notch effects in metal fatigue: a review. Fatigue Fract. Eng. Mater. Struct. 43, 637–659 (2020)

Liu, Y.J., Sun, Q.: A dynamic ductile fracture model on the effects of pressure, Lode angle and strain rate. Mater. Sci. Eng. A 589, 262–270 (2014)

Longère, P.: Adiabatic shear banding assisted dynamic failure: some modeling issues. Mech. Mater. 116, 49–66 (2018)

Longère, P., Dragon, A.: Dynamic vs. quasi-static shear failure of high strength metallic alloys: experimental issues. Mech. Mater. 80, 203–218 (2015)

Majzoobi, G.H., Mahmoudi, A.H., Moradi, S.: Ductile to brittle failure transition of HSLA-100 steel at high strain rates and subzero temperatures. Eng. Fract. Mech. 158, 179–193 (2016)

Mohr, D., Marcadet, S.J.: Micromechanically-motivated phenomenological Hosford-Coulomb model for predicting ductile fracture initiation at low stress triaxialities. Int. J. Solids Struct. 67, 40–55 (2015)

Molinari, A., Mercier, S., Jacques, N.: Dynamic failure of ductile materials. Procedia IUTAM 10, 201–220 (2014)

Molinari, A., Ravichandran, G.: Constitutive modeling of high-strain-rate deformation in metals based on the evolution of an effective microstructural length. Mech. Mater. 37, 737–752 (2005)

Moody, N.R., Garrison, W.M., Smugeresky, J.E., Costa, J.E.: The role of inclusion and pore content on the fracture toughness of powder-processed blended elemental titanium alloys. Metall. Trans. A 24, 161–174 (1993)

Nahshon, K., Hutchinson, J.W.: Modification of the Gurson model for shear failure. Eur. J. Mech. A/Solids 27, 1–17 (2008)

Nguyen, C.T., Oterkus, S., Oterkus, E.: An energy-based peridynamic model for fatigue cracking. Eng. Fract. Mech. 241, 107373 (2020)

Nielsen, K.L., Tvergaard, V.: Ductile shear failure or plug failure of spot welds modelled by modified Gurson model. Eng. Fract. Mech. 77, 1031–1047 (2010)

Osovski, S., Srivastava, A., Ponson, L., Bouchaud, E., Tvergaard, V., Ravi-Chandar, K., Needleman, A.: The effect of loading rate on ductile fracture toughness and fracture surface roughness. J. Mech. Phys. Solids 76, 20–46 (2015)

Owen, D.M., Zhuang, S., Rosakis, A.J., Ravichandran, G.: Experimental determination of dynamic crack initiation and propagation fracture toughness in thin aluminum sheets. Int. J. Fract. 90, 153–174 (1998)

Özel, T., Karpat, Y.: Identification of constitutive material model parameters for high-strain rate metal cutting conditions using evolutionary computational algorithms. Mater. Manuf. Process. 22, 659–667 (2007)

Pan, H., Liu, J., Choi, Y., Xu, C., Bai, Y., Atkins, T.: Zones of material separation in simulations of cutting. Int. J. Mech. Sci. 115, 262–279 (2016)

Piao, M., Huh, H., Lee, I., Ahn, K., Kim, H., Park, L.: Characterization of flow stress at ultra-high strain rates by proper extrapolation with Taylor impact tests. Int. J. Impact Eng. 91, 142–157 (2016)

Placidi, L., Barchiesi, E., Misra, A.: A strain gradient variational approach to damage: a comparison with damage gradient models and numerical results. Math. Mech. Complex Syst. 6, 77–100 (2018a)

Placidi, L., Misra, A., Barchiesi, E.: Two-dimensional strain gradient damage modeling: a variational approach. Z. Angew. Math. Phys. 69, 56 (2018b)

Placidi, L., Misra, A., Barchiesi, E.: Simulation results for damage with evolving microstructure and growing strain gradient moduli. Contin. Mech. Thermodyn. 31, 1143–1163 (2019)

Rittel, D., Weisbrod, G.: Dynamic fracture of tungsten base heavy alloys. Int. J. Fract. 112, 87–98 (2001)

Roth, C.C., Mohr, D.: Effect of strain rate on ductile fracture initiation in advanced high strength steel sheets: Experiments and modeling. Int. J. Plast. 56, 19–44 (2014)

Rusinek, A., Rodríguez-Martínez, J.A.: Thermo-viscoplastic constitutive relation for aluminium alloys, modeling of negative strain rate sensitivity and viscous drag effects. Mater. Des. 30, 4377–4390 (2009)

Shahba, A., Ghosh, S.: Crystal plasticity FE modeling of Ti alloys for a range of strain-rates. Part I: a unified constitutive model and flow rule. Int. J. Plast. 87, 48–68 (2016)

Shojaei, A., Voyiadjis, G.Z., Tan, P.J.: Viscoplastic constitutive theory for brittle to ductile damage in polycrystalline materials under dynamic loading. Int. J. Plast. 48, 125–151 (2013)

Siddiq, A.: A porous crystal plasticity constitutive model for ductile deformation and failure in porous single crystals. Int. J. Damage Mech. 28, 233–248 (2019)

Siddiq, A., Arciniega, R., El Sayed, T.: A variational void coalescence model for ductile metals. Comput. Mech. 49, 185–195 (2012)

Siddiq, A., Schmauder, S.: Simulation of hardening in high purity niobium single crystals during deformation. Steel Grips J. Steel Relat. Mater. 3, 281–286 (2005)

Sjöberg, T., Kajberg, J., Oldenburg, M.: Fracture behaviour of Alloy 718 at high strain rates, elevated temperatures, and various stress triaxialities. Eng. Fract. Mech. 178, 231–242 (2017)

Smerd, R., Winkler, S., Salisbury, C., Worswick, M., Lloyd, D., Finn, M.: High strain rate tensile testing of automotive aluminum alloy sheet. Int. J. Impact Eng. 32, 541–560 (2005)

Spagnuolo, M., Barcz, K., Pfaff, A., Dell’Isola, F., Franciosi, P.: Qualitative pivot damage analysis in aluminum printed pantographic sheets: numerics and experiments. Mech. Res. Commun. 83, 47–52 (2017)

Sung, J.H., Kim, J.H., Wagoner, R.H.: A plastic constitutive equation incorporating strain, strain-rate, and temperature. Int. J. Plast. 26, 1746–1771 (2010)

Tanimura, S., Tsuda, T., Abe, A., Hayashi, H., Jones, N.: Comparison of rate-dependent constitutive models with experimental data. Int. J. Impact Eng. 69, 104–113 (2014)

Tvergaard, V.: Influence of voids on shear band instabilities under plane strain conditions. Int. J. Fract. 17, 389–407 (1981)

Ulacia, I., Salisbury, C.P., Hurtado, I., Worswick, M.J.: Tensile characterization and constitutive modeling of AZ31B magnesium alloy sheet over wide range of strain rates and temperatures. J. Mater. Process. Technol. 211, 830–839 (2011)

Vaz-Romero, A., Rodríguez-Martínez, J.A., Arias, A.: The deterministic nature of the fracture location in the dynamic tensile testing of steel sheets. Int. J. Impact Eng. 86, 318–335 (2015)

Voyiadjis, G.Z., Abed, F.H.: Effect of dislocation density evolution on the thermomechanical response of metals with different crystal structures at low and high strain rates and temperatures. Arch. Mech. 57, 299–343 (2005a)

Voyiadjis, G.Z., Abed, F.H.: Microstructural based models for bcc and fcc metals with temperature and strain rate dependency. Mech. Mater. 37, 355–378 (2005b)

Wang, B., Xiao, X., Astakhov, V.P., Liu, Z.: The effects of stress triaxiality and strain rate on the fracture strain of Ti6Al4V. Eng. Fract. Mech. 219, 106627 (2019)

Wierzbicki, T., Bao, Y., Lee, Y.W., Bai, Y.: Calibration and evaluation of seven fracture models. Int. J. Mech. Sci. 47, 719–743 (2005)

Yu, X., Li, L., Li, T., Qin, D., Liu, S., Li, Y.: Improvement on dynamic fracture properties of magnesium alloy AZ31B through equal channel angular pressing. Eng. Fract. Mech. 181, 87–100 (2017)

Yu, T., Hyer, H., Sohn, Y., Bai, Y., Wu, D.: Structure-property relationship in high strength and lightweight AlSi10Mg microlattices fabricated by selective laser melting. Mater. Des. 182, 108062 (2019)

Zener, C., Hollomon, J.H.: Effect of strain rate upon plastic flow of steel. J. Appl. Phys. 15, 22–32 (1944)

Zerilli, F.J., Armstrong, R.W.: Dislocation-mechanics-based constitutive relations for material dynamics calculations. J. Appl. Phys. 61, 1816–1825 (1987)

Zheng, C., Wang, F., Cheng, X., Liu, J., Fu, K., Liu, T., Zhu, Z., Yang, K., Peng, M., Jin, D.: Failure mechanisms in ballistic performance of Ti-6Al-4V targets having equiaxed and lamellar microstructures. Int. J. Impact Eng. 85, 161–169 (2015)

Acknowledgements

The first author would like to thank Dr. Osman Darıcı for his kind help to obtain some articles.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Communicated by Marcus Aßmus and Andreas Öchsner.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Akçay, F.A., Oterkus, E. A criterion for dynamic ductile fracture initiation of tensile mode. Continuum Mech. Thermodyn. 35, 1087–1101 (2023). https://doi.org/10.1007/s00161-021-00983-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00161-021-00983-8