Abstract

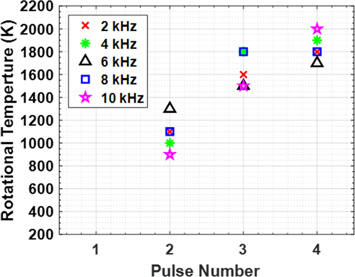

Transient plasma ignition (TPI) employs highly non-equilibrium plasmas driven by nanosecond high-voltage pulses for combustion ignition. The effects of rise time and pulse repetition frequency (PRF) on combustion ignition are evaluated when transient plasmas, powered by 10-ns, kilovolt pulses, are employed to initiate combustion of lean, stoichiometric, or rich methane-dry air mixtures at atmospheric pressure. It was found that the plasmas driven by high voltage pulses with a faster rise time and PRF between 6–10 kHz enhanced combustion with higher peak pressure and/or shorter ignition delay. A mode transition in the plasma, corresponding to the combustion initiation, was observed based on voltage and current waveforms of four consecutive pulsed plasmas driven by a pulse burst at kilohertz PRFs. Although benefits in combustion ignition from a shorter rise time and optimal PRF were observed for all three equivalence mixture ratios, the highest peak pressure and shortest ignition delay were associated with the stoichiometric mixtures. In addition, the gas temperature of the transient plasma was measured by determining the rotational temperature of the 2nd positive system of nitrogen to be ∼1000 K for the first pulse and increased up to 2000 K after the application of the 4th pulse in a four-pulse burst TPI.

Export citation and abstract BibTeX RIS

1. Introduction

Challenges for combustion ignition systems include increasing thermal efficiency, reducing fuel consumption, and reducing emission. Transient plasma ignition (TPI) uses nanosecond pulsed plasmas to achieve energy-efficient combustion ignition and has been proposed as a promising solution to overcome the challenges [1, 2]. TPI has been shown to improve lean-fuel combustion, rate of combustion, and to have the potential to reduce emissions [1, 2]. Nanosecond, high voltage pulses drive an igniter to generate highly non-equilibrate plasmas that ignite air-fuel mixtures to achieve a more voluminous combustion, differing from arc plasma, which initiates combustion through thermal decomposition [3–5]. During a typical TPI process a more turbulent ignition kernel is developed and it propagates faster leading to reduced ignition delay times and allowing lean-fuel ignition [6]. Reducing ignition delay time (td) and extending the lean-fuel limit without misfire are associated with reduced burn time and increased fuel economy, both of which are important to applications in internal combustion engines or any combustion-driven propulsion systems [1]. In addition, TPI has the potential to reduce harmful combustion byproducts such as NOx, by lean-fuel ignition [1].

Ignition by different pulse types has been investigated to improve combustion efficiency and lower emission [1, 2, 5, 7–11]. In 1976, Kono et al studied bursts of two 0.5 μs duration, 6–7.8 kV high voltage pulses to generate spark discharges for combustion ignition [7]. The pulses were applied across a variable discharge gap of 1.5–3 mm. Results showed that the igniting ability of two successive sparks is highest at a frequency of 10–50 kHz varying slightly dependent upon the electrode gap. The investigation indicates that pulse repetition frequency (PRF) is a more dominate factor than pulse duration. Maly et al examined flame fronts by breakdown, arc, and glow discharge ignition devices [8]. Results indicated that breakdown, a discharge with 1–10 ns duration, applied voltage of 10 kV, was far better for inflaming combustible mixtures due to an energy transfer efficiency of 95%. The findings indicate that the fast pulse driving scheme during the plasma initiation is also critical. TPIs driven by nanosecond (10 ns–50 ns) high voltage pulses were studied in the 2000s [10]. Results of the study showed combustion pressure td could be reduced by a factor of 2.5 employing higher PRF (e.g. 30 kHz) or voltage (e.g. 80 kV) [1, 10]. More recently, Lo et al investigated bursts of 22 pulses across a range of PRF from 2–90 kHz [2]. For a constant energy per burst, there was an optimum PRF associated with the inter electrode gap; for an inter electrode gap of 3 mm the optimal PRF was 15 kHz and for an inter electrode gap of 1.2 mm the optimal PRF was 60 kHz [2].

The volumetric effect created by nanosecond gas discharges or TPIs was demonstrated by Singleton, et al examining the development of ignition kernels during the streamer propagation and afterglow, and was considered beneficial to emission reduction and combustion efficiency [5]. In addition, the dominant combustion ignition process can be very different depending on the initial reduced electric field, E/N, where E is the electric field and N is the number density of the gas. Rusterholtz et al performed a detailed experimental investigation of the mechanisms of ultrafast heating and oxygen dissociation with 10 ns duration, 5.7 kV pulses at 10 kHz PRF [11]. The findings indicated that electron impact and dissociative quenching of O2 by electronically excited nitrogen molecules are important at E/N < 200 Td and dissociative charge transfer starts play more important roles in addition to other processes at higher reduced electric field, e.g. E/N > 400 Td [11].

To understand the limitation and potential of high repetitive, ultrafast pulsed plasmas on combustion ignition, we report here a study of the effects of rise time (tr) and PRF on TPI for a constant pulse duration of 10 ns full-width at half-maximum (FWHM). Two different rise times, tr = 5 ns and 10 ns, are examined at a range of PRF's from 1–6 kHz. Ignition is carried out in a static combustion chamber containing methane and dry air mixtures at atmospheric pressure. A conventional spark plug (Champion N11YC) is investigated as the electrode powered by high voltage pulses. Although tungsten electrodes with specific radii were typically used by others [2, 7, 10] to have a better controlled breakdown condition, we chose to use a commercially available spark plug electrode to have the findings more relevant to common igniters used in internal combustion engines. Combustion performance characteristics of lean, stoichiometric, and rich mixtures are evaluated and compared. Combustion performance is evaluated in terms of the ignition td, and peak pressure. The total energy for bursts of pulses and the individual energy of each pulse in a burst are calculated based on the voltage and current measurements. Additionally, the gas temperature of each transient plasma in a burst, prior to the combustion is determined using the rotational temperature of the second positive system of nitrogen.

2. Experimental setup and procedures

Schematic of the experimental setup is shown in figure 1. Experiments were conducted in a 700 cm3 stainless steel chamber equipped with a fused quartz window. Gas mixing and pressure were monitored by a low-pressure gauge (Snap-on, EEPV511) and controlled with needle valves. Before each run, the combustion chamber would be evacuated to a pressure of less than 1 mbar by a rotary vane vacuum pump (Alcatel 2008A) and then filled with the working mixture up to a total pressure of 1 bar (14.5 psi). Dry air (AirGas, < 7 ppm H2O) and methane (AirGas, 99.5% methane) were mixed at three different ratios, i.e. stoichiometric (λ = 1), lean (λ = 1.033), and rich (λ = 0.967) air-fuel ratios for this ignition study.

Figure 1. Schematic of the experimental setup. The ballast resistor, current monitor, and voltage probe are all contained within the shielded V-I monitor.

Download figure:

Standard image High-resolution imageA conventional spark plug (Champion N11YC) with an inter electrode gap of 3.0 mm was used to ignite fuel-air mixtures. The high-voltage electrode is a non-resistive conventional spark plug in a shape of cylindrical rod with an outer diameter of 2.4 mm. A 90-ohm ballast resistor was connected to the high-voltage electrode in series as part of the electrode system in order to better match the electrode system (or the load system) to the transmission line and reduce reflection. A calibrated, custom-built voltage-current monitor (V-I monitor) [12, 13] was inserted between the ballast resistor and the spark-plug electrode for voltage and current measurements. The ballast, voltage, and current probes were housed inside a shielded structure connected between the coaxial line and the spark plug. The V-I monitor consists of a 600-MHz voltage attenuator and a current monitor (Pearson 6585). A high-speed digital oscilloscope (Tektronix DPO 5204) was connected to the V-I monitor for measurements. For this study, two pulse generators were used: Pulse generator #1 (FID FPG 20-10NKN5) and Pulse generator #2 (TPS SSPG-20X-HP1). Both pulse generators provide up to 20 kV in amplitude, 10 ns FWHM pulses. Pulse generator #1 supports up to 6 kHz repetition rate and 100 A maximum current at 20 kV peak voltage. The pulse rise time was rated for 1.5 ns for a matched load and measured to be 5 ns for this applied ignition system. Pulse generator #2 is capable of 10 kHz repetition rate and 400 A peak current at 20 kV. The pulse rise time applied to the ignition system was measured to be 10 ns.

An Omega Model PX409 piezo resistive pressure transducer (0–250 PSIG, cut-off frequency 1.5 kHz) was used to measure the pulsed pressure trace during combustion. Combustion performance was evaluated in terms of ignition delay time tid and peak pressure. Ignition delay time tid is the duration between the first pulse in a burst of 10-ns high voltage pulses and the time when ten percent of the maximum combustion pressure is reached. Peak pressure is the maximal pressure achieved in the static chamber once the combustion is initiated.

Spectroscopic measurements were performed to determine the time characteristics of OH emission during the combustion process and rotational temperature of the transient plasma prior to combustion. In addition to OH, ozone, oxygen atoms and electronically excited O2 were also highly relevant to plasma-assisted combustion [14–16]. In this study, only OH emission was measured due to its high yield during the combustion event and relatively low requirement for optical sensitivity. A photomultiplier tube (PMT) (Hamamatsu, R928, response time of 2.2 ns) with a TECHSPEC bandpass filter (λ0 = 310 nm, Δλ = 10 nm) was used to collect the OH emission. A spectrograph (Princeton Instruments, SpectraPro SP2750) coupled with an intensified charge coupled device (ICCD) camera (Princeton Instruments, PI-MAX 4) was used to collect emission between 300–800 nm with a spectral resolution of 0.2 Å. Synchronization of the emission spectroscopy for the 10-ns pulsed transient plasmas was achieved using a combination of function generators (SRS DG645 and DG535), and a jitter of 3 ns was obtained.

3. Results and discussion

3.1. Voltage, current, and energy

In this study each combustion event was initiated with a burst of four pulses. The voltage and current of each pulse of two different tr at a PRF = 2 kHz are shown in figure 2. The current is displayed upside down for clarity. For the first pulse, same voltage amplitude was applied to the electrode for tr = 5 ns and 10 ns pulses, respectively, as shown in figure 2(A). The current is relatively in phase with the voltage, implying a highly resistive impedance of the electrode system. Similar in-phase voltage and current pair was observed for the 2nd pulse (figure 2(B)) but the peak voltage dropped by approximately 20%–25% for both rise times. For the 3rd pulse, 2 times increase in peak current and a drop to half of the initial peak voltage were observed for the case of tr = 5 ns, as shown in figure 2(C). A phase shift indicating a more reactive impedance of the load was also observed along with the changes in voltage and current. This impedance change in the electrode system implies a mode change in the transient plasma; a less conductive, weakly ionized plasma is transitioning to a more conductive ionization channel. Similar mode change was reported by others [10]. This mode change in plasma electrode system is associated with the combustion occurrence; the combustion is initiated when the mode transition is observed in the voltage and current waveforms. In comparison, the mode change was observed for tr = 10 ns on the 3rd pulse, as shown in figure 2(C). In addition, PRF could also play an important role in impacting combustion ignition. Figure 3 shows that at a higher PRF, e.g. 6 kHz, the mode change occurred earlier, on the 2nd pulse, for the faster rise time pulses, i.e. tr = 5 ns. However, ignition consistently occurred on the 3rd pulse without difference for tr = 10 ns pulses. The results showed that faster tr can reduce the number of pulses necessary for combustion ignition. Additionally, increased PRF combined with faster tr can further reduce the number of pulses necessary for ignition. Impact of PRF on ignition energy for combustion is detailed later with figures 4 and 5.

Figure 2. Comparison of voltage and current of the pulsed plasma excited by the first (A), second (B), third (C), and fourth (D) pulses delivered at 2 kHz PRF but with different tr. Note that the right axes are inverted to display the current upside down to avoid overlapping in the voltage and current waveforms.

Download figure:

Standard image High-resolution imageFigure 3. Voltage and current of the pulsed plasma excited by the first (A), second (B), third (C), and fourth (D) pulses delivered at 6 kHz PRF with different tr. Note that the right axes are inverted to display the current upside down for clarity.

Download figure:

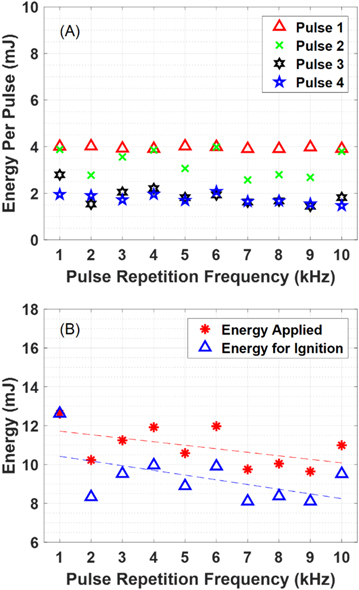

Standard image High-resolution imageFigure 4. Energy delivered to TPI with respect to PRF: (A) Energy of each pulse in a four-pulse burst, and (B) the total energy applied and needed for ignition of the transient plasma initiated by 10-ns duration, 10-ns tr, 10 kV pulses for different PRFs.

Download figure:

Standard image High-resolution imageFigure 5. (A) Energy of each pulse in a four-pulse burst, and (B) the total energy applied and needed for ignition of the transient plasma initiated by 10-ns duration, 5-ns tr, 10 kV pulses for different PRFs.

Download figure:

Standard image High-resolution imageA significant takeaway from the mode change phenomena is that, within our experimental conditions, combustion closely follows the large increase in peak current. Increasing PRF enabled combustion with less required number of pulses, which will allow less ignition energy as well as ultimately increase the lifetime of the electrodes.

The energy delivered by each pulse, Ep, was calculated as a function of the integral over the pulse duration, of the product of voltage V(t) and current i(t).

The total energy of a four-pulse burst, Et, was calculated as the sum of the energy of each pulse.

TPI for combustion ignition driven by pulses with pulse repetition frequencies of 1–6 kHz of the fast tr pulse and PRF of 1–10 kHz of the slower tr pulse were examined. The difference in the range of PRF's is due to equipment limitations. Figures 4 and 5 show the PRF dependence of the energy deposition in TPI for tr = 10 ns and 5 ns, respectively. The energy per pulse of each pulse in a four-pulse burst varies with respect to PRF, as shown in figures 4(A) and 5(A). Energy of the first pulse was recorded to be 3.95 mJ ± 0.02 mJ, which was two times energy of the 3rd or 4th pulse regardless of PRF. Since the energy data corresponds to a single pulsing event, up to 14% fluctuation in energy was observed particularly for the 2nd pulse over the range of PRFs tested and is attributed to the ionization state of the transient plasma forming across the gap between the electrodes. The fluctuation does not appear in the 1st pulse because the initial condition always starts off the same, i.e. the same mixture, pressure, and electrically appears to be an open circuit (with relatively high impedance). The fluctuation does not appear in the 3rd and 4th pulse because the conductivity of the plasma remains relatively consistent once an ionized channel is formed across the gap. The differences in the energies of 3rd and 4th pulses are small. Importantly, the energy per pulse of the 3rd/4th pulses dropped to half or less of the energy of the 1st pulse, indicating that the deposited energy in the system decreases significantly when the combustion was initiated. With the shorter rise time, i.e. tr = 5 ns, the energy of the first pulse, was 5.44 mJ ± 0.21 mJ, higher than that with tr = 10 ns, as shown in figure 5(A). This indicates that more energy can be delivered to the electrode system with faster pulses. Interestingly, the energy at the 3rd and 4th pulse was about 2 mJ, similar as those measured for tr = 10 ns and when combustion was initiated. The differences between the applied total energy and the actual energy needed for combustion ignition were compared in figures 4(B) and 5(B). It is evident that the less pulse numbers needed to initiate the combustion, the greater the difference between the applied energy and ignition energy. When the combustion was initiated at the 2nd pulse for tr = 10 ns at 6 kHz, for instance, the required ignition energy dropped to 70% of the total applied energy comparing to only 8% for others at 1–5 kHz, even thorough the total energy was already the lowest at 6 kHz. These pulsed energy measurements are important as they provide a simple indicator showing the ignition status and agree well with the mode transitions observed in voltage and current waveforms. In addition, they agree well the findings reported by others where similar nanosecond discharges at different voltages and pulse numbers in bursts were used [2, 12].

In addition to applications of repetitive 2–4 pulses in a burst to drive the plasma and achieve combustion ignition, the fuel-air mixture can also be ignited by one single pulse. Experiments were conducted to compare combustion initiated with single-pulsed discharges driven by pulses with two different rise times. A minimum of 23 and 21 kV of the peak voltage are needed to achieve combustion ignition using the single-pulsed TPI for tr = 10 ns and 5 ns, respectively. The corresponding energy of the single-shot ignition was 7.9 mJ and 6.2 mJ for the slower and faster rise times, respectively.

Note that single shot ignition uses similar or slightly lower energy compared with that required when using 2 or 4 pulse bursts but requires almost twice of the peak voltage in order to achieve ignition. The higher voltage requirement incurred in the single-shot TPI may pose challenges in the pulsed power source design and electrode insulation of the combustion system, which makes the high-PRF pulse burst TPI more appealing to the application. In addition, electrode or spark-plug erosion is one of the most important factors that impact the lifetime of the internal combustion engines [10]. It is hence important for the application to know the minimum number of pulses needed to initiate combustion, so that the electrode lifetime can be extended with reduced erosion [10]. Moreover, applying the minimum number of pulses also reduces energy consumed per event, and improves the energy efficiency of the system.

3.2. Combustion performance

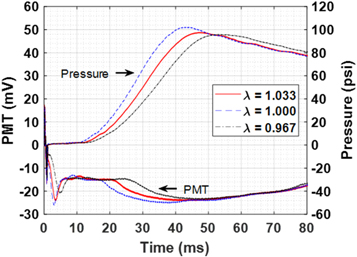

Peak pressure and ignition delay were measured for different voltage tr and PRF at three different equivalence ratios: lean, stoichiometric, and rich. OH emission from OH(A-X) transition indicating the relative production of OH(A) during the combustion ignition was also recorded and compared for these different TPI conditions. As an example, figure 6 shows the temporal development of pressure and OH emission during the combustion initiation for different air-fuel mixtures that were ignited by four-pulse bursts consisting of 10-ns high voltage pulses with tr = 5 ns at 6 kHz. The maximal peak pressure and shortest ignition delay were obtained for the stoichiometric air-fuel mixture comparing with the other mixtures. Under this pulse condition, the use of lean fuel mixture resulted in shorter ignition delay comparing with the rich mixture. The similar maximal value and delay time were also observed in the PMT signal for three mixture ratios, indicating that the OH emission aligns well with the combustion performance in pressure, as shown in figure 6.

Figure 6. Combustion performance of different air-fuel mixtures (lean, λ = 1.033; stoichiometric, λ = 1; and rich, λ = 0.967) initiated by four-pulse bursts with tr = 5 ns at 6 kHz.

Download figure:

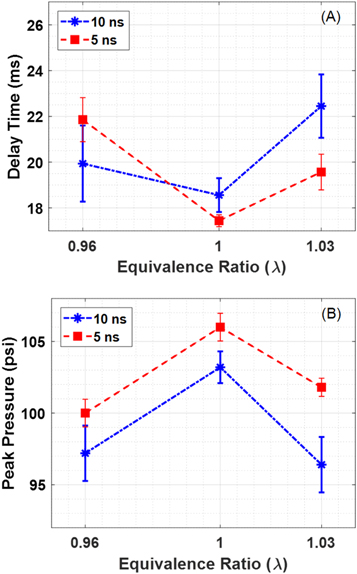

Standard image High-resolution imageThe impact of the voltage rise time tr on the combustion performance was evaluated by comparing the peak pressure and delay time for three different mixture ratios ignited with 4-pulse bursts with tr = 5 ns and 10 ns at a PRF of 6 kHz, as shown in figure 7. Each combustion measurement under the same pulse and mixture condition was repeated 10 times to obtain the average peak pressure, ignition delay and the corresponding standard deviations. For both the voltage rise times, the shortest ignition delay time and maximal peak pressure were observed for the equivalence ratio λ = 1. With shorter tr, less or similar ignition delay time and higher peak pressure were obtained for all three mixture ratios, as shown in figure 7. The advantage of the application of pulses with shorter rise times was also observed in our previous studies, where transient plasma ignition of stoichiometric mixtures was driven by single pulses. Comparison of TPIs driven by 10 ns-duration pulses with two different rise times showed that TPI powered by faster pulses (pulses with a shorter rise time) consistently produced combustion with greater peak pressure and reduced ignition delay time [17]. The advantage of shorter risetime concurs with the studies by Zhang, Xie et al for plasma actuators where a higher reduced electric field E/N was obtained at a shorter rise time, enabling higher energy gain in the starting vortex by the surrounding air flow [18, 19].

Figure 7. Comparison of the (a) ignition delay time and (b) peak pressure of the TPI using air-fuel mixtures with different equivalence ratios ignited by four-pulse bursts with two different voltage tr at 6 kHz. Each marker represents the average of ten combustion events.

Download figure:

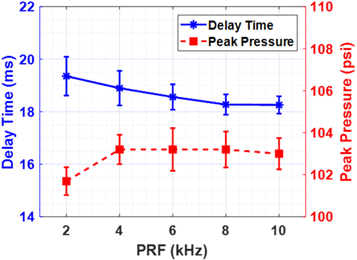

Standard image High-resolution imageThe effects of PRF on the combustion performance were evaluated similarly. Figure 8 compares the ignition delay and peak pressure of TPI driven by four-pulse bursts with a voltage rise time of 10 ns at two different PRF's: 2 kHz and 6 kHz. Each measurement was repeated 10 times to obtain the average value and standard deviation. Although the difference is small considering the error of ∼5%, shorter ignition delay and higher peak pressure were obtained for TPI driven by pulses at 6 kHz comparing with 2 kHz for all the equivalence ratios. Using the stoichiometric mixture, TPI driven by voltage pulses with the same rise time, e.g. tr = 10 ns, at different PRF's ranging from 2 kHz to 10 kHz was tested to further evaluate the effects of PRF. Figure 9 shows the ignition delay time decreases and the peak pressure increases with increasing PRF from 2 kHz to 6 kHz. Further increasing the PRF from 6 kHz to 10 kHz, the changes in both ignition delay time and peak pressure become less; although the ignition delay decreases slightly with PRF, the difference in peak pressure is insignificant.

Figure 8. Comparison of the (a) ignition delay time and (b) peak pressure of the TPI using air-fuel mixtures with different equivalence ratios ignited by four-pulse bursts with voltage tr = 10 ns at different PRF's of 2 and 6 kHz. Each marker represents the average of ten combustion events.

Download figure:

Standard image High-resolution imageFigure 9. Ignition delay time and peak pressure with respect to PRF for TPIs of stoichiometric air-fuel mixtures driven by 4-pulse bursts consisting of 10 ns-FWHM pulses with tr = 10 ns over a range of PRF's from 2 to 10 kHz.

Download figure:

Standard image High-resolution imageAlthough the residual plasma species and accumulated heat due to increased PRFs [18] could benefit the combustion ignition, research has shown that there is an optimal PRF for given an interelectrode gap distance under a constant pulse waveform with different PRF's [2, 7]. In this study, the reduced dependence of the ignition delay and peak pressure on the PRF that is increasing from 6 kHz to 10 kHz suggests that a similar optimal PRF exists for this TPI system, where a 3 mm spark-plug gap is used. Applications of pulses with higher PRF's are needed to determine the optimal PRF for this system but have not been carried out due to the limitation in the pulse generators used in this study.

3.3. Gas temperature of the transient plasma

Gas temperature of the transient plasma is important to understand the chemical kinetics during the combustion initiation. Gas temperature during combustion was well investigated by others with similar pulse characteristics [5, 7, 9, 10, 20]. Gas temperature, of 10 pulses of 5 kV amplitude at 30 kHz PRF, atmospheric pressure, and a 1.5 mm discharge gap, of the first three pulses were not measured, the temperature of the fourth pulse, the one before break down measured approximately 300 K [10]. The fifth pulse, where break down occurred, measured approximately 1000 K [10]. All the pulses following breakdown pulse measured 3000 K [10]. Similarly, the temperature of the first pulse of this work was not measured. In this study, the gas temperature of the plasma driven by the four-pulse burst was determined by measurements of the rotational temperature of the second positive system of nitrogen [21]. The emission spectra of N2 (C3Πu − B3Πg) transition was collected and compared with the simulation using Specair (Specair.com, version 2.2). The gas temperature of each plasma driven by the 2nd–4th pulse during a four-pulse burst was measured, as shown in figure 10. The rotational temperature was measured only for the tr = 10 ns pulse characteristic, it was measured over a range of PRF's from 2–10 kHz PRF, with an interval of 2 kHz. Each emission image was obtained from an accumulation of ten repeated images taken at the same pulse condition (including a constant pulse sequence number and a constant PRF) for a stoichiometric fuel-air mixture at atmospheric pressure. An average emission spectrum was obtained based on the spatial integration of the image over the entire interelectrode gap where a full length of the plasma was developed. The full-length plasma was not detectable at the first pulse and hence only the 2nd, 3rd and 4th pulsed plasma was recorded for temperature measurements. Figure 10 shows that the gas temperature of the plasma increases with the pulse number. At the 2nd pulse, the gas temperature was measured in the range of 900–1300 K. The temperature increased to 1500–1800 K at the 3rd pulse and remained almost constant or increased slightly up to 2000 K at the 4th pulse. The deviation in temperature is estimated to be ±200 K, which is relatively big due to the fluctuation in plasma emission as well as the uncertainty in the electrode location where the plasma occurs.

Figure 10. Rotational temperature of each pulsed plasma in a burst with respect to the pulse number in the sequence for tr = 10 ns and different PRF's.

Download figure:

Standard image High-resolution imageThe difference in temperature for the same pulse number with different PRF's is hence insignificant. The gradual increase in gas temperature with the pulse number increasing for the tested PRF range, i.e. >2 kHz, indicates that the relaxation time for heavy particles such as N2(C) is longer than 500 μs and the heating from the pulsed energy accumulates with pulses.

4. Conclusions

Combustion ignition of a methane-dry air mixture in a static chamber at atmospheric pressure was achieved by transient plasmas driven by 10-ns FWHM, 10 kV pulse bursts at kHz repetition rates. Single pulsed TPI driven by the same pulse width was also able to initiate combustion but requires at least twice of the voltage amplitude. Comparison of TPIs powered by 10-ns FWHM pulse bursts with different rise times, i.e., tr = 5 ns and 10 ns, showed faster pulses benefit the combustion ignition with higher peak pressure, shorter ignition delay and reduced energy needed to initiate combustion. Studies of the effects of PRFs in the range of 1 kHz and 10 kHz showed that there was a possible optimal PRF within 6–10 kHz, which was associated with the best combustion performance, i.e. the highest peak pressure and shortest ignition delay. In addition, the gas temperature of the transient plasma was relatively independent of the PRF applied, implying that the gas temperature is not playing a significant role in the difference in combustion ignition by the TPIs with different PRFs. It is hence expected that the combination of fast pulses and an optimal PRF in the range of kilohertz would improve the combustion performance with increased energy efficiency and without an elevation in gas temperature. The combination has the potential to reduce electrode erosion and are hence be beneficial to the lifetime of the combustion system. In addition, high repetition rate multi pulse bursts for TPI helps to reduce peak voltage to less than half of what was needed for single-shot TPI, which simplifies system design and makes the high-voltage nanosecond-pulsed implementation more achievable.

Acknowledgments

This work was supported in part by the Department of Energy (Phase I STTR, DE-SC001788) and the Air Force Office of Scientific Research (Award No. FA9550-17-1-0257). The authors thank Mr Shutong Song for help with the rotational temperature measurements.