Abstract

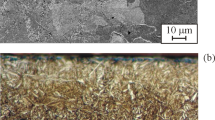

The wear-resistant coatings formed by the vacuum ion-plasma codeposition of titanium and carbon have been studied in this work. Single-layer and multilayer coatings with the systematically repeated [(Ti1 – xCx/a-C] pair are deposited onto P8M5 and 18KhN10T steel substrates. The highest erosion resistance is inherent in the multilayer [Ti0.2C0.8/a-C]40 coating with a layer thickness of 25 nm. The erosion wear rate of this coating is 1.6–1.8 times lower than the wear rate of the single-layer а-С and Ti0.2C0.8 coatings. The wear of [Ti0.2C0.8/a-C]40 occurs layer by layer without crumbling of individual square sections of the coating, thus increasing its service life. The interphase boundaries in the Ti0.2C0.8 composite layer, as well as the Ti1 ‒ xCx → а-С interface boundaries, serve as a barrier for the propagation of microcracks, decreasing the probability of macrocracking, which destroys the continuity of a coating.

Similar content being viewed by others

REFERENCES

N. Kumar, G. Natarajan, R. Pandian, A. Bahuguna, S. K. Srivastava, T. R. Ravindran, S. Rajagopalan, S. Dash, A. K. Tyagi, R. Dumpala, and M. S. Rao Ramachandra, “Microstructure and phase composition dependent tribological properties of TiC/a–C nanocomposite thin films,” Surf. Coat. Technol. 258, 557–565 (2014).

A. B. Vladimirov, S. A. Plotnikov, I. Sh. Trakhtenberg, A. P. Rubshtein, and E. G. Volkova, “Nanocomposite films prepared by arc-plasma deposition of titanium and carbon,” Prot. Met. Phys. Chem. Surf. 51, 230–233 (2015).

I. Sh. Trakhtenberg, N. V. Gavrilov, D. R. Emlin, S. A. Plotnikov, A. B. Vladimirov, E. G. Volkova, and A. P. Rubshtein, “Nanocomposite vacuum-Arc TiC/a‑C:H coatings prepared using an additional ionization of acetylene,” Phys. Met. Metallogr. 115, 723–729 (2014).

A. P. Rubshtein, A. B. Vladimirov, Yu. V. Korkh, Y. S. Ponosov, and S. A. Plotnikov, “The composition, structure and surface properties of the titanium-carbon coatings prepared by PVD technique,” Surf. Coat. Technol. 309, 680–686 (2017).

U. Jansson and E. Lewin, “Sputter deposition of transition-metal carbide films—a critical review from a chemical perspective,” Thin Solid Films 536, 1–24 (2013).

V. M. Finkel’, Physical Basics of Inhibition of Destruction (Metallurgiya, Moscow, 1977), p. 348 [in Russian].

A. N. Panckow, J. Steffenhagen, B. Wegener, L. Dubner, and F. Lierath, “Application of novel vacuum-arc ion-plating technologies for the design of advanced wear resistant coatings,” Surf. Coat. Technol. 138, 71–76 (2001).

H. Gleiter, “Nanostructured materials: basic concepts and microstructure,” Acta Mater. 48, 1–29 (2000).

A. S. Vereshchaka and A. A. Vereshchaka, “Improving the tool efficiency by controlling the composition, structure and properties of coatings,” Uprochnyayushchie Tekhnologii i Pokrytiya, No. 9, 9–18 (2005).

J. B. Cai, X. L. Wang, W. Q. Bai, D. H. Wang, C. D. Gu, and J. P. Tu, “Microstructure, mechanical and tribological properties of a-C/a-C:Ti nanomultilayer film,” Surf. Coat. Technol. 232, 403–411 (2013).

R. Chen, J. P. Tu, D. G. Liu, Y. L. Yu, S. X. Qu, and C. D. Gu, “Structural and mechanical properties of TaN/a-CNx multilayer films,” Surf. Coat. Technol. 206, 2242–2248 (2012).

B. Bouaouina, A. Besnard, S. E. Abaidia, and F. Haid, “Residual stress, mechanical and microstructure properties of multilayer Mo2N/CrN coating produced by R.F Magnetron discharge,” Appl. Surf. Sci. 395, 117–121 (2017).

V. C. Teles, J. D. B. Mello, and W. M. Silva, “Abrasive wear of multilayered/gradient CrAlSiN PVD coatings: Effect of interface roughness and of superficial flaws,” Wear 376–377, 1691–1701 (2017).

W. Q. Bai, L. L. Li, X. L. Wang, F. F. He, D. G. Liu, G. Jin, and J. P. Tu, “Effects of Ti content on microstructure, mechanical and tribological properties of Ti-doped amorphous carbon multilayer films,” Surf. Coat. Technol. 266, 70–78 (2015).

P. Wiecinski, J. Smolik, H. Garbacz, J. Bonarski, A. Mazurkiewicz, and K. J. Kurzydłowski, “Microstructure and properties of metal/ceramic and ceramic/ceramic multilayer coatings on titanium alloy Ti6Al4V,” Surf. Coat. Technol. 309, 709–718 (2017).

D. Kumar, N. Kumar, S. Kalaiselvam, S. Dash, and R. Jayave, “Wear resistant super-hard multilayer transition metal-nitride coatings,” Surf. Interfaces. 7, 74–82 (2017).

S. Ghasemi, A. Shanaghi, and P. K. Chu, “Nano mechanical and wear properties of multi-layer Ti/TiN coatings deposited on Al 7075 by high-vacuum magnetron sputtering,” Thin Solid Films 638, 96–104 (2017).

A. Vereschaka, V. Tabakov, S. Grigoriev, A. Aksenenko, N. Sitnikov, G. Oganyan, A. Seleznev, S. l. Shevchenko, “Effect of adhesion and the wear-resistant layer thickness ratio on mechanical and performance properties of ZrN–(Zr,Al,Si)n coatings,” Surf. Coat. Technol. 357, 218–234 (2019).

X. Sui, J. Liu, S. Zhang, J. Yang, and J. Hao, “Microstructure, mechanical and tribological characterization of CrN/DLC/Cr-DLC multilayer coating with improved adhesive wear resistance,” Appl. Surf. Sci. 439, 24–32 (2018).

ISO 14577-1:2002, Metallic Materials—Instrumented Indentation Test for Hardness and Materials Parameters—Part 1: Test Method.

E. Martinez, J. L. Andujar, M. C. Polo, J. Esteve, J. Robertson, and W. I. Milne, “Study of the mechanical properties of tetrahedral amorphous carbon films by nanoindentation and nanowear measurements,” Diamond Relat. Mater. 10, 145–152 (2001).

A. P. Rubshtein, I. Sh. Trakhtenberg, V. A. Yugov, A. B. Vladimirov, S. A. Plotnikov, and Yu. S. Ponosov, “Temperature effect on the formation of a relief of diamond-like carbon coatings and its modification by ion bombardment,” Phys. Met. Metallogr. 102, 626–631 (2006).

W. G. Cui, Q. B. Lai, L. Zhang, and F. M. Wang, “Quantitative measurements of sp3 content in DLC films with Raman spectroscopy,” Surf. Coat. Technol. 205, 1995–2002 (2010).

Funding

This study was performed within the state task of the Ministry of Education and Science of Russia (project “Function” no. AAAA-A19-119012990095-0) under partial financial support from the Russian Foundation for Basic Research (project no. 20-48-660065).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Glushachenkova

Rights and permissions

About this article

Cite this article

Rubshtein, A.P., Vladimirov, A.B. & Plotnikov, S.A. Specific Features of the Erosion Wear of Coatings with a Ti1 – xCx–Diamond-Like Carbon Structure Forming Pair (х = 0.2, 0.8). Phys. Metals Metallogr. 121, 1203–1210 (2020). https://doi.org/10.1134/S0031918X20120121

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X20120121