Abstract

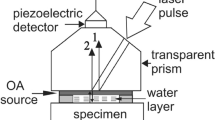

A laser optoacoustic method for quantitative assessment of the volumetric porosity of cast dispersion-strengthened metal-matrix composite materials has been proposed and experimentally implemented. The method is based on a statistical analysis of the distribution of amplitudes of backscattered broadband pulses of longitudinal acoustic waves in the tested materials. Laser excitation and piezoelectric recording of ultrasound is implemented with one-way access to the test object using a special laser-ultrasonic transducer. Silumin-based composites reinforced with silicon carbide microparticles in various volume concentrations (0.033–0.135) and composites obtained by reaction injection moulding based on aluminum reinforced with intermetallic \({\text{A}}{{{\text{l}}}_{3}}{\text{Ti}}\) (volume concentration 0.04–0.115) have been studied. For both types of composites, the distribution of amplitudes of backscattered ultrasonic signals is approximated by a Gaussian distribution function applicable for a large number of statistically independent quantities. The empirically obtained dependence of the half-width of this distribution on the volumetric porosity of composites of two different types is approximated by the same linear function regardless of the manufacturing technology, as well as of the type, size, and concentration of strengthening particles.

Similar content being viewed by others

REFERENCES

Hunt, W.H., Jr., Metal matrix composites, in Comprehensive Composite Materials, Kelly, A. and Zweben, C., Eds., Amsterdam: Elsevier, 2000, vol. 6, pp. 57–66.

Kainer, K.U., Basics of metal matrix composites, in Metal Matrix Composites: Custom-Made Materials for Automotive and Aerospace Engineering, Kainer, K.U., Ed., Weinheim: Wiley-VCH, 2006, pp. 1–54.

Chernyshova, T.A., Kurganova, Yu.A., Kobeleva, L.I., and Bolotova, L.K., Litye dispersno-uprochnennye alyumomatrichnye kompozitsionnye materialy: izgotovlenie, svoistva, primenenie (Cast Dispersion-Hardened Aluminum Matrix Composite Materials: Production, Properties, Application), Ul’yanovsk: Ul’yanovsk. Gos. Tekh. Univ., 2012.

Chernyshova, T.A., Kobeleva, L.I., Kurganova, Yu.A., Bolotova, L.K., Kalashnikov, I.E., Katin, I.V., Panfilov, A.V., and Panfilov, A.A., Dispersion-filled composite materials for sliding friction pairs, Konstr. Kompozit. Mater., 2007, no. 3, pp. 38–48.

Konovalov, A.V. and Smirnov, S.V., State of the art and trends of research of metal-matrix composites of the Al/SiC system (a review), Konstr. Kompozit. Mater., 2015, no. 1, pp. 30–35.

Ibrahim, I.A., Mohamed, F.A., and Lavernia, E.J., Particulate reinforced metal matrix composites—A review, J. Mater. Sci., 1991, vol. 26, pp. 1137–1156.

Bindumadhavan, P.N., Wah, H.K., and Prabhakar, O., Assessment of particle-matrix debonding in particulate metal matrix composites using ultrasonic velocity measurements, Mater. Sci. Eng. A, 2002, vol. 323, nos. 1–2, pp. 42–51.

Tekmen, C., Ozdemir, I., Cocen, U., and Onel, K. The mechanical response of Al—Si—Mg/SiCp composite: Influence of porosity, Mater. Sci. Eng. A, 2003, vol. 360, nos. 1–2, pp. 365–371.

Campbell, J., Porosity, in Complete Casting Handbook. Metal Casting Processes, Metallurgy, Techniques and Design, Amsterdam: Butterworth-Heinemann, Elsevier, 2015, pp. 341–415.

Tjong, S.C. and Ma, Z.Y., Microstructural and mechanical characteristics of in situ metal matrix composites, Mater. Sci. Eng. R: Rep., 2000, vol. 29, pp. 49–113.

Varin, R.A., Intermetallic-reinforced light-metal matrix in-situ composites, Metall. Mater. Trans. A, 2002, vol. 33, pp. 193–201.

Chernyshova, T.A., Bolotova, L.K., Kalashnikov, I.E., Kobeleva, L.I., and Bykov, P.A., Effect of refractory nanoparticles on the structural modification of metal-matrix composites, Russ. Metall., 2007, vol. 2007, no. 3, pp. 236–241.

Murasheva, V.V., Burkovskaya, N.P., and Sevost’yanov, N.V., Methods for obtaining high-temperature Nb-Si in-situ composites (A review), Konstr. Kompoz. Mater., 2015, no. 2, pp. 27–38.

Pineau, A., Benzerga, A.A., and Pardoen, T., Failure of metals I: Brittle and ductile fracture, Acta Mater., 2016. vol. 107, pp. 424–483.

Vary, A., Material property characterization, in Nondestructive Testing Handbook. Ultrasonic Testing, Moore, P.O., Ed., Columbus: ASTM, 2007, pp. 365–431.

Rokhlin, S.I., Chimenti, D.E., and Nagy, P.B., Physical Ultrasonics of Composites, Oxford: Oxford Univ. Press, 2011.

Schobel, M., Requena, G., Fiedler, G., Tolnai, D., Vaucher, S., and Degischer, H.P., Void formation in metal matrix composites by solidification and shrinkage of an AlSi7 matrix between densely packed particles, Compos. Part A: Appl. Sci. Manuf., 2014, vol. 66, pp. 103–108.

Fitting, D.W. and Adler, L., Ultrasonic Spectral Analysis for Nondestructive Evaluation, New York: Plenum, 1981.

Gusev, V.E. and Karabutov, A.A., Lazernaya optoakustika (Laser Optoacoustics), Moscow: Nauka, 1991.

Ivochkin, A.Yu., Karabutov, A.A., Lyamshev, M.L., Pelivanov, I.M., Rohatgi, U., and Subudkhi, M., Measurement of velocity distribution for longitudinal acoustic waves in welds by a laser optoacoustic technique, Acoust. Phys., 2007, vol. 53, no. 4, pp. 471–477.

Ismagilov, I.R., Golenishchev-Kutuzov, V.A., Kalimullin, R.I., Migachev, S.A., and Khasanov, A.A., Detecting surface and volume defects in metals by the laser-acoustic method, Russ. J. Nondestr. Test., 2014, vol. 50, no. 6, pp. 318–324.

Gurevich, S.Yu., Petrov, Yu.V., and Golubev, E.V., Thickness gauging of thin metalware with ultrasound excited by laser nanopulses, Russ. J. Nondestr. Test., 2018, vol. 54, no. 3, pp. 147–150.

Kim, K.-B., Hsu, D.K., and Barnard, D.J., Estimation of porosity content of composite materials by applying discrete wavelet transform to ultrasonic backscattered signal, NDT & E Int., 2013, vol. 56, pp. 10–16.

Karabutov, A.A. and Podymova, N.B., Nondestructive porosity assessement of CFRP composites with spectral analysis of backscattered laser-induced ultrasonic pulses, J. Nondestr. Eval., 2013, vol. 32, no. 3, pp. 315–324.

Kartashev, V.G., Kachanov, V.K., Sokolov, I.V., Shalimova, E.V., Kontsov, R.V., and Voronkova, L.V., Ultrasonic structural probing of products based on materials with a complex structure by analyzing the statistical characteristics of the structural noise, Russ. J. Nondestr. Test., 2015, vol. 51, no. 6, pp. 360–373.

Kachanov, V.K., Kartashev, V.G., Sokolov, I.V., Voronkova, L.V., and Shalimova, E.V., Strukturnyi shum v ul’trazvukovoi defektoskopii (Structure-Borne Noise in Ultrasonic Flaw Detection), Moscow: Mosk. Energ. Inst., 2016.

Romanishin, R.I. and Romanishin, I.M., Processing of backscattered signal in ultrasonic testing, Russ. J. Nondestr. Test., 2018, vol. 54, no. 6, pp. 394–399.

Romanishin, R.I. and Romanishin, I.M., Assessment of scattered damage in structural materials, Russ. J. Nondestr. Test., 2019, vol. 55, no. 2, pp. 111–121.

Podymova, N.B., Kalashnikov, I.E., Bolotova, L.K., and Kobeleva, L.I., Laser-ultrasonic nondestructive evaluation of porosity in particulate reinforced metal-matrix composites, Ultrasonics, 2019, vol. 99, p. 105959.

Zwicker, U., Titan und titanlegierungen, Berlin: Springer, 1974.

Adler, L., Rose, J.H., and Mobley, C., Ultrasonic method to determine gas porosity in aluminum alloy castings: Theory and experiment, J. Appl. Phys., 1986, vol. 59, pp. 336–347.

Ying C.F., Truell R. Scattering of a plane longitudinal wave by a spherical obstacle in an isotropically elastic solid, J. Appl. Phys., 1956, vol. 27, pp. 1086–1097.

Evans A.G., Tittmann B.R., Ahlberg L., Khuri-Yakub B.T., Kino G.S. Ultrasonic attenuation in ceramics, J. Appl. Phys., 1978, vol. 49, pp. 2669–2679.

Funding

This work was carried out according to state order no. 075-00746-19-00.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Podymova, N.B., Kalashnikov, I.E. & Kobeleva, L.I. Laser Optoacoustic Method for Quantitative Estimation of Porosity in Cast Dispersion-Strengthened Metal-Matrix Composite Materials. Russ J Nondestruct Test 56, 949–959 (2020). https://doi.org/10.1134/S1061830920120086

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830920120086