Abstract

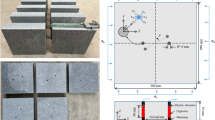

Affected by the disturbance of blasting activities, deformation instability and rock dynamic disasters are prone to occur in deep hard rock roadways. Thus, it is particularly necessary to understand the failure behavior of rocks and roadways under dynamic loads. In this study, a series of impact loading tests were carried out on sandstone samples with and without a circular cavity by a modified split Hopkinson pressure bar (SHPB) test system. The mechanical properties and energy evolution of the samples were systematically investigated, and the effect of cavity size was analyzed. The results showed that the presence of the cavity in the samples weakens the dynamic compressive strength by more than 10%, and the peak strain and brittleness are also reduced to varying degrees. Under dynamic loading, spalling cracks occur first on the roof and floor of the cavity, and then different numbers of shear cracks are formed on the sample diagonals. The eventual shear failure mode is the result of the connection of the shear cracks and the cavity. As the cavity radius increases, the dissipated energy density and fractal dimension both grow accordingly, leading to smaller and smaller rock fragments. The dynamic failure behavior of the circular cavity can be well explained based on the dynamic stress distribution law. Overall, this study can provide a reference for the study of the mechanism of rock burst in deep roadways.

Similar content being viewed by others

References

Lee H, Jeon S (2011) An experimental and numerical study of fracture coalescence in pre-cracked specimens under uniaxial compression. Int J Solids Struct 48(6):979–999. https://doi.org/10.1016/j.ijsolstr.2010.12.001

Saadat M, Taheri A (2019) A numerical approach to investigate the effects of rock texture on the damage and crack propagation of a pre-cracked granite. Comput Geotech 111:89–111. https://doi.org/10.1016/j.compgeo.2019.03.009

Cao RH, Cao P, Lin H, Pu CZ, Ou K (2016) Mechanical behavior of brittle rock-like specimens with pre-existing fissures under uniaxial loading: experimental studies and particle mechanics approach. Rock Mech Rock Eng 49(3):763–783. https://doi.org/10.1007/s00603-015-0779-x

Huang YH, Yang SQ (2019) Mechanical and cracking behavior of granite containing two coplanar flaws under conventional triaxial compression. Int J Damag Mech 28(4):590–610. https://doi.org/10.1177/1056789518780214

Bobet A (2000) The initiation of secondary cracks in compression. Eng Fract Mech 66(2):187–219. https://doi.org/10.1016/S0013-7944(00)00009-6

Bi J, Zhou XP, Qian QH (2016) The 3D numerical simulation for the propagation process of multiple pre-existing flaws in rock-like materials subjected to biaxial compressive loads. Rock Mech Rock Eng 49(5):1611–1627. https://doi.org/10.1007/s00603-015-0867-y

Jin J, Cao P, Chen Y, Pu CZ, Mao DW, Fan X (2017) Influence of single flaw on the failure process and energy mechanics of rock-like material. Comput Geotech 86:150–162. https://doi.org/10.1016/j.compgeo.2017.01.011

Bobet A, Einstein HH (1998) Fracture coalescence in rock-type materials under uniaxial and biaxial compression. Int J Rock Mech Min 35(7):863–888. https://doi.org/10.1016/S0148-9062(98)00005-9

Gao YH, Feng XT (2019) Study on damage evolution of intact and jointed marble subjected to cyclic true triaxial loading. Eng Fract Mech 215:224–234. https://doi.org/10.1016/j.engfracmech.2019.05.011

Yang SQ, Huang YH (2017) An experimental study on deformation and failure mechanical behavior of granite containing a single fissure under different confining pressures. Environ Earth Sci 76:364–385. https://doi.org/10.1007/s12665-017-6696-4

Aliha MRM, Ayatollahi MR, Smith DJ, Pavier MJ (2010) Geometry and size effects on fracture trajectory in a limestone rock under mixed mode loading. Eng Fract Mech 77(11):2200–2212. https://doi.org/10.1016/j.engfracmech.2010.03.009

Erarslan N, Williams DJ (2013) Mixed-mode fracturing of rocks under static and cyclic loading. Rock Mech Rock Eng 46(5):1035–1052. https://doi.org/10.1007/s00603-012-0303-5

Dang WG, Konietzky H, Herbst M, Frühwirt T (2020) Cyclic frictional responses of planar joints under cyclic normal load conditions: laboratory tests and numerical simulations. Rock Mech Rock Eng 53:337–364. https://doi.org/10.1007/s00603-019-01910-9

Dang WG, Konietzky H, Li X (2019) Frictional responses of concrete-to-concrete bedding planes under complex loading conditions. Geomech Eng 17(3):253–259. https://doi.org/10.12989/gae.2019.17.3.253

Li XB, Zhou T, Li DY (2017) Dynamic strength and fracturing behavior of single-flawed prismatic marble specimens under impact loading with a split-Hopkinson pressure bar. Rock Mech Rock Eng 50(1):29–44. https://doi.org/10.1007/s00603-016-1093-y

Bahaaddini M, Sharrock G, Hebblewhite BK (2013) Numerical investigation of the effect of joint geometrical parameters on the mechanical properties of a non-persistent jointed rock mass under uniaxial compression. Comput Geotech 49:206–225. https://doi.org/10.1016/j.compgeo.2012.10.012

Wong LNY, Li HQ (2013) Numerical study on coalescence of two pre-existing coplanar flaws in rock. Int J Solids Struct 50(22-23):3685–3706. https://doi.org/10.1016/j.ijsolstr.2013.07.010

Zhao YL, Zhang LY, Wang WJ, Pu CZ, Wan W, Tang JZ (2016) Cracking and stress-strain behavior of rock-like material containing two flaws under uniaxial compression. Rock Mech Rock Eng 49(7):2665–2687. https://doi.org/10.1007/s00603-016-0932-1

Feng P, Dai F, Liu Y, Xu NW, Fan PX (2018) Effects of coupled static and dynamic strain rates on mechanical behaviors of rock-like specimens containing pre-existing fissures under uniaxial compression. Can Geotech J 55(5):640–652. https://doi.org/10.1139/cgj-2017-0286

Li DY, Han ZY, Sun XL, Zhou T, Li XB (2019) Dynamic mechanical properties and fracturing behavior of marble specimens containing single and double flaws in SHPB tests. Rock Mech Rock Eng 52:1623–1643. https://doi.org/10.1007/s00603-018-1652-5

Haeri H, Khaloo A, Marji MF (2015) Experimental and numerical analysis of Brazilian discs with multiple parallel cracks. Arab J Geosci 8(8):5897–5908. https://doi.org/10.1007/s12517-014-1598-1

Germanovich LN, Salganik RL, Dyskin AV, Lee KK (1994) Mechanisms of brittle fracture of rock with pre-existing cracks in compression. Pure Appl Geophys 143(1-3):117–149. https://doi.org/10.1007/BF00874326

Dyskin AV, Sahouryeh E, Jewell RJ, Joer H, Ustinov KB (2003) Influence of shape and locations of initial 3-D cracks on their growth in uniaxial compression. Eng Fract Mech 70(15):2115–2136. https://doi.org/10.1016/S0013-7944(02)00240-0

Zhang ZN, Wang DY, Zheng H, Ge XR (2012) Interactions of 3D embedded parallel vertically inclined cracks subjected to uniaxial compression. Theor Appl Fract Mech 61:1–11. https://doi.org/10.1016/j.tafmec.2012.08.001

Mondal S, Olsen-Kettle L, Gross L (2019) Simulating damage evolution and fracture propagation in sandstone containing a preexisting 3-D surface flaw under uniaxial compression. Int J Numer Anal Met 43(7):1448–1466. https://doi.org/10.1002/nag.2908

Zhou T, Zhu JB, Ju Y, Xie HP (2019) Volumetric fracturing behavior of 3D printed artificial rocks containing single and double 3D internal flaws under static uniaxial compression. Eng Fract Mech 205:190–204. https://doi.org/10.1016/j.engfracmech.2018.11.030

Zhou T, Zhu JB, Xie HP (2020) Mechanical and volumetric fracturing behaviour of three-dimensional printing rock-like samples under dynamic loading. Rock Mech Rock Eng 53:2855–2864. https://doi.org/10.1007/s00603-020-02084-5

Hoek E (1965) Rock fracture under static stress conditions. University of Cape Town, Cape Town, South Africa

Wong RHC, Lin P, Tang CA (2006) Experimental and numerical study on splitting failure of brittle solids containing single pore under uniaxial compression. Mech Mater 38(1-2):142–159. https://doi.org/10.1016/j.mechmat.2005.05.017

Sammis CG, Ashby MF (1986) The failure of brittle porous solids under compressive stress states. Acta Metall Sin 34(3):511–526. https://doi.org/10.1016/0001-6160(86)90087-8

Zhao XD, Zhang HX, Zhu WC (2014) Fracture evolution around pre-existing cylindrical cavities in brittle rocks under uniaxial compression. Trans Nonferrous Metals Soc 24(3):806–815. https://doi.org/10.1016/S1003-6326(14)63129-0

Carter BJ, Lajtai EZ, Petukhov A (1991) Primary and remote fracture around underground cavities. Int J Numer Anal Met 15(1):21–40. https://doi.org/10.1002/nag.1610150103

Zeng W, Yang SQ, Tian WL (2018) Experimental and numerical investigation of brittle sandstone specimens containing different shapes of holes under uniaxial compression. Eng Fract Mech 200:430–450. https://doi.org/10.1016/j.engfracmech.2018.08.016

Wu H, Zhao GY, Liang WZ (2020) Mechanical properties and fracture characteristics of pre-holed rocks subjected to uniaxial loading: a comparative analysis of five hole shapes. Theor Appl Fract Mec 105:102433. https://doi.org/10.1016/j.tafmec.2019.102433

Fakhimi A, Carvalho F, Ishida T, Labuz JF (2002) Simulation of failure around a circular opening in rock. Int J Rock Mech Min Sci 39:507–515. https://doi.org/10.1016/S1365-1609(02)00041-2

Zhang SR, Sun B, Wang C, Yan L (2014) Influence of intermediate principal stress on failure mechanism of hard rock with a pre-existing circular opening. J Cent South Univ 21:1571–1582. https://doi.org/10.1007/s11771-014-2098-x

Wang SY, Sloan SW, Tang CA (2013) Three-dimensional numerical investigations of the failure mechanism of a rock disc with a central or eccentric hole. Rock Mech Rock Eng 47(6):2117–2137. https://doi.org/10.1007/s00603-013-0512-6

Zhao ZL, Jing HW, Shi XS, Han GS (2019) Experimental and numerical study on mechanical and fracture behavior of rock-like specimens containing pre-existing holes flaws. Eur J Environ Civ Eng 1–21. https://doi.org/10.1080/19648189.2019.1657961

Yang SQ, Huang YH, Tan WL, Zhu JB (2017) An experimental investigation on strength, deformation and crack evolution behavior of sandstone containing two oval flaws under uniaxial compression. Eng Geol 217:35–48. https://doi.org/10.1016/j.enggeo.2016.12.004

Zhou ZL, Tan LH, Cao WZ, Zhou ZY, Cai X (2017) Fracture evolution and failure behaviour of marble specimens containing rectangular cavities under uniaxial loading. Eng Fract Mech 184:183–201. https://doi.org/10.1016/j.engfracmech.2017.08.029

Wu H, Zhao GY, Liang WZ (2019) Mechanical response and fracture behavior of brittle rocks containing two inverted U-shaped holes under uniaxial loading. Appl Sci 9(24):5327. https://doi.org/10.3390/app9245327

Lin P, Wong RHC, Tang CA (2015) Experimental study of coalescence mechanisms and failure under uniaxial compression of granite containing multiple holes. Int J Rock Mech Min Sci 77:313–327. https://doi.org/10.1016/j.ijrmms.2015.04.017

Huang YH, Yang SQ, Ranjith PG, Zhao J (2017) Strength failure behavior and crack evolution mechanism of granite containing pre-existing non-coplanar holes: experimental study and particle flow modeling. Comput Geotech 88:182–198. https://doi.org/10.1016/j.compgeo.2017.03.015

Huang YH, Yang SQ, Tian WL (2019) Cracking process of a granite specimen that contains multiple pre-existing holes under uniaxial compression. Fatigue Fract Eng Mater Struct 42:1341–1356. https://doi.org/10.1111/ffe.12990

Jespersen C, Maclaughlin M, Hudyma N (2010) Strength, deformation modulus and failure modes of cubic analog specimens representing macroporous rock. Int J Rock Mech Min Sci 47(8):1349–1356. https://doi.org/10.1016/j.ijrmms.2010.08.015

Haeri H, Khaloo A, Marji MF (2015) Fracture analyses of different pre-holed concrete specimens under compression. Acta Mech Sinica 31:855–870. https://doi.org/10.1007/s10409-015-0436-3

Wang SY, Sloan SW, Sheng DC, Tang CA (2012) Numerical analysis of the failure process around a circular opening in rock. Comput Geotech 39:8–16. https://doi.org/10.1016/j.compgeo.2011.08.004

Spetz A, Denzer R, Tudisco E, Dahlblom O (2020) Phase-field fracture modelling of crack nucleation and propagation in porous rock. Int J Fract 224:31–46. https://doi.org/10.1007/s10704-020-00444-4

Yin Q, Jing HW, Ma GW (2015) Experimental study on mechanical properties of sandstone specimens containing a single hole after high-temperature exposure. Géotech Lett 5(1):43–48. https://doi.org/10.1680/geolett.14.00121

Qiu JD, Li XB, Li DY, Zhao YZ, Hu CW, Liang LS (2020) Physical model test on the deformation behavior of an underground tunnel under blasting disturbance. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-020-02249-2

Zhou Z, Cai X, Li X, Cao WZ, Du XM (2020) Dynamic response and energy evolution of sandstone under coupled static–dynamic compression: insights from experimental study into deep rock engineering applications. Rock Mech Rock Eng 53(3):1305–1331. https://doi.org/10.1007/s00603-019-01980-9

Qiu JD, Li DY, Li XB, Zhu QQ (2020) Numerical investigation on the stress evolution and failure behavior for deep roadway under blasting disturbance. Soil Dyna Earthq Eng 137:106278. https://doi.org/10.1016/j.soildyn.2020.106278

Xia KW, Yao W (2015) Dynamic rock tests using split Hopkinson (Kolsky) bar system – a review. J Rock Mech Geotech Eng 7(1):27–59. https://doi.org/10.1016/j.jrmge.2014.07.008

Dai F, Huang S, Xia KW, Tan ZY (2010) Some fundamental issues in dynamic compression and tension tests of rocks using split Hopkinson pressure bar. Rock Mech Rock Eng 43:657–666. https://doi.org/10.1007/s00603-010-0091-8

Zhang QB, Zhao J (2014) A review of dynamic experimental techniques and mechanical behaviour of rock materials. Rock Mech Rock Eng 47:1411–1477. https://doi.org/10.1007/s00603-013-0463-y

Luo Y, Gong FQ, Liu DQ, Wang SY, Si XF (2019) Experimental simulation analysis of the process and failure characteristics of spalling in D-shaped tunnels under true-triaxial loading conditions. Tunn Undergr Sp Tech 90:42–61. https://doi.org/10.1007/s00603-013-0463-y

Cai X, Zhou ZL, Du XM (2020) Water-induced variations in dynamic behavior and failure characteristics of sandstone subjected to simulated geo-stress. Int J Rock Mech Min Sci 130:104339–104748. https://doi.org/10.1016/j.ijrmms.2007.08.013

Li XB (2014) Rock dynamics fundamentals and applications. Science Press, Beijing

Han ZY, Li DY, Zhou T, Zhu QQ, Ranjith PG (2020) Experimental study of stress wave propagation and energy characteristics across rock specimens containing cemented mortar joint with various thicknesses. Int J Rock Mech Min Sci 131:104352. https://doi.org/10.1016/j.ijrmms.2020.104352

Cai X, Zhou ZL, Zang HZ, Song ZY (2020) Water saturation effects on dynamic behavior and microstructure damage of sandstone: phenomena and mechanisms. Eng Geol 276:105760. https://doi.org/10.1016/j.enggeo.2020.105760

Li XB, Zhou T, Li DY, Wang ZW (2016) Experimental and numerical investigations on feasibility and validity of prismatic rock specimen in SHPB. Shock Vib 2016:7198980–7198913. https://doi.org/10.1155/2016/7198980

Wu H, Kulatilake PHSW, Zhao GY, Liang WZ, Wang EJ (2019) A comprehensive study of fracture evolution of brittle rock containing an inverted U-shaped cavity under uniaxial compression. Comput Geotech 116:103219. https://doi.org/10.1016/j.compgeo.2019.103219

Perfect E (1997) Fractal models for the fragmentation of rocks and soils: a review. Eng Geol 48(3–4):185–198. https://doi.org/10.1016/S0013-7952(97)00040-9

Wu H, Zhao GY, Liang WZ (2019) Investigation of cracking behaviour and mechanism of sandstone specimens with a hole under compression. Int J Mech Sci 163:105084. https://doi.org/10.1016/j.ijmecsci.2019.105084

Tao M, Ma A, Cao WZ, Li XB, Gong FQ (2017) Dynamic response of pre-stressed rock with a circular cavity subject to transient loading. Int J Rock Mech Min Sci 99:1–8. https://doi.org/10.1016/j.ijrmms.2017.09.003

Feng F, Chen SJ, Li DY, Hu ST, Huang WP, Li B (2019) Analysis of fractures of a hard rock specimen via unloading of central hole with different sectional shapes. Energy Sci Eng 7(6):2265–2286. https://doi.org/10.1002/ese3.432

Zhu WC, Li ZH, Zhu L, Tang CA (2010) Numerical simulation on rockburst of underground opening triggered by dynamic disturbance. Tunn Undergr Sp Tech 25(5):587–599. https://doi.org/10.1016/j.tust.2010.04.004

Li XB, Gong FQ, Tao M, Dong LJ, Du K, Ma CD, Zhou ZL, Yin TB (2017) Failure mechanism and coupled static-dynamic loading theory in deep hard rock mining: a review. J Rock Mech Geotech Eng 9(4):767–782. https://doi.org/10.1016/j.jrmge.2017.04.004

Acknowledgments

The authors are very grateful to Prof. Xibing Li, one of the pioneers in the field of rock dynamics, for affording excellent laboratory facilities for impact loading tests. His fruitful achievements and forward-looking academic ideas also provide strong support for this research.

Funding

This study received the financial support from the National Natural Science Foundation of China (grant numbers: 51774321 and 51804163) and the China Postdoctoral Science Foundation (grant number: 2018M642678).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, H., Dai, B., Cheng, L. et al. Experimental Study of Dynamic Mechanical Response and Energy Dissipation of Rock Having a Circular Opening Under Impact Loading. Mining, Metallurgy & Exploration 38, 1111–1124 (2021). https://doi.org/10.1007/s42461-021-00405-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-021-00405-y