Abstract

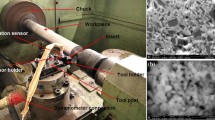

This novel work focuses on turning Inconel 718 alloy using different sustainable lubricating-cooling techniques. Cryogenic machining (Cryo), minimum quantity lubrication (MQL) and nanofluid MQL (NFMQL) were applied and their performances in terms of obtainable surface integrity evaluated in comparison with dry cutting (dry) and wet machining (wet). The surface integrity was analyzed from the aspect of surface roughness, surface morphology and defects, microhardness, microstructure, and chip morphology. The experimental results revealed that Cryo offered overall better performances when compared to dry, wet, MQL and NFMQL strategies: lower surface roughness, fewer surface defects and lower chip compression ratio were observed. Furthermore, increasing the cutting speed led to higher surface roughness and incidence of surface defects for all the applied strategies, except for Cryo.

Similar content being viewed by others

Abbreviations

- Cryo:

-

Cryogenic machining

- MQL:

-

Minimum quantity lubrication

- NFMQL:

-

Nanofluid MQL

- Dry:

-

Dry cutting

- Wet:

-

Wet machining

- LN2 :

-

Liquid nitrogen

- Vc:

-

Cutting speed

- f:

-

Feed rate

- ap :

-

Depth of cut

- CBN:

-

Cubic boron nitride

- NFMQL_5:

-

Nanofluid MQL with 5 µm graphene nanoplatelets

- NFMQL_15:

-

Nanofluid MQL with 15 µm graphene nanoplatelets

- GNPs:

-

Graphene nanoplatelets

- PVD:

-

Physical vapor deposition

- GNF_5:

-

Graphene(5 μm)-LB2000 nanofluid

- GNF_15:

-

Graphene(15 μm)-LB2000 nanofluid

- SEM:

-

Scanning electron microscope

- ETD:

-

Everhart–Thornley Detector

- BSED:

-

Back Scattered Electron Detector

- tc :

-

Chip thickness

- λ:

-

Chip compression ratio

- t0 :

-

Uncut chip thickness

References

Wang, B., Liu, Z., Song, Q., Wan, Y., & Ren, X. (2020). An approach for reducing cutting energy consumption with ultra-high speed machining of super alloy Inconel 718. International Journal of Precision Engineering and Manufacturing-Green Technology, 7, 35–51. https://doi.org/10.1007/s40684-019-00125-1.

Zeilmann, R. P., Fontanive, F., & Soares, R. M. (2017). Wear mechanisms during dry and wet turning of Inconel 718 with ceramic tools. The International Journal of Advanced Manufacturing Technology, 92, 2705–2714. https://doi.org/10.1007/s00170-017-0329-7.

Devillez, A., Le Coz, G., Dominiak, S., & Dudzinski, D. (2011). Dry machining of Inconel 718, workpiece surface integrity. Journal of Materials Processing Technology, 211, 1590–1598. https://doi.org/10.1016/j.jmatprotec.2011.04.011.

Musavi, S. H., Davoodi, B., & Niknam, S. A. (2018). Environmental-friendly turning of A286 superalloy. Journal of Manufacturing Processes, 32, 734–743. https://doi.org/10.1016/j.jmapro.2018.04.005.

Tamang, S. K., Chandrasekaran, M., & Sahoo, A. K. (2018). Sustainable machining: an experimental investigation and optimization of machining Inconel 825 with dry and MQL approach. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 40, 374. https://doi.org/10.1007/s40430-018-1294-2.

Gong, L., Bertolini, R., Ghiotti, A., He, N., & Bruschi, S. (2020). Sustainable turning of Inconel 718 nickel alloy using MQL strategy based on graphene nanofluids. The International Journal of Advanced Manufacturing Technology, 108, 3159–3174. https://doi.org/10.1007/s00170-020-05626-x.

Şirin, Ş, & Kıvak, T. (2019). Performances of different eco-friendly nanofluid lubricants in the milling of Inconel X-750 superalloy. Tribology International, 137, 180–192. https://doi.org/10.1016/j.triboint.2019.04.042.

Hong, S. Y., Ding, Y., & Jeong, J. (2002). Experimental evaluation of friction coefficient and liquid nitrogen lubrication effect in cryogenic machining. Machining Science and Technology, 6, 235–250. https://doi.org/10.1081/MST-120005958.

Ayed, Y., Germain, G., Melsio, A. P., Kowalewski, P., & Locufier, D. (2017). Impact of supply conditions of liquid nitrogen on tool wear and surface integrity when machining the Ti-6Al-4V titanium alloy. The International Journal of Advanced Manufacturing Technology, 93, 1199–1206. https://doi.org/10.1007/s00170-017-0604-7.

Pereira, O., Rodríguez, A., Barreiro, J., Fernández-Abia, A. I., & de Lacalle, L. N. L. (2017). Nozzle design for combined use of MQL and cryogenic gas in machining. International Journal of Precision Engineering and Manufacturing-Green Technology, 4, 87–95. https://doi.org/10.1007/s40684-017-0012-3.

Musfirah, A. H., Ghani, J. A., & Haron, C. C. (2017). Tool wear and surface integrity of inconel 718 in dry and cryogenic coolant at high cutting speed. Wear, 376, 125–133. https://doi.org/10.1016/j.wear.2017.01.031.

Shokrani, A., Dhokia, V., & Newman, S. T. (2016). Investigation of the effects of cryogenic machining on surface integrity in CNC end milling of Ti–6Al–4V titanium alloy. Journal of Manufacturing Processes, 21, 172–179. https://doi.org/10.1016/j.jmapro.2015.12.002.

Schoop, J., Sales, W. F., & Jawahir, I. S. (2017). High speed cryogenic finish machining of Ti-6Al4V with polycrystalline diamond tools. Journal of Materials Processing Technology, 250, 1–8. https://doi.org/10.1016/j.jmatprotec.2017.07.002.

Grzesik, W., Niesłony, P., Habrat, W., Sieniawski, J., & Laskowski, P. (2018). Investigation of tool wear in the turning of Inconel 718 superalloy in terms of process performance and productivity enhancement. Tribology International, 118, 337–346. https://doi.org/10.1016/j.triboint.2017.10.005.

Hua, Y., & Liu, Z. (2018). Effects of cutting parameters and tool nose radius on surface roughness and work hardening during dry turning Inconel 718. The International Journal of Advanced Manufacturing Technology, 96, 2421–2430. https://doi.org/10.1007/s00170-018-1721-7.

Jafarian, F., Amirabadi, H., & Fattahi, M. (2014). Improving surface integrity in finish machining of Inconel 718 alloy using intelligent systems. The International Journal of Advanced Manufacturing Technology, 71, 817–827. https://doi.org/10.1007/s00170-013-5528-2.

Cantero, J. L., Díaz-Álvarez, J., Miguélez, M. H., & Marín, N. C. (2013). Analysis of tool wear patterns in finishing turning of Inconel 718. Wear, 297, 885–894. https://doi.org/10.1016/j.wear.2012.11.004.

Madariaga, A., Esnaola, J. A., Fernandez, E., Arrazola, P. J., Garay, A., & Morel, F. (2014). Analysis of residual stress and work-hardened profiles on Inconel 718 when face turning with large-nose radius tools. The International Journal of Advanced Manufacturing Technology, 71, 1587–1598. https://doi.org/10.1007/s00170-013-5585-6.

Rakesh, M., & Datta, S. (2019). Effects of cutting speed on chip characteristics and tool wear mechanisms during dry machining of Inconel 718 using uncoated WC tool. Arabian Journal for Science and Engineering, 44, 7423–7440. https://doi.org/10.1007/s13369-019-03785-y.

Thakur, D. G., Ramamoorthy, B., & Vijayaraghavan, L. (2010). Investigation and optimization of lubrication parameters in high speed turning of superalloy Inconel 718. The International Journal of Advanced Manufacturing Technology, 50, 471–478. https://doi.org/10.1007/s00170-010-2538-1.

Xavior, M. A., Manohar, M., Madhukar, P. M., & Jeyapandiarajan, P. (2017). Experimental investigation of work hardening, residual stress and microstructure during machining Inconel 718. Journal of Mechanical Science and Technology, 31, 4789–4794. https://doi.org/10.1007/s12206-017-0926-2.

Behera, B. C., Setti, D., Ghosh, S., & Rao, P. V. (2017). Spreadability studies of metal working fluids on tool surface and its impact on minimum amount cooling and lubrication turning. Journal of Materials Processing Technology, 244, 1–16. https://doi.org/10.1016/j.jmatprotec.2017.01.016.

Hribersek, M., Pusavec, F., Rech, J., & Kopac, J. (2018). Modeling of machined surface characteristics in cryogenic orthogonal turning of inconel 718. Machining Science and Technology, 22, 829–850. https://doi.org/10.1080/10910344.2017.1415935.

Calleja, A., Urbikain, G., González, H., Cerrillo, I., Polvorosa, R., & Lamikiz, A. (2018). Inconel® 718 superalloy machinability evaluation after laser cladding additive manufacturing process. The International Journal of Advanced Manufacturing Technology, 97, 2873–2885. https://doi.org/10.1007/s00170-018-2169-5.

Pusavec, F., Deshpande, A., Yang, S., M’Saoubi, R., Kopac, J., Dillon, O. W., Jr., & Jawahir, I. S. (2014). Sustainable machining of high temperature Nickel alloy–Inconel 718: part 1–predictive performance models. Journal of Cleaner Production, 81, 255–269. https://doi.org/10.1016/j.jclepro.2014.06.040.

Sen, B., Mia, M., Krolczyk, G. M., Mandal, U. K., & Mondal, S. P. (2019). Eco-friendly cutting fluids in minimum quantity lubrication assisted machining: a review on the perception of sustainable manufacturing. International Journal of Precision Engineering and Manufacturing-Green Technology. https://doi.org/10.1007/s40684-019-00158-6.

Li, W., Dong, Y., Zhang, X., & Liu, X. (2019). Preparation and performance analysis of graphite additive/paraffin composite phase change materials. Processes, 7, 447. https://doi.org/10.3390/pr7070447.

Rahmati, B., Sarhan, A. A., & Sayuti, M. (2014). Morphology of surface generated by end milling AL6061-T6 using molybdenum disulfide (MoS2) nanolubrication in end milling machining. Journal of Cleaner Production, 66, 685–691. https://doi.org/10.1016/j.jclepro.2013.10.048.

Esfe, M. H., Arani, A. A. A., & Esfandeh, S. (2018). Improving engine oil lubrication in light-duty vehicles by using of dispersing MWCNT and ZnO nanoparticles in 5W50 as viscosity index improvers (VII). Applied Thermal Engineering, 143, 493–506. https://doi.org/10.1016/j.applthermaleng.2018.07.034.

Esfe, M. H., Afrand, M., Gharehkhani, S., Rostamian, H., Toghraie, D., & Dahari, M. (2016). An experimental study on viscosity of alumina-engine oil: effects of temperature and nanoparticles concentration. International Communications in Heat and Mass Transfer, 76, 202–208. https://doi.org/10.1016/j.icheatmasstransfer.2016.05.013.

Alarifi, I. M., Alkouh, A. B., Ali, V., Nguyen, H. M., & Asadi, A. (2019). On the rheological properties of MWCNT-TiO2/oil hybrid nanofluid: An experimental investigation on the effects of shear rate, temperature, and solid concentration of nanoparticles. Powder Technology, 355, 157–162. https://doi.org/10.1016/j.powtec.2019.07.039.

Esfahani, M. R., Languri, E. M., & Nunna, M. R. (2016). Effect of particle size and viscosity on thermal conductivity enhancement of graphene oxide nanofluid. International Communications in Heat and Mass Transfer, 76, 308–315. https://doi.org/10.1016/j.icheatmasstransfer.2016.06.006.

Rashin, M. N., & Hemalatha, J. (2013). Viscosity studies on novel copper oxide–coconut oil nanofluid. Experimental Thermal and Fluid Science, 48, 67–72. https://doi.org/10.1016/j.expthermflusci.2013.02.009.

Tiwari, A. K., Pandya, N. S., Shah, H., & Said, Z. (2020). Experimental comparison of specific heat capacity of three different metal oxides with MWCNT/water-based hybrid nanofluids: proposing a new correlation. Applied Nanoscience. https://doi.org/10.1007/s13204-020-01578-6.

Teng, T. P., & Hung, Y. H. (2014). Estimation and experimental study of the density and specific heat for alumina nanofluid. Journal of Experimental Nanoscience, 9, 707–718. https://doi.org/10.1080/17458080.2012.696219.

Wang, L., Tan, Z., Meng, S., Liang, D., & Li, G. (2001). Enhancement of molar heat capacity of nanostructured Al2O3. Journal of Nanoparticle Research, 3, 483–487. https://doi.org/10.1023/A:1012514216429.

Iturbe, A., Hormaetxe, E., Garay, A., & Arrazola, P. J. (2016). Surface integrity analysis when machining inconel 718 with conventional and cryogenic cooling. Procedia CIRP, 45, 67–70. https://doi.org/10.1016/j.procir.2016.02.095.

Chetan, G., & S., & Rao, P. V. . (2019). Comparison between sustainable cryogenic techniques and nano-MQL cooling mode in turning of nickel-based alloy. Journal of cleaner production, 231, 1036–1049. https://doi.org/10.1016/j.jclepro.2019.05.196.

Yang, H. C., Chen, Z. T., & Zhou, Z. T. (2015). Influence of cutting speed and tool wear on the surface integrity of the titanium alloy Ti-1023 during milling. The International Journal of Advanced Manufacturing Technology, 78, 1113–1126. https://doi.org/10.1007/s00170-014-6593-x.

Shah, P., Khanna, N., & Chetan. . (2020). Comprehensive machining analysis to establish cryogenic LN2 and LCO2 as sustainable cooling and lubrication techniques. Tribology International, 148, 106314. https://doi.org/10.1016/j.triboint.2020.106314.

Wang, F., Zhao, J., Li, A., & Zhang, H. (2014). Effects of cutting conditions on microhardness and microstructure in high-speed milling of H13 tool steel. The International Journal of Advanced Manufacturing Technology, 73, 137–146. https://doi.org/10.1007/s00170-014-5812-9.

Kaynak, Y., Karaca, H. E., & Jawahir, I. S. (2015). Cutting speed dependent microstructure and transformation behavior of NiTi alloy in dry and cryogenic machining. Journal of Materials Engineering and Performance, 24, 452–460. https://doi.org/10.1007/s11665-014-1247-6.

Zhang, S., Li, J., Zhu, X., & Lv, H. (2013). Saw-tooth chip formation and its effect on cutting force fluctuation in turning of Inconel 718. International Journal of Precision Engineering and Manufacturing, 14, 957–963. https://doi.org/10.1007/s12541-013-0126-7.

Venkatesan, K., Ramanujam, R., & Kuppan, P. (2017). Investigation of machinability characteristics and chip morphology study in laser-assisted machining of Inconel 718. The International Journal of Advanced Manufacturing Technology, 91, 3807–3821. https://doi.org/10.1007/s00170-017-9987-8.

Rahman, S. S., Ashraf, M. Z. I., Amin, A. N., Bashar, M. S., Ashik, M. F. K., & Kamruzzaman, M. (2019). Tuning nanofluids for improved lubrication performance in turning biomedical grade titanium alloy. Journal of Cleaner Production, 206, 180–196. https://doi.org/10.1016/j.jclepro.2018.09.150.

Zaman, P. B., & Dhar, N. R. (2019). Design and evaluation of an embedded double jet nozzle for MQL delivery intending machinability improvement in turning operation. Journal of Manufacturing Processes, 44, 179–196. https://doi.org/10.1016/j.jmapro.2019.05.047.

Acknowledgements

The authors wish to acknowledge with financial support of this research by China Scholarship Council (Grant No. 201906830023) and Nanjing University of Aeronautics and Astronautics PhD short-term visiting scholar project (Grant No. 190114DF05).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gong, L., Bertolini, R., Bruschi, S. et al. Surface Integrity Evaluation When Turning Inconel 718 Alloy Using Sustainable Lubricating-Cooling Approaches. Int. J. of Precis. Eng. and Manuf.-Green Tech. 9, 25–42 (2022). https://doi.org/10.1007/s40684-021-00310-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-021-00310-1