Abstract

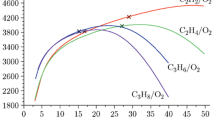

A CCDS2000 detonator for acetylene, ethylene, propylene, and a multicomponent methylacetylene–allene fraction (MAF) fuel is used to perform experiments on measuring the detonation velocity and recording a detonation front cell in a tube 26 mm in diameter and 2 m in length. The experiments are carried out at atmospheric pressure in stoichiometric mixtures diluted by nitrogen to air concentrations and in air–fuel mixtures with a varying fuel content in them. In the case where the explosive mixture components are fed as a flow by stratifying an explosive charge in an initiation zone, a self-sustaining detonation is stably ignited up to limiting (spin) modes. The concentration limits of the detonation existence are determined. In the air–fuel mixtures of acetylene and ethylene, as the values become lower than the limits, there is multiheaded detonation. For propylene and MAF, a tube diameter of 26 mm is near-critical: only single- and two-headed spin is observed in the entire range of existence. Calculation results are in good agreement with the experiment.

Similar content being viewed by others

REFERENCES

A. A. Borisov and S. A. Loban’, “Detonation Limits of Hydrocarbon–Air Mixtures in Tubes," Fiz. Goreniya Vzryva13 (5), 729–733 (1977) [Combust., Expl., Shock Waves13 (5), 618–621 (1977); DOI: 10.1134/S0010508219040166].

A. A. Shtertser, V. Yu. Ul’yanitskii, and D. K. Rybin, “Suspension Detonation Spraying of Ceramic Coatings," Fiz. Goreniya Vzryva55 (4), 121–128 (2019) [Combust., Expl., Shock Waves55 (4), 483–490 (2019)].

A. A. Shtertser, V. Yu. Ul’yanitskii, I. S. Batraev, and D. K. Rybin, “Obtaining Nanosized Detonation Carbon on a Pulsed Gas Detonation Installation," Pis’ma Zh. Teor. Fiz. 44(9), 65–72 (2018).

S. M. Frolov, Pulse Detonation Engines (Izd. TORUS PRESS, Moscow, 2006) [in Russian].

F. A. Bykovskii and S. A. Zhdan, Continuous Spin Detonation (Izd. Sib. Otd. Ross. Akad. Nauk, Novosibirsk, 2013) [in Russian].

V. Yu. Ul’yanitskii, “CCDS2000 Is the New Generation Equipment for Detonation Spraying," Uproch. Tekhnol. Pokr., No. 10, 36–41 (2013).

K. Yushehenko, E. Astakhov, Y. Borisov, et al., “Application of Detonation Spraying in Scandinavia," in Proc. of the 14th ITSC’95, Kobe, Japan, May 22–26, 1995.

T. P. Gavrilenko and V. Yu. Ul’yanitskii, “Application of Propane–Butane in Detonation Deposition Facilities," Fiz. Goreniya Vzryva 47 (1), 92–98 (2011) [Combust., Expl., Shock Waves 47 (1), 81–86 (2011)].

B. G. Gill, “Super D-Gun," Aircraft Eng. Aerospace Technol.62 (8), 10–33 (1990).

V. Ulianitsky, I. Batraev, D. Dudina, and I. Smurov, “Enhancing the Properties of WC/Co Detonation Coatings Using Two-Component Fuels," Surf. Coat. Technol. 318, 244–249 (2017).

J. E. Jackson, “Fuel–Oxidant Mixture for Detonation Gun Flame-Plating," U.S. Patent No. 4902539, Patented February 20, 1990.

V. Yu. Ul’yanitskii, A. A. Shtertser, and I. S. Batraev, “Detonation of a Gas Fuel Based on Methyl Acetylene and Allene," Fiz. Goreniya Vzryva 51 (2), 118–124 (2015) [Combust., Expl., Shock Waves 51 (2), 246–251 (2015)].

D. K. Rybin, V. Yu. Ul’yanitskii, and I. S. Batraev, “Detonation of Ethylene– and Propylene–Oxygen Explosive Mixtures and Their Use in Detonation Spraying Technology," Fiz. Goreniya Vzryva56 (3), 115–122 (2020) [Combust., Expl., Shock Waves56 (3), 353–360 (2020); DOI: 10.1134/S0010508220030120].

T. Gavrilenko, Yu. Nikolaev, V. Ulianitsky, et al., “Computational Code for Detonation Spraying Process, Thermal Spray," inMeeting the Challenges of the 21st Century, May 25–29, 1998, Nice, France (ASM Int., 1998).

R. Knystautas, C. Guirao, J. H. Lee, and A. Sulmistras, “Measurement of Cell Size in Hydrocarbon–Air Mixtures and Predictions of Critical Tube Diameter, Critical Initiation Energy and Detonability Limits," in Prog. Astronaut. Aeronaut., Vol. 94:Dynamics of Shock Waves, Explosions and Detonations(New York, 1983).

I. S. Batraev, A. A. Vasil’ev, V. Yu. Ul’yanitskii, et al., “Investigation of Gas Detonation in Over-Rich Mixtures of Hydrocarbons with Oxygen," Fiz. Goreniya Vzryva 54 (2), 89–97 (2018) [Combust., Expl., Shock Waves 54 (2), 207–215 (2018); DOI: 10.1134/S0010508218020107].

A. A. Vasil’ev, “Cell Size As the Main Geometric Parameter of Multifront Detonation Wave," J. Propul. Power. 22(6), 1245–1260 (2006).

A. A. Vasil’ev, V. V. Mitrofanov, and M. E. Topchiyan, “Detonation Waves in Gases," Fiz. Goreniya Vzryva 23 (5), 109–131 (1987) [Combust., Expl., Shock Waves 23 (5), 605–623 (2087)].

A. A. Vasil’ev and A. V. Pinaev, “Formation of Carbon Clusters in Deflagration and Detonation Waves in Gas Mixtures," Fiz. Goreniya Vzryva 44 (3), 81–94 (2008) [Combust., Expl., Shock Waves44 (3), 317–329 (2018)].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Batraev, I.S., Rybin, D.K. & Ul’yanitskii, V.Y. Detonation Parameters of Mixtures Produced by Injecting Gaseous Components into the Barrel of a Pulse Gas Detonation Installation. Combust Explos Shock Waves 57, 23–29 (2021). https://doi.org/10.1134/S0010508221010032

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0010508221010032