Abstract

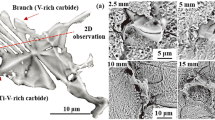

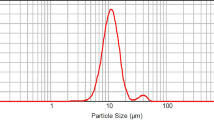

In this work, active screen plasma nitriding (AS_PN) of EN8, EN24, and EN41B low alloy steel was carried out to improve its surface properties. The process parameters of 500 °C temperature for 4 h with the gas flow in the ratio of H2:N2 = 1:1 were used for the treatment. The improvement in the surface was assessed by the microhardness as well as characterized by SEM and XRD. The microhardness measurements reveal an increase in surface hardness by more than 4, 3.4, and 2.7 times from the base material for EN41B, EN8, and EN24. The compound zone/layer ranges from 4.9 microns (μm) for EN8 to as high as 9.1 microns (μm) for EN41B after nitriding. On analyzing the nitride layer thickness through SEM, the results found from microhardness measurement were confirmed. The XRD results also approve the predominant development of γ'-Fe4N and ɛ-Fe2–3 N phases on the treated sample surface, although its compound layer surges with different nitride forming elements. Further, SEM analysis also reveals a white layer formation without transformed austenite (γ). Further, EDS analysis was also performed on the treated samples. Finally, a comparative corrosion study for AS_PN treated and bare (untreated) material samples were done to find the influence of the treatment.

Similar content being viewed by others

References

Ashrafizadeh F, Surf Coat Technol 174 (2003) 1196.

Nishimoto A, Nagatsuka K, Narita R, Nii H and Akamatsu K, Surf Coat Technol 205 (2010) S365.

Alves Jr C, Da Silva E F and Martinelli A E, Surf Coat Technol 139 (2001) 1.

Alves Jr C, De Araújo F O, Ribeiro K J B, Da Costa J A P, Sousa R R M, and de Sousa R S, Surf Coat Technol 201 (2006) 2450.

Georges J, US patent 5,989,363, No. 23 (1999)

Georges J, in Proceeding 12th International Federation of Heat Treating and Surface Engineering congress 2000, Melbourne, Australia, 3 (2000) 229.

Mittemeijer E J, ASM Int 4 (2013) 554.

Colijin P, Mittemeijer E J and Rozendal H C, Zeitschrift Fur Met 74 (1983) 620.

Jack D and Jack K, Mater Sci Eng 11 (1973) 127.

Liang W, Bin X, Zhiwei Y, and Yaqin S, Surf Coat Technol 130 (2000) 304.

Li CX and Bell T, Corr Sci 48 (2006) 2036.

Corengia P, Ybarra G, Moina C, Cabo A and Broitman E, Surf Coat Technol 187 (2004) 63.

40CAD6.12 905M31 DIN1.8509 41CrAlMo7 EN41B Nitriding Steel, Fushun Special Steel Co Ltd. https://www.fushunspecialsteel.com/40cad6-12-905m31-din1-8509-41cralmo7-en41b-nitriding-steel/. Accessed 19 Feb 2020.

Inokuti Y, Nishida N and Ohashi N, Metal Trans A 6 (1975) 773.

Metin E, Inal O T, J. Mater Sci 22 (1987) 2783.

Figueroa U, Oseguera J and Schabes-Retchkiman P S, Surf Coat Technol 86 (1996) 728.

Madanipour H, Soltanieh M and Nayebpashaee M, Mat Des 51 (2013) 43. doi:https://doi.org/10.1016/j.matdes.2013.03.077

Bindumadhavan P, Makesh S, Gowrishankar N, Keng Wah H and Prabhakar O, Surf Coat Technol 127 (2000) 252.

Gautam D, Ganguli B, and Sharma S, Mat Perfor and Charac 6 (2017) 581. doi:https://doi.org/10.1520/MPC20160084

Alsaran A, Altun H, Karakan M, and Çelik A, Surf Coat Technol 176 (2004) 344.

Berg M, Budtz-Jørgensen C, Reitz H, Schweitz Y, Chevallier J, Kringhøj P, and Bøttiger J, Surf. Coat. Technol. 124 (2000) 25.

Kugler C, Fink M, Laimer J, and Störi H, Surf Coat Technol 142-144 (2001) 424.

Basu A, Majumdar J D, Alphonsa J, Mukherjee S, and Manna I, Materials Letters 62 (2008) 3117.

Ensinger W, Schröer A, and Wolf G, Surf Coat Technol 51, (1992) 217.

Yang L, Yongyong H, JunJie X, Wei W, YiJie Z and Baoguo H, Surf Coat Technol 329 (2017) 184.

Naeem M, Shafiq M, Zaka-ul-Islam M, Ashiq A, Díaz-Guillén J C, Shahzad M, and Zakaullah M, Mater Des 108 (2016) 745.

Esfandiari M, and Dong H, Surf Coat Technol 202 (2007) 466.

Saeed A, Khan A W, Jan F, Abrar M, Khalid M, and Zakaullah M, Appl Surf Sci 273 (2013) 173. doi:https://doi.org/10.1016/j.apsusc.2013.02.008

Acknowledgments

The authors are thankful to Mr. Hardik Patel, Scientific Assistant-C, IPR Gandhinagar, India, and Mr. Subrat Kumar Das, Scientific Assistant-C, FCIPT Gandhinagar, India, for their help in performing SEM analysis for the present investigation. The authors are also thankful to Mr. Vyom Desai, Ph.D. scholar, FCIPT, for his help in performing XRD analysis. The authors are also thankful to the reviewers for their exhaustive review of the manuscript in order to rectify the shortcomings and to upsurge the standard of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kumar, N., Ganguli, B., Roy, B. et al. Investigation of Surface Properties of EN8, EN24, and EN41B Low Alloy Steel Treated by Active Screen Plasma Nitriding. Trans Indian Inst Met 74, 799–810 (2021). https://doi.org/10.1007/s12666-021-02191-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02191-z