Abstract

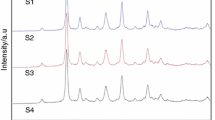

In the present research, NiO–SDC (Samarium doped Ceria) nanopowder was synthesized through sol–gel combustion method using citric acid as a reducing agent (fuel) and metal nitrates as an oxidant. The characteristics of the synthesized powder were thoroughly analyzed by DTA/TG, XRD, BET and FESEM/EDX. Tubular gel-casted porous specimens of NiO–SDC (50:50 wt%) composite materials were produced after stabilizing suspensions of composite powder in an aqueous environment by addition of 3 wt% dispersant and 2.5 wt% agar as the gel builder. The effect of Dolapix CE64 as a dispersant, agar as a gel-builder and the amount of solid loadings on the processing and properties of porous ceramics was investigated. Viscosity measurements, zeta potentials of suspensions with and without dispersant and sedimentation measurement were used to determine the optimum dispersant concentration and solid concentration needed to prepare a stable slurry. The phase composition and microstructure of sintered samples were studied by X-ray diffraction (XRD) and scanning electron microscopy (SEM). Moreover, the distribution and porosity of the samples were determined through mercury porosimetry method. Results confirmed that stable NiO–SDC slurries with high solid loading (60 %) were achieved with Dolapix CE64, which also met the requirements to reach porous tubular samples with up to 60% porosity.

Highlights

-

Nano composite powder with the composition of NiO/Sm0.2-Ce0.8O1.9 (50:50) was synthesized by the sol-gel combustion method to achieve uniform distribution of elements.

-

The porous tubular samples formed by the gel casting water based method led to achieve porous sample desired for Electrode in Solid Oxide Fuel cells.

-

The mean open porosity of the sintered sample was 60%, the most pores ranged from 2 to 4 μm in size.

Similar content being viewed by others

References

Lu X, Wang X, Xiao P (2006) Nanoindentation and residual stress measurements of yttria-stablized zirconia composite coatings produced by electrophoretic deposition. Thin Solid Films 494:223–227

Chen M et al. (2008) Synthesis and performances of Ni–SDC cermets for IT-SOFC anode. J Eur Ceram Soc 28(15):2947–2953

Chen M et al. (2010) Effect of Ni content on the microstructure and electrochemical properties of Ni–SDC anodes for IT-SOFC. Solid State Ion 181:1119

Swatsitang E et al. (2016) Characterization of Sm-doped CeO2 nanoparticles and their magnetic properties. Phys B: Condens Matter 485:14–20

Mandal B et al. (2015) Sm doped mesoporous CeO2 nanocrystals: aqueous solution-based surfactant assisted low temperature synthesis, characterization and their improved autocatalytic activity. Dalton Trans 45(4):1679–1692

Patil KC, Aruna ST, Mimani T (2002) Combustion synthesis: an update. Curr Opin Solid State Mater Sci 6(6):507–512

Wang Y et al. (2003) Low-temperature fabrication and electrical property of 10 mol% Sm2O3-doped CeO2 ceramics. Sci Technol Adv Mater 4(3):229–238

Lackner M (2010) Combustion synthesis: novel routes to novel materials. http://public.ebookcentral.proquest.com/choice/publicfullrecord.aspx?p=864295

Varma A et al. (2016) Solution combustion synthesis of nanoscale materials. Chem Rev 116(23):14493–14586

Epifani M et al. (2007) Precursors for the combustion synthesis of metal oxides from the sol–gel processing of metal complexes. J Eur Ceram Soc 27(1):115–123

Altincekic T, Öksüzömer M (2010) Synthesis of nanocrystalline samarium-doped CeO2 (SDC) powders as a solid electrolyte by using a simple solvothermal route. INT - CERAM INT 36:1101–1107

Lian JS et al. (2004) Synthesis of nanocrystalline NiO/doped CeO2 compound powders through combustion of citrate/nitrate gel. Mater Lett 58(7):1183–1188

Yue Z et al. (2000) Synthesis of nanocrystalline NiCuZn ferrite powders by sol–gel auto-combustion method. J Magn Magn Mater 208(1):55–60

Rajagopal P et al. (2020) Gel combustion synthesis and characterization of ZnO/NiO nanocomposite for supercapacitor application. International Journal of Innovative Technology and Exploring Engineering (IJITEE) 9(2S2):2278–3075

Wen W, Wu J-M (2014) Nanomaterials via solution combustion synthesis: a step nearer to controllability. RSC Adv 4(101):58090–58100

Zhou Q et al. (2014) Effect of fuel-to-oxidizer ratios on combustion mode and microstructure of Li2TiO3 nanoscale powders. J Eur Ceram Soc 34(3):801–807

Skalar T, Zupan K, Marinšek M (2019) Microstructure tailoring of combustion-derived Ni-GDC and Ni-SDC composites as anode materials for intermediate temperature solid oxide fuel cells. J Aust Ceram Soc 55(1):123–133

Ortega F et al. (2008) The rheological behavior and surface charging of gelcasting alumina suspensions. Ceram Int 34:237–241

Janney M et al. (1998) Development of low toxicity gelcasting system. J Am Ceram Soc 81:581–591

Navarro ME et al. (2012) Manufacturing of anode-supported tubular solid oxide fuel cells by a new shaping technique using aqueous gel-casting. J Power Sources 200:45–52

Jadhav L et al. (2013) Solution combustion synthesis: role of oxidant to fuel ratio on powder properties. Mater Sci Forum 757:85–98

Hadke S et al. (2015) Role of fuel and fuel-to-oxidizer ratio in combustion synthesis of nano-crystalline nickel oxide powders. Ceram Int 41(10, Part B):14949–14957

Dean JA, Lange NA (1999) Lange’s handbook of chemistry. New York: McGraw-Hill

Kaur I et al. (2017) Dispersion of nanomaterials in aqueous media: towards protocol optimization. J Vis Exp 130:56074.

Li X (2012) Aqueous tape casting of SDC with a multifunctional dispersant. J Ceram Process Res 13:324–329

Mahmood T et al. (2011) Comparison of different methods for the point of zero charge determination of NiO. Ind Eng Chem Res 50(17):10017–10023

Rahaman MN (2017) Ceramic processing. https://public.ebookcentral.proquest.com/choice/publicfullrecord.aspx?p=5477211

Rao S, Tripathy S, Raichur A (2007) Dispersion studies of sub-micron zirconia using dolapix CE 64. Colloids Surf A: Physicochem Eng Asp 302:553–558

Sánchez-Herencia A (2007) Water based colloidal processing of ceramic laminates. key engineering materials. KEy Eng Mat 333:39–48

Hu Y, Dai J (2003) Hydrophobic aggregation of alumina in surfactant solution. Miner Eng 16:1167–1172

Palmqvist L et al. (2006) Dispersion mechanisms in aqueous alumina suspensions at high solids loadings. Colloids Surf A: Physicochem Eng Asp 274(1):100–109

Garrido LB, Califano AN (2007) Effect of an excess of polyelectrolyte on viscoelastic properties of suspensions of alumina and zircon mixtures. Colloids Surf A: Physicochem Eng Asp 302(1):24–30

Michálková M, Ghillányová K, Galusek D (2010) The influence of solid loading in suspensions of a submicrometric alumina powder on green and sintered pressure filtrated samples. Ceram Int 36(1):385–390

Morales M et al. (2012) Processing of graded anode-supported micro-tubular SOFCs based on samaria-doped ceria via gel-casting and spray-coating. Ceram Int 38:3713–3722

Kim H et al. (2002) Fabrication of highly porous yttria-stabilized zirconia by acid leaching nickel from a nickel-yttria-stabilized zirconia cermet. J Am Ceram Soc 85(6):1473–1476

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Oveisi, S., khakpour, Z., Faghihi-sani, M.A. et al. Processing study of gel-cast tubular porous NiO/SDC composite materials from gel-combustion synthesized nanopowder. J Sol-Gel Sci Technol 97, 581–592 (2021). https://doi.org/10.1007/s10971-021-05475-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-021-05475-4