Abstract

The oscillation of erbium doped fiber lasers (EDFL) in the Q-switch mode is investigated. Etched out fiber tapers coated with two types of saturable absorbers (SA) are tested as passive Q-switches. SA of the first type comprises two-component silicone with nano-flakes of a Bi2Te3 single crystal dissolved in it. A thin film of Bi2Te3 synthesized by the Metalorganic Chemical Vapor Deposition (MOCVD) method on the surface of the fiber taper and coated with the same silicone served as SA of the second type. Housed within a refrigerator the fabricated sample of fiber taper with SA was in series plug into the fiber ring of the laser. A maximum is observed in the temperature dependence of the EDFL pulse repetition rate with both types of Q-switches. A decrease in temperature to –4 °C (for the first type) and to 9.5 °C (for the second one) led to the oscillation wavelength change from 1560 to 1530 nm. Cooling of Q-switches of the first and second types was accompanied by a decrease in the duration of laser pulses by a factor of 2.5 and 3.5, respectively, at a pump power corresponded to the conversion of laser oscillation from CW to repetitively-pulsed mode. At a given laser pump power, a 20% and 40% increment in the pulse repetition rate is observed upon cooling of passive Q-switches based on Bi2Te3 nanopowder-in-polymer and Bi2Te3 thin-film, up to temperatures of –14.8 °C and 4.4 °C, respectively, as compared to that one at room temperature. A diminution in the temperature of a passive Q-switch made it possible to obtain pulsed laser oscillation in a circuit that did not support the pulsed mode at room temperature.

Export citation and abstract BibTeX RIS

1. Introduction

One of the ways to obtain a repetitively pulsed mode of laser generation is Q-switching [1]. A possible option for achieving such a regime can be the incorporation of passive Q-switches for example, saturable absorbers (SA) into the design of the resonator [2, 3].

A common type of Q-switch for pulsed SA-driven fiber lasers [4–7] is a thinned section of a fiber with a saturable absorber layer deposited on its surface [5, 8]. In this design, the SA material in the form of a thin film [9, 10] or nanopowder [6, 11] interacts only with the evanescent field of the fiber mode localized in the fiber core [12] and has an extended region of interaction with the light wave along the entire length the cylindrical surface of the thinned fiber section. Since the SA material is exposed only to a small (evanescent) portion of the light field, which is localized mainly in the light-guiding fiber core, it is not exposed to high-intensity light typical for laser circuits. This prevents from degradation of SA material characteristics caused by a local temperature increase.

To ensure a more effective interaction of nanopowder absorbing materials with the evanescent mode field, special transparent media, for example, polymers [5, 13, 14], are used as the outer coating of the optical fiber. Such a coating with a high refractive index contributes to the pulling of the evanescent field of the mode from inside fiber, and also acts as a protection against external chemical and mechanical influences. Ambient temperature strongly affects the refractive index of polymers [15–17] used as an outer coating, and, therefore, the evanescent field strength inside the SA material.

Unlike Q-switch modulators built upon nanopowder-polymer mixtures as SA, devices with SA deposited directly onto the surface of the core in the form of thin films are capable of functioning without a coating medium, but the process of their synthesis is more labor-intensive and technologically complex. The deposited SA thin films are subjected to coating with polymers primarily to prevent oxidation in air [18].

Bismuth Telluride Bi2Te3 [19, 20] has shown oneself to be an efficient saturable absorber for the fabrication of passive Q-switches for fiber lasers. This material belongs to the class of topological insulators [21] having surface states resistant to environmental conditions, especially temperature [22]. Bismuth telluride demonstrates nonlinear optical properties from the visible to terahertz spectral ranges, while it has a low saturation threshold and ultra-short relaxation time of charge carriers [23, 24]. By Bi2Te3 in combination with an amorphous medium in the form of a polymer, one can expect a strong dependence of the properties of the resulting mixture on the ambient temperature. With cooling, the equilibrium concentration of thermally excited electrons in the conduction band decreases. In the limiting case, all electrons will be in the ground state in the valence band.

Since the band gap of bismuth telluride is relatively small, one can expect a significant impact of temperature changes on it properties. With the decrease of temperature, a more portion of energy carrying via light becomes located outside the light-guiding core due to an increase of the refractive index of a polymer applied for sample preparation. As the result, more intense light interacts with the saturable absorber. Thin film SA stronger interacts with the evanescent field of light as compared to coating with mixture with nanoparticles due to a larger covering area of homogeneous coating of the fiber. To the best of our knowledge, no immediate comparison of the action of temperature on repetitively-pulsed laser oscillation governed via passive Q-switches under consideration is carried out.

In the present study, we investigated the effect of cooling on the functioning of passive Q-switches based on a Bi2Te3 nanopowder and thin film and, as a consequence, on the operation mode of a ring EDFL. The main objective of the study is to find out the differences in application efficiency of composition (Bi2Te3-nanopowder)/silicone and (Bi2Te3-thin film)/silicone for the fabrication of passive Q-switch modulators.

2. Preparation of samples

A standard SMF-28 Corning® single-mode fiber was chosen as a basis for the Q-switch. The fiber was thinned to the required diameter over a 0.5–1.0 cm length by means of isotropic chemical etching in a mixture of NH4F–(NH4) 2SO4. The selected composition of the etchant at a temperature of 24 °C ensured a decrease in the fiber diameter at a rate of 0.6 μm min−1. Diameter and surface quality were monitored with the help of an optical microscope. Etching lasted until the waist diameter was 8–14 μm. The residues of the etching agent were removed by repeated rinsing with bidistilled water. The procedure of chemical thinning of optical fibers is described in detail in [25]. After chemical thinning of the fiber to a diameter of less than 20 μm, the fragility issue of tapers becomes important. In the process of applying the material, the fiber breaks at the thinned section with minimal curvature or twisting, which makes it difficult to manufacture samples. This problem is particularly important when utilizing the MOCVD method. Optical losses in etched fibers did not exceed 0.2 dB in the wavelength range from 900 nm to 1700 nm.

The first of the two methods exploited in this work to fabricate passive fiber Q-switches was the application of a composition of SA nanopowder with a polymer on the surface of the etched out taper. For this purpose, a Bi2Te3 was thoroughly powdered in a mortar for an hour. Then the resulting nano-powder was mixed with Polydimethylsiloxane elastomer (PDMS) 'SIEL' brand having a refractive index of ∼1.40 at a temperature of 24 °C. After completing the mixing, the resulting suspension was applied to the taper with the help of a small glass rod. The manufactured passive Q-switch was kept in air at room temperature for a week until complete solidification. After that, the sample becomes strong enough to be used in laser circuits, including during the cooling process, without the additional worry of damaging it. During this time, the optical transmission of the sample changed to a value in the range from 45 to 5% at a wavelength of 1560 nm. At room temperature, this value for sample #1 amounted to 28%, for a taper having a diameter of 9 μm and a length of 6.2 mm. The concentration of bismuth telluride powder in the two-component silicone was 0.6 wt%.

The second series of passive Q-switches was fabricated by deposition of a Bi2Te3 thin film upon the taper surface via MOCVD [26]. For this purpose, a piece of fiber with a removed protective cladding and an etched out taper section was put into a silica tubular reactor, which was uniformly heated by a resistance furnace. The process was carried out in a hydrogen atmosphere at a temperature of 390 °C and a pressure close to atmospheric with the use of trimethylbismuth and diethyltelluride as starting reagents. To ensure the stoichiometry of the deposited Bi2Te3 film, a 10-fold excess of diethyltelluride in the vapor phase was preset. This technology made it possible to apply uniform coatings on the cylindrical surface of optical fibers. During the deposition process, the optical transmission of the fiber was continuously monitored in the wavelength range of 900–1700 nm by means of a NIRQuest-512 spectrometer. LS-1 Ocean Optics halogen lamp served as a light source. By means of this technology sample #2 has been fabricated. In order to do that Bi2Te3 thin film was deposited on the surface of 10 μm in diameter and 5 mm long fiber taper. The optical transmission of this sample at a wavelength of 1560 nm amounted to 84%. After extraction from the reactor, the section with the film was covered by pure silicone and retained for a week at room temperature in air for solidification similar to sample #1. As the result of the protecting coating solidification optical transmission of the sample decreased to 19%. The coating deposited on the taper surface is a discontinuous film that occupies about 10%–15% of the area. The thickness of the islands was from 1 to 10 nm.

In the process of creating samples, it was found that for taper diameters more than 14 μm, it is almost impossible to achieve a pulsed mode using both methods of applying the material to the surface in a wide transmission range of the final sample (from 1 to 95% at a wavelength of 1560 nm). Further reduction in fiber diameter meant that less absorbent material had to be used to create a certain transmission. This applies to both types of passive Q-switches. In addition, with the same film thickness and powder concentration, the transmission for a thinner taper was lower, and, therefore, the power density would be higher. However, this also leads to the fact that it is more difficult to get into the required transmission range, applying a thin film, the growth time of which is limited to seconds.

3. Experimental setup

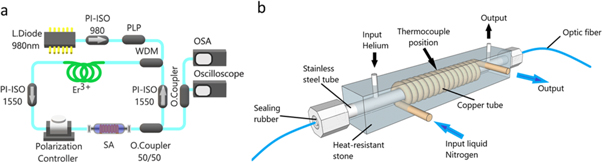

The fabricated samples of Q-switches were built into the ring of the fiber laser circuit as it shown in figure 1(a). All fiber components and connectors in the circuit were made up with the use of SMF-28 single-mode fiber. 980 nm wavelength a single-mode fiber pigtailed laser diode of up to 300 mW output power served as a pump source in the experiments. A home-made erbium doped alumosilicate core optical fiber was used as an active medium. Its losses in the active fiber at wavelengths 980 (at which the ring laser is pumped), 1530 and 1560 nm (at which the ring laser emits light) are 10, 14.6 and 5.4 dB m−1, respectively. The length of the active fiber section in the laser scheme was 2.4 meters and was selected in such a way as to provide a laser peak at a wavelength of about 1560 nm. Polarization-independent isolators with a transmission window in the vicinity of 1550 nm wavelength (PI-ISO 1550) created conditions for unidirectional circulation of light in the ring. The spectrum and average power of laser radiation were recorded with a The Keysight Agilent 86140 B spectrum analyzer, and the shape, amplitude, and pulse repetition rate—with a Picometrix-AP-300 photodetector connected to a Keysight MSOX3102T oscilloscope. The upper recording frequencies for these devices are 1.5 and 1 GHz, respectively.

Figure 1. (a)—Scheme of a ring repetitively-pulsed EDFL, (b)—refrigerator for cooling fiber Q-switches.

Download figure:

Standard image High-resolution imageTo perform measurements at different temperatures we applied a homemade refrigeration unit (refrigerator) to cool the fiber Q-switches built into the fiber ring of the EDFL (figure 1(b)). A fiber section with a modulator was placed inside a stainless steel tubular chamber and sealed on both sides with vacuum rubber rings. The inner volume of the chamber was filled helium gas to improve heat transfer and greater stability of temperature maintenance. The helium atmosphere inside the refrigerator also prevented environmental moisture from condensing on the fiber surface. Cooling occurred by pumping liquid nitrogen through a copper tube wound around the chamber and filled in with crumpled copper wire. The temperature inside the chamber with helium was measured with the help of a copper-constantan thermocouple. The entire structure was housed in a heat-insulating casing. Current configuration allowed the refrigerator to drop the temperature to 200 K in less than 20 min and return to room temperature in 60 min.

With the help of the above-described refrigeration unit, temperature dependences of energy, duration and repetition rate of laser pulses, as well as average output light power, temperature shift of the lasing peak wavelength, and conversion efficiency of the optical pump power were obtained. Also, over time, samples with the use of a polymer slightly changed their characteristics, so the measurements were carried out after the polymer solidified, after three months and after a year. The data presented in the article were obtained one year after the samples were manufactured.

4. Results and discussion

The beginning stage of fabricated Q-switches testing is to determine the lower temperature limit at which it is still possible to apply them in a laser circuit. A caused by cooling increase of refractive index of silicone used in the Q-switch leads to polymer-coated taper optical transmission drop down to zero at the laser wavelength. This can lead to the destruction of the SA material, since the optical power dissipated in the Q-switch during laser operation leads to deposition of heat in the SA material [27].

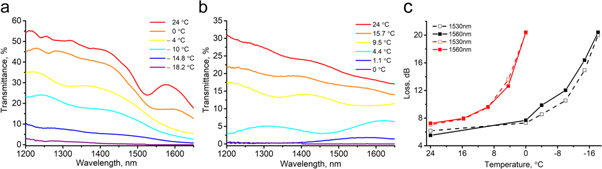

Figure 2 shows transmission spectra of modulators at different temperatures: (a)—Bi2Te3 nanopowder in silicone (sample #1), (b)—Bi2Te3 thin film covered by silicone (sample #2).

Figure 2. Transmission spectra of fiber tapers coated with: (a)—a composition of polymer-nanopowder Bi2Te3, (b)—a thin film of Bi2Te3 and a polymer at different temperatures; (c)—temperature dependence of losses at 1530 nm and 1560 nm wavelengths: black line—sample #1 (nano-powder), red—sample #2 (film).

Download figure:

Standard image High-resolution imageAs seen from the graphs in figures 2(a) and (b), the minimum temperature limits at which transmission at 1560 nm wavelength becomes less than 1% are different for samples #1 and #2 and amount to –18.5 °C and 0 °C, respectively. The polymer we used has the property of increasing the refractive index at the polymer/fiber interface [28]. Since the entire mass of the thin film is concentrated at this boundary, in contrast to the powder, scattered over the polymer volume, the change in transmission with decreasing temperature will be faster for sample #2 (figure 2(c)). The dip in the transmission spectrum of sample #1 at room temperature is due to local stress in the taper section of the optical fiber due to an inhomogeneously solidified polymer. With these diameters of the thinned part, any microbends or pressure on the surface produces a response in the transmission spectrum. It is well known that PDMS in near infrared has normal dispersion, that is, its refractive index increases with decreasing wavelength [29]. Obviously, with an increase in the polymer refractive index, the evanescent field fraction increases. This leads to the fact that, upon cooling, the transmission spectrum of the fiber-optic taper is more sensitive to changes in the refractive index, and, consequently, temperature in the short-wavelength part of the spectrum. As a result, the slope of the transmission spectrum changes with decreasing temperature. This explains the presence of an inflection in the transmission spectrum upon cooling of the polymer/film sample, which is absent in the sample with the applied polymer/powder mixture.

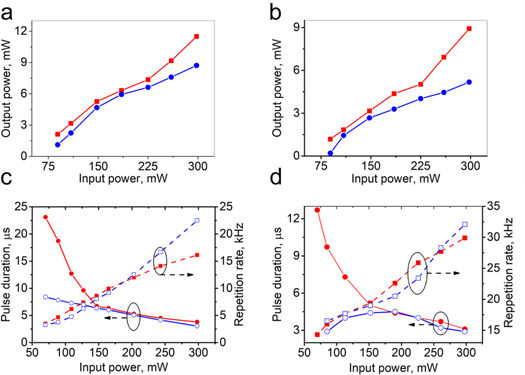

Inclusion of the obtained samples in the fiber circuit of the ring laser (figure 1) let one record the variation of lasing parameters caused by cooling of the passive Q-switch at a permanent pump power of 150 mW. At this power, a stable pulsed-repetitive regime took place at all temperatures. Figure 3 illustrates the change of the laser oscillation caused by cooling of samples #1 and #2.

Figure 3. Temperature dependencies of: (a), (b)—emission spectra; (c), (d)—1530 nm (black) and 1560 nm (red) emission peak intensity; (e), (f)—pulse duration and repetition rate; (g), (h)—pulse energy versus temperature of the passive Q-switch for sample #1 (left plots) and #2 (right plots).

Download figure:

Standard image High-resolution imageThe increase of loss in the fiber of resonator ring due to transmission drop of a passive Q-switch caused by cooling led to energy decrease of laser pulses for both samples. The duration of pulses remained unchanged to an accuracy of 6%–7%. At temperatures of –4 °C for nanopowder (#1) and 9.5 °C for thin film (#2) Q-switches an additional emission peak in the laser emission spectrum in the vicinity of 1530 nm wavelength becomes clearly seen. For sample #1, the FWHM of the lasing peaks at 1560 nm and 1530 nm is equal to 3.4 nm and 2.1 nm, respectively. Cooling leads to broadening of the peaks by 0.2 nm. And for the sample #2 FWHM lasing peaks at the same waves were 6.5 and 4 nm. For this sample, the broadening of the lasing peaks upon cooling is greater and equal to 0.5 nm. At the same time, the pulse repetition rate begins to sharply increase, and reaches a maximum value at temperatures of –14.8 and 4.4 °C, for samples #1 and 2, respectively, exceeding room temperature values by more than 20% and 40% in both cases. Simultaneously, laser radiation power at a wavelength of 1530 nm begins to significantly exceed this value at a wavelength of 1560 nm. Further cooling leads to a decrease in the pulse repetition rate. The appearance of a second emission peak with an increase in resonator loss is characteristic of fiber circuits containing an erbium doped fiber as an active medium, which gain is greater in a shorter wavelength region of the gain spectrum [29]. An increase of loss in the laser ring upon Q-switch cooling leads to the fact that the launched pump power becomes insufficient to excite the entire length of the active fiber and, therefore, to maintain laser oscillation at a wavelength of 1560 nm. However, the remaining 'pumped' fiber length is sufficient to support lasing at 1530 nm, since an optimal length of the active fiber required to achieve maximum gain at 1530 nm wavelength is shorter than in the case of 1560 nm [30]. The duration and repetition rate of pulses can be calculated as follows [31]:

where  —is the pulse duration,

—is the pulse duration,  —is the resonator round-trip time,

—is the resonator round-trip time,  —is the modulation depth,

—is the modulation depth,  —is the pulse repetition rate,

—is the pulse repetition rate,  —is the weak signal gain,

—is the weak signal gain,  —is the lifetime of active ions of the gain medium at the upper energy level. The duration of pulses shown in figures 3(e) and (f) practically does not change with the decrease of the temperature, therefore, according to equation (1) one can conclude that cooling does not affect the modulation depth of SA. Whereas the radiation power absorbed by SA obviously increases (figure 2), therefore, at a given pump power, SA operates within a saturation plateau. The increase in the pulse repetition rate is caused by the appearance of a shorter-wavelength emission peak and the superposition of pulse trains from the two emission lines. Since the erbium active fiber has a gain at 1530 nm higher than at 1560 nm [30], the pulses arising from this peak have a higher repetition rate. A train of these pulses, when superimposed on the initial one at a wavelength of about 1560 nm, lead to an increase in the resulting repetition rate. Its maximum occurs when only a shorter-wavelength laser line remains. Further cooling leads to an increase in loss and a decrease of the peak intensity at 1530 nm, that causes a decrease in the total laser pulse repetition rate. Such behavior of the repetition rate is applicable to both test samples. Having defined a temperature range in which the transmission of passive Q-switches does not drop below 1%, changes in the characteristics of output radiation of the fabricated laser circuits were investigated at a fixed temperature, below room temperature, in a wide range of pump powers.

—is the lifetime of active ions of the gain medium at the upper energy level. The duration of pulses shown in figures 3(e) and (f) practically does not change with the decrease of the temperature, therefore, according to equation (1) one can conclude that cooling does not affect the modulation depth of SA. Whereas the radiation power absorbed by SA obviously increases (figure 2), therefore, at a given pump power, SA operates within a saturation plateau. The increase in the pulse repetition rate is caused by the appearance of a shorter-wavelength emission peak and the superposition of pulse trains from the two emission lines. Since the erbium active fiber has a gain at 1530 nm higher than at 1560 nm [30], the pulses arising from this peak have a higher repetition rate. A train of these pulses, when superimposed on the initial one at a wavelength of about 1560 nm, lead to an increase in the resulting repetition rate. Its maximum occurs when only a shorter-wavelength laser line remains. Further cooling leads to an increase in loss and a decrease of the peak intensity at 1530 nm, that causes a decrease in the total laser pulse repetition rate. Such behavior of the repetition rate is applicable to both test samples. Having defined a temperature range in which the transmission of passive Q-switches does not drop below 1%, changes in the characteristics of output radiation of the fabricated laser circuits were investigated at a fixed temperature, below room temperature, in a wide range of pump powers.

For both samples, this temperature corresponds to a decrease in transmission by 5%–10% at a wavelength of 1560 nm, and amounts to 0 °C and 15 °C for samples #1 and 2, respectively. The data obtained were compared with the laser oscillation characteristics measured at room temperature. The results of the comparison are present in figure 4.

Figure 4. Output power (a,) (b), pulse duration and repetition rate (c), (d) for the ring EDFL at different temperatures of the passive Q-switch #1 (left) and #2 (right). Red graphs correspond to a temperature of 24 °C, blue ones to 0 °C on the left and 15 °C on the right.

Download figure:

Standard image High-resolution imageAn obvious decrease in the energy conversion efficiency owing to an increase of loss in the laser circuit is observed. The reduced temperature of sample #1 led to a higher threshold of pump power for the onset of pulsed regime: 64 mW versus 54 mW at room temperature, but led to 2.75 times shorter laser pulses at a pump power of up to 100 mW and, higher repetition rates, at power exceeding 295 mW than at room temperature. Cooling led to an increase in the pulse repetition rate by 45% at a pump power of 295 mW. Cooling of the passive Q-switch with a thin polymer-coated Bi2Te3 film also increased the threshold for the onset of the pulsed oscillation regime from 68 mW at room temperature to 82 mW; however, pulses at a pump power of up to 100 mW are 3.5 times narrower than at room temperature.

As pulse duration and repetition rate changed over time, the oscillation mode is unstable. With the increase in pump power up to 150 mW, the oscillation mode becomes stable. At room temperature, an increment in the pump power leads to an increase in repetition rate and a reduction in pulse duration. Such behavior is typical for passive Q-switch mode oscillation [6, 7, 32–35].

A cooled saturable absorber in the form of a Bi2Te3 thin film coated with a polymer demonstrates an increase in the duration of laser pulses with increasing pump power. In addition, the sevenfold pulse duration decrease in a laser circuit caused by cooling SA down, from room temperature may indicate to a decrease in the modulation depth of the transmission caused by saturation absorption in the deposited film. This decrease is associated with the film temperature rise due to heat deposition with an increased pump power. The latter leads to an increase in the concentration of equilibrium carriers thermally activated into the conduction band. This, in turn, cuts down the concentration of photoinduced charge carriers in the bands necessary for the manifestation of the saturation absorption effect and leads to the onset of absorption saturation at a lower light intensity and, therefore, to a decrease in modulation depth of the transmission.

The maximum pulse duration appears at a pump power of 190 mW and begins to decrease with a further increase in the pump power.

With the pump power increase, accompanied by an increase of the pulse repetition rate, Q-switch loss the form of heat deposition increases as well, that leads to an energy decrease stored in the ring resonator.

The quality factor of the resonator can be expressed by the equation [36]:

where Q—is the quality factor,  —is the stored energy,

—is the stored energy,  —is the energy lost per round trip of the resonator. At a pump power greater than 225 mW, the amount of stored energy becomes sufficient for the Q-factor to increase and the pulses begin to narrow.

—is the energy lost per round trip of the resonator. At a pump power greater than 225 mW, the amount of stored energy becomes sufficient for the Q-factor to increase and the pulses begin to narrow.

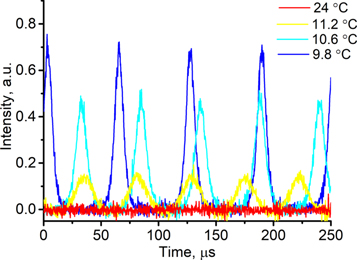

In conducted MOCVD experiments on the fabrication of Q-switches based on thin Bi2Te3 films, there was a high percentage of unusable samples. Due to a high deposition rate, it was not always possible to stop timely the film growth yielding the transmission of the coated taper close to 45%. The latter is necessary to maintain the repetitively-pulse oscillation mode as the result of the Q-switch instalment into the laser circuit. Since the required coating thickness is reached within a few seconds of the deposition process, it is technically difficult to get within the required absorption range repeating deposition runs. An alternative to the film growing process is to increase absorption by applying an additional silicone covering. In some cases, the absorption of the taper with the film became sufficient to obtain the repetitively-pulse mode. The transmission of sample #3 with a 4 mm long thinned part of 12 μm in diameter, changed from 87 to 34% at a wavelength of 1560 nm as the result of silicone covering. At room temperature, no repetitively-pulse mode for the laser with this SA sample is observed in the entire studied range of pump powers. This is associated with the insufficiently strong interaction of light with the material of the SA film. By lowering the temperature of the silicone, we achieved repetitively-pulse oscillation mode due to an increase of the light absorption with the SA film. Figure 5 shows trains of pulses for the ring EDFL at a pump power of 125 mW corresponded to the different temperatures of the SA (sample #3).

Figure 5. Evolution of EDFL pulse trains on cooling fiber taper #3 covered by a Bi2Te3/silicone film structure.

Download figure:

Standard image High-resolution imageAs soon as the necessary loss level is achieved, a repetitively-pulse oscillation mode similar to sample #2 (see figure 2) arises in the cavity. The pulse repetition rate increases upon cooling to a temperature of 10.6 °C, and then drops, down to the complete termination of the repetitively-pulse oscillation mode because of the too great loss increase.

5. Conclusion

Repetitively-pulse oscillation from a ring erbium-doped fiber laser is studied at different temperatures of a fiber taper coated with a saturable absorber layer as a Q-switch. It is found that a decrease of the temperature of saturable absorbers in the form of Bi2Te3 nanopowder-polymer composition and in the form of polymer covered Bi2Te3 thin film makes it possible up to 20% and 40% add to the pulse repetition rate at the same pump power. EDFL with both types of Q-switches showed the presence of a maximum in the dependence of pulse repetition rate on temperature. During the cooling process, the laser oscillation peak wavelength changes from 1560 to 1530 nm. This is due to growth of loss in the resonator's a fiber ring caused by cooling, so that the launched pump power becomes insufficient to completely pump total length of the active fiber and hence to maintain laser oscillation at a wavelength of 1560 nm. The reduced steady-state temperature (0 °C) of the passive Q-switch in the form of a Bi2Te3 nanopowder in a polymer results in 2.75 times shorter pulses at the onset of laser oscillation and by 50% higher repetition rate than at room temperature at the maximum pump power of 295 mW. An insignificant steady-state cooling (up to 15 °C) of the passive Q-switch with a polymer covered Bi2Te3 thin film led to the decrease in the pulse duration by a factor of 3.25 as compared to room temperature, at the pump power that ensures the transition of the laser from CW to repetitively-pulsed oscillation mode. A saturable absorber in the form of a thin film of bismuth telluride in a passive Q-switch demonstrates higher pulsed lasing frequencies and shorter pulses, compared to the nanopowder implementation. It also increases the pulse repetition rate more with cooling. Taking all this into account, a Bi2Te3 thin film is more preferable as a saturable absorber. Moreover, by variation of the passive Q-switch temperature, it is possible to realize repetitively-pulsed oscillation in a circuit which did not support this oscillation mode at room temperature.

Acknowledgments

This study was performed work with the support by the Academic Excellence Project 5–100 proposed by Peter the Great St. Petersburg Polytechnic University (D P Sudas) and according to a State Job of the Kotelnikov Institute of Radio Engineering and Electronics RAS, and supported partly by the Russian Foundation for Basic Research, projects no. 20–07–00326.

Data availability statement

All data that support the findings of this study are included within the article (and any supplementary files).