Abstract

Biomaterials are natural/synthetic materials used to perform the functions of living tissues in the body. Biomaterials are in contact with fluids continuously or for a certain period. The body's reactions to these materials are extremely different. For this reason, the correct selection of biomaterials is essential. In this research, a novel multi-criteria decision-making procedure (Reference Ideal Method) has been used for orthopedists/practitioners, prosthesis and implant manufacturers. This method produces successful results, especially in target-based problems. The method has not been used for the selection of target-based biomaterials before. In this study, it was applied to two different biomaterial selection problems from the literature. Consistent results have been produced with studies in the literature.

Similar content being viewed by others

1 Introduction

Engineers/manufacturers handle the problem of choosing materials in design engineering. Due to progress in materials and manufacturing science, several materials are now available. Consequently, the choice of materials can be a complicated issue. Multiple criteria decision making (MCDM) procedure can derive a mathematical framework for the material selection process. Target-based MCDM methods can be significant when goal values are desired in the selection process. When all kinds of criteria are considered in target-based MCDM, it can be an extensive form of conventional decision-making (DM) with several criteria.

In different problems based on material selection, the selected materials should be consistent in terms of different methods. Thus, target values should be taken into account for materials characteristics to provide compatibility [1]. A target value should be defined for the thermal expansion coefficient to select electrical insulating materials [2]. Material hardness, density and elastic modulus are other examples for target-based criteria [3]. The material characteristics are essential to choosing appropriate implants and prostheses’ materials [4, 5]. DM procedures with target-based criteria attracted the attention of several researchers. Jahan and Edwards [6] studied the target-based Vise Kriterijumska Optimizacija I Kompromisno Resenje (VIKOR) procedure for knee prosthesis material selection. They enhanced the Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) and VIKOR models to choose materials for the femoral element of a hip prosthesis using target values. Liu et al [7] presented a hybrid approach by incorporating Analytic Network Process (ANP) model based on the decision-making trial and evaluation laboratory (DEMATEL) approach and the target-based VIKOR procedure to choose bush of a split journal bearing’s material. Hafezalkotob and Hafezalkotob [5] resolved different problems based on biomaterial selection via target-based MULTIMOORA method. Jahan and Edwards [2] reviewed the uses of target-based normalization techniques. Petkovic et al [8] developed a decision support system by hybridizing three MCDM tools to select desired bone implants biomaterial alternative. Abd et al [9] used a fuzzy approach for the TOPSIS technique to select hip joint prosthesis material. Kabir and Lizu [10] developed a hybrid FAHP/PROMETHEE method for the femoral material selection problem. Chowdary et al [11] determined a new strategy to rank bioengineering materials under a hybrid approach (fuzzy AHP and TOPSIS). The article suggests that Polyether ether ketone (PEEK) material is appropriate for biomedical implantations. Xue et al [12] used an original target-based norm in a multi-attributive border approximation area comparison (MABAC) technique to choose the suitable hip implant material. Hafezalkotob and Hafezalkotob [13] used an interval MULTIMOORA technique using target values of criteria and interval distance and preference degree were taken into account. Two different studies, which are hip and knee joint prosthesis materials selection, were used. Ristic et al [14] designed a fuzzy expert system for implant biomaterial selection. Hafezalkotob et al [15] used a normalization procedure based on an exponential target for developing Weighted Aggregated Sum Product Assessment (WASPAS) technique to choose olive harvester machinery. Liao et al [16] derived an extended target-based formula to solve MCDM problems using the benefit, cost and target criteria. Practically the ideal solution is not necessarily one of the extreme values, but maybe a value somewhere in between. For several MCDM techniques, the techniques are based on the data; this implies that when adding a new option or only by changing the data of one of the options, it is then essential to carry out the aggregation of the information for all the options. This problem is called rank reversal problem in the literature. The methods used in target-based criteria problems do not solve the rank reversal problem in the literature. Reference Ideal Method (RIM) is a novel MCDM procedure designed by Cables et al [17]. The procedure is used to eliminate the problems mentioned before. It can be used to solve target-based criteria problems. Newly, Cables et al [18] proposed the RIM in a fuzzy MCDM environment. Also, Lozano and Rodriguez [19] studied Fuzzy RIM to select military training aircraft.

In this article, a novel MCDM (RIM) method has been used for orthopedists/practitioners, and prosthesis and implant manufacturers. Two different biomaterial selection case studies (hip prosthesis material selection and femur component material selection problems) have been selected to use this method. This procedure has not been used in biomaterial applications to the best of our knowledge, which is one of the target-based criteria problems. In the study, a new hybrid approach was proposed for RIMs with different subjective and objective weighting methods (modified digital logic (MDL), SIMOS, standard deviation and dependency weighting).

In the first stage of the research, the RIM stages and a newly proposed method are given. In the second step, two different biomaterial selection applications from the literature are explained. In the third stage, the solution of these problems with RIM is mentioned. The results are compared to the literature. Results and suggestions are included in the last stage.

2 Methods

2.1 RIM

This technique was proposed by Cables et al [17]. The procedure is given as follows.

-

Step 1: Normalization stage. The reference ideal interval is determined. The interval contains label sets and simple values that show the maximum importance or relevance (Eqs. 1–3).

$$ di_{min} \left( {x,\left[ {C,D} \right]} \right) = {\text{min}}\left( {\left| {x - C} \right|\left| {x - D} \right|} \right) $$(1)$$ \left( {x,\left[ {A,B} \right],\left[ {C,D} \right]} \right) = \left\{ {\begin{array}{*{20}c} 1 & {{\text{if}}\;{\text{x}} \in \left[ {{\text{C}},{\text{D}}} \right]} \\ {1 - \frac{{di_{min} \left( {x,\left[ {C,D} \right]} \right)}}{{\left| {A - C} \right|}}} & {if\;x \in \left[ {A,C} \right] \wedge A \ne C} \\ {1 - \frac{{di_{min} \left( {x,\left[ {C,D} \right]} \right)}}{{\left| {D - B} \right|}}} & {{\text{if}}\;x \in \left[ {{\text{D}},{\text{B}}} \right] \wedge {\text{D}} \ne {\text{B}}} \\ \end{array} } \right\} $$(2)$$ y = \left[ {f\left( {x_{ik} ,t_{k} ,s_{k} } \right)} \right] $$(3)\(\left[ {A, B} \right]\): range for universe of discourse

\(\left[ {C,D} \right]\): reference ideal interval

\(di\): distance to reference ideal interval

\(s_{k} :\) reference ideal

x is the value for a given approach

x∈[A,B] and [C,D]⊂[A,B] should be satisfied.

The function f allows finding a value that belongs to the unitary interval.

k = 1 to m (number of criteria)

i = 1 to n (number of options)

-

Step 2: Compute the weighted normalized matrix \((\dot{y}_{ik} )\).

-

Step 3: Compute the variation to the normalized reference ideal for each option (Eqs. 4–5)

$$ I_{e}^{ - } = \sqrt {\mathop \sum \limits_{k = 1}^{m} \left( {\dot{y}_{ik} } \right)^{2} } $$(4)$$ I_{e}^{ + } = \sqrt {\mathop \sum \limits_{k = 1}^{m} \left( {\dot{y}_{ik} - w_{k} } \right)^{2} } $$(5) -

Step 4: Compute the relative index (\(R_{e} )\) using Eq. 6.

$$ R_{e} = \frac{{I_{e}^{ - } }}{{I_{e}^{ - } + I_{e}^{ + } }} $$(6) -

Step 5: Rank the options.

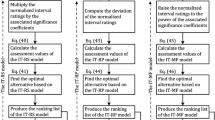

2.2 Proposed method

In this study, a new hybridized RIM was proposed. Different criteria weighting methods (MDL, SIMOS, standard deviation and dependency weighting) were used to weight criteria. Later, RIM was used to obtain final rankings. Also, the criteria weighting methods were combined to perform sensitivity analysis. More information about these methods are given in the literature [20,21,22,23]. The flowchart of the proposed method is given in figure 1.

3 Case studies

3.1 Case study-1: hip prosthesis material selection

A hip replacement consists of three primary components: femoral component, acetabular cup and acetabular interface. The femoral component is a hard metal pin. The hip socket (acetabulum) is placed with an acetabular cup. The acetabular interface is placed between the femoral component and the acetabular cup. It includes various material combinations to reduce friction-related wear residues. Appendex A lists the materials/criteria used in the analysis.

3.2 Case study-2: femur component material selection

The knee replacement is implanted into the human body to restore function and form. To obtain a natural knee performance, prosthetic materials need to have a variety of properties. In this matrix, currently used metallic biomaterials (biocompatible materials) and newly developed metallic biomaterials that could potentially be used for the femoral component of knee joint implants are taken into account. For any knee implant to be successful, it must have high wear resistance, high modulus of elasticity and high biocompatibility. Appendex B summarizes the range of parameters used in the analysis.

4 Results and discussion

4.1 Case study-1

Different criteria weighting methods used in the literature were selected in this study. The criteria weights used are given in table 1. MDL approach was used for subjective criteria weighting, whereas standard deviation method was used for objective criteria weighting. When the criteria weights are evaluated the criteria of tissue tolerance and corrosion resistance have the highest weight for subjective weighting, while corrosion resistance and relative toughness have the highest weight for objective weighting. The determined matrices are given as follows:

Different criteria weights were integrated into the RIM method. Thus, final rankings were obtained. The rankings are shown in table 2. Co–Cr alloys-wrought alloy and Ti6Al4V are the best alternatives, whereas Composites (fabric reinforced) Epoxy-63% carbon and Composites (fabric reinforced) Epoxy-62% aramid are the worst alternatives according to the ranking results. In terms of different assigned weights, the Spearman test was used to evaluate significance of the difference between Jahan and Edwards’s [20] literature ranking in table 2. There is no significant difference between the rankings (r > 0.61, p < 0.05). As a result, it can be said that the result does not change significantly according to different criteria weights.

According to Jahan and Edwards’s [20] weighting method, different λ values were tried to perform sensitivity analysis. In the analysis, subjective, objective and dependency weights were integrated as given in Eq. (7).

\(w_{j}^{s}\): subjective weighting (MDL)

\(w_{j}^{o}\): objective weighting (standard deviation)

\(w_{j}^{c}\): dependency weighting

\(\lambda\): sensitivity coefficient \(0 \le \lambda \le 1\)

n: the number of criteria.

The results were compared in terms of the correlation test of Spearman. The final results are shown in table 3. The rankings are nearly the same (r > 0.73, p < 0.05). Co–Cr alloys-wrought alloy and Ti6AlV are the best options. The undesired options are nearly the same as those with the rankings in table 2.

4.2 Case study-2

Different criteria weighting methods used in the literature were used in case study-2. The weights are shown in table 4. Two subjective criteria weighting methods (MDL and SIMOS weighting) were used. When the criteria weights are evaluated, it is seen that the highest criterion weight belongs to the wear resistance and the lowest criterion weight to density. The determined matrices are given as follows:

Different criteria weights in table 4 are integrated into the RIM method. Thus, final rankings were obtained. The rankings are given in table 5. According to the results, NiTi SMA and Porous NiTi SMA are the best alternatives. The Spearman correlation test was used to verify statistical significance with Bahraminasab and Jahan’s [21] ranking in terms of different criteria weights. This test indicates no statistical difference and the rankings are nearly the same (r > 0.8, p < 0.05). As a result, it can be said that the result does not change significantly according to different criteria weights.

According to Bahraminasab and Jahan’s [21] weighting method, different λ values were tried to perform sensitivity analysis. Eq. (8) was used to perform the analysis:

\(w_{j}\): average weight

\(w_{j}^{1}\): pairwise comparing weight (MDL)

\(w_{j}^{2}\): direct weight (SIMOS)

\(\lambda\): sensitivity coefficient, \(0 \le \lambda \le 1\)

n: the number of criteria.

The results were compared in terms of Spearman correlation test. The final results are given in table 6. The rankings are nearly the same (r > 0.98, p < 0.05). NiTi SMA and Porous NiTi SMA are the best options. Stainless steel (annealed) is the worst option, as in table 5.

4.3 Limitation of the study

The absence of Pareto optimality limited this study. Several criteria may be mutually conflicting. In such a scenario, a Pareto-optimality determination can be more appropriate than a weighting method. Multi-objective optimization based upon the notion of Pareto-optimality and evolutionary algorithms has been applied earlier for biomaterials. Reduced Space Searching, Artificial Neural Network and Genetic algorithms were used to design Ti alloys for bio-applications [24,25,26]. In future studies, these methods can be considered and hybridized.

5 Conclusions

In this research, a new MCDM method (RIM) has been used for biomaterial selection. The method has been tested on two different biomaterial selection problems taken from the literature. The results were compared to the studies in the literature. Co–Cr alloys-wrought alloy and Ti6Al4V are the desired options for hip prosthesis material. For femur component selection problem, NiTi SMA and Porous NiTi SMA are the best alternatives. The rankings are consistent in terms of the Spearman correlation test (p < 0.05). Also, according to sensitivity analysis, the rankings are nearly the same (p < 0.05). In general, it has been observed that the method does not depend on the criteria weight values (p < 0.05). In future studies, RIM can be hybridized with different criteria weighting methods. Besides, a program can be developed using C++ platform to make the DM process more interactive. Moreover, the price can be considered as a criterion for femur component selection problem.

References

Farag M M 2013 Materials and process selection for engineering design, 3rd ed. Boca Raton: CRC

Jahan A and Edwards K L 2015 A state-of-the-art survey on the influence of normalization techniques in ranking: improving the materials selection process in engineering design. Mater. Des. 65: 335–342

Cavallini C, Giorgetti A, Citti P and Nicolaie F 2013 Integral aided method for material selection based on quality function deployment and comprehensive VIKOR algorithm. Mater. Des. 47: 27–34

Bahraminasab M, Sahari B, Edwards K, Farahmand F, Jahan A, Hong T S and Arumugam M 2014 On the influence of shape and material used for the femoral component pegs in knee prostheses for reducing the problem of aseptic loosening. Mater. Des. 55: 416–428

Hafezalkotob A and Hafezalkotob A 2015 Comprehensive MULTIMOORA method with target-based attributes and integrated significant coefficients for materials selection in biomedical applications. Mater. Des. 87: 949–959

Jahan A and Edwards K L 2013 VIKOR method for material selection problems with interval numbers and target-based criteria. Mater. Des. 47: 759–765

Liu H C, You J X, Zhen L and Fan X J 2014 A novel hybrid multiple criteria decision making model for material selection with target based criteria. Mater. Des. 60: 380–390

Petkovic D, Madic M, Radenkovic G, Manic M and Trajanovic M 2015 Decision support system for selection of the most suitable biomedical material. In: Proceedings of the 5th International Conference on Information Society and Technology, Serbia, pp. 27–31

Abd K, Hussein A and Ghafil A 2016 An intelligent approach for material selection of sensitive components based on fuzzy TOPSIS and sensitivity analysis. In: Proceedings of the 30th Academics World International Conference, Australia, pp. 13–18

Kabir G and Lizu A 2016 Material selection for femoral component of total knee replacement integrating fuzzy AHP with PROMETHEE. J. Intell. Fuzzy Syst. 30: 3481–3493

Chowdary Y, Sai Ram V, Nikhil E V S, Vamsi Krishna P N S and Nagaraju D 2016 Evaluation and prioritizing of biomaterials for the application of implantation in human body using fuzzy AHP and TOPSIS. Int. J. Control Theory Appl. 9: 527–533

Xue Y X, You J X, Lai X D and Liu H C 2016 An interval-valued intuitionistic fuzzy MABAC approach for material selection with incomplete weight information. Appl. Soft Comput. 38: 703–713

Hafezalkotob A and Hafezalkotob A 2017 Interval MULTIMOORA method with target values of attributes based on interval distance and preference degree: biomaterials selection. J. Ind. Eng. Int. 13: 181–198

Ristic M, Manic M, Mišic D, Kosanovic M and Mitkovic M 2017 Implant material selection using expert system.Facta Univ. Ser. Mech. Eng. 15: 133–144

Hafezalkotob A, Hami-Dindar A, Rabie N and Hafezalkotob A 2018 A decision support system for agricultural machines and equipment selection: a case study on olive harvester machines. Comput. Electron. Agric. 148: 207–216

Liao H, Wu X and Herrera F 2018 DNBMA: a double normalization based multi-aggregation method. In: Proceedings of the IPMU: International Conference on Information Processing and Management of Uncertainty in Knowledge-Based Systems, Spain, pp. 63–73

Cables P E, Lamata M T and Verdegay J L 2016 RIM-reference ideal method in multicriteria decision making. Inf. Sci. 337–338: 1–10

Cables E, Lamata M T and Verdegay J L 2018 FRIM—fuzzy reference ideal method in multicriteria decision making. In: Collan M and Kacprzyk J (Eds) Soft Computing Applications for Group Decision-making and Consensus Modeling. Studies in Fuzziness and Soft Computing. Cham: Springer, vol. 357. https://doi.org/10.1007/978-3-319-60207-3_19

Lozano S J M and Rodríguez O N 2020 Application of fuzzy reference ideal method (FRIM) to the military advanced training aircraft selection. Appl. Soft Comput. 88: 106061

Jahan A and Edwards K L 2013 Weighting of dependent and target based criteria for optimal decision-making in materials selection process: biomedical applications. Mater. Des. 49: 1000–1008

Bahraminasab M and Jahan A 2011 Material selection for femoral component of total knee replacement using comprehensive VIKOR. Mater. Des. 32: 4471–4477

Shanian A, Milani A S, Carson C and Abeyaratne R C 2008 A new application of ELECTRE III and revised Simos’ procedure for group material selection under weighting uncertainty. Knowl. Based Syst. 21: 709–720

Dehghan-Manshadi B, Mahmudi H, Abedian A and Mahmudi R 2007 A novel method for materials selection in mechanical design: combination of non-linear normalization and a modified digital logic method. Mater. Des. 28: 8–15

Datta S, Zhang Q, Sultana N and Mahfouf M 2013 Optimal design of titanium alloys for prosthetic applications using a multiobjective evolutionary algorithm. Mater. Manuf. Processe. 28: 741–745

Thomas K A, Dey S, Sultana N, Sarkar K and Datta S 2020 Design of Ti composite with bioactive surface for dental implant. Mater. Manuf. Process. 35: 643–651

Chakraborti N 2014 Critical assessment 3: the unique contributions of multi-objective evolutionary and genetic algorithms in materials research. Mater. Sci. Technol. 30: 1259–1262

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sofuoğlu, M.A. A new biomaterial selection approach using reference ideal method. Sādhanā 46, 36 (2021). https://doi.org/10.1007/s12046-021-01559-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-021-01559-7