Abstract

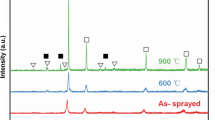

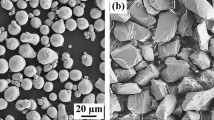

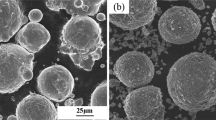

This study deals with Al2O3-13wt.%TiO2-reinforced CoCrFeMnNi high-entropy alloy (HEA) composite coatings prepared by plasma spraying. The effect of the Al2O3-TiO2 ceramic phase on the microstructure, mechanical properties and high-temperature tribological performance of the as-sprayed composite coatings was investigated. The results showed that the composite coatings consisted of a HEA phase with a FCC (face-centered cubic) structure and an Al2O3-TiO2 ceramic phase with a three-dimensional network structure. The coatings presented a typical layered structure with less porosity than pure HEA coatings. The three-dimensional network structure was mainly due to partially melted Al2O3-13wt.%TiO2 particles during the spraying process. The composite coating with Al2O3-TiO2 ceramic phase had an improved plastic deformation resistance and a reduced elastic recovery resistance. Its wear rate was lower than that of the pure HEA coating. The main wear mechanisms included oxidation, wear and adhesive wear. The Al2O3-TiO2 ceramic phase reduced the adhesive wear and promoted the tribological behavior of the HEA composite coating at low temperature. The excellent wear resistance of the as-sprayed coating at high temperatures was mainly due to the formation of an oxide layer on the worn surface.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Nanostructured High-entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6(5), p 299-303

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Microstructural Development in Equiatomic Multicomponent Alloys, Mater. Sci. Eng. A, 2004, 375, p 213-218

Z. Lyu, C. Lee, S. Wang, X. Fan, J.W. Yeh, and P.K. Liaw, Effects of Constituent Elements and Fabrication Methods on Mechanical Behavior of High-Entropy Alloys: A Review, Metall. Mater. Trans. A, 2019, 50(1), p 1-28

A. Meghwal, A. Anupam, B.S. Murty, C.C. Berndt, R.S. Kottada, and A.S.M. Ang, Thermal Spray High-Entropy Alloy Coatings: A Review, J. Therm. Spray Tech., 2020, 29, p 857-893

D.B. Miracle and O.N. Senkov, A Critical Review of High Entropy Alloys and Related Concepts, Acta Mater., 2017, 122, p 448-511

J. Li, Y. Huang, X. Meng, and Y. Xie, A Review on High Entropy Alloys Coatings: Fabrication Processes and Property Assessment, Adv. Eng. Mater., 2019, 21(8), p 1900343

J. Cheng, Y. Feng, C. Yan, X. Hu, R. Li, and X. Liang, Development and Characterization of Al-Based Amorphous Coating, JOM, 2019, 72(2), p 745-753

Z. Piao, B. Xu, H. Wang, and X. Yu, Rolling Contact Fatigue Behavior of Thermal-Sprayed Coating: A Review, Crit. Rev. Solid State, 2019, 2019, p 1-28

Y. Han, H. Chen, D. Gao, G. Yang, B. Liu, Y. Chu, J. Fan, and Y. Gao, Microstructural Evolution of NiCoCrAlHfYSi and NiCoCrAlTaY Coatings Deposited by AC-HVAF and APS, J. Therm. Spray Techn., 2017, 26(8), p 1-18

J. Xiao, H. Tan, Y. Wu, J. Chen, and C. Zhang, Microstructure and Wear Behavior of FeCoNiCrMn High Entropy Alloy Coating Deposited by Plasma Spraying, Surf. Coat. Tech., 2020, 385, p 125430

A.S.M. Ang, C.C. Berndt, M.L. Sesso, A. Anupam, S. Praveen, and R.S. Kottada, Plasma-Sprayed High Entropy Alloys: Microstructure and Properties of AlCoCrFeNi and MnCoCrFeNi, Metall. Mater. Trans. A, 2015, 46(2), p 791-800

C. Wang, J. Yu, Y. Zhang, and Y. Yu, Phase Evolution and Solidification Cracking Sensibility in Laser Remelting Treatment of the Plasma-Sprayed CrMnFeCoNi High Entropy Alloy Coating, Mater. Des., 2019, 182, p 108040

A. Piglione, B. Dovgyy, C. Liu, C.M. Gourlay, P.A. Hooper, and M.S. Pham, Printability and Microstructure of the CoCrFeMnNi High-Entropy Alloy Fabricated by Laser Powder Bed Fusion, Mater. Lett., 2018, 224, p 22-25

J. Ahn, Y.K. Kim, S.H. Yoon, and K.A. Lee, Tuning the Microstructure and Mechanical Properties of Cold Sprayed Equiatomic CoCrFeMnNi High-Entropy Alloy Coating Layer, Met. Mater. Int., 2020, 2020, p 1-10

J. Cheng, D. Liu, X. Liang, and Y. Chen, Evolution of Microstructure and Mechanical Properties of In Situ Synthesized TiC-TiB2/CoCrCuFeNi High Entropy Alloy Coatings, Surf. Coat. Tech., 2015, 281, p 109-116

J. Wang, B. Zhang, Y. Yu, Z. Zhang, S. Zhu, X. Lou, and Z. Wang, Study of High Temperature Friction and Wear Performance of (CoCrFeMnNi)85Ti15 High-entropy Alloy Coating Prepared by Plasma Cladding, Surf. Coat. Tech., 2020, 384, p 125337

L. Jiang, W. Wu, Z. Cao, D. Deng, and T. Li, Microstructure Evolution and Wear Behavior of the Laser Cladded CoFeNi2V0.5Nb0.75 and CoFeNi2V0.5Nb High-entropy Alloy Coatings, J. Therm. Spray Tech., 2016, 25(4), p 806-814

H. Liu, J. Liu, P. Chen, and H. Yang, Microstructure and High Temperature Wear Behaviour of In-situ TiC Reinforced AlCoCrFeNi-based High-entropy Alloy Composite Coatings Fabricated by Laser Cladding, Opt. Laser Technol., 2019, 118, p 140-150

S. Wang, Q. Zhao, D. Liu, and N. Du, Microstructure and Elevated Temperature Tribological Behavior of TiO2/Al2O3 Composite Ceramic Coating Formed by Microarc Oxidation of Ti6Al4V Alloy, Surf. Coat. Tech., 2015, 272, p 343-349

W. Tian, Y. Wang, and Y. Yang, Three Body Abrasive Wear Characteristics of Plasma Sprayed Conventional and Nanostructured Al2O3-13%TiO2 Coatings, Tribol. Int., 2010, 43(5), p 876-881

V.F. Gorban, N.A. Krapivka, M.V. Karpets, A.D. Kostenko, A.N. Samelyuk, and E.V. Kantsyr, Effect of Temperature on Wear Behavior of High-entropy Alloys, J. Frict. Wear, 2017, 38(4), p 292-296

G. Deng, A.K. Tieu, X. Lan, L. Su, L. Wang, Q. Zhu, and H. Zhu, Effects of Normal Load and Velocity on the Dry Sliding Tribological Behaviour of CoCrFeNiMo0.2 High Entropy Alloy, Tribol. Int., 2020, 144, p 106116

G. Jin, Z. Cai, Y. Guan, X. Cui, Z. Liu, Y. Li, M. Dong, and D. Zhang, High Temperature Wear Performance of Laser-cladded FeNiCoAlCu High-entropy Alloy Coating, Appl. Surf. Sci., 2018, 445, p 113-122

S. Yang, Z. Liu, and J. Pi, Microstructure and Wear Behavior of the AlCrFeCoNi High-Entropy Alloy Fabricated by Additive Manufacturing, Mater. Lett., 2019, 261, p 127004

J. Joseph, N. Haghdadi, K. Shamlaye, P. Hodgson, M. Barnett, and D. Fabijanic, The Sliding Wear Behaviour of CoCrFeMnNi and AlxCoCrFeNi High Entropy Alloys at Elevated Temperatures, Wear, 2019, 428, p 32-44

Z. Chu, X. Zheng, C. Zhang, J. Xu, and L. Gao, Study the Effect of AT13 Addition on the Properties of AT13/Fe-based Amorphous Composite Coatings, Surf. Coat. Tech., 2019, 379, p 125053

A. Anupam, R.S. Kottada, S. Kashyap, A. Meghwal, B.S. Murty, C.C. Berndt, and A.S.M. Ang, Understanding the Microstructural Evolution of High Entropy Alloy Coatings Manufactured by Atmospheric Plasma Spray Processing, Appl. Surf. Sci., 2019, 505, p 144117

Y. Yang, Y. Wang, W. Tian, D. Yan, J. Zhang, and L. Wang, Influence of Composite Powders’ Microstructure on the Microstructure and Properties of Al2O3-TiO2 Coatings Fabricated by Plasma Spraying, Mater. Design, 2015, 65, p 814-822

Y. Wang, W. Tian, and Y. Yang, Thermal Shock Behavior of Nanostructured and Conventional Al2O3/13 wt% TiO2 Coatings Fabricated by Plasma Spraying, Surf. Coat. Tech., 2007, 201(18), p 7746-7754

H. Luo, P. Song, A. Khan, J. Feng, J.J. Zang, X.P. Xiong, J.G. Lü, and J.S. Lu, Alternant Phase Distribution and Wear Mechanical Properties of an Al2O3-40 wt%TiO2 Composite coating, Ceram. Int., 2017, 43(9), p 7295-7304

D. Goberman, Y. Sohn, L. Shaw, E. Jordan, and M. Gell, Microstructure Development of Al2O3-13wt.%TiO2 Plasma Sprayed Coatings Derived from Nanocrystalline Powders, Acta Mater., 2002, 50(5), p 1141-1152

B.D. Beake, V.M. Vishnyakov, and A.J. Harris, Relationship between Mechanical Properties of Thin Nitride-Based Films and Their Behaviour in Nano-Scratch Tests, Tribol. Int., 2011, 44(4), p 468-475

J. Musil, F. Kunc, H. Zeman, and H. Polakova, Relationships Between Hardness, Young’s Modulus and Elastic Recovery in Hard Nanocomposite Coatings, Surf. Coat. Tech., 2002, 154(2–3), p 304-313

R.J. Hudson, P. Zioupos, and P.P. Gill, Investigating the Mechanical Properties of RDX Crystals Using Nano-Indentation, Propell. Explos. Pyrot., 2012, 37(2), p 191-197

D.D. Liang, X.S. Wei, T.C. Ma, B. Chen, H.R. Jiang, Y. Dong, and J. Shen, Sliding Tribocorrosion Behavior of Fe-Based Bulk Metallic Glass under Corrosive Environments, J. Non-Cryst. Solids, 2019, 510, p 62-70

Z. Xiang, X. Liu, J. Ren, J. Luo, S. Shi, Y. Chen, G. Lian, S. Shao, and H. Wu, Investigation of Laser Cladding High Temperature Anti-wear Composite Coatings on Ti6Al4V Alloy with the Addition of Self-lubricant CaF2, Appl. Surf. Sci., 2014, 313, p 243-250

Y.H. Lv, J. Li, Y.F. Tao, and L.F. Hu, High-temperature Wear and Oxidation Behaviors of TiNi/Ti2Ni Matrix Composite Coatings with TaC Addition Prepared on Ti6Al4V by Laser Cladding, Appl. Surf. Sci., 2017, 402, p 478-494

M. Annasamy, N. Haghdadi, A. Taylor, P. Hodgson, and D. Fabijanic, Dynamic Recrystallization Behaviour of AlxCoCrFeNi High Entropy Alloys during High-temperature Plane Strain Compression, Mater. Sci. Eng., A, 2019, 745, p 90-106

T. Luo, X. Wei, H. Zhao, G. Cai, and X. Zheng, Tribology Properties of Al2O3/TiO2 Nanocomposites as Lubricant Additives, Ceram. Int., 2014, 40(7), p 10103-10109

Acknowledgments

This research work is supported by the National Key R&D Program of China (2018YFC1902404), National Natural Science Foundation of China (51775259), Natural Science Foundation of Jiangsu Province (BE2018091) and the Six Talent Peaks Project in Jiangsu Province.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Shuaishuai Zhu and Zhijia Zhang share the first authorship of this paper.

Rights and permissions

About this article

Cite this article

Zhu, S., Zhang, Z., Zhang, B. et al. Microstructure and Properties of Al2O3-13wt.%TiO2-Reinforced CoCrFeMnNi High-Entropy Alloy Composite Coatings Prepared by Plasma Spraying. J Therm Spray Tech 30, 772–786 (2021). https://doi.org/10.1007/s11666-021-01170-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-021-01170-6