Abstract

This paper provides an introduction to the topic of water shutoff and conformance improvement. After indicating the volumes of water produced during oilfield operations, a strategy is provided for attacking excess water production problems. Problem types are categorized, typical methods of problem diagnosis are mentioned, and the range of solutions is introduced for each problem type. In the third section of the paper, the concept of disproportionate permeability reduction is introduced—where polymers and gels may reduce permeability to water more than to oil or gas. When and where this property is of value is discussed. The fourth section describes the properties of formed gels as they extrude through fractures and how those properties can be of value when treating conformance problems caused by fractures. Section 5 covers the efficiency with which gels block fractures after gel placement—especially, the impact of fluids injected subsequent to the gel treatment.

Similar content being viewed by others

1 Volumes of water produced

Large volumes of saline water are produced during oil and gas production. In 2000, Bailey et al. (2000) reported that 3 barrels of water were produced for each barrel of oil—amounting to about 75 billion barrels of water at that time and costing an estimated $40 billion for disposal. Clark and Veil (2009) reported that 21 billion barrels of water were produced in the USA during 2007. Veil (2019) updated this number to 24.4 billion barrels for the year, 2017. Roughly half of this water is re-injected for waterflooding or enhanced oil recovery, and roughly half is injected into disposal wells. Although the salinity of this water can vary over a wide range (0.1%–40% total dissolved solids, TDS), the median salinity is 3.23% TDS and not usable for drinking or agricultural purposes (Benko and Drewes 2008).

From the operator’s viewpoint, produced water is generally a nuisance that adds cost to hydrocarbon production. There are lifting costs (associated with lifting the water from the formation to the surface), processing costs (associated with oil/water separation), and disposal costs (associated with injecting water into a disposal well, if the water is not recycled for waterflood use). Further, produced water can accentuate costs associated with corrosion, scale formation, sand production, formation damage, and environmental spills. One might consider half of the produced water as useful, in that it is re-injected for waterflooding operations (to displace oil). For the other half, it seems only a detriment.

Despite the costs and nuisance associated with water production, most operators choose to live with it. For example, with the recent boom in shale oil production in Southeast New Mexico (USA), typically four barrels of highly saline water were produced with each barrel of oil—with roughly 1 million BOPD produced here in early 2020 (Cather 2020). Because of infrastructure limitations, much of this water must be trucked to disposal wells, followed by injection at a cost of $0.65 per bbl. In spite of these costs, there was little interest in reducing the volume of water production. The zeal toward producing oil at $50–70/bbl greatly outweighed the cost of water treatment and disposal. Interestingly, for this area, less than 10% of the original oil in place will be recovered, given current projections.

Beyond living with the produced water, the next most common practice is either to sell the well or property or to simply shut in high water-cut wells. This approach is reasonable if the oil saturation is low in the area around the well. If not, what should be done? This chapter is directed toward what can be done, other than just accepting the water production. Improving sweep efficiency and reducing channeling are also very relevant to enhanced oil recovery—since the operator would much prefer that expensive injected fluids (surfactant, polymer, CO2, steam, etc.) stay in the reservoir and displace oil rather than be produced too quickly. Thus, the concepts in this chapter should be of value for any enhanced oil recovery project.

2 A strategy to attack excess water production problems

There are many different reasons why water might be produced during oil and gas production. Table 1 provides a list of many of those reasons (Seright et al. 2003).

Because each type of problem in Table 1 has a different character, each type of problem requires a different approach for solution. With unrestricted resources, the problem would be thoroughly characterized before attempting a solution. Unfortunately, for various reasons (most commonly, financial or manpower-related), adequate characterization of the water production problem often does not occur. To help this situation, many people have offered strategies to attack water production problems (Aamodt et al. 2018; Chou et al. 1994; Elphick and Seright 1997; Kabir 2001; Love et al. 1998; Mennella et al. 1999; Pappas et al. 1996; Seright et al. 2003; Smith et al. 2006; Soliman et al. 2000; Sydansk and Romero-Zeron 2011) and suggested various categorizations of problems, in an attempt to simplify the analysis. The strategy that we advocate involves looking for and solving the easiest water production problems first. The problems in Table 1 are listed roughly in increasing order of difficulty to solve. Our strategy also advocates beginning the diagnostic process using information that is already available. Thus, our approach advocates first examining existing information to determine whether any of the first listings in Table 1 are the problem, before assuming that any of the last listings are the problem. If uncertainty exists about the nature of the problem, the first new money spent on additional diagnosis would be better directed at the earlier problems on the list, rather than the later problems.

The strategy involves asking four questions in the following order:

-

1.

Is there a problem?

-

2.

Does the problem occur right at the wellbore?

-

3.

Is the problem due to a fracture or fracture-like feature?

-

4.

Is the problem accentuated by crossflow?

2.1 Is there a problem?

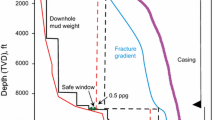

For the first question (Is there a problem?), one must ask whether the existing hydrocarbon recovery is unreasonably low for the pattern or collection of wells under consideration. The expected recovery depends on time, drive mechanism, pore volumes of fluid injected (usually water), water/oil mobility ratio, vertical heterogeneity, and pattern configuration. In a homogeneous, permeable reservoir with low oil viscosity that is efficiently produced by an edge-water drive, the expected recovery can be quite high. For example, the East Texas field (Wang et al. 2008) has produced over 5.42 billion barrels of ~ 7 billion barrels original oil in place (OOIP). For a linear waterflood in a thin homogeneous reservoir, fractional flow calculations generated Fig. 1—which plots expected oil recoveries as a function of pore volumes injected and oil/water viscosity ratio (using the conditions specified in the figure). When water displaces light (low viscosity) oil, most of the mobile oil saturation can be displaced very efficiently by injected water. However, as the oil viscosity increases, the efficiency of displacement decreases. In Fig. 1, note that at 1 PV of water injection, the mobile oil recovered decreases by about 10 percentage points for each factor of 10 increase in oil viscosity.

If the injection-production pattern changes from a perfect linear displacement (as in Fig. 1, or perhaps, between parallel horizontal injection/production wells) to a homogeneous five-spot pattern, the efficiency of waterflooding decreases by about 20% for a unit-mobility ratio (Craig 1971; Willhite 1986). Vertical heterogeneity (i.e., layering, fractures) can dramatically decrease reservoir sweep efficiency, especially for unfavorable mobility ratios with free crossflow (Craig 1971). Craig (1971) and Willhite (1986) discussed estimation of recovery efficiency as a function of well pattern, reservoir layering, permeability contrast, and oil viscosity. These references (along with standard reservoir engineering calculations/simulations) should be consulted to assess whether the observed producing water/oil ratio is unexpectedly high for your particular reservoir and wells.

2.2 Does the problem occur right at the wellbore?

The easiest excess water production problems to fix occur right at the wellbore—including flow behind pipe, casing leaks, and isolated water zones. Cement is the most common water-control material (Smith 1990), especially since it is used for all completions—to seal between the formation and the casing so that hydrocarbon-productive zones are isolated from non-productive zones.

2.2.1 Flow behind pipe

Problems with flow behind pipe (Fig. 2) exist if the primary cement placement was inadequate or if the primary cement fails (separates from the pipe or formation) after completion of the well. Common ways to detect flow behind pipe (Bassiouni 1994; Hill 1990) include cement bond logs, temperature surveys, and noise logs (if gas flows behind pipe). Problems with flow behind pipe are most commonly addressed using cement squeezes (Smith 1990). These methods usually require a workover rig, and consequently, are expensive to perform. If the channel behind pipe is quite narrow (often associated with gas or separation of the cement from the formation or pipe), cement may not be able to penetrate effectively into the channel. For these cases, gel treatments have often worked (Odorisio and Curtis 1992; Perez et al. 1997; Whitney et al. 1996). Gels are able to penetrate into very narrow channels, whereas cement often cannot. Once set, gels can have sufficient strength to resist significant pressure gradients within narrow channels or within porous media. However, they usually rupture very easily in wider channels. In contrast, cements have much greater compressive and tensile strengths (many 1000s of psi) (Smith 1990).

2.2.2 Casing leaks

Casing leaks (Fig. 3) are most commonly treated with either cement or mechanical devices (casing patches, packers, etc.) (Ernens et al. 2019; Al-Dhafeeri et al. 2020; Macrae 1997; Smith 1990). For very small leaks (pinhole leaks), cement often is ineffective—again because of limitations in penetrating small openings. Gels have been used at times to treat these small leaks (Creel and Crook 1997; Jia et al. 2020; Jurinak and Summers 1991; Urdahl et al. 1992). Leaks are commonly diagnosed with pressure tests, flow surveys (e.g., spin flowmeter), or wellbore televiewers (Johns et al. 2009; Smith 1990; Ward et al. 1994).

2.2.3 Isolated water zones

In many cases, the natural stratification provides flow barriers (e.g., shale, anhydride layers) between oil zones and water zones (Fig. 4). For those instances, isolation within the wellbore is typically pursued. In particular, for cases where water from an underlying aquifer gradually rises to flood oil zones, plug backs can effectively shut off encroaching water (Smith 1990)—where cement is placed in the bottom of the well. For cases where isolated water zones exist above isolated oil zones, mechanical devices are commonly used to stop water inflow. Gels have been used in some cases (Fulleylove et al. 1996; Plahn et al. 1997). The reader must recognize that these methods cannot be effective if fluids can crossflow beyond the wellbore. Effective barriers that isolate the water zone are detected most effectively by observing a significant pressure difference between the water zone and other zones (after accounting for gravity) (Seright et al. 2003). Flow profiles and well logs are also helpful (Bassiouni 1994; Hill 1990).

2.2.4 Deviated or horizontal wells

Deviated or horizontal wells present a special challenge for water control. On the one hand, the well can be drilled exclusively in the hydrocarbon zone of interest—thereby, theoretically avoiding water zones. Unfortunately, hydrocarbon zones still possess heterogeneity in the areal and vertical directions. Water inflow from an underlying formation can be uneven because of variations in formation thickness, vertical permeability, and placement of the well. In particular, vertical fractures or non-sealing faults can cross these wells—and allow water inflow from other formations. Diagnosis of when water enters the horizontal well is crucial information and can be accomplished using flow profiles (Cramer et al. 2020; Cui et al. 2016; Yoshioka et al. 2007). However, because of the cost and technical challenges associated with obtaining flow profiles, they are not commonly performed. Thus, making flow profiles more cost-effective or easier to perform is an important need.

Various completion types have been used for horizontal wells, including open hole, cased hole with cemented screens, pre-drilled or slotted liners, and various inflow control devices (Aljubran and Horne 2020; Furui et al. 2007; Thompson et al. 2011). Most of these allow little or no control over fluid inflow after they are installed. Common inflow flow devices are basically pipe with a certain number of openings/holes per unit of length (Augustine et al. 2008; Daneshy et al. 2012; Dikshit et al. 2020; Montero Pallares et al. 2020). More advanced inflow flow devices have mechanically activated sliding sleeves to open or cover the openings (Al-Khelaiwi et al. 2010; Augustine and Meijs 2011; Langaas et al. 2019; Li et al. 2011).

Autonomous inflow control devices have been offered which claim to selectively allow hydrocarbon entry while reducing or eliminating water entry into the pipe (Yang et al. 2020). These claims appear misleading or dubious. If the formation provides a certain fractional flow of water and oil to a particular opening in the pipe, a mass balance dictates that fractional flow must be maintained. Thus, even if these static pieces of metal could distinguish between oil and water, they cannot change the fractional flow. One could argue that a device might allow some degree of selectivity by changing the flow from laminar to turbulent at the point of entry into the pipe. In laminar flow, flow capacity is directly proportional to fluid viscosity, while in turbulent flow, flow capacity is directly proportional to density and much less sensitive to viscosity. If the oil is viscous, one might argue that forcing the flow to become turbulent favors oil entry over water (because the water is denser than oil). There are multiple flaws with this argument. First, changing the flow regime from laminar to turbulent necessarily means that the pressure drop across the device is increased dramatically, so all fluids will experience more resistance to entering the pipe. Second, if you knew enough about the local pressure conditions and fluids present at the device’s location to predict whether flow could transition from laminar to turbulent, it would be far more cost-effective to either complete or not complete the interval without using the expensive autonomous inflow control device.

Another type of passive inflow control device uses buoyant balls to open or close an opening, depending on whether oil or water is present (Augustine and Meijs 2011). Although these devices have a reasonable underlying concept, their acceptance is not yet widespread.

Some of the mechanical methods used for vertical wells are also used to control water in horizontal and deviated wells, including through-tubing bridge plugs (Al-Ghasham 2005; Al-Zubail et al. 2003), through-tubing bridge plugs with cement (Dashash et al. 2008), and coiled tubing with inflatable packers (Al-Dhafeeri et al. 2012; Al-Shahrani et al. 2007).

Intelligent completions (smart wells) are another method for control in multilateral wells (Al-Zain et al. 2016). Valves are located downhole where a lateral segment joins the main lateral. By adjusting these valves, the contributions from the high water-cut laterals can be reduced or shutoff, while allowing open flow from the more productive laterals.

2.3 Is the problem caused by a fracture or fracture-like feature?

If fractures are the source of the excess water production, cement and mechanical methods are generally ineffective—unless the fracture crosses perpendicular to the axial direction of the well (i.e., a horizontal fracture cutting through a vertical well or a transverse vertical fracture cutting through a horizontal well).

Fractured wells are very common. A large fraction of newly drilled wells is intentionally (hydraulically) fractured for stimulation of injectivity or productivity (Gidley et al. 1989). Many (perhaps most) injection well are fractured unintentionally because of poor injection water quality or because of needs to meet injectivity requirements (van den Hoek et al. 2009). Further, natural fractures are very common, especially in tighter reservoirs (Aguilar 1980).

With the proper length and orientation, fractures can enhance injectivity, productivity, and sweep efficiency (Seright 2017). Unfortunately, with the wrong length and orientation, they can accentuate channeling between injector–producer pairs or from an aquifer into a production well (Seright 2017).

2.3.1 Diagnosis

A number of methods can be used to diagnose whether a well intersects fractures. The well history can be valuable in learning whether a well has been intentionally fractured previously. Examination of well injectivity or productivity is often an easy way to judge if the well has fractures (Seright et al. 2003). In particular, if the observed injectivity or productivity is five or more times greater than the flow capacity calculated by Darcy’s law for radial flow (i.e., inputting the matrix rock permeability and thickness), a fracture must be present. Very rapid transit of a tracer between an injector–producer pair is also a definitive indicator of a fracture channel (Wagner 1977). Borehole televiewers, formation imaging logs, examination of cores, and other methods can also be of value.

There are a number of different scenarios where fractures cause excess water production. Each scenario has a somewhat different goal for solution. One of the simplest scenarios involves a single fracture that leads all the way from an injection well to a production well (Fig. 5). One might think that plugging the entire fracture might be desirable. However, this course would substantially reduce injectivity for the injection well and productivity for the production well. So, in this case the ideal solution is to plug the middle third of the fracture. That would allow high injectivity and productivity and actually increase sweep efficiency over the case were no fracture was present (Seright 2005).

A second scenario involves a system of natural fractures that connect an injection well and a production well (Fig. 6). For this case, the goal would be to block the most direct fracture while leaving the secondary fractures open to allow high injectivity (for the injection well) and productivity (for the production well). One might think that blocking the most direct channel would be of limited value because injected water would simply channel through the next most direct fracture. However, one must realize that natural fractures tend to follow a log-normal distribution of widths (Macaulay et al. 2016). Also, the conductivity of a given fracture is proportional to the third power of fracture width (Gidley et al. 1989; Seright and Lee 1999). Thus, only one or two fractures are likely responsible for the vast majority of the channeling problem. If the second-most conductive fracture has half the width of the most conductive fracture, the second-most conductive fracture will have only one-eighth the conductivity of the most conductive fracture. If the most conductive fracture is plugged, water channeling could be reduced by over 80% (so water is diverted into other parts of the reservoir to displace oil).

In a vertical production well, a single hydraulic fracture might lead from the well down into an aquifer (Fig. 7). In this case, one would like to plug the lower part of the fracture (in the aquifer), while leaving the upper of the fracture open so that oil can flow freely to the well (Seright et al. 1998, 1993).

For a vertical production well in a naturally fractured reservoir, a system of fractures may lead down to an aquifer (Fig. 8). Here, the goal would be to plug the fractures leading down into the aquifer while leaving the fractures open in the oil zone (Amaury et al. 2002).

In a horizontal production well, a fracture or fault may cross the well and lead to an aquifer (Fig. 9). In this case, the goal would be to plug the fracture without damaging those parts of the horizontal well in the remainder of the oil zone (Lane and Sanders 1995; O’Brien et al. 1999).

Gels are the most effective means that we currently have to treat excess water production through fractures (Borling 1994; Hild and Wackowski 1999; Lane and Sanders 1995; O’Brien et al. 1999; Sydansk and Moore 1992; Sydansk and Southwell 2000). Cement cannot penetrate into narrow fractures, and in wide fractures, gravity segregation makes the cement drop to the lower part of the fracture—leaving the upper part open (Seright 1995a; Seright et al. 2003). Foams may reduce fracture conductivity during injection, but wash out of fractures too easily (Hughes et al. 1999; Kantzas et al. 1999) during chase floods.

Continuous injection of foam reduces fracture channeling (Haugen et al. 2014), but may be considered a method for enhanced oil recovery rather than a fracture remediation approach, and requires a high ratio of injected gas compared to surfactant enriched water.

2.4 If the problem is associated with matrix flow, is the problem accentuated by crossflow?

Beyond the possibilities listed above, one can envision several scenarios where fractures are not responsible for excess water production. Figure 10 illustrates the case where water cones up through matrix (no fractures) from an underlying aquifer to a production well.

Figure 11 illustrates the case where water cusps through matrix (no fractures) from a nearby aquifer to a production well.

Figure 12 illustrates the cases where water channels through matrix (no fractures) from a nearby injection well to a production well.

The above problems are generally very difficult and/or expensive to correct. In concept, the coning and cusping problems in Figs. 10 and 11 could be solved by reducing the production rate enough so that gravity prevents the water from rising into the well. However, in most cases, the necessary rate reductions would not allow economic oil production rates (Richardson et al. 1987; Seright et al. 1993). A more common approach has been to use horizontal production wells instead of vertical producers (Jiang and Butler 1998). Under some circumstances, horizontal wells can reduce pressure gradients sufficiently that water does not rise into the producer. The chance of this approach working increases by (1) placing the horizontal well near the top of the oil column, (2) having a thick oil column, and (3) having a relatively light (low density and low viscosity) oil.

Several tools have helped to diagnose whether crossflow through matrix occurs in a reservoir. Well logs can identify low-permeability (e.g., shale or anhydrite) barriers that can inhibit crossflow (Bassiouni 1994; Hill 1990). Perhaps, the most effective means to assess crossflow is to place a packer between the zones of interest and examine whether a pressure difference can be maintained (Russell and Prats 1962; Seright et al. 2003).

2.4.1 WOR diagnostic plots

A valuable indication of the origin of an excess water problem can come from plots of water/oil ratio (WOR) versus time (Chan 1995; Seldal 1997; Seright 1997a). When viewed along with other information, these plots can also help identify the cause of the problem. In spite of aggressive claims to the contrary, these diagnostic plots (of WOR or WOR derivative versus time) should not be used alone to diagnose excessive water production mechanisms and problems (Seldal 1997; Seright 1997a). WOR diagnostic plots were touted as capable of distinguishing whether premature water breakthrough is caused by water coning or channeling through high-permeability layers (Chan 1995). Supposedly, gradually increasing WOR curves with negative derivative slopes are unique for coning problems, and rapidly increasing WOR curves with positive derivative slopes are indicative of a channeling problem. This method is not used to distinguish between linear flow (fracture or flow behind pipe) and radial flow for either channeling or coning. Previous work (Seright 1995a) has proven that the distinction between linear flow (associated with fractures) or radial flow (associated with unfractured matrix) is extremely important to water shutoff and conformance improvement—much more so than whether the problem is due to generic channeling or coning.

Reservoir models were built for water coning and channeling, and sensitivity analyses were conducted using numerical simulation (Seldal 1997; Seright 1997a). Reservoir and fluid parameters were varied to examine WOR and WOR derivative behavior for both coning and channeling production problems. The study demonstrated that multi-layer channeling problems could easily be mistaken as bottom-water coning, and vice versa, if WOR diagnostic plots are used alone to identify an excessive water production mechanism. Consequently, WOR diagnostic plots can easily be misinterpreted and should not be used alone to diagnose the specific cause of a water production problem (Seldal 1997; Seright 1997a).

2.4.2 Polymer flooding

In particular for reservoirs with viscous oils, polymer flooding can be an effective solution for the problem in Fig. 12 (Green and Willhite 1998; Seright 2010, 2017; Sorbie and Seright 1992). With the proper design and conditions, a polymer front can displace oil out of low-permeability zones as efficiently as in an adjacent high-permeability zone (Seright 2010, 2017; Sorbie and Seright 1992). Polymer flooding is a proven technology. Nevertheless, despite claims to the contrary, we would not characterize polymer flooding as a mature technology. Many improvements remain to be made in cost-effectiveness, polymer stability, polymer propagation (i.e., retention), process design, and understanding of mechanism of action (especially regarding the feasibility of displacement of capillary-trapped residual oil). Polymer floods involve significant expense and commitment since typically polymer banks injected must be in the range of 50%–100% pore volume (Seright 2017).

2.4.3 In-depth profile modification

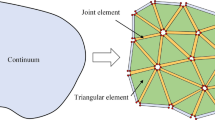

An alternative method was proposed and commercialized (Fletcher et al. 1992; Sorbie and Seright 1992) to treat problems like those in Fig. 12. A detailed examination of this method (illustrated in Fig. 13) is presented in Seright et al. (2012).

In this method, a block is placed in the high-permeability zone. This idea requires (1) the blocking agent must have a low viscosity (ideally a unit-mobility displacement) during placement, (2) the rear of the blocking-agent bank in the high-permeability zone must outrun the front of the blocking-agent bank in adjacent less-permeable zones, and (3) an effective block to flow must form at the appropriate location in the high-permeability zone (Seright et al. 2012; Sorbie and Seright 1992).

This in-depth profile modification is most appropriate for high-permeability contrasts (e.g., 10:1), high thickness ratios (e.g., less-permeable zones being 10 times thicker than high-permeability zones), and relatively low oil viscosities (Seright et al. 2012). Because the blocking agent is relatively expensive relative to HPAM (typically 5–6 times more expensive), economics favor small blocking-agent bank sizes (e.g., 5% of the pore volume in the high-permeability layer). Although short-term economics may favor in-depth profile modification, ultimate recovery will normally be considerably lower than from a traditional polymer flood (Seright et al. 2012).

The commercial process (Pritchett et al. 2003) usually involves reservoirs with a thermal front. Cold water is sometimes injected into hot reservoirs, creating a thermal front that moves through the reservoir more slowly and evenly than the displacement front (Fletcher et al. 1992). If a gelant is injected that is heat-activated, a plug could form in the high-permeability strata after the formulation passes the thermal front. With correct planning, no plug forms in the less-permeable strata because the gelant never reaches the thermal front (so the gelant never becomes hot enough to react and form a gel).

The commercialized concept uses polymer particles that pop or swell when activated (Chang et al. 2002; Frampton et al. 2004). The material contains cross-linked sulfonate-containing microparticles (0.1–3 µm in diameter) with both labile and stable internal cross-links (Frampton et al. 2004). The kernel particles are produced as a 30% dispersion in light mineral oil. This dispersion is diluted using a surfactant (surfactant/polymer ratio of 1:2–1:3) to prepare polymer concentrations from 3000 ppm to 4500 ppm (Fethi et al. 2010; Pritchett et al. 2003). The polymer cost $5.71/lb in 2003 (Pritchett et al. 2003). Activation commonly occurs upon heating. The polymer particles are intended to swell when they pass the thermal front in high-permeability watered-out strata, thus diverting subsequently injected water/fluids into the less-permeable oil strata. Estimated resistance factors for the popped polymer ranged from 11 to 350 (Frampton et al. 2004; Husband et al. 2010; Ohms et al. 2010). Field applications of the process have occurred in Indonesia (Pritchett et al. 2003), Argentina (Paez Yanez et al. 2007), Alaska (Husband et al. 2010; Ohms et al. 2010), and Tunisia (Fethi et al. 2010). Ohms et al. (2010) reported injecting ~ 40,000 lbs of polymer (38,000 bbl with 3,300-ppm polymer), and recovering ~ 60,000 bbl of oil. Husband et al. (Husband et al. 2010) reported injecting ~ 200,000 lbs of polymer (190,000 bbl with 3000 ppm polymer) into three wells, and recovering ~ 500,000 bbl of oil. Interestingly, successful polymer floods commonly recover two or more times more oil per pound of polymer than observed with this in-depth profile modification method (Taber et al. 1997). In general, polymer flooding is a much less complicated, less risky, and more cost-effective method than in-depth profile modification (Seright et al. 2012). Seright et al. (2012) provide a much more detailed comparison.

2.4.4 Foams

In theory, there are circumstances where foams could provide improved sweep compared to polymer solutions (Zhang and Seright 2007). These circumstances require the following: (1) foam forms in high-permeability pathways but not in low-permeability strata, (2) no crossflow occurs between high- and low-permeability strata, and (3) the foam resistance factor in the high-permeability strata is high enough to overcome the permeability contrast and the unfavorable mobility ratio between the gas bank and the oil/water bank in the less-permeable strata. Foams will generally not be superior to polymers under other circumstances unless gravity effects provide a fortuitous benefit. Other limitations for foams must be recognized, including (1) difficulties formulating foams to meet the above requirements, (2) challenges with foam propagation, especially due to surfactant retention, (3) compression costs associated with foam injection, and (4) limitations on foam stability under reservoir conditions. Another major challenge is control of the effective viscosity or mobility reduction provided in situ. In a given mobility control application, there is an optimum level of mobility desired for the injected fluid. Too little viscosity (or mobility reduction) leads to inefficient displacement, while too much viscosity leads to injectivity problems. For polymer solutions, any desired viscosity level can be achieved very accurately simply by adjusting the polymer concentration. In contrast, most foams allow little or no control over the level of mobility reduction provided. Although several applications of foams have been reported in an attempt to improve conformance (Li et al. 2010; Wang et al. 2001; Zhdanov et al. 1996), they cannot yet be considered a proven technology for water shutoff. Foams could, however, be more useful for gas shutoff purposes and beneficial when using CO2 in enhanced oil recovery applications (Sharma et al. 2020). Using CO2 as a foam processing solvent may replace organic solvents such as chlorofluorocarbons that are being phased out for environmental reasons, and promote improved CO2 storage in mature oil reservoirs (Alcorn et al. 2019). Combinations of polymer and foam injection, like polymer enhanced foams and foamed gels could overcome some inherent drawbacks of both methods but have not been widely investigated (Hughes et al. 1999; Kantzas et al. 1999).

2.4.5 Colloidal dispersion gels

Colloidal dispersion gels (Chang et al. 2004; Manrique et al. 2014; Spildo et al. 2009) are formulations that typically contain low concentrations of polymer (e.g., 300-ppm HPAM) and a cross-linker (e.g., 15-ppm Al3+ or Cr3+). Typically, a 10% (or less) pore-volume bank of the formulation is injected (Manrique et al. 2014). These formulations have been claimed to plug high-permeability strata without entering or damaging less-permeable strata and/or acting as a lower-cost, more effective polymer-flooding agent. These claims are false. A detailed analysis and review of colloidal dispersion gels is available (Seright 2015). This review reveals that that colloidal dispersion gels cannot propagate deep into the porous rock of a reservoir, and at the same time, provide resistance factors (effective viscosity in porous media) or residual resistance factors (permeability reduction in porous media) that are greater than those for the same polymer formulation without the cross-linker. As with most particulate materials, gel particles that approach the size of pore throats are quickly filtered from solution during flow through porous media (Ranganathan et al. 1998). Gel particles that are too small have no significant effect on liquid mobility.

2.4.6 Microorganisms, emulsions, particulates, precipitates, and nanoparticles

A number of other materials have been proposed for use in conformance improvement, and especially for in-depth profile modification, including microorganisms, emulsions, particulates, precipitates, and nanoparticles (Bae et al. 1996; Chan 1988; El-karsani et al. 2014; Kabir 2001; Lenchenkov et al. 2019; Schmidt et al. 1984; Seright 1988; Seright and Liang 1995; Spildo et al. 2009). The potential and claims for these materials must be viewed in the same light as for conformance-improvement gels. Specifically, whenever a material is considered for in-depth profile modification (Seright 1988), one should ask (1) why should the material not enter less-permeable, hydrocarbon-productive strata? (2) How far will the material penetrate into the less-permeable, hydrocarbon-productive strata? And (3) how much loss of flow capacity will the material cause to the less-permeable, hydrocarbon-productive strata after the material is in place? For the materials listed in the title of this section, they are very much in the research and development stage. None of them should be considered proven technologies. For the particular case of nanoparticles, one must ask, what advantage would a nanoparticle have or other conformance materials (especially gels). The small size of nanoparticles is of no obvious value in penetrating into formations. Further, nanoparticles have shown high adsorption/retention in porous rock (Lenchenkov et al. 2019)—suggesting difficulties with penetration very far into a given geologic stratum.

3 Use of disproportionate permeability reduction

3.1 What is it and why does it occur?

Some polymers and gels can reduce permeability to water more than to oil or gas. Many different mechanisms have been suggested to explain this phenomenon (Al-Sharji et al. 1999; Ganguly et al. 2003; Liang et al. 1995; Liang and Seright 2001; Nguyen et al. 2006; Seright 1995b; Seright et al. 2006; Willhite et al. 2002). A coherent and generally accepted gel dehydration mechanism has been offered to explain disproportionate permeability reduction for pore-filling gels in porous media (Al-Sharji et al. 1999; Ganguly et al. 2003; Nguyen et al. 2006; Seright et al. 2006; Willhite et al. 2002). A pore-filling gel is simply a gel that completely fills all the aqueous pore space after the gelation reaction is complete. The gel typically contains more than 90% water—and often more than 99% water. These aqueous pore-filling gels are actually porous media in themselves and thus have a very low but finite permeability to water—ranging from nano-darcys to micro-darcys, depending on the concentration of polymer (Seright 1999a). One can think of the polymer strands that make up the gel to basically be a filter made from fibers. The more fibers (i.e., the higher the concentration of polymer), the lower the permeability. If pressure gradients are kept sufficiently low, so that injected water does not fracture through the gel, the water can enter one side of the gel and come out the other side—while leaving the gel’s structure intact with its original (very low) permeability. Thus, if the gel forms in a stratum where only water flows, the permeability can permanently be lowered to a very low value, and the water production is efficiently shutoff from that zone. In a stratum where oil or gas flows, gelant can also enter during placement, and the aqueous gel forms in the aqueous pore space (Liang et al. 1993). Oil or gas cannot enter the aqueous gel structure, so the gel’s effective permeability to oil or gas is zero. However, under a pressure gradient, the oil or gas can deform the gel. This deformation forces a small amount of water out the opposite side of the gel and forms a small dimple on the oil and gas side of the gel. With time under the pressure gradient, this dimple grows to form a finger or wormhole through the gel—with more water being forced from the gel as the wormhole grows (basically dehydrating a pathway through the gel). Eventually, the oil or gas wormhole penetrates all the way through the gel—restoring a relatively high effective permeability to oil or gas (Seright 2006, 2009; Seright et al. 2006; Willhite et al. 2002). The rate of restoration of effective permeability for a gelant-invaded hydrocarbon strata increases with increased pressure gradient, decreased polymer content in the gel, and decreased distance of gel penetration into the hydrocarbon strata (Seright 2006, 2009).

Disproportionate permeability reduction (also called relative permeability modification) can also be observed with adsorbed polymers (Barreau et al. 1997) and weak or particulate-form gels (Seright 1992; Seright and Martin 1993; Wang et al. 2003). Weak or particulate-form gels are usually the product of incomplete gelation, so that the gel does not fill most or all of the aqueous pore space (Seright 1992; Seright and Martin 1993). They provide permeability reduction dominantly by lodging in pore throats and causing some degree of flow restriction. On the positive size, their level of permeability reduction is modest—typically in the range from a factor of 2–100. However, a major disadvantage of these materials is that their level of permeability reduction is usually extremely variable (Seright 2009). In one example, nine nearly identical tests of a commercial product in ~ 300-mD Berea sandstone gave permeability reductions ranging from 1.5 to 400. In contrast, a pore-filling gel have very consistent permeability reductions (down to about 200 µD in cores ranging from 100 to 7000 mD, regardless of wetting properties of the core (Seright 2009)). Because particle-form gels are commonly the product of an uncontrolled and incomplete gelation reaction, the concentration of particles produced and the size and size distribution of the particles produced is not controlled or predictable. Since their mechanism of permeability reduction involves clogging pore throats, this makes their level of permeability reduction unpredictable.

Most previous field applications of disproportionate permeability reduction (by service companies) have targeted vertical wells with no reported fractures. Their goal was to avoid zone isolation during gelant placement, and rely on disproportionate permeability reduction to reduce water production with minimum damage to hydrocarbon zones (Liang et al. 1993; Seright 2009). However, simple calculations using Darcy’s law for radial flow reveal that in order for this idea to work, the gel must reduce permeability to hydrocarbon by no more than a factor of two (Fig. 14), while at the same time providing at least a factor of ten permeability reduction to water.

It is important to understand that disproportionate permeability reduction is of no value if all fluids are flowing within a single stratum (Liang et al. 1993). Even if the gel could reduce permeability to water without causing any permeability reduction to hydrocarbon, a mass balance dictates that the fractional flow of water and hydrocarbon must remain the same within a given zones (at least over the short-term). If a gel or magic membrane could allow hydrocarbon to pass without allowing water, the water saturation would accumulate—driving the hydrocarbon saturation down, driving the relative permeability to hydrocarbon down, and thus forming a water block. Disproportionate permeability reduction will only be of value in production wells. It has no value in injection wells (because usually only water is injected there).

3.2 Misleading parallel linear corefloods

At present, no known material will significantly reduce permeability to water without causing some permeability reduction to oil (Al-Sharji et al. 1999; Ganguly et al. 2003; Liang et al. 1993, 1995; Liang and Seright 2001; Nguyen et al. 2006; Seright 1995b, 1999a; Seright et al. 2006; Willhite et al. 2002). However, one can easily manipulate laboratory parallel linear corefloods to make it appear that a given material has reduced water permeability in a high-permeability core without causing any damage to a parallel less-permeable core. Thus, the buyer should beware of any attempt to use parallel linear corefloods to prove the conformance merits of a product.

To understand why parallel linear corefloods can be misleading, consider Fig. 15. First, consider the perfect theoretical case (involving only mathematical calculations and no actual experimentation). Assume two sets of parallel corefloods—one linear and one radial (as illustrated in Fig. 15). Within each set, two cores have exactly the same dimensions and porosity, but Core 1 has 10 times the permeability of Core 2 (i.e., k1/k2 = 10). Also assume that both cores in a given set are initially filled only with water. A gelant is injected that has the same viscosity as water (i.e., the resistance factor of the gelant is one, Fr = 1). Within a given core set, the gelant provides a perfect piston-like displacement until it reaches the outlet of the most-permeable core. For the radial case, the gelant is injected into a shared injection well until it reaches the outer radius of Core 1. For both the linear and radial cases, the volume of gelant injected into Core 2 will be 10% of that injected into Core 1. For linear flow, the gelant penetrates 10% of the way through Core 2. In contrast, in radial flow, the gelant penetrates in Core 2 to a radius that is about one-third of the radius in Core 1—because of the πr2 relation associated with radial flow.

After the gelant has been placed, the gel is allowed for form. Assume that wherever the gel does form, it reduces permeability to subsequent water flow by a factor of 10 (i.e., the residual resistance factor is 10, Frr = 10). At this point, Darcy’s law for flow in parallel and series is used to calculate the loss of flow capacity (i.e., injectivity) in the various cores (Ganguly et al. 2003; Seright 2015). As indicated by the table in Fig. 15, Core 1 experiences a 90% loss of flow capacity for both the linear and radial cases (because the entire core is completely filled with gel that reduces permeability by a factor of 10). In the Core 2 for the linear case, the flow capacity is reduced by 47%. Thus, for the parallel linear corefloods, the gel treatment reduced flow capacity considerably more in the high-permeability core than in the low-permeability core—so the flow profile was improved considerably. The downside of this treatment, however, was a 47% loss of flow capacity in Core 2. If Core 2 represented an oil zone, the result would translate to a substantial loss of oil productivity.

Now consider the case of radial flow. Here, Core 2 experiences an 87% loss of flow capacity, while Core 1 experiences a 90% loss of flow capacity. Thus, for the radial case, both Cores 1 and 2 were damaged to about the same extent, so no significant improvement in flow profile occurred. Thus, the gel treatment was pointless for the radial case. The net result of the gel treatment was only to substantially damage the flow capacity of both zones. The point of this exercise is that even if parallel linear corefloods worked in a theoretically perfect way, the result would be grossly unrepresentative of expectations in an unfractured vertical well. Thus, even in the ideal case, parallel linear corefloods are a very poor way to imitate what might be expected for an unconfined (i.e., no zone isolation) gelant placement in an unfractured vertical well.

Next, consider an experiment performed using parallel linear corefloods. Typically, a flow line leads from the gelant pump and splits before reaching the inlets of the two cores (as indicated by the lines preceding the linear cores in Fig. 15). The correct way to perform this experiment is to fill the flow lines completely with gelant all the way to the entrance of both cores before starting the experiment. In contrast, too many reported experiments had these lines filled with water at the start of the experiment. For the latter cases, the gelant rapidly fills the flow line leading to the high-permeability core—and much (or all) of the high-permeability core. But because the low-permeability core is much less permeable, the gelant requires much more time to fill the flow line leading to Core 2. It is possible that little or no gelant entered Core 2 by the end of gelant placement—thus giving the false impression that the gelant would not damage the less-permeable core.

Even if the experiment is performed correctly (meaning the flow lines are completely filled with gelant before the start of the experiment), diffusion can distort the results in an overly optimistic way. For small molecules (as in a monomer-based gelant, such as silica, acrylamide monomer, or phenol–formaldehyde), the diffusion coefficient is on the order of 10–5 cm2/s—translating to about 1 cm/day for movement at a concentration front (Seright 1991b). For field gelant treatments, this rate of movement is insignificant compared to the sizes of the gelant banks in both high- and low-permeability zones (Liang et al. 1993; Seright 1988, 1991a, b; Ye and Seright 1996). In contrast, the very small gelant bank in the less-permeable core in a laboratory experiment could be diluted enough by diffusion to compromise the gelant bank—thus, again giving the false impression that the gelant treatment might not damage less-permeable zones. Other phenomena can also lead to overly optimistic interpretations of parallel linear corefloods (Liang et al. 1993; Seright 1988, 1991a, b; Ye and Seright 1996).

In summary, we strongly recommend that parallel linear corefloods NOT be used to evaluate the potential for materials as agents for profile modification.

3.3 Disproportionate permeability reduction in fractures

Disproportionate permeability reduction has its greatest potential in treating fractures that cut through both water and hydrocarbon zones (Amaury et al. 2002; Seright et al. 1998, 1993). Figure 16 illustrates this concept for the case where hydraulic fracturing was used to stimulate an oil zone, but inadvertently cut through a shale barrier into an underlying aquifer. During gelant injection, the gelant will flow very rapidly down the length of a fracture, while leaking off a short distance into the porous rock matrix next to the fracture. The degree of gelant leakoff will be dictated by the strata permeabilities and fractional flow concepts (Liang et al. 1993; Seright et al. 1998, 1993). However, to a first approximation, one should expect the gelant to leak off significantly into both oil and water zones. The reduction of flow capacity in a given zone is dictated by the product of permeability reduction and the distance of gelant leakoff (Seright et al. 1998). For example, assume that a gelant leaks off 0.2 ft into both the oil zone and the water zone in Fig. 16. Also assume that after gelation, the gel reduces permeability to oil by a factor of 50, while reducing permeability to water by a factor of 5000. Pore-filling gels are able to provide this level of disproportionate permeability reduction (Seright 2006, 2009). For this example, the gel barrier would provide resistance equivalent to flowing through 0.2 ft × 5000 = 1000 ft of additional rock in order to enter the fracture. Thus, the gel substantially retards water flow into the fracture. In contrast, in the oil zone, the gel barrier provides resistance equivalent to flowing through 0.2 ft × 50 = 10 ft of additional rock in order to enter the fracture. Certainly, some loss of flow capacity has occurred in the oil zone, but not enough to significantly impair oil productivity.

Although the concept shown in Fig. 16 has tremendous potential, it has not been applied much to date. A service company sold a qualitative version of this concept by incorporating a disproportionate–permeability–reduction polymer into fracturing fluids (Vasquez and Eoff 2013). The concept was that if a hydraulic fracture inadvertently cut into a water zone, the disproportionate-permeability-reduction polymer would automatically inhibit water entry into the fracture. Unfortunately, the concept, as sold, had two major technical flaws. First, the distance of leakoff from the fracture faces was not known or estimated. Second, no attempt was made to quantify the permeability reduction in the oil and water zones. Thus, the process had no control over the reduction of flow capacity in either the oil or water zones.

A quantitative design procedure for application of the concept in Fig. 16 was developed for hydraulically fractured vertical production wells (Seright et al. 1998). Extensions of this procedure were also developed for application in hydraulically fractured horizontal production wells (Liang et al. 2020) and in naturally fractured production wells (Amaury et al. 2002).

4 Gel extrusion through fractures

Use of gels for water shutoff has conventionally involved injecting gelant solutions, and relying on the process of gelation to form a plug after placement of the material. Gelant is defined as the fluid chemical solution before gelation, while gel is technically the product of the gelation reaction.

4.1 Field observations

In this section, we focus on extrusion of formed gel material through fractures. This topic has an interesting history. In the early 1980s, Marathon implemented conventional polymer floods in Wyoming (Milton et al. 1983). However, because the target reservoirs were highly fractured, much of the polymer solution simply channeled directly from injectors and producers through the natural fracture systems. To slow down the movement of the polymer through the reservoir, a chromium cross-linker was added. During this time, Sydansk (Sydansk 1990; Sydansk and Moore 1990; Sydansk and Southwell 2000) developed the Cr(III)-acetate-HPAM gel system. In the same time frame, Phillips (Moradi-Araghi et al. 1993; Mumallah 1988) developed the analogous Cr(III)-propionate-HPAM gel system. These gel systems were a major advance over previous gels for enhanced oil recovery, because their performance was reasonably insensitive to pH and salinity. Previous gels had little buffering capacity and gelled optimally at non-neutral pH values. For example, the Cr(VI)-HPAM system gelled optimally around pH = 4 (Seright 1992), and phenolic-based gels formed optimally around pH = 9 (Seright 1993; Seright and Martin 1993). Because the older gel systems did not have much buffer capacity, contact with carbonate and clay minerals quickly changed the formulations’ pH shortly after injection. Thus, the gels did not form well (and sometimes did not form at all) inside the reservoir. The Cr(III)-acetate and propionate systems greatly improved the predictability and controllability of gel systems (Jain et al. 2005; Marty et al. 1991; McCool et al. 1991, 2000; Moradi-Araghi et al. 1993; Mumallah 1988; Seright 1993; Sydansk 1990; Sydansk and Moore 1990).

Key field applications of the Cr(III)-acetate-HPAM gel involved injecting large gel volumes, notably by Marathon in the Oregon Basin field in Wyoming (Sydansk 1990; Sydansk and Moore 1990; Sydansk and Southwell 2000), by Amoco in the Wertz field in Wyoming (Seright 1995a), and by Chevron in the Rangely field in Colorado (Friedmann et al. 1999; Hild and Wackowski 1999; Hughes et al. 1999). Injected gel volumes ranged from 5000 to 37,000 bbl over the course of 1 week to 1 month, with an average around 15,000 bbl over the course of two weeks (Borling 1994; Hild and Wackowski 1999; Sydansk and Moore 1992; Sydansk and Southwell 2000). Under the conditions in the particular field applications, gelation of the Cr(III)-acetate-HPAM formulations occurred from 1 h (e.g., at 60 °C) to 15 h (e.g., at room temperature). Thus, the gel formulations were injected for substantially longer than the gelation time. Once gelation takes place, the product of the cross-linking (i.e., the gel) will not flow through porous rock (i.e., less than 10 darcys) using any realistic field pressure gradient (i.e., < 10 psi/ft) (Seright 1995a, 1997b, 1998, 1999b, 2001a, 2003a). These facts lead to the realization that formed gels must extrude through fractures during most of the gel injection during the field applications. For practical reasons, it is best to keep the formulations fluid (i.e., as gelant) in the surface facilities and during the initial part of pumping downhole. However, the formulations exist as gel, partially formed gel, or preformed gel during most of the process of gel placement within the reservoir. That fact raises the question: What are the properties of gels as they extrude through fractures?

4.2 Stable pressure behavior during extrusion

This question led to a number of experiments where gels where extruded through fractured cores after gel formation (Brattekås et al. 2020; Liu and Seright 2001; Seright 1995a, 1997b, 1998, 1999b, 2001a, 2003a, b; Sydansk et al. 2004a, b; Wang and Seright 2006). A key question was whether a gel would propagate through a fracture in a stable way, or whether screen-outs would occur in the early part of the fracture (as happens with sand, cement, and other relatively rigid materials). Figure 17 reveals that a one-day-old gel with 0.5% HPAM (5 million g/mol Mw with 5%–10% degree of hydrolysis) and 0.0417% Cr(III) acetate does propagate stably through a 1-mm-(0.04-inch) wide, 122-cm-(48-inch)-long fracture (i.e., a fracture in a Berea sandstone core) at 41 °C (Sydansk et al. 2004b). When injecting at a fixed rate, the pressure gradient remained stable (without wild swings in the pressure gradient) over the course of injecting 75 fracture volumes of gel. The highly stretchy nature of this gel promotes this behavior. More rigid gels (and other materials) would screen out early within the fracture (Gidley et al. 1989; Seright 1995a; Smith 1990).

4.3 Rate insensitivity during extrusion

An interesting feature of gel extrusion is that it shows very different rheology than conventional fluids. In particular, for a given gel composition and fracture width, the gel will not extrude if the pressure gradient is below some critical value (Seright 1998, 2001a). Above that critical value, the pressure gradient during gel extrusion is quite insensitive to the rate of extrusion. Table 2 illustrates this point for the same one-day-old Cr(III)-acetate-HPAM gel used in Fig. 17. Even though the flow rate increased by a factor of 80, the pressure gradient averaged about 30 psi/ft (actually ranging from 18 to 40 psi/ft). This effect has practical consequences. Normally, there is always a desire to inject fluids quickly—either because of time constraints or because of a desire to push oil out faster. However, this desire is tempered by a fear that injecting too fast will cause fractures to extend too far, and possibly accentuate channeling between wells (Gadde and Sharma 2001; Seright 2017; Seright et al. 2009). This fear is predicated on higher injection rates causing higher pressures and pressure gradients. In contrast, Table 2 suggests that the pressures and pressure gradients generated will be insensitive to injection rate.

The minimum pressure gradient for gel movement impacts the distance that a gel can be expected to propagate in a given fracture (Seright 1998, 1999b, 2001a). For example, assume that a pressure gradient of 10 psi/ft is needed to initiate flow for a gel in a facture. If the downhole injection pressure is limited to 2000 psi (perhaps because of regulations or equipment constraints) and if the reservoir pressure is 1000 psi (so there is a 1000 psi pressure differential between the injector and the reservoir), the gel will stop flowing once it reaches 100 ft along the fracture [i.e., (2000 psi minus 1000 psi)/(10 psi/ft) = 100 ft]. After propagating 100 ft along the fracture, the pressure gradient will fall below the minimum 10 psi/ft needed to move the gel.

4.4 Dependence on fracture width

As expected qualitatively, the pressure gradient required to extrude a gel through a fracture decreases with increased fracture width (Seright 2001a). Based on a force balance (Liu and Seright 2001; Wang and Seright 2006), one might expect the pressure gradient for gel extrusion to vary inversely with fracture width (Liu and Seright 2001; Wang and Seright 2006). However, experimental observations (Seright 2001a) indicate that the required pressure gradient varies closer to the inverse square of the fracture width (Fig. 18). For the extrusion experiments shown in Fig. 18, the pressure gradient for gel extrusion did not depend on the permeability or lithology of the porous rock that contained the fracture (between 1.5 mD and 650 mD). The trend in Fig. 18 also has implications for field applications of gels—specifically that gels will propagate much farther in wide fractures than in narrow fractures. For the example given in the previous paragraph, assume the pressure gradient for gel extrusion is 10 psi/ft in a 1-mm-wide fracture but 2.5 psi/ft in a 2-mm-wide fracture. Given the same conditions as above, the gel is expected to extrude 100 ft in the 1-mm-wide fracture but 400 ft in the 2-mm-wide fracture.

4.5 Dependence on polymer concentration and temperature

As expected, the pressure gradient for gel extrusion increases with increased concentration of polymer in the gel (Seright 2003a). Figure 19 shows an empirical correlation between pressure gradient for gel extrusion and HPAM concentration in the gel. For these experiments, the ratio of HPAM to Cr(III) acetate was fixed at 12:1. The figure also shows that the ratio of elastic modulus of the gel (G’, measured in a rheometer) to fracture width (wf) follows a trend that parallels the pressure gradient trend—but has values that are two orders of magnitude lower (for a given polymer concentration in the gel.)

For a one-day-old Cr(III)-acetate-HPAM gel (with 0.5% HPAM and 0.0417% Cr(III) acetate), Fig. 20 reveals that the pressure gradient for gel extrusion is insensitive to temperature between 20 and 80 °C (Seright 2001b). This finding was somewhat unexpected since the viscosity of water decreased by a factor of 2.8 between 20 and 80 °C.

4.6 Gel dehydration during extrusion

Gels dehydrate during extrusion through fractures (Seright 1998, 1999b, 2001a, 2003a). Gels used for water shutoff typically contain over 90% water—and often over 99% water (Marty et al. 1991; Seright 1993). As the gel extrudes through a given fracture, the water leaves the gel and leaks off through the fracture faces into the porous rock. In contrast, the cross-linked polymer cannot enter the porous rock (Seright 1995a, 1997b, 1998, 1999b, 2001a, 2003a), so it remains behind in the fracture—making a more concentrated gel. These points can be appreciated by considering Table 2. Note in the four experiments that the gel did not arrive at the end of the fractures after injecting only one fracture volume of gel. Instead, it took 15 fracture volumes of gel to fill the fracture at the slowest gel injection rate and 1.7 fracture volumes at the highest rate. Further, at the end of each experiment, the fracture was opened—revealing a concentrated rubbery gel. These gels in the fractures were analyzed (for polymer and cross-linker) to reveal that they were considerably more concentrated than the gel that was injected (Seright 1998). For the slowest experiment, the gel was 27 times more concentrated than the injected gel, while for the fastest experiment, the gel was concentrated by a factor of 4. Gels have been concentrated by factors up to 40 times by this extrusion process (Seright 1998). Interestingly, the gel that exits the end of the fracture had the same composition and rheological properties as the gel that was injected—even after extruding 32 feet through a 1-mm-wide fracture (Seright 2001a, 2003a). This finding indicates that the gel that moves within the fracture has the same composition as the injected gel. In other words, once an element of gel dehydrates and concentrates, it remains immobile at that point in the fracture. Since the injected gel is far less concentrated than the dehydrated/concentrated gel, the injected gel is far more mobile than the dehydrated gel—resulting in a very unfavorable mobility ratio and displacement process. Thus, the mobile injected gel forms viscous fingers or wormholes through the dehydrated/concentrated gel (Seright 2003a). Figure 21 shows a picture of this worm-holing process. In this experiment, two Berea sandstone slabs (each 15 × 15 × 8 cm in dimension) were placed together, separated by a 1-mm gap (to make the fracture). A large volume of clear 1-day-old Cr(III)-acetate-HPAM gel (containing 0.5% HPAM and 0.0417% Cr(III) acetate) were extruded through the fracture (top to bottom in Fig. 21). Near the end of the procedure, injection was switched to a gel with exactly the same composition and age—except the gel contained a blue dye. Then, the experiment was stopped, and the fracture was pried open to reveal the fracture faces and gel inside the fracture—shown in Fig. 21. This figure clearly shows the wormhole pattern. Gel samples were analyzed throughout the fracture—revealing that gel in the blue wormholes had the same composition as the injected gel, but the colorless gel was 12 times more concentrated (Seright 2001a, 2003a).

4.7 Water leakoff during gel extrusion and predicting gel propagation through fractures

During these gel extrusion experiments, taps in the rock matrix (located away from the fracture) allowed collection of the water of dehydration from the gel (Seright 2001a, 2003a). Analysis of this fluid confirmed that no cross-linked polymer penetrated any significant distance into the porous rock during the extrusion process. Collection of this leakoff fluid also allowed determination of the rate of leakoff as a function of time, although in situ imaging could also be necessary in some experiments (Brattekås et al. 2020). Leakoff rates from a large number of experiments are shown in Fig. 22 (Seright 2003a). Although there is some scatter, most of the leakoff data followed the green line and equation shown, where the leakoff rate (ui, expressed in ft/d or ft3 of fluid leaking off per ft2 of fracture area per day) varied inversely with time (t) raised to the 0.5 power. This type of relation is consistent with leakoff behavior during hydraulic fracturing and during filtration experiments (Seright 2003a). This relation can be combined with a mass balance to predict (1) the distance of gel propagation through a fracture as a function of time and volume of gel injected (qtot) and (2) the degree of concentration of gel within the fracture (C/Co). Specifically, assuming that a vertical fracture (of height, hf, and width, wf) contains two wings, the rate of gel propagation (dL/dt) is:

This differential equation has been solved and presented in excel spreadsheets, to allow convenient predictions at http://www.prrc.nmt.edu/groups/res-sweep/gel-treatments/.

Figure 23 plots predictions of gel propagation through a two-wing 1-mm-(0.04-inch)-wide vertical fracture for three volumetric injection rates. This plot reveals several points that are of practical significance in a field application. First, the distance of gel penetration into a fracture is not linearly dependent on the gel volume injected. Normally, one might think that a fracture would be filled with gel after injecting one fracture volume. However, because of the dehydration effect, substantially more gel may be required (as revealed in Table 2). Detailed consideration of the slopes of the curves in Fig. 23 reveals that doubling the distance of gel penetration along a fracture requires approximately tripling the injected gel volume. The figure also reveals that for a given volume of gel injection, the distance of gel propagation will be maximized by injecting at the highest practical injection rate. Put another way, if the goal was to reach a given distance along a fracture, injecting faster requires less gel to reach the objective. For example, in this case, if the desired distance of gel penetration is 200 ft along a 1-mm-wide fracture, 400 bbl of gel are required when injecting at 1 barrel per minute (BPM), but only 80 bbl of gel is needed when injecting at 10 BPM. On the other hand, injecting at a faster rate reduces the degree of dehydration for the gel after placement. One might wish to inject slower to make the gel stronger, and perhaps more resistant to washout during subsequent injection of water or other fluid after gel placement (Seright 2001a).

The behavior described in Figs. 17 through 23 was based on work with moderated-to-high molecular-weight HPAM cross-linked with Cr(III) acetate. However, we anticipate that the behavior will be mimicked by any gel formed from polymers with a similar degree of polymerization and using any cross-linker, including guar-borate gels (Seright 2003a), HPAM cross-linked with polyethylene imine (Al-Muntasheri et al. 2007a, b, 2006, 2008; Jayakumar and Lane 2012, 2013; Zhu et al. 2019), phenol–formaldehyde (Alvarez et al. 2001; Amaury et al. 2002), hydroquinone-hexamethylenetetramine (Dovan et al. 1997; Glasbergen et al. 2014; Unomah et al. 2018), and preformed particle gels (PPGs) (Alhuraishawy et al. 2019; Bai and Zhang 2011; Imqam et al. 2015, 2017; Pu et al. 2019; Sun et al. 2020; Wang and Bai 2018; Wang et al. 2019).

A model of Filter-Cake Formation was developed based on observations during gel extrusion through fractures. Many people know of the Carter filter-cake model (Howard and Fast 1970) that has been a cornerstone of hydraulic fracturing. The Carter model assumes that the filtrate or fluid-loss material will build up in thickness evenly (from an areal viewpoint) on a fracture surface as the fracture fluid leaks off into the porous rock (left side of Fig. 24). With some thought, one should realize that this cannot happen if the fracture has a fixed or confined width. To correct this deficiency, an alternative model was proposed (Seright 2003a) where the filter cake builds up unevenly over the fracture area (right side of Fig. 24). Whereas in the Carter model, the filter cake increases in thickness with time, the new model assumes that the filter-cake thickness is generally about the width of the fracture, but the area covered by filtrate decreases with time. The new model is consistent with Fig. 21, while the Carter model is not. Details of the development of this new model are described by Seright (Seright 2003a), but the solid red curve in Fig. 22 compares predictions from the new model with those of the Carter model (solid green curve in Fig. 22). As can be seen, both curves are consistent with the experimental observations. When presented with the new model, one famous hydraulic fracturing pioneer asked if the two models predict the same thing, big deal—why bother? The only response available was that the new model incorporates more correct physics of the leakoff process than the Carter model. There may be circumstances where that becomes important. That point will be revisited in the next section.

5 Gel blocking efficiency

When the purpose of polymer gel placement in fractures is to reduce conductivity during chase floods (e.g., subsequent water injection), the behavior and properties of dehydrated gel are of considerable importance. Gel ability to block fractures depend on several factors, which we will summarize in this section. An important and logical deduction, common for all factors, is that gel is only capable of completely blocking a fracture as long as the entire fracture volume is filled with gel.

5.1 Rupture pressure

Subsequent injections of chase fluids (e.g., water) will implement a pressure gradient across the gel-filled fracture, which may reduce the gel volume (Al-Sharji et al. 1999; Bai and Zhang 2011; Dawe and Zhang 1994; Howard and Fast 1970; Imqam et al. 2015; Imqam et al. 2017; Krishnan et al. 2000; Wang and Bai 2018). The gel will maintain fracture blocking and complete filling of the fracture at pressure gradients below the rupture pressure. When the rupture pressure is reached, however, water (or other injected fluids) are again allowed to pass through some parts of the fracture. The rest of the fracture will remain gel-filled. Gel rupture pressure measurements (Brattekås et al. 2015; Ganguly et al. 2002; Seright 2003b) reflect the complex nature of gel, and the rupture pressure cannot be directly projected based on injection parameters. Repeated core floods have shown that the rupture pressure in a given segment of the fracture increases with increased gel throughput and decreased gel placement rates (summarized in Fig. 25). This follows directly from Sect. 4: the leakoff rate is insensitive to the gel flow rate. Hence, gel propagating slowly through a fracture will dehydrate more compared to faster moving gel, consequently increasing its concentration and pressure resistance. This finding should not be perceived as a suggestion to reduce the gel placement rate: because gel extrusion pressure is also insensitive to the placement rate, the gel propagation distance in a fracture may be maximized by injecting gel at the highest practical injection rate. When a longer segment of the fracture is gel-filled, the overall expected rupture pressure for the gel treatment will also increase. Thus, gel dehydration is beneficial for gel blocking efficiency during subsequent floods, where the manner in which dehydration occurs is also highly important.

5.2 Blocking ability of ruptured gel

Both filter-cake models (Carter and new model, Sect. 4.7) assume gel dehydration during extrusion through fractures, resulting in a concentrated gel that is more rigid and with a higher tolerance toward imposed pressure compared to gel of original composition. Macroscopically, the models predict similar leakoff rates, but the Filter-Cake Formation within the fracture volume takes place in a quite different manner. This distinction becomes important during chase floods. According to the Carter model, gel dehydration and deposition occur on the fracture surfaces, with less concentrated gel present in the middle of the fracture. The least concentrated gel is first washed out of the fracture during subsequent injections. Consequently, the active water flow path will resemble a narrow version of the fracture according to the Carter model (Fig. 24), and its width will determine fracture flow capacity. The permeability reduction provided by gel (residual resistance factor) would in this case decrease quickly toward one, as gel occupancy decreases and the active flow path expands (Fig. 26). Experimental observations do not correspond with these low expectations; and gel permeability reduction remains high although water flow occupies up to 40% of the fracture volume (Fig. 26). Gel blocking ability has also been observed to vary with flow rate (i.e., implemented pressure gradient, Fig. 27), which cannot be explained by the Carter model. The new leakoff model proposes a volumetrically uneven filter-cake, where less concentrated gel resides in wormholes within dehydrated gel. Gel rupture will in this case occur when less concentrated gel is displaced out of the wormholes. The wormholes will thereafter conduct the flow of water through the fracture. Observations such as resistance factor dependency on flow rate (Fig. 27) supports the new filter-cake model; which attribute this behavior to the elasticity of the gel filter-cake, allowing wormholes to collapse and expand depending on the imposed pressure gradient (Seright 2003a).

Calculated residual resistance factor for a fracture initially filled with concentrated gel, using the cubic law kf = wf/12 (Witherspoon et al. 1980). Gel washes out of the middle of the fracture first according to the Carter model, and fracture conductivity is determined by the width of the active flow path. Experimental observations (Brattekås et al. 2017) do not corroborate the quickly decreasing gel permeability reduction

Permeability reduction provided by gel remains high over time and varies with injection rate and pressure. Full dataset available in Brattekås et al. (2015)

Gel blocking ability during chase floods is often studied using core floods, where differential pressure measurements and effluents produced from matrix and fractures give information about flow paths within the fracture. Direct visualization of wormholes was previously not possible within opaque porous media to confirm either filter-cake model. However, new in situ imaging methods give insight to local flow patterns, and can be used to visualize water flow through gel-filled fractures (Brattekås and Fernø 2016). In situ imaging by magnetic resonance imaging (MRI) or positron emission tomography (PET) showed the formation and development of wormholes during chase waterfloods, and strongly supported the new leakoff model (Brattekås and Fernø 2016; Brattekås and Seright 2020, 2018; Brattekås et al. 2017). Wormhole development after gel rupture is exemplified in Fig. 28. Gel rupture created a heterogeneous active flow path through the gel-filled fracture. Increasing injection rates expanded the initial wormhole, occasionally adding new rupture paths (Brattekås et al. 2017). The wormholes remained in the same shape and location for the entire waterflood, and changes in the active flow path were mainly attributed to gel erosion and elasticity. Expansion of the wormholes was observed with increasing flow rates, as expected, but the residual resistance factor (the factor by which the effective permeability was reduced by the gel) was maintained. The wormhole covered almost 35% of the fracture after long-term waterflooding—i.e., water flows through more than one-third of the fracture. The gel permeability reduction was still maintained at a high level (residual resistance factor > 22,000, Fig. 26 experimental observations are based on this experiment). Gel permeability reduction increased when the flow rate was decreased as expected (Fig. 27), but no visual evidence of significant wormhole collapse was found using imaging. Imaging did, however, confirm the existence of wormholes, and showed that they had significant variations in width within the fracture. Because the wormholes represent the active flow path for water, narrow constrictions in the wormholes (measured to < 0.001 cm) may act as natural chokes on fluid flow. This mechanism is only possible when the filter-cake forming during gel dehydration is heterogeneous. Consequently, the wormholes forming during gel rupture are naturally non-uniform and dependent on local gel concentrations.

Wormhole development within a 1-mm-wide fracture captured by PET imaging. Injected water was labeled with positron-emitting isotope 18F-FDG. Upon combinations between emitted positrons and adjacent electrons, a photon pair with 511 keV energy is emitted, and this event can be spatially and temporally determined. Details are provided by Brattekås et al. (2017)

5.3 Gel shrinking

The volume of gel filling a fracture may clearly be influenced by mechanical stimuli, as described in the previous section, but can also interact with its surroundings. Shrinking of gel may open parts of the fracture to fluid flow and be detrimental to gel blocking efficiency, as shown in Fig. 29. The possible reasons for gel shrinking after placement in fractures are briefly summarized here.

Syneresis (Romero-Zeron et al. 2008; Sydansk 2007; Vargas-Vasquez et al. 2009; Vossoughi 2000) expels water from the gel structure, consequently shrinking the gel by up to 90%. The main cause for syneresis is excess cross-linker in the gel solution or increased cross-link density over time, which may be prevented by formulating the gel without exceeding the optimum cross-linker concentration (Vargas-Vasquez et al. 2009). Chemical modifications of the polymer may also cause syneresis, and may occur when gel is in contact with sea water over time at high temperatures (Sydansk 2007). For convenience in field applications, bulk gel tests may be performed to assess the sensitivity of gel toward brine formulations and temperature, where test parameters may be designed to target specific reservoirs (Sydansk and Moore 1990). Gel degradation, which causes solvent to separate from the gel, may also be assessed through bulk gel tests (Albonico and Lockhart 1993).