Abstract

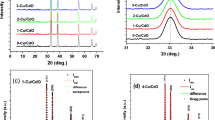

In this research, the solution casting technique has been used to synthesize composite with different weights of VCl3 embedded in polyvinyl alcohol (PVA), in the form of films. X-ray diffraction (XRD) patterns display a broad peak with low intensity of high doping composite films, reflecting an increase in the non-crystallinity and the internal strain. The complex formation between the OH– groups and the V3+ ions has been outlined through Fourier transform IR spectroscopy (FTIR). The film’s surface morphology via SEM images shows an increase in the agglomeration with the doping ratio of VCl3. The optical band gap and the width of localized states were changed from 4.86 to 3.03 eV and 0.85 to 2.54 eV. The average refractive index was estimated from band gap energy, as it increased to 2.46 for a composite of high doping ratio (VPVA6). Moreover, the optical susceptibilities χ(1) and χ(3) and the non-linear refractive index n(2) values indicate the possibility of applying this novel composite material on a wide scale of optoelectronic applications. The samples have reduced the power of the two lasers (632.8 and 532 nm) to 25 and 21%. The AC electrical conductivity was increased with doping ratio, and its relation with frequency is following Jounscher’s law. The improved characteristics, optical performance, and low band gap make them promising in UV-protector and linear/non-linear optoelectronic instruments.

Similar content being viewed by others

REFERENCES

A. Badawi, Appl. Phys. A 126, 335 (2020).

A. Badawi, S. S. AlHarthi, N. Y. Mostafa, M. G. AlThobaiti, and T. AlTalhi, Appl. Phys. A 125, 858 (2019).

F. M. Ali, I. M. Ashraf, and S. M. AlQahtani, Phys. B (Amsterdam, Neth.) 527, 24 (2017).

Y. Khairy, H. I. ElSaeedy, M. I. Mohammed, H. Y. Zahran, and I. S. Yahia, Polym. Bull. 2019, 1 (2019).

N. B. Kumar, V. Crasta, and B. M. Praveen, Phys. Res. Int. 2014, 26 (2014).

M. Abdelaziz and M. M. Ghannam, Phys. B (Amsterdam, Neth.) 405, 958 (2010).

E. M. Abdelrazek, I. S. ElAshmawi, and S. Labeeb, Phys. B (Amsterdam, Neth.) 405, 2021 (2010).

A. Hashim and A. Hadi, Sensor Lett. 15, 858 (2017).

M. Bulinski, V. Kuncser, C. Plapcianu, S. Krautwald, H. Franke, P. Rotaru, and G. Filoti, J. Phys. D: Appl. Phys. 37, 2437 (2004).

S. A. Nouh, A. F. Said, K. Abdel-Megeed, and F. M. Hafez, Rad. Eff. Def. Solids 161, 23 (2006).

I. S. ElAshmawi, E. M. Abdelrazek, A. M. Hezma, and A. Rajeh, Phys. B (Amsterdam, Neth.) 434, 57 (2014).

H. E. Ali and Y. Khairy, Phys. B (Amsterdam, Neth.) 572, 256 (2019).

H. Elhosiny Ali, Y. Khairy, H. Algarni, H. I. ElSaeedy, A. M. AlShehri, H. Alkharis, and I. S. Yahia, Opt. Quantum Electron. 51, 47 (2019).

H. ElHosiny Ali and Y. Khairy, Phys. B (Amsterdam, Neth.) 570, 41 (2019).

Y. Khairy, M. M. Abdel-Aziz, H. Algarni, A. M. Alshehri, and I. S. Yahia, and H. ElHosiny Ali, Mater. Res. Express 6, 115346 (2019).

N. M. Shash, H. Khoder, F. Metawe, and A. A. Negm, J. Appl. Polymer Sci. 129, 2796 (2013).

T. A. Hanafy, J. Appl. Phys. 112, 034102 (2012).

T. A. Hamdalla and T. A. Hanafy, Optik 127, 878 (2016).

S. Mahmoudi and S. Boudjadar, Acta Metall. Sin. (Engl. Lett.) 26, 742 (2013).

R. H. Kretsinger, V. N. Uversky, and E. A. Permyakov, Encyclopedia of Metalloproteins (Springer, New York, 2013). https://doi.org/10.1007/978-1-4614-1533-6

O. Pravakar, T. Siddaiah, P. V. R. K. Ramacharyulu, N. O. Gopal, C. Ramu, and H. Nagabhushana, J. Sci.: Adv. Mater. Dev. 4, 267 (2019).

K. Sreekanth, T. Siddaiah, N. O. Gopal, Y. M. Kumar, and C. Ramu, J. Sci.: Adv. Mater. Dev. 4, 230 (2019).

R. J. Sengwa and S. Choudhary, J. Appl. Polymer Sci. 131, 16 (2014).

F. M. Ali and F. Maiz, Phys. B (Amsterdam, Neth.) 530, 19 (2018).

S. Sreedhanya, N. Smijesh, R. Philip, and C. I. Muneera, J. Mater. Chem. C 1, 3851 (2013).

I. S. Yahia, A. Bouzidi, H. Y. Zahran, W. Jilani, S. AlFaify, H. Algarni, and H. Guermazi, J. Mol. Struct. 1156, 492 (2018).

Y. Khairy and I. S. Yahia, and H. El Hosiny Ali, J. Mater. Sci.: Mater. Electron. 31, 8072 (2020).

S. F. Bdewi, O. G. Abdullah, B. K. Aziz, and A. A. Mutar, J. Inorg. Organomet. Polym. Mater. 26, 326 (2016).

N. Rajeswari, S. Selvasekarapandian, C. Sanjeeviraja, J. Kawamura, and S. A. Bahadur, Polym. Bull. 71, 1061 (2014).

H. I. ElSaeedy, H. E. Ali, H. Algarni, and I. S. Yahia, Appl. Phys. A 125, 79 (2019).

I. S. Yahia and S. M. Keshk, Opt. Laser Technol. 90, 197 (2017).

M. Abdelaziz, Phys. B (Amsterdam, Neth.) 406, 1300 (2011).

F. M. Ali, J. Inorg. Organomet. Polym. Mater. 30, 2418 (2020).

A. M. Albu, I. Maior, C. A. Nicolae, and F. L. Bocãnealã, Electrochim. Acta 211, 911 (2016).

K. K. Kumar, M. Ravi, Y. Pavani, S. Bhavani, A. K. Sharma, and V. N. Rao, Phys. B (Amsterdam, Neth.) 406, 1706 (2011).

R. F. Bhajantri, V. Ravindrachary, A. Harisha, V. Crasta, S. P. Nayak, and B. Poojary, Polymer 47, 3591 (2006).

H. Hashim, M. Abdallh, and E. Yousif, Al-Nahrain J. Sci. 15, 40 (2012).

O. G. Abdullah, S. B. Aziz, and M. A. Rasheed, Res. Phys. 6, 1103 (2016).

F. F. Muhammad, S. B. Aziz, and S. A. Hussein, J. Mater. Sci.: Mater. Electron. 26, 521 (2015).

H. E. Ali, Y. Khairy, H. Algarni, H. I. ElSaeedy, A. M. Alshehri, and I. S. Yahia, J. Mater. Sci.: Mater. Electron. 29, 20424 (2018).

T. A. Hamdalla, T. A. Hanafy, and A. E. Bekheet, J. Spectrosc. 2015, 204867 (2015).

T. S. Moss, Phys. Status Solidi B 131, 415 (1985).

P. Herve and L. K. Vandamme, J. Infrared Phys. Technol. 35, 609 (1994).

N. M. Ravindra, S. Anuch, and V. K. Srivastava, Phys. Status Solidi B 93, K115 (1979).

R. R. Reddy, K. R. Gopal, K. Narasimhulu, L. S. S. Reddy, K. R. Kumar, G. Balakrishnaiah, and M. R. Kumar, J. Alloys Compd. 473, 28 (2009).

V. Kumar and J. K. Singh, Indian J. Pure Appl. Phys. 48, 571 (2010).

M. Anani, C. Mathieu, S. Lebid, Y. Amar, Z. Chama, and H. Abid, J. Comput. Mater. Sci. 41, 570 (2008).

V. R. Shinde, C. D. Lokhande, R. S. Mane, and S.‑H. Han, Appl. Surf. Sci. 245, 407 (2005).

H. Ahmed, H. M. Abduljalil, and A. Hashim, Trans. Electr. Electron. Mater. 20, 218 (2019).

M. B. Mohamed and M. H. Abdel-Kader, Appl. Phys. A 125, 209 (2019).

O. G. Abdullah, S. B. Aziz, K. M. Omer, and Y. M. Salih, Mater. Electron. 26, 5303 (2015).

M. Frumar, B. Frumarova, P. Nemec, T. Wagner, J. Jedelsky, and M. Hrdlicka, J. Non-Cryst. Solids 352, 544 (2006).

M. M. El-Nahass, G. M. Youssef, and S. Z. Noby, J. Alloys Compd. 604, 253 (2014).

H. Ticha and L. Tichy, J. Optoelectron. Adv. Mater. 4, 381 (2002).

V. Ganesh, I. S. Yahia, S. AlFaify, and M. Shkir, J. Phys. Chem. Solids 100, 115 (2017).

M. M. El-Nahass, H. S. Soliman, B. A. Khalifa, and I. M. Soliman, Mater. Sci. Semicond. Process. 38, 177 (2015).

C. C. Wang, Phys. Rev. B 2, 2045 (1970).

E. G. El-Metwally, D. A. Nasrallah, and M. Fadel, Mater. Res. Express 6, 085312 (2019).

M. Shkir, V. Ganesh, S. AlFaify, I. S. Yahia, and H. Y. Zahran, J. Mater. Sci.: Mater. Electron. 29, 6446 (2018).

M. Shkir, M. T. Khan, V. Ganesh, I. S. Yahia, B. U. Haq, A. Almohammedi, and S. AlFaify, Opt. Laser Technol. 108, 609 (2018).

M. M. Abutalib and I. S. Yahia, J. Mater. Sci.: Mater. Electron. 29, 19798 (2018).

A. Tataroglu, Ş. Altındal, and M. M. Bülbül, Microelectron. Eng. 81, 140 (2005).

S. Choudhary, Polym. Compos. 39, E1788 (2018).

R. C. Smith, C. Liang, M. Landry, J. K. Nelson, and L. S. Schadler, IEEE Trans. Dielectr. Electr. Insul. 15, 187 (2008).

S. Choudhary and R. J. Sengwa, J. Inorg. Organomet. Polym. Mater. 29, 592 (2019).

F. D. C. Fim, N. R. Basso, A. P. Graebin, D. S. Azambuja, and G. B. Galland, J. Appl. Polymer Sci. 128, 2630 (2013).

I. S. Yahia and M. I. Mohammed, J. Mater. Sci.: Mater. Electron. 29, 8555 (2018).

R. Kandulna, R. B. Choudhary, R. Singh, and B. Purty, J. Mater. Sci.: Mater. Electron. 29, 5893 (2018).

Funding

The authors express their appreciation to the Deanship of Scientific Research at King Khalid University, Saudia Arabia, for funding this work through research groups program under grant number R.G.P.-217-41.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Ali, H.E., Khairy, Y., Yahia, I.S. et al. Vanadium Chloride Impregnated Polyvinyl Alcohol Composite as Efficient Linear, Non-Linear, and Limiting Optical Applications: Microstructure, Electrical, and Optical Properties. Phys. Solid State 63, 165–182 (2021). https://doi.org/10.1134/S1063783421010091

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063783421010091