Abstract

The forming limit curve (FLC) of zirconium alloys plays a significant role in the fabrications of spacer grid used for nuclear fuel assembly. The theoretical prediction of FLC has provided a convenient method to calculate the strain limit during the sheet forming process, but the prediction accuracy of zirconium alloy is still unsatisfactory due to its close-packed-hexagonal (HCP) structure. In this paper, to find a suitable yield surface exponent of zirconium alloys for improving the prediction accuracy, the theoretical FLCs of SZA6 zirconium alloy were calculated by self-programmed numerical codes with different exponent values and the results were compared with the experiments. To explain the mechanism of how the yield surface exponent affects the plastic behavior of SZA6 zirconium alloy, the strain distributions and element strain paths of Nakajima test were analyzed by finite element methods. At last, a suggested value of the yield surface exponent suitable for the FLC prediction of this zirconium alloy is acquired.

Similar content being viewed by others

References

Vasnin AM, Gol'tsev VY, Markochev VM, Rivkin EY (1975) Resistance to fracture of a zirconium alloy containing 2.5% Nb. Strength Mater 6(12):1535–1539

Kolesnik M, Aliev T, Likhanskii V (2019) The modeling of the hydrogen solid solubility hysteresis in zirconium alloys. Acta Mater 177:131–140. https://doi.org/10.1016/j.actamat.2019.07.044

Jung Y-I, Lee M-H, Choi B-K, Park J-Y, Jeong Y-H (2009) Development of a manufacturing process for Zr-based spacer grid materials. J Nucl Mater 392(3):482–486. https://doi.org/10.1016/j.jnucmat.2009.04.012

Chen J, Hu Q, Lv X, Li X (2017) Numerical simulation and experiment study on the nuclear fuel spacer grid stamping of Inconel 718. Procedia Eng 207:1534–1539

Kim M, Rickhey F, Lee H, Kim N (2016) Analytical determination of forming limit curve for zirlo and its experimental validation. J Manuf Process 23:122–129. https://doi.org/10.1016/j.jmapro.2016.06.006

Gensamer M (2017) Strength and ductility. Metallogr Microstruct Anal 6(2):171–185

Banabic D, Kami A, Comsa D-S, Eyckens P (2021) Developments of the Marciniak-Kuczynski model for sheet metal formability: A review. J Mater Process Technol 287:116446. https://doi.org/10.1016/j.jmatprotec.2019.116446

Keeler SP (1961) Plastic instability and fracture in sheets stretched over rigid punches. Doctoral dissertation, Massachusetts Institute of Technology

Keeler SP (1965) Determination of Forming Limits in Automotive Stampings (No. 650535). SAE Technical Paper. https://doi.org/10.4271/650535

Goodwin GM (1968) Application of strain analysis to sheet metal forming problems in the press shop. SAE Trans:380–387. https://doi.org/10.4271/680093

Dizaji SA, Darendeliler H, Kaftanoğlu B (2018) Prediction of forming limit curve at fracture for sheet metal using new ductile fracture criterion. Eur J Mech- A/Solids 69:255–265

Ma B, Liu ZG, Jiang Z, Wu X, Diao K, Wan M (2016) Prediction of forming limit in DP590 steel sheet forming: an extended fracture criterion. Mater Des 96:401–408

Considère M (1885) L’emploi du fer et l’acier dans les constructions. Ann des Ponts et Chausses 9:574–775

Swift HW (1952) Plastic instability under plane stress. J Mech Phys Solids 1(1):1–18

Hill R (1952) On discontinuous plastic states, with special reference to localized necking in thin sheets. J Mech Phys Solids 1(1):19–30

D. Banabic, Multiscale Modelling in sheet metal forming, 2016

Marciniak Z, Kuczyński K (1967) Limit strains in the processes of stretch-forming sheet metal. Int J Mech Sci 9(9):609–620

Cheng C, Wan M, Wu XD, Cai ZY, Zhao R, Meng B (2017) Effect of yield criteria on the formability prediction of dual-phase steel sheets. Int J Mech Sci 133:28–41. https://doi.org/10.1016/j.ijmecsci.2017.08.033

Hill RA Theory of the Yielding and Plastic Flow of Anisotropic Metals. Proc R Soc Lond 193(1033):281–297. https://doi.org/10.1098/rspa.1948.0045 Published 27 May 1948

Yan Y, Wang H, Li Q (2015) The inverse parameter identification of Hill 48 yield criterion and its verification in press bending and roll forming process simulations. J Manuf Process 20:46–53. https://doi.org/10.1016/j.jmapro.2015.09.009

Nurcheshmeh M, Green DE (2016) Prediction of forming limit curves for nonlinear loading paths using quadratic and non-quadratic yield criteria and variable imperfection factor. Mater Des 91:248–255. https://doi.org/10.1016/j.matdes.2015.11.098

Hill R (1979) Theoretical plasticity of textured aggregates. Math Proc Camb Philos Soc 85(1):179–191. https://doi.org/10.1017/S0305004100055596

Hosford WF (1985) Comments on anisotropic yield criteria. Int J Mech Sci 27(7):423–427

Hosford WF (1979) On yield loci of anisotropic cubic metals. In: Proceedings of the Seventh North American Metal working Conference SME, pp 191–197

Hosford WF (1972) A generalized isotropic yield criterion. J Appl Mech 39(2):607–609

Barlat F, Lian K (1989) Plastic behavior and stretchability of sheet metals. Part I: A yield function for orthotropic sheets under plane stress conditions. Int J Plasticity 5(1):51–66

Hill R (1993) A user-friendly theory of orthotropic plasticity in sheet metals. Int J Mech Sci 35(1):19–25

Banabic D (2010) Sheet metal forming processes. Springer, Berlin, Heidelberg

Hu G, Cai X, Rong Y (2010) Fundamentals of Materials Science. Jiao Tong University Press, Shanghai

Vial-Edwards C (1997) Yield loci of FCC and BCC sheet metals. Int J Plast 13(5):521–531

Cazacu O, Barlat F (2001) Generalization of Drucker's yield criterion to Orthotropy. Math Mech Solids 6(6):613–630

Cazacu O, Barlat F (2003) Application of the theory of representation to describe yielding of anisotropic aluminum alloys. Int J Eng Sci 41(12):1367–1385

Cazacu O, Barlat F (2004) A criterion for description of anisotropy and yield differential effects in pressure-insensitive metals. Int J Plast 20(11):2027–2045

Banabic D, Kuwabara T, Balan T, Comsa DS, Julean D (2003) A new yield criterion for orthotropic sheet metals under plane-stress conditions. Int J Mech ences 45(5):797–811

Banabic D, Aretz H, Comsa DS, Paraianu L (2005) An improved analytical description of orthotropy in metallic sheets. Int J Plast 21(3):493–512

Liu C, Huang Y, Stout MG (1997) On the asymmetric yield surface of plastically orthotropic materials: a phenomenological study. Acta Mater 45(6):2397–2406

Pilthammar J, Banabic D, Sigvant M (2020) BBC05 with non-integer exponent and ambiguities in Nakajima yield surface calibration. Int J Mater Form. https://doi.org/10.1007/s12289-020-01545-0

Cazacu O, Plunkett B, Barlat F (2006) Orthotropic yield criterion for hexagonal closed packed metals. Int J Plast 22(7):1171–1194

Plunkett B, Lebensohn RA, Cazacu O, Barlat F (2006) Anisotropic yield function of hexagonal materials taking into account texture development and anisotropic hardening. Acta Mater 54(16):4159–4169

Hutchinson JW, Neale KW, N. A (1978) Sheet Necking—I. Validity of Plane Stress Assumptions of the Long-Wavelength Approximation. In: Koistinen DP, Wang NM (eds) Mechanics of Sheet Metal Forming Plenum, pp 111–126

Hutchinson JW, N. KW (1978) Sheet Necking-II. Time-Independent Behavior. In: Koistinen DP, Wang NM (eds) Mechanics of Sheet Metal Forming Plenum, pp 127–153

Hu Q, Li X, Chen J (2018) New robust algorithms for Marciniak–Kuczynski model to calculate the forming limit diagrams. Int J Mech Sci 148:293–306

Backofen WA (1973) Deformation processing. Metall Trans A 4(12):2679–2699

Hosford WF, Caddell RM (2011) Metal forming: mechanics and metallurgy. Cambridge University Press. https://doi.org/10.1017/CBO9780511811111

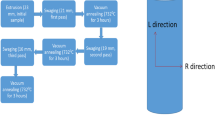

Le C, Zhongbo Y, Jun Q, Bo L, Weijun L, Xiaofeng H, Lian W (2017) Effect of heat treatment on tensile properties and microstructure of new domestic zirconium alloys. Nuclear Power Eng 38(06):129–133

ASTM E8/E8M-16a Standard Test Methods for Tension Testing of Metallic Materials. (Published year: 2016)

Morrison WB (1968) Superplasticity of low-alloy steels. ASM-Trans 61:423–434

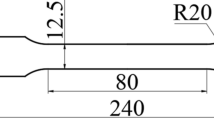

International Standard ISO 12004–2, metallic materilas-sheet and strip-determinations of forming limit curves-part 2: determinations of forming limit curves in laboratory (2008)

Barlat F (1987) Crystallographic texture, anisotropic yield surfaces and forming limits of sheet metals. Mater Sci Eng A 91:55–72

Ma BL, Wan M, Zhang H, Gong XL, Wu XD (2018) Evaluation of the forming limit curve of medium steel plate based on non-constant through-thickness normal stress. J Manuf Process 33:175–183

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lei, C., Mao, J., Zhang, X. et al. A comparison study of the yield surface exponent of the Barlat yield function on the forming limit curve prediction of zirconium alloys with M-K method. Int J Mater Form 14, 467–484 (2021). https://doi.org/10.1007/s12289-021-01616-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-021-01616-w