Abstract

The rising use of radioactive elements is increasing radioactive pollution and calling for advanced materials to protect individuals. For instance, polymers are promising due to their mechanical, electrical, thermal, and multifunctional properties. Moreover, composites made of polymers and high atomic number fillers should allow to obtain material with low-weight, good flexibility, and good processability. Here we review the synthesis of polymer materials for radiation protection, with focus on the role of the nanofillers. We discuss the effectivness of polymeric materials for the absorption of fast neutrons. We also present the recycling of polymers into composites.

Similar content being viewed by others

Introduction

Radiation is energy that comes from a source and travels through space and may be able to penetrate various materials. Radiation can be classified according to its capability to ionize matter into two main categories: (1) ionizing radiation and (2) nonionizing radiation (Singh et al. 2014a, b). Nonionizing radiation does not possess enough energy to eject electrons from the atom and produce ions such as visible light, microwaves, radio waves, alpha, beta particles from radioactive substances, or neutrons from nuclear reactors, infrared, and sunlight (Oto et al. 2015). Ionizing radiation is electromagnetic radiation that carries higher energy than nonionizing radiation that makes them capable of ejecting electrons from atoms and produces negatively charged free electrons and positively charged ionized atoms. Ionizing radiation consists of any types of photons (X-rays and gamma (γ)-rays) or particles (alpha, beta, and neutrons) (Harish et al. 2012).

The use of high-energy ionizing radiations especially gamma rays is rapidly growing in many sectors like industries, nuclear reactors, medical diagnostics, nuclear research establishment, food irradiation, nuclear waste storage sites, biological studies, defects detecting in metal castings nuclear medical imaging, and therapy, space exploration, and high-energy physics experiments, and so on (Sayyed et al. 2017a, b). Inadvertent exposure to gamma rays which possess a highly energetic and penetrating nature is of great concern due to its detrimental effects on human life, the environment, and other materials. Further, for humans, this can engender radiation sickness, organ damage, cell mutation, cancer, component failure, and other harmful effects (Sayyed et al. 2019). Therefore, protection from the inimical effects of radiation for the human population and the environment is very important and it depends on four important factors: time, distance, shielding, and activity. By minimizing exposure time and increasing the distance, the dose from the source of radiation can be reduced. Since the distance from the source follows inverse square law which means that if the distance is doubled, then the dose/dose rate at the new location will quarter (Woodhead 2002). The activity, measured in Becquerel (Bq), is defined as the strength of a radioactive source which represents the number of atoms that decay and emit radiation in one second. Radioactive substances of different activities contain different hazards and thus must be handled accordingly (Choppin et al. 2002). Shielding is generally preferred for radiation protection. Shielding has merits such as it has independent efficacy in safe working conditions over the time of exposure and distance that require continued managerial regulation (Vahabi et al. 2017). Thus, an appropriate shielding against nuclear radiation is constantly in demand for a secure life and a healthy environment as the radiation uses are consistently viable in various human activities (Kumar 2017).

Researchers have investigated various radiation shielding materials to protect life and its surroundings from debasing consequences that occurred from radiation exposure under attenuation or absorption of unwanted radiations (Singh et al. 2014a, b; Al-Buriahi et al. 2020; Levet et al. 2020; More et al. 2020a, b; Rani et al. 2020). Weight, space, cost, and attenuation or absorption capabilities of the materials used for radiological protection are key points that defy researchers to synthesize and develop appropriate shielding materials. A good radiation shield is one that can attenuate, absorb, or block the maximum part of incident gamma radiation. The nature and mechanism of interaction between gamma rays and materials is a critical issue to study to determine the ability of these radiations to diffuse and crack in the medium that according to the mechanism of interaction helps to choose the more applicable radiation shield. Materials that are supposed to be used as shields against gamma photons should have higher atomic number and density as such materials impose a higher probability of interactions that implies larger energy transfer with gamma rays (Chang et al. 2015). Withal, materials with lower atomic number (lower-Z) and density can make up of increased thickness as significantly as high atomic number (high-Z) materials in radiation protection (Luković et al. 2015; Mostafa et al. 2017). Customarily, lead, multiple layers of single slabs of pure elements such as barium (Ba), lead (Pb), aluminum (Al), copper (Cu), iron (Fe), and concrete are reliable efficient materials that prevent humans from getting affected by the obnoxious effects of ionizing radiations (Sayyed et al. 2017a, b). Despite having great radiation attenuation properties, lead and concrete are discarded due to the heterogeneous nature of lead, and moisture variation in concretes makes it hard to predict radiation protection (Singh et al. 2015) and insidious hazards are proposed by lead to human health and the environment (Thuyavan et al. 2015). In contrast to the past, polymer and its composites offer promising suitable alternative candidates to lead and concrete in the field of radiation shielding due to its lightweight, durability, flexibility along with superior physical, mechanical, optical, and radiation resistance properties (Ambika et al. 2017; Alavian et al. 2020). Besides, polymers can easily be doped with sizeable amounts of high atmic number (high-Z) materials to form their composites that are more competent radiation shields (Atashi et al. 2018).

Latterly, investigators working in the field of radiation protection have focused and reported numerous polymer matrices that can be used as gamma-ray shields like bismuth oxide (Bi2O3) filled poly (methyl methacrylate) composites; high-density polyethylene (HDPE) composite loaded with tungsten (W), molybdenum sulfide (MoS2), and boron carbide (B4C); micro- and nanosized tungsten oxide (WO3) dispersed emulsion polyvinyl chloride (EPVC) polymer composites; lead oxide filled isophthalic resin polymer composites; silicone rubber composites containing bismuth content; polymer bricks (PolyBiz); polyester composites reinforced with zinc; composites of high-density polyethylene with zinc oxide; lead oxide; and cadmium oxide (Plionis et al. 2009; El-Fiki et al. 2015; Aghaz et al. 2016; Mahmoud et al. 2018a, b; Afshar et al. 2019; Alsayed et al. 2019, 2020; El-Khatib et al. 2019; Cao et al. 2020; Kaçal et al. 2020).

The incorporation of a filler in a microsize range within the composite material leads to the enhancement of composite properties. Chemical and intermolecular forces render the bond between the polymer and the matrix. But on the nanometer scale, a nanofiller can be dispersed within the polymer matrix. Thus, the molecular interactions between the matrix and the filler are improved via chemical bonding leading to further enhancement in the mechanical and physical properties of the new polymer nanocomposites (Kumar et al. 2009). Nanofillers are characterized by a high surface-to-volume ratio which affects the alteration in the macromolecular state around the nanoparticles. The addition of nanofiller enhances the characteristics of the polymer such as increased elastic stiffness and strength, heat and barrier resistance, decreased gas permeability, and flammability. The optical, magnetic, electrical, and dielectric properties are also enhanced (Phong et al. 2013; Kumar et al. 2014). Another aspect that signifies the use of nanoparticles as additives to the polymer matrix is that the loading requirements are quite low compared to others. Various types of inorganic nanomaterials such as zeolite, zinc oxide, titanium oxide, and silicon dioxide were used with nanoclay materials to manufacture nanocomposite membrane which is effective in removing salts and minerals from seawater by process called desalination (Hebbar et al. 2017). Moreover, intensive recent studies focus on the evidence of low toxicity of mostly used nanoparticles such as copper, silver, and titania nanoparticles which were found to be having low toxicity in various natural media when to subjected oxic/anoxic suspension, and incubation with natural organic matter (Mulenos George et al. 2020).

Generally, polymers have very low mechanical characteristics but are useful because of their flexibility in applications requiring such a property. They are usually deformed at high strain under loading. The improvement in mechanical properties such as tensile strength, modulus, or stiffness is done by adding inorganic particles via reinforcement mechanisms. Such properties can indeed be tailored by changing the volume fraction, shape, and size of the filler particles. The better enhancement in mechanical properties can be gained with the reinforcement of nanofillers having a very large aspect ratio and stiffness in a polymer matrix (Bhattacharya 2016). Polymer nanocomposites offer the promise of a new generation of lightweight hybrid materials with numerous possibilities for automotive, general, and industrial applications. It includes the potential for utilization as radiation shielding materials over traditional materials. The high kinetic energy of neutrons makes them capable of passing through most materials and interacts immediately with atoms of the target material. Neutrons are generally used for the production of nuclear energy in nuclear power plants and workers there get exposed to neutrons. Besides them, aircraft personnel is prone to exposure to neutrons. Exposure to neutrons is considered critical due to the detrimental effects on the human body as they generate much denser ion paths while they deposited their energy (Mirji and Lobo 2017a, b). Thus, there is a demand for efficient, durable, lightweight, and cost-effective materials to get protected from different types of radiation.

Since polymer composites are considered cornerstone’s as engineering materials for many applications such as building, civil engineering, aerospace technology, electronics, and electrical engineering (Alavian and Tavakoli-Anbaran 2020). In addition, an important issue to be considered is the surface functionalization of polymer composites when nano-objects are added to ameliorate the performance of the synthesized material (Makvandi et al. 2020). An interesting problem arises from the use and storage of polymer composite materials as wastes. The accumulation of wastes from polymer composite materials can lead to a serious burden on humans and the environment by causing pollution to nature.

Recently, many researchers dedicated their efforts to develop new technologies for recycling and treatment of polymer composite materials waste (Turner et al. 2011). Recycling and incorporation of different filler materials in recycled polymers which can be easily composted (Adeosun et al. 2012) are extremely important to provide environmentally friendly and sustainable materials (Okamoto 2003). Many attempts have been dedicated to using biodegradable fillers which at the same time can enhance the performance of the composite (Lee et al. 2008; Qu et al. 2010). Other researchers were concerned about developing thermoplastic composites with recyclable fibers to diminish the use of fillers without any harm to the environment and keeping it clean and healthy (Kaushik et al. 2010; Zadegan et al. 2011).

In this review, the leading edge of polymer and its composites especially with nanomaterials’ as radiation-shielding materials are epitomized. In "Polymers properties and applications" section, the properties of polymer materials have been discussed. "Physical and radiation shielding properties" section gives information about physical and radiation shielding properties of polymer materials, whereas "Polymers used in radiological protection" gives an overview and historical perspective along with a brief literature review of the polymer materials. In Sect. 5, synthesis methods of polymer composites have been discussed. Also, the contemporaneous work on polymer materials and the development of polymer composites as promising candidates for radiation shielding is broadly categorized and a brief literature review is presented. Improvement in the shielding abilities of polymers by the incorporation of nanofillers is presented in Sect. 6. In Sects. 7 and 8, recycling of polymers and the use of processed and post-consumed polymers as composite materials for different applications were covered, respectively. In Sect. 9, the use of polymeric materials for neutron shielding has been covered. The comparative study of polymer composites is given in Sect. 10. Conclusions and future aspects have been outlined in Sects. 11 and 12, respectively.

Polymers properties and applications

Polymers are substances containing a large number of structural units joined by the same type of linkage. These substances often form a chain-like structure. It has been approximately 60 years since researchers first began exposing polymeric materials to ionizing radiations, and today, a substantial commercial industry is in place based on the processing of polymers with radiation. Polymers are of low atomic number and low density and thus lightweight materials. Polymers possess high durability, and they are tough. Also, they are cost-effective, need low maintenance, and stable over a wide temperature range (Alavian and Tavakoli-Anbaran 2019). Based on processing under changing temperature, polymers are categorized as thermosets and thermoplastics as listed in Fig. 1, also thermoplastics including elastomers can be divided into semicrystalline and amorphous polymers. Both the thermoset and thermoplastic polymers have some pros and cons, but thermoplastics are preferred for radiation shielding applications due to their superior properties as shown in Table 1. Also, thermoplastic polymers are highly recyclable and possess remolding abilities and eco-friendly manufacturing is possible using them (Cassagnau et al. 2007).

Polymers proved their effectiveness in wide range of applications including CO2 capture (Chatterjee and Krupadam 2018), safe gene delivery (Daima et al. 2018), dye removal (Grégorio et al. 2019), water and wastewater treatment (Lichtfouse et al. 2019), metal ions removal from wastewater (Salipira et al. 2007; Gu et al. 2018; Mao et al. 2018), and drug delivery (Parhi 2020).

Physical and radiation shielding properties

Density

“Density (ρ) is a measure of mass (M) per unit volume (V) of a substance.” Its unit is g/cm3. Density is an important physical characteristic of a material that helps to decide the radiation shielding ability of a material. It is well known that the higher the density of the material, the higher will be the chance of the probability of interaction between the incident photon and absorbing material (Hellström et al. 2017).

Hardness

Hardness also known as structural strength is an important characteristic of the material that states the maximum load that the material can bear. There are several methods for calculating the hardness of a material such as young's modulus of rigidity, Rockwell hardness test, and Vickers microhardness tester. The hardness of the material makes it able to resist plastic deformation, penetration, and scratching (Chandler 1999).

Linear and mass attenuation coefficients

A parallel beam of mono-energetic gamma-ray photons is attenuated in the matter according to the Lambert–Beer law,

where I0 and I are the un-attenuated and attenuated photon intensities respectively, t (cm) is the sample thickness, μ (cm−1) is the linear attenuation coefficient, and ρ (g/cm3) is a measured density of the sample (More et al. 2016).

The mass attenuation coefficient (µ/ρ) for any chemical compound or mixture of elements is given by

where wi is the weight fraction and (µ/ρ)i is the mass attenuation coefficient of the ith constituent element. For a chemical compound, the weight fraction is given by

where Ai is the atomic weight of ith element and ai is the number of formula units. Figure 2 represents the schematic view of the narrow beam good geometry setup including a radioactive point source which is set based on a specific measurements, the sample, the detector, a high-voltage source (HV), an amplifier (Amp), and a multi-channel analyzer (MCA) which are all connected to a dedicated computer software.

Narrow beam good geometry setup including a radioactive point source which is set based on a specific measurements, the sample, the detector, a high-voltage source (HV), an amplifier (Amp), and a multichannel analyser (MCA) which are all connected to a dedicated computer software (Alsayed et al. 2020)

Effective atomic and electron number

An effective atomic number (Zeff) is an important parameter for the determination of a substitute material for an element associated with the required energy. It fluctuates with energy, resembles the atomic number of elements, and describes the material's composition based on equivalent elements. The effective atomic number is obtained by the following equation (More et al. 2016)

Here, σa and σe are total atomic cross section and electronic cross section, respectively, and are given as follows (Sayyed et al. 2017a, b):

where fi is the fractional abundance of ith constituent element and it can be given as the following:

Effective electron density (Neff) is related to the effective atomic number and is given in the number of electrons per unit mass by the next equation (Azadbakht and Bagheri 2019):

where \(\langle\hbox{A}\rangle\) is the average atomic mass of the material.

Relaxation length

The average distance between two successive interactions is called the relaxation length. It is also called as photon mean free path (λ). It can be calculated using the value of the linear attenuation coefficient, μ (cm−1) (Akkurt and El-Khayatt 2013).

Half-value layer and tenth value layer

Half-value layer (HVL) and tenth value layer (TVL) are defined as the thickness or layer of a shield or absorber that lessens the intensity of radiation by a factor of one half and one tenth of the initial intensity, respectively (Mann et al. 2016).

Radiation protection efficiency

The radiation protection efficiency of a material is an important parameter to know material's shielding ability and is determined as follows (Harima 1983):

Buildup factor

There are several reported methods for the calculation of buildup factors (Taylor 1954; Suteau and Chiron 2005; Vahabi and Shamsaie Zafarghandi 2020). The computation of energy absorption and exposure buildup factors (EABF and EBF) using widely used G-P fitting method and equivalent atomic number for selected Polymers is given step by step as follows:

Calculation of equivalent atomic number (Z eq)

The equivalent atomic number, Zeq, depends on the chemical composition of materials. The obtained values of Compton partial mass attenuation coefficient, (µ/ρ)Comp, and the total mass attenuation coefficient, (µ/ρ)total, values for the elements Z = 4–30, and for the selected materials using the XCOM/WinXCom program (Berger and Spencer 1959; Berger and Hubbell 1987; Gerward et al. 2004). The equivalent atomic number, for a given material, is then determined by matching the ratio, (µ/ρ)Comp/(µ/ρ)total, of that material at given energy with the corresponding ratio of a pure element at the same energy. If this ratio lies between the two ratios for known elements, then the value of Zeq is interpolated using the following formula (Singh et al. 2014a, b):

where Z1 and Z2 are the atomic numbers of elements corresponding to the (µ/ρ)Comp/(µ/ρ)total ratios, R1 and R2, respectively, and R is the corresponding ratio for a given polymer at given energy that lies between R1 and R2.

Estimation of geometric progression (G-P) parameters

Utilizing buildup factor data provided by American National Standards (ANSI/ANS 1991), geometric progression (G.P.) fitting parameters (b, c, a, Xk, and d) for selected polymer material in the energy range of 0.015–15 meV up to penetration depth of 40 mean free path (mfp) is computed with the help of equivalent atomic number (Zeq) using interpolation formula. Interpolation values were obtained with the use of the following equation:

where P1 and P2 are the values of the coefficients of G-P fitting parameters corresponding to the atomic numbers Z1 and Z2, respectively, at given energy and Zeq is the equivalent atomic number of the selected material. Z1 and Z2 are the elemental atomic numbers between which the equivalent atomic number Z of the chosen samples lies.

Calculation of energy absorption and exposure buildup factor

The energy absorption and exposure buildup factors for the selected samples for incident photon energies (0.015–15 meV) up to a penetration depth of 40 mean free paths have been calculated using estimated five geometric progression (G.P.) fitting parameter which is given below (Singh et al. 2014a, b):

where E is the source energy and x is the penetration depth in the units of mean free path (mfp). Parameters b and K are corresponding to a buildup factor at 1 mean free path and a multiplication factor of dose through 1 mean free path (mfp) photon penetration, respectively, and a, b, c, d, and Xk are geometric progression (G.P.) fitting parameters.

Polymers used in radiological protection

Overview and historical perspective

Many types of materials have been used as radiation shielding barriers to keep a safe environment for everyday practice in all radiation facilities. Many features can categorize the proper shielding material to be used including a high atomic number (high-Z) for gamma radiation shieldings such as barium (Ba), lead (Pb), and bismuth (Bi) (Kaçal et al. 2021), whereas elements of low atomic numbers are preferably used for neutron attenuation. However, many constraints burden the use of such traditional shielding materials such as the cost, heaviness, and toxicity.

The urgent need for alternative materials in radiation shielding stimulated synthesis, and manufacturing of polymeric and plastic materials, which became a cornerstone in the materials science industry. Polymers in the form of bonded molecules (Callister 2007) are proposed in the radiation shielding industry due to their significant properties such as elasticity, compatibility, low cost, and lightness which nominate them as good candidates for radiation attenuation. Furthermore, polymers are materials containing elements with a low atomic number such as carbon (C), hydrogen (H), oxygen (O), and nitrogen (N) which are extremely important in medical applications used as tissue equivalent and phantom materials that resemble the human body. Polymers are frequently used in everyday life such as industrial (Kaphle et al. 2017), research, tissue engineering (Song et al. 2018), electronics, and drug delivery (Alavian and Tavakoli-Anbaran 2020). So the interaction of polymer material with radiation determines their contribution to the fields of science and applications. Usually, materials having dense structures are better in radiation resistance due to a high degree of symmetry. The interaction between organic material and radiation is governed by many mechanisms such as oxidation, gas production, and depolymerization (Tsepelev et al. 2019; Wady et al. 2019). In polymers, radiation resistance depends on oxygen rate and volume present in the material. Organic polymer materials are characterized by lightweight, corrosion resistance, low dielectric constant, and lightness, which allow their application in many fields containing radiation hazard.

Brief literature review

Many researchers reported the use of polymers and polymer-based materials in the field of radiation shielding. This concern has been growing towards using eco-friendly and lead-free materials since lead poses a great hazard to both human health and the environment.

The X-ray and gamma radiation shielding properties of silicon polymers such as polymer A-poly dimethyl siloxane (C2H6OSi), polymer B-polymethyl hydro-siloxane (CH4SiO), polymer C-per hydro-polysiloxane (H3SiN), polymer D-poly dimethyl siloxane (C2H6Si), polymer E-methylsilses quinoxaline (C12H32O8Si8), and polymer F-silalkalyene polymer (SiC3H8) were studied. So that polymethyl hydro-siloxane (CH4SiO) possessed the lowest values of half-value layer, tenth value layer and mean free path (HVL, TVL, and λ), and the highest attenuation coefficient (Nagaraja et al. 2020). Another type of polymer blends was prepared via compression molding, where MCNP5 simulation geometry would be suitable to study the radiation shielding performance of polyamide 6/acrylonitrile butadiene styrene blends against gamma rays for various energies (Abdel-Haseiba et al. 2018). Using a spectrophotometric technique, the radiation effect of 60Co gamma rays on a polycarbonate detector was investigated and the obtained results indicated that the polycarbonate revealed good performance to be used as a gamma radiation dosimeter (Galante and Campos 2010).

Besides, polymers proved their performance and applicability in nuclear medicine as radiation shielding against Technetium-99m, where complexed grafted low-density polyethylene films revealed that the protection efficiency of complexed grafted films was higher than in grafted and virgin films (Awadallah-F and Antar 2014). Also, most frequently used polymers such as POM—polyoxymethylene, PAN—polyacrylonitrile, NR—natural rubber, PEA—polymethyl acrylate, PPM—poly-phenyl-methacrylate, PET—polyethylene terephthalate (Bhosale et al. 2017) and polyamide (nylon 6) (PA-6), polyacrylonitrile (PAN), polyvinylidene chloride (PVDC), polyaniline (PANI), polyethylene terephthalate (PET), polyphenylene sulfide (PPS), polypyrrole (PPy), and polytetrafluoroethylene (PTFE) (Kaçal et al. 2019) were studied in terms of their gamma radiation attenuation. Polyacrylonitrile, natural rubber, and polyvinylidene chloride have the highest attenuation coefficient values. Furthermore, there is a remarkable increase in attenuation especially in the high energy region for barite, marble, and limra (Akkurt et al. 2009) and also for polyvinyl chloride (PVC) among six polymer and plastic materials: bone-equivalent plastic (B-100), polyvinyl chloride (PVC), air-equivalent plastic (C-552), radio chromic dye film (nylon base), polyethylene terephthalate (mylar), polymethyl methacrylate (PMMA), and concrete (NBS) in the energy range 10–1400 keV. Polyvinylidene chloride (PVC) revealed the highest shielding performance against gamma rays (Mann et al. 2015a, b). Also, resin 250 WD revealed good performance in neutron shielding applications compared to K-resin, epoxy resin, and resin which were studied by Elmahroug et al. (2014) for gamma (γ) ray and neutron absorption. Among the selected samples, resin 250 WD is a good material for neutrons shielding applications. Epoxy resin and resin showed slightly better gamma rays shielding abilities than those of the other resin for applications. Using Monte Carlo simulation code, bone-equivalent plastic, polyvinylidene chloride, air-equivalent plastic, radio chromic dye film, polyethylene terephthalate, and polymethyl methacrylate was investigated in terms of values of mass attenuation coefficient and half-value layer (μm and HVL) showing that the nylon-based radio chromic dye film has better shielding effectiveness than concrete for energies above 100 keV (Gurler and Akar Tarim 2016). Applying MCNP simulation for low atomic number (low-Z) materials such as polypropylene, perspex, bakelite, teflon, polyethylene, poly-carbonate, nylon 6–6, and polymethyl methacrylate (PMMA) polymers in the energy range of 59.5–1332.5 keV revealed good agreement with experimental and XCOM values. Thus, the used simulation geometry in the reported work can be used as an alternative method for the experiments for MCNP simulation for low-Z materials (Singh et al. 2015). Also, dimethyl sulfoxide (DMSO) and polyethylenimine (PEI) polymers have been studied by (Sayyed 2016) for their possible application for γ-rays and neutron shielding. Mass attenuation coefficient (µ/ρ), effective atomic and electron number (Zeff and Ne) in the wide energy range of 1 keV–100 GeV along with macroscopic removal cross section for fast neutrons (∑R) have been calculated. Dimethyl sulfoxide showed superior shielding properties than polyethylenimine for gamma (γ)-ray, whereas polyethylenimine is a good material for neutron absorption. Moreover, the interaction parameters linear and mass attenuation coefficient, mass energy absorption coefficients, kinetic energy released per unit mass, and equivalent atomic number (μ, μ/ρ, μen/ρ, KERMA, and Zeq) of gamma rays for different materials in the wide energy range of 1 keV–100 GeV were studied for bone-equivalent plastic, air-equivalent plastic, radio chromic dye film, polyethylene terephthalate, polymethyl methacrylate (PMMA), and polyvinyl chloride (PVC) polymers. Polyvinyl chloride showed better shielding performance, and it is even superior to NBS concrete (Mann et al. 2016). Also, in the energy range, 300–2000 keV, polymers including polyethylene (PE), polystyrene, polycarbonate, poly(vinyl alcohol), polyvinyl chloride, polyethylene terephthalate, polyvinyl pyrrolidone, polytetrafluoroethylene, polypropylene, and polymethyl methacrylate showed values of mass attenuation coefficients in good agreement with NIST data 300–2000 keV for all studied polymers. These data would use in selecting good shielding material (Mirji and Lobo 2017a, b). Vahabi et al. (2017) have reported mass attenuation coefficients for determined using MCNP4C code and XCOM program for poly-propylene, perspex, bakelite, teflon, polyethylene, polycarbonate, nylon 6–6, and polymethyl methacrylate (PMMA). It was observed that simulated results fit well with XCOM values and experimental results in the energy range of 59.5–1332.5 keV. From the results, it can be concluded that the simulation geometry used here can be used as an alternative method for the experiments. FLUKA Monte Carlo code and XCOM program were used as an efficient alternative tool to determine radiological parameters mass attenuation coefficient, relaxation length, half and tenth value layer, electronic and atomic cross section, effective atomic number, and electron density (μm, λ, TVL, HVL, σt,el, σt,a, Zeff, and Nel) of the polymeric materials: polytetrafluoroethylene, bakelite, polyethylene terephthalate, polypropylene, polysulfone, polystyrene, polyethylene, natural rubber, polymethyl methacrylate, and polyvinylchloride (Sharma et al. 2019). Polymers that are best suited to gamma irradiation for manufacturing N95 masks were identified. The findings showed that having the lowest (tenth and half-value layer) TVL, HVL, and mean free path (MFP), the N2 sample [polyvinylchloride (PVC)] has the best radiation attenuation performance and is the most promising mask sample when it comes to gamma-ray attenuation features (Kilicoglu et al. 2021).

Mass attenuation coefficient (μm) and other derived parameters such as linear attenuation coefficient, atomic, total and electronic cross section, effective atomic number, electron density, half-value layer, and tenth value layer (μ, σa, σt, σe, Zeff, Nel, λ, HVL, and TVL) for few thermoplastic polymers with the help of NaI (Tl) detector and WinXCom program revealed good agreement between experimental, theoretical, and simulated values of all parameters confirming the competency of the tested polymers in nuclear medicine gamma shielding (More et al. 2020a, b). Also, using the same experimental setup, few polymers have been studied with the determination of mass attenuation coefficient, total cross section, molar extinction coefficient, effective atomic number, and electron density (μm, σt, σe, ε, Zeff, and Neff) for gamma-ray shielding application using NaI (Tl) scintillation detector and XCOM program. Among the chosen samples, nylon 1,1 showed better shielding capabilities (More et al. 2017). Polymethyl methacrylate and kapton polyimide polymers were investigated and their gamma-ray attenuation parameters such as mass attenuation coefficient, total and electronic cross section, molar extinction coefficient, effective atomic number, and electron density were measured using NaI (Tl) crystal detector in the energy range 84–1330 keV. Energy absorption and exposure buildup factors have also been calculated and reported for the selected polymers (Manjunatha 2017). For a locally developed polymeric material, namely poly-boron, mass attenuation coefficient values have been computed using the analytical method for shielding application. The calculated values were compared with values calculated based on the WinXCom program, and a good agreement has been observed between these two values. Also, linear attenuation coefficients and relaxation length have been determined. Linear and mass attenuation coefficient values for poly-boron were found to be greater than those for pure polyethylene and borated polyethylene (Biswas et al. 2016).

All these studies for pure polymers for their use in radiological protection are very useful. These studies have great significance to choose a better polymer material that would be used in radiation shielding. Once getting complete information about a better polymer material, it becomes easy to reinforce it for the needed application. Furthermore, it can be noticed that researchers have to focus on thermoplastic materials such as polyetherimide, kapton, polysulfone, polypropylene, polyether ketone, polymethyl methacrylate, poly (butylene terephthalate), poly (ether sulfone), polymethyl pentane, poly (butyl methacrylate), poly (phenylene oxide), high-density polyethylene, poly (ethylene isophthalate) and these thermoplastic materials help in control plastic pollution as they can be recycled.

Preparation methods for polymer composites

Several types of commercially available inorganic filler molecules can be incorporated in the polymer matrix to enhance their properties by the use of several synthesis methods. A few techniques for the fabrication of polymer composites are discussed below:

In situ synthesis

There are three types of in situ synthesis as follows: in situ polymerization, in situ synthesis of inorganic nanoparticles in a polymer matrix, and in situ intercalative polymerizations. In situ polymerization methods, the inorganic nanoparticles, are introduced to the monomer precursor for the desired polymer matrix in the liquid state, dispersed thoroughly, either in the presence or in the absence of a solvent, and then the monomer is polymerized with the nanofiller by adding the appropriate catalyst or initiators under certain conditions. Thermoplastic- and thermoset-based nanocomposites can be synthesized via this route.

Figure 3 reveals the in situ technique for polymer nanocomposites where nanoparticles are added to polymer matrix to form polymer nanocomposite. This method is significant and efficient for synthesizing composites starting from nanoparticles as precursors with the presence of polymer matrices. The first step in this process is explained by the nucleation of nanoparticles and their growth within the matrix of the polymer so that the aggregation of nanoparticles caused by handling and isolation is hindered. This technique represents a good advantage in terms of stabilization of the functional groups attributed to the polymer with the synthesized nanoparticles. Thus, particle size can be controlled and the agglomeration of nanoparticles is prevented as well as good spatial distribution is maintained (Ameen et al. 2012).

In situ intercalative polymerization is a highly efficient technique with a simple procedure based on the dispersion of the filler in the polymer precursors. It is usually utilized to prepare nanocomposites based on thermoset polymers. In a monomer solution, the fillers as nanoparticles are inflated to form intercalated sheets with the polymer matrix. There are two ways to initiate the polymerization: heat and radiation via diffusing an appropriate filler as an initiator or via caption exchange taking place after nanoparticle swelling. In situ intercalative polymerization technique possesses several advantages such as it is theoretically solvent-free and combines the polymerization and intercalation steps into a single, simultaneous process (Chen et al. 2009).

In situ intercalative polymerization

In situ intercalative polymerization is a highly efficient technique with a simple procedure based on the dispersion of the filler in the polymer precursors. It is usually utilized to prepare nanocomposites based on thermoset polymers (Avella et al. 2001). In this technique, the nanofillers are swollen within the liquid monomer or a monomer solution so the polymer formation can take place between the intercalated sheets. Polymerization can be initiated either by heat or radiation, by the diffusion of a suitable initiator, or by an organic initiator or catalyst fixed through cation exchange inside the interlayer before the swelling step by the monomer. In situ intercalative polymerization technique possesses several advantages such as it is theoretically solvent-free and combines the polymerization and intercalation steps into a single, simultaneous process.

Melt intercalation

Melt intercalation and hot pressing processes (also called melt blending method) are the typical standard approaches for synthesizing thermoplastic polymer nanocomposites. As shown by Fig. 4, it involves annealing the polymer matrix at high temperatures (above its softening point) statistically or under the shear, adding the nanofiller, and finally blending the composite to optimize the polymer–filler interactions and achieve uniform distribution. The melt intercalation technique has great advantages over either in situ intercalative polymerization of polymer solution intercalation. For example, melt intercalation is highly specific for the polymer, leading to new hybrids that were previously inaccessible. Besides, the lack of organic solvent usage makes melt intercalation an environmentally friendly and economically favorable method for industries from a waste perspective (Zeng et al. 2002).

Sol-gel process

The sol-gel synthesis (SGS) illustrated in Fig. 5 is a process of solidifying a compound which contains a highly reactive component via solgel or solution which is followed by annealing and heat treatment. This process belongs to waste-free methods, and recently, it has been employed not only to prepare organic/inorganic composites but also to provide high-performance materials at lower temperatures and lower cost. The sol-gel route has been applied broadly because of its capability to control the miscibility between organic and inorganic components at the molecular level (Camargo et al. 2009). The major advantage of the sol-gel process is the high purity, high chemical homogeneity, and rigorous stoichiometry control associated with mild conditions, such as relatively low temperature and pressure.

Ultrasound cavitation

The ultrasound cavitation technique is considered one of the most promising techniques for intensifying chemical/physical processing applications. Figure 6 summarizes the steps in the ultrasound cavitation technique; a solution containing a nanopolymer composite is prepared after mixing two solutions A and B, after that a sonicator probe is immersed, and using a pulse controller, ultrasound is applied. A sound wave consisting of successive compression (increase in local pressure) and rarefaction (decrease in local pressure) cycles is applied to a liquid. Then, the liquid starts oscillating tuned with the sound waves. Cavitation is mainly due to the generation, growth, and collapse of cavities which produce high energy densities at plenty of locations in a reactor simultaneously, thus resulting in very high conditions of pressure and temperature locally, with the overall ambient temperature of the environment. The subsequent formation of these cavities is called cavitation. By introducing ultrasound, the cavitational energy can be used for the cracking of the petroleum residue.

Direct mixture of polymer and particulates

Direct mixing of nanoparticles with a polymer melt in technical polymer processes, such as extrusion, is a classical method for preparing composite materials from thermoplastic polymers. As illustrated in Fig. 7, the melt processing extrusion technique involves direct mixing the host nanofillers with a polymer powder by a twin-screw extruder or blender, pressing the mixture into a pellet, and heating at the appropriate temperature.

Template synthesis

In this technique, a template is used to form nanocomposite materials of a particular shape, for example layered and hexagonal shape. The soluble polymer acts as a template for the formation of layers. The technique is based on self-assembly forces, and the polymer serves as a nucleating agent and promotes the growth of the inorganic filler crystals. As those crystals grow, the polymer is trapped within the layers and thus forms the nanocomposite. Generally, template synthesis is an easy procedure with large-scale production (Alexandre and Dubois 2000).

Mechanical milling

Mechanical milling is a well-established technique in polymer composite synthesis which involves continuous mixing with repeated high-intensity plastic deformation. These deformations can provoke composites with atomic-scale dimensions. So, the main objective of this technique is to reduce the particle size and blend the particles in new phases. As illustrated in Fig. 8, the method involves the use of agate balls in a ball mill jar where the nanoparticles are milled simultaneously with the polymer to produce a polymer nanocomposite. Mechanical milling is solid-state mixing that enhances the homogeneous dispersion of filler into the polymer matrix and is a better ecological and economical alternative. It works at low temperatures and can be used for almost any type of polymer matrix. More advanced materials can be prepared when working at low temperatures, with any type of polymer, and without any extremely important solvent.

Nonconventional methods

To facilitate better dispersion of the filler in the polymer matrix for improved properties of final composites, researchers investigated different routes based on the traditional methods mentioned previously. For instance, in situ polymerization can be customized to be redox or catalytic chain transfer or even photo-induced polymerizations. Others include microwave-induced synthesis, one-pot synthesis, template-directed synthesis, electrochemical synthesis, self-assembly synthesis, and intermatrix synthesis (IMS).

Polymer composites for gamma-radiation shielding

Development of polymer composites as gamma-radiation shielding materials

To improve the polymer performance and characteristics, a stiff material called filler can be added to the polymer matrix to form a polymer composite. The combination between filler and polymer matrix provokes the formation of a mixture that influences the polymer–composite properties by retaining the properties of both the filler and the polymer. The composite materials are named according to the reinforcement and the matrix material constituting them. There are many types of matrix materials such as metal matrix composites, polymer matrix composites, ceramic matrix composites, and epoxy resin matrix composites. The availability of radiation shielding materials that can be moulded into specific shapes and used even at high temperatures is quite significant for medical and industrial procedures.

The resistance of a material to radiation is attributed to many factors such as the type of radiation used, the rate of absorbed dose, radiation exposure (pulsed or continuous), area and size of the material, the surrounding environment (pressure, temperature, electric, or magnetic field) (McMillan 2019). But in inorganic materials, the radiation resistance depends on the type of chemical bond and crystal structure of the material (Wozniak et al. 2017). Due to relatively high processing ability and durability, polymer composite materials are vastly used in various fields of industry. Since 1916, the first polymer composite was used as phenol–formaldehyde resin (wood flour) by bakelite. Recently, about 10,000 fillers are known and used. The main duty of the filler is to provide the material with special properties and cost-effectiveness. Composites of polymer materials are superior due to their merits in flexibility, low cost, workability, mechanical stability, high aspect ratio. Also, the research studies confirmed that composite materials not only are better in radiation resistance but also have thermal stability and high mechanical properties (Zezin et al. 2004). Numerous studies are reporting the use of polymer composites as gamma-radiation shields.

Different barite concentrations 0%, 10%, 20%, 30%, 40%, and 50% were added to epoxy, and the linear attenuation coefficients of the composites increased with the increase in barite concentrations (Al-Sarray et al. 2017). Styrene-butadiene rubber (SBR-1502)/montmorillonite nanocomposites in the presence of ferric oxide (Fe2O3), zinc oxide (ZnO), molybdenum oxide (MoO), and titanium dioxide (TiO2) were synthesized to investigate their effectiveness in shielding against gamma radiation. Styrene-butadiene rubber/molybdenum oxide (SBR/MoO) composite confirmed the best performance as a radiation shield and its effectiveness in nuclear medicine departments (Atta et al. 2015). The gamma-rays radiation shielding properties for composites of natural rubber (NR) and styrene-butadiene rubber (SBR-1502) incorporated with different concentrations of the lead were investigated by using 137Cs as a gamma radiation source. The results confirmed that the linear attenuation coefficient µ increased significantly with the increase in filler content (Gwaily 2002). Multiple ABS (acrylonitrile butadiene styrene) with different addition concentrations of bismuth (1.2–2.7 g/cm3) was synthesized and tested, and the radiation attenuation behavior was improved by increasing bismuth concentration (Ceh et al. 2017). Also, polylactic acid (PLA) nanocomposites containing 3%, 5%, and 7% zeolite were prepared by solution casting method. The increment in zeolite content promoted the increase in radiation resistance due to polymer interaction with radiation and the formation of reactive (Yildirim and Oral 2018). Gamma-ray shielding performance of 3-dimensional (3D)-printed poly-ether-ether-ketone/tungsten composites (Wu et al. 2020) and poly(vinyl alcohol)–bismuth oxide composites (Muthamma et al. 2019) for X-ray and gamma (γ)-ray shielding applications were investigated.

Polycarbonate (PC) loaded with different filler levels equal to 0.1, 0.2, 0.3, 0.5, 0.75, 1.0, 2.5, 3.5, and 5.0 wt% (weight percent) of bismuth nitrate pentahydrate (Bi(NO3)3·5H2O or BNP) was prepared via dispersing of filler in polycarbonate solution, followed by casting. The radiation attenuation parameters showed considerable variation with a strong dependence on the energy of the incident gamma-ray photon and the concentration of bismuth nitrate pentahydrate (BNP) incorporated as filler within the polycarbonate matrix (Mirji and Lobo 2020). Gadolinium oxide/poly-ether-ether-ketone (Gd2O3/PEEK) composites were synthesized using a twin‐screw extruder. The X‐ray shielding properties of composites improved with the increment of the Gd2O3 (gadolinium oxide) (Wang et al. 2015). Polyethylene/boron carbide composites were fabricated using conventional polymer processing techniques. The sample containing 2 wt% (weight percent) boron carbide composite showed the best radiation shielding measurements (Harrison et al. 2008). Photon shielding properties for bismuth oxychloride (BiClO) 5, 10, 15, and 20% filled polyester concretes were studied in the energy range of 59.5–1408 keV using an HPGe detector. The experimental values are in good agreement with those obtained from XCOM and FLUKA code. In the prepared polymer composites, bismuth oxychloride (20%) filled polyester has the best radiation shielding property among the selected samples (Sharma et al. 2020). Gamma-ray and neutron shielding characteristics of polypropylene fiber-reinforced heavyweight concrete exposed to high temperatures were studied and barite concrete for simultaneously achieving better residual compressive strength, gamma ray, and neutron shielding capability were recommended (Demir et al. 2020).

Four samples have been prepared by different proportions (5–20%) of filler materials (barium titanate, BaTiO3, and calcium tungsten oxide, CaWO4). Experimentally determined values of the linear attenuation coefficients, radiation protection efficiencies, half-value layers, mean free paths, and effective atomic numbers of studied polymer composites have been supported with theoretical results. Among the prepared polymer composites, barium titanate (20%) and calcium tungsten oxide (20%) have better gamma-ray attenuation characteristics than the other tested polymer composites. Calcium tungsten oxide, CaWO4 (20%), has slightly better gamma-ray attenuation properties than barium titanate, BaTiO3 (20%) (Akman et al. 2020). Gamma-ray attenuation characteristics of poly (methyl methacrylate) composites with 0–44 wt% of bismuth trioxide (Bi2O3) filler were investigated. The fast ultraviolet curing method was used for the preparation of polymer composites. The physical and mechanical properties of prepared polymer composites have also been studied. The high loading of bismuth trioxide in the polymethyl methacrylate (PMMA) samples improved the microhardness to nearly seven times that of the pure PMMA (polymethyl methacrylate) (Cao et al. 2020). Using NaI detector for gamma rays detection, the attenuation parameters of including the mass attenuation coefficient (µ/ρ), mean atomic number (<Z>), effective atomic cross section (σa), effective atomic number (Zeff) plus electron number (Neff) for the samples: pure epoxy, aluminum oxide (Al2O3) epoxy (6 and 15 weight %), and ferric oxide (Fe2O3) epoxy/(6 and 15 weight %), were determined. With the increase in gamma-ray energy, mass attenuation coefficient and effective atomic cross-section values were decreased, whereas effective atomic and electron number values were increased (Al-Dhuhaibat et al. 2020).

Gamma-ray shielding properties of polyester composite reinforced with different proportions of cadmium telluride (CdTe) have been investigated experimentally using HPGe detector and theoretically using XCOM program in the energy range of 59.5–1408.0 keV. Remarkable radiation protection efficiency was obtained by filler material cadmium telluride (Akman et al. 2021). Photon attenuation characteristics such as mass attenuation coefficient, half and tenth value layer, mean free path, effective atomic number and electron density, and buildup factors of polyvinyl alcohol (PVA) mixed with lead nitrate, Pb(NO3)2 (0–30 weight%) were studied experimentally along with using XCOM values and MCNP5 simulations. With the increase in additive material, radiation shielding characteristics of polymer matrix were observed to be increased (Issa et al. 2019). A skin-interactive metal-free spongy electrode in the piezoelectric sensor was reported where highly aligned poly(vinylidene fluoride) (PVDF) nanofibers (NFs) arrays are introduced as piezoelectric active component and conducting polyaniline-coated polyvinylidene difluoride (PANI-PVDF) nanofibers mats served as flexible electrodes. Ninety-nine percent yield of piezoelectric phases of the aligned polyvinylidene difluoride arrays is the key factor to exhibit promising mechano-sensitivity performance that in turn helps in human health monitoring (Maity et al. 2020). The radiation shielding properties of flexible polyvinyl alcohol/iron oxide polymer composite with five different concentrations of magnetite were investigated in the energy range of 15 keV–20 meV. 0.5% of the magnetite which gives superior shielding properties compared with other concentrations (Srinivasan and Samuel 2017).

For filler-enhanced materials, innovation has led to greatly improved properties and functions with nanofillers, which cannot be obtained using traditional macro- and microtechnology within normal filler loading levels. Filler-enhanced polymer nanocomposite technology is one of the driving forces in stimulating and promoting nanotechnology development and has attracted considerable interest in both academia and industry. At present, nanotechnology has expanded into almost every aspect of science and technology.

Advances in polymer composites by the use of nanofillers

In general, the incorporation of nanofillers into the composite material leads to the enhancement of composite properties. The filler is bonded to the polymer matrix via weak chemical and intermolecular forces. But on the nanometer scale, a nanofiller can be dispersed within the polymer matrix. Thus, the molecular interactions between the matrix and the filler are improved via chemical bonding leading to further enhancement in the mechanical and physical properties of the new polymer nanocomposites (Kumar et al. 2009). The nanofillers are characterized by a high surface-to-volume ratio which causes the alteration in the macromolecular state around the nanoparticles. Promising features of the polymer are enhanced by the addition of nanofiller, such as increased elastic stiffness and strength, heat and barrier resistance, decreased gas permeability, and mainly radiation resistance. Also, nanoparticles offer a great advantage compared to other additives to the polymer since the loading requirements are quite low. Many factors can influence polymer nanocomposites including the type of filler, the ratio of the filler to matrix, synthesis technique, and its conditions. By dispersing nanofillers within a polymer matrix, an obvious enhancement in the composite properties is obtained.

Many polymers can be added as the base matrix, and polyethylene (PE) as an example is a widely used material in many applications; however, many environmental factors affect this polymer such as solar radiation, temperature, thermal cycling, humidity, weather, and pollutants. Other types of polymers such as low-density polyethylene (LDPE), high-density polyethylene (HDPE), polyvinyl alcohol (PVA), polystyrene (PS), polypropylene (PP), and polyvinyl pyrrolidone (PVP) are also important and widely used. An important feature that characterizes polymer nanocomposites is their good performance in radiation shielding. Protection and convenient shielding against ionizing radiation are essential to minimize the harmless effect on both humans and the environment. As illustrated in Fig. 9, many forms of nanoplates, nanoparticles, fibers, tubes, and whiskers can be added to polymer matrix to synthesize polymer composites which can be used as radiation shielding materials in radiation facilities, nuclear power plants, and also nuclear cleaning of environment. Various studies focused on the effect of adding nanofiller on the radiation shielding behavior of polymer composites. The incorporation of different types of fillers into the polymer matrices has shown interesting results in the attenuation of gamma radiation.

The incorporation of nanofillers mainly carbon-based and metal/metal oxide nanoparticles into polymeric membrane matrixes improved the filtration capability of nanocomposite membranes to separate pollutants from water which has been a global challenge due to the great demand for clean water supply (Wen et al. 2019). The degradation of fragmented microplastic residues containing low-density polyethylene (LDPE) via visible-light-induced heterogeneous photocatalysis enhanced by zinc oxide nanorods showed an increase in brittleness, cracks on the surface, and in carbonyl index of residues with a value of 30% (Tofa et al. 2019). High-density polyethylene (HDPE) composite loaded with tungsten (W), molybdenum disulfide (MoS2), and boron carbide (B4C) demonstrated that the flexible composite sheet of high-density polyethylene/45% (wt) tungsten provided comparable X‐ray absorption to the non‐flexible lead sheet but much lighter in weight (Afshar et al. 2019). Micro- and nanosized tungsten oxide (WO3) were added to polyvinyl chloride (PVC) and studied against low energy X-rays, and nanostructured tungsten oxide/polyvinyl chloride shields have higher photon attenuation compared to the microsized samples (Aghaz et al. 2016). Cerium oxide (CeO2) nanoparticles were synthesized by the solgel method and were further used to develop polysulfone–cerium oxide mixed-matrix membrane with enhanced gamma radiation-resistant property (Bedar et al. 2019).

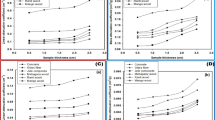

The gamma-ray attenuation parameters of high-density polyethylene/zinc oxide composite prepared via compression moulding technique by mixing bulk and nanozinc oxide of weight percent (10, 20, 30, and 40 weight %) with high-density polyethylene as a polymer matrix were studied. The results obtained for radiation shielding parameters of nanozinc oxide blended with high-density polyethylene were found to be more promising and efficient for radiation protection against gamma-ray. Mass attenuation coefficient, molecular, and atomic cross-section (μm, σmol, and σatm) values decreased with incident photon energy and increased with the weight percentage of both bulk and nanozinc oxide filler (Alsayed et al. 2019, 2020). Epoxy composite samples filled with lead oxide (PbO) and lead tetraoxide (Pb3O4) were fabricated to investigate the mass attenuation characteristics of the composites to X-rays in the diagnostic imaging energy range. The effect of density on the attenuation ability of the composites for radiation shielding purposes was studied using a calibrated X-ray machine (Azman et al. 2013). By varying the amounts of powdered fillers lead oxide (PbO) and tungsten oxide (WO3) added to low density-polyethylene, the attenuation performance against gamma radiation was studied revealing that the samples of high filler loadings showed good attenuation performance against gamma radiation (Belgin and Aycik 2015). Also, zirconium dioxide (ZrO2) nanoparticles with various weight percent (1, 2, 3, 5, and 10 wt%) were added to synthesize poly(vinylidene fluoride–tryfluorethylene)/zirconium dioxide [P(VDF-TrFE)/ZrO2] polymer composites and investigate their protective shielding of patients during radiological procedures (Fontainha et al. 2016).

Ultra-high-molecular-weight polyethylene (UHMWPE) fiber epoxy composite hybridized with gadolinium, boron nanoparticles (Mani et al. 2016), and nanoepoxy (Zhong et al. 2009) showed good neutron shielding performance. Moreover, high-density polyethylene/bismuth (HDPE/Bi) composite prepared by adding different weight percentages (0%, 10%, 20%, and 40%) of bismuth in high-density polyethylene (HDPE) matrix showed the shielding efficiency of synthesized high-density polyethylene/bismuth composites increases with an increase in the weight percentage of bismuth (Sheela et al. 2019). The physicochemical properties of low-density polyethylene and ethylene–vinyl acetate composites cross-linked by ionizing radiation by melt mixing showed that low-density polyethylene/ethylene–vinyl acetate copolymer/carbon black (LDPE/EVA/CB) and ethylene–vinyl acetate copolymer/carbon black (EVA/CB) composites tend to crosslink by irradiation (Basfar and Ali 2011). Using Ba‐133, Cs‐137, and Co‐60 gamma-ray sources, the effect of adding bismuth oxide as a reinforcement to unsaturated polyester was investigated, revealing that by increasing filler content, the radiation shielding properties increase. The half and tenth value layer and relaxation length of the composites were found to decrease with an increase in the filler concentration (Ambika et al. 2017). Nanotungsten (W) dispersed polymer composite was significant 75% for 133Ba (≈ 0.3 meV) compared to the microtungsten (W) composites (Das et al. 2009), and also silicone rubber matrix dispersed with 37.5% weight of tungsten (W) and bismuth oxide (Bi2O3) confirmed good gamma-ray-shielding performance compared to lead (Atashi et al. 2018). Tungsten oxide (WO3) and bismuth oxide (Bi2O3) nanoparticles improved the radiation shielding properties of hematite–serpentine concrete (HSC) (Tekin and Issa 2018) and emulsion polyvinyl chloride (EPVC) (Shik and Gholamzadeh 2018).

The effect of adding lead (Pb) powder to natural rubber (NR) and wood/natural rubber composites was investigated, and their performance in radiation shielding was efficient in attenuating low-intensity gamma rays (Ninyong et al. 2019). Iso-phthalate-based unsaturated polyester resin filled with different concentrations of lead monoxide particulate polymer composites was prepared for gamma rays of energy 0.662 meV from 137Cs point source, and linear attenuation coefficient was found to increase with increased filler content in the composites (Harish et al. 2012). The radiation shielding properties of concrete were improved for gamma rays of 662, 1173, and 1332 keV using 137Cs and 60Co sources via adding nano lead compounds (Hassan et al. 2015). Nanogadolinium oxide (Gd2O3) composites were more efficient in shielding X- and gamma ray than microgadolinium oxide (Gd2O3) composites, and an enhanced effect of ~ 28% was obtained with gadolinium oxide (Gd2O3) content of around 5 weight percent at 59.5 keV (Li et al. 2017). The addition of micro- and nanocadmium oxide (CdO) particles to the high-density polyethylene matrix increased the mass attenuation coefficients of the composites mainly at low gamma-ray energies (El-Khatib et al. 2019). The polymer–matrix composites based on high-density polyethylene with either lead oxide (PbO) nanoparticles or lead oxide bulk using 10 and 50% weight fractions synthesized by solid-state intermixing and thermal pressing technique showed interesting gamma-rays shielding properties especially for high filler loadings (Mahmoud et al. 2018a, b).

X- and gamma-rays attenuation parameters for polyacrylamide and zinc oxide (ZnO) composites were evaluated as light-shielding materials using MCNP and XCOM simulation. The obtained results showed that the composites were better in gamma-ray shielding performance compared to the bulk of zinc oxide (Nasehi and Ismail 2019). Extensive investigation on gamma-ray shielding features of palladium/silver (Pd/Ag)-based alloys in the energy range 81 keV-1333 keV by using an HPGe detector, revealing that palladium/silver (Pd75/Ag25) alloy sample had superior photon shielding characteristics among all composites (Agar et al. 2019). Unsaturated polyester containing 5 weight percent nanoclay and different amounts of lead monoxide particles (0, 10, 20, and 30 weight percent) were investigated by 192Ir, 137Cs, and 60Co gamma radiation sources, the mass, and linear attenuation coefficients which were increased by increasing lead monoxide content (Bagheri et al. 2018). The radiation shielding performance of natural fiber high-density polyethylene and lead oxide composites revealed that the mass attenuation value decreased sharply from 10 keV to 0.8 meV and then smoothly decrease above 0.8 up to15 MeV (Abdo et al. 2003). Nanostructured natural bentonite clay coated by polyvinyl alcohol polymer materials (Hager et al. 2019) were developed for gamma rays attenuation.

The radiological parameters of composite filler, zirconium, and acrylic coating materials used in dental treatment revealed that maximum attenuation occurred for samples of 1 mm thickness where 21%, 10%, and 2% of the incident radiation were absorbed by zirconium, composite, and acrylic samples, respectively (Abbasova et al. 2019). The attenuation coefficients against gamma radiation were studied for polyvinyl alcohol–polyethylene glycol–polyvinyl pyrrolidinone with zirconium oxide (PVA–PEG–PVP–ZrO2) nanocomposites which showed to increase with zirconium oxide content (Agool et al. 2017). Also, tungsten/bismuth oxide/methyl vinyl silicone rubber (W/Bi2O3/VMQ) composites exhibited higher X-ray-shielding properties in the X-ray energy ranging from 48 to 185 keV (Chai et al. 2016). Ultra-high-molecular-weight polyethylene (UHMWPE) with boron carbide, B4C, and tungsten, W, nanopowders were fabricated by solid-state intermixing and thermal pressing, and the gamma protection properties increased with tungsten content in the composite (Kaloshkin et al. 2012). Polymer composites with different aluminum oxide percentages (x = 0, 10, 20, 30, 40, and 50 weight percent) were prepared, and the composites of 40 weight percent (wt%) aluminum oxide (Al2O3) revealed the highest values of radiation attenuation (Osman et al. 2015). Bismuth nanoparticles with cellulose nanofibers and polydimethylsiloxane (PDMS) polymer can effectively shield X-ray radiation at a lower mass ratio in the polymer matrix (Li et al. 2018). Novel polyvinyl alcohol (PVA)/tungsten oxide (WO3) composite consisting tungsten oxide (WO3) at sizes of 10 μm and 30 nm with a weight concentration of 50 weight % was studied for gamma-ray shielding (Kazemi et al. 2019).

The polyacrylamide (PAGAT) gel and metal nanoparticle (different concentrations of gold and silver) verified the water equivalency based on an effective atomic number (Sathiyaraj et al. 2017). Different percentages of tungsten carbide (50, 60, and 70%) were added and tested against gamma radiation (137Cs and131I and 241Am), and the best shielding efficiency against gamma radiation was revealed by the composite with 70% tungsten carbide (WC) (Soylu et al. 2015). Different percentages of tungsten carbide (50, 60, and 70%) were added and tested against gamma radiation (137Cs and 131I and 241Am), the best shielding efficiency against gamma radiation was revealed by the composite with 70% tungsten carbide (Özdemir et al. 2018). Graphite/epoxy composite showed the highest performance in gamma radiation attenuation among epoxy/graphite, epoxy/lead, and epoxy/boron (Saiyad et al. 2014). A proportional relationship between photon attenuation coefficients and barite concentration was revealed when barite and boron carbide-doped radiation shielding polymer composite was prepared for radiation shielding (Evcın et al. 2017). Blended powdered polyethylene glycol and lead oxide prepared by physical mixing revealed that the shielding properties of polyethylene glycol increased with the addition of lead oxide (Hussain et al. 1997).

The influence of bismuth contents on mechanical and gamma-ray attenuation properties of silicone rubber composite was studied, showing that the increase in bismuth content induced an increase in radiation shielding performance (El-Fiki et al. 2015). Four different colemanite Ca2B6O11·5H2O (CMT) concentration levels (such as 5, 15, 30, and 40 weight percent) were examined to investigate the radiation protective shielding properties of poly(methyl methacrylate)/colemanite (PMMA/CMT) composite. Colemanite reinforcement of poly(methyl methacrylate) increased the radiation shielding capacity by 11.1% for gamma photons of Cs-137 radioisotope (Bel et al. 2018). By blending epoxy resin with different weight percent of tungsten powder, tungsten/epoxy composites were prepared and investigated by using two different activities of Co-60 source showing that with the increment of tungsten loading, the shielding property of composites increased (Chang et al. 2015). Besides, ethylene–vinyl acetate (EVA)–tungsten composite (Yurt Lambrecht et al. 2016) and polyimide/bismuth oxide (Pavlenko et al. 2019) composites revealed high radiation-protective characteristics. The shielding effect and the protective properties of the samples of aluminum alloys with a protective coating were evaluated revealing that tungsten–aluminum oxide (W–Al2O3) and tungsten–boron nitride (W–BN) coatings contribute significantly to the attenuation of ionizing radiation fluxes (Vilkov et al. 2017). Poly (lactic acid) (PLA) nanocomposites containing 3%, 5%, and 7% zeolite were prepared and investigated against gamma radiation at the absorbed doses of 10, 15, and 20 kGy. The results revealed that increasing zeolite content in the structure promoted the recombination of the reactive species formation with the interaction of the radiation in the polymer and increased the radiation resistance (Yildirim and Oral 2018).

Silica nanoparticles combined with composites are widely used for various applications (Soundharraj et al. 2020) such as glucose biosensors when combined with gold nanoparticles to form mesoporous silica composite, by incorporating silica nanoparticles to carbon dots for bioimaging applications, in drug delivery when mesoporous mobil composition of matter (MCM)-41-silica is loaded with ibuprofen, monodispersed silica with uniform hollow-core mesoporous shell carbon nanospheres for supercapacitor applications. Different types of metal and metal oxide nanoparticles including silver, copper, palladium, zinc oxide, magnesium oxide, tin oxide are synthesized with various polymers and used for antimicrobial activity, food packaging, and improving shelf-life of food (Rai et al. 2018). Carbon-based nanostructures such as semiconductor compounds and polyoxometalates are used for water purification (Lopes et al. 2021).

Recycling of polymers

Materials that have reached their end of life after primary use or of no use must be dismissed, and materials that remain from production are considered waste. Plastic waste is a part of this term. The primary constituents of municipal, industrial, and agricultural plastic wastes are generally thermoplastics because of the large volume and low cost of these materials such as high-density polyethylene, polypropylene, ethylene–propylene copolymer, polystyrene, low-density polyethylene, polyamide, polyethylene terephthalate, polyvinyl chloride, and these thermoplastics can be recycled. Besides, it consists of small amounts of thermosets like epoxy resins and polyurethane rubber and these thermoset plastics cannot be recycled (Miskolczi et al. 2004). Nowadays, the Covid-19 pandemic has posed a huge plastic pollution worldwide, which lead to urgent and massive use of fossil fuel-derived plastic (Sorrentino et al. 2020).

Plastic wastes are a mixture of different types of plastics along with some contaminations. Microplastics which are considered plastic particles smaller than 5 mm represent slowly degrading contaminants in soil and water exposing human health and environment to toxic incorporation of these materials (Padervand et al. 2020). Also, this waste is big in volume, and for the waste management of plastic waste, an integrated waste management approach is needed. There are three ways for disposal of municipal and industrial plastic waste: incineration (with or without energy recovery), landfilling, and recycling. The incineration method for plastics wastes is always accompanied by the emission of harmful, greenhouse gases. More energy is dissipated in the process of plastic incineration. Also, landfilling is not an efficient technique because suitable and safe deposits are expensive (Grigoriadou et al. 2011). Thus, recycling is the best way to manage plastic wastes since it reduces environmental impact, resource depletion, and pollution. Besides, recycling of the plastics consumes a smaller amount of energy when compared to energy consumption in new virgin resin production. Fundamentally, high levels of recycling, as with a reduction in use, reuse, and repair or re-manufacturing can allow for a given level of product service with lower material input that would otherwise be required. Therefore, recycling can decrease energy and material used per unit of production and so yield improved eco-efficiency (Hamim et al. 2016).

Recycling can be divided into two categories: mechanical recycling and chemical recycling (Miskolczi et al. 2004). Chemical recycling is virtually a thermal method by which the long alkyl chains of polymers are broken into a mixture of lighter hydrocarbons. Several chemical reactions such as pyrolysis, cracking, glycolysis, and gasification can be used for the decomposition of polymers (Lee et al. 2002), whereas mechanical recycling is a physical method. It usually consists of contamination removal of the plastic wastes by sorting and washing, followed by grinding or conversion into flakes, granulates, or pellets, then drying, and melt processing to make the new product by extrusion. It is noted that mechanical recycling is the better method for recycling as is relatively simple, environmentally friendly, and requires low investment (Awaja and Pavel 2005).

Collection of post-consumer plastic wastes, separation, processing (manufacturing), and marketing are the four steps in plastic recycling (Shent et al. 1999). Different types of polymers need to be separated from each other from the collected plastics waste to get better quality of recycled plastic. Several techniques can be used to separate mixed plastic wastes based on their physicochemical properties such as gravity separation, contact charging, hydro-cyclones and centrifuges, and froth flotation (Pascoe 2003). The produced recycled plastic can be used to manufacture new products such as automobile parts, floor carpets, flower vases, park benches, picnic tables, waste paper baskets, crates, plastic lumber, wood–plastic composites which will provide an additional market for recycled plastics. Sustainable and low-cost radiation shielding materials can be fabricated using composite materials from post-consumer recycled thermoplastics for various applications such as space, industry, and radiation facilities as shown in Fig. 10 (Cholake et al. 2017; Mahmoud et al. 2018a, b). Massive amounts of polyethylene terephthalate, high-density polyethylene, polyvinyl chloride, low-density polyethylene, polypropylene, polystyrene, and miscellaneous plastics can be recycled to fuels via many thermomechanical technologies including pyrolysis, liquefaction, and gasification (Nanda and Berruti 2020). Cellulose nanoparticles were extracted from from conventional and nonconventional lignocellulosic biomass for food packaging applications to avoid the extensive use of nonbiodegradable materials. The synthesized cellulosic nanocomposites exhibited promising optical, biodegradation, mechanical, and barrier properties due to the large surface area of nanoscale structure (Qasim et al. 2020). Nanomaterials play also an important role in moisture absorbing packaging in food industry taking into consideration all the safety concerns and toxcitiy issues (Gaikwad et al. 2018). Cerium dioxide and composites are used as adsorbents for water decontamination to remove contaminants such as arsenic, fluoride, lead, and cadmium (Olivera et al. 2018).

The use of processed and post-consumed polymers as composite materials for different applications

The world's main focus nowadays is the use of new materials that are eco-friendly to reduce the burden of pollution via recycling these materials and enhancing their sustainability. This urged the need and synthesis of new composite materials via adding fillers as alternatives for replacing toxic and harmful fabricated materials. New attempts to process and refine post-consumed polymers are obtained. Many researchers are concerned about the use and processing of composite materials for various types of applications.

Iron-based magnetic (Marcelo et al. 2020) and silver–magnetic nanocomposites (Surendhiran et al. 2017) are of great importance as they display promising performance in removing pollutants from water, adsorption of heavy metal ions, photocatalysis, soil conditioning (Sharma et al. 2018), and many other applications such as optical application, hydrogen storage, magnetic resonance imaging,, and cancer diagnosis (Siddiqui et al. 2018). Also, the use of thermosets, fabrics, and textiles-based materials as polymer matrices has been extensively reported and investigated. Conversion of waste-derived high-density polyethylene to three-dimensional (3D) printing filament has important technological implications. A facile strategy to expand the palette of waste-derived polymer materials for fused filament fabrication (FFF) three-dimensional (3D) printing was explained in details (Gudadhe et al. 2019). The polymer–matrix composites based on recycled high-density polyethylene with either lead oxide nanoparticles or lead oxide bulk using 10 and 50% weight fractions were synthesized by solid-state intermixing and thermal pressing technique. This study suggests that the recycled high-density polyethylene/lead oxide nanocomposites could be used as sustainable gamma-radiation shields and these composites of the recycled polymer are environmentally effective (Mahmoud et al. 2018a, b).