Abstract

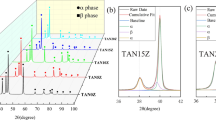

The problems of high elastic modulus and poor friction and wear properties should be investigated and solved for further promotion of the application of biomedical alloys. For the first time, Zr–4Cu–xNb–xSn (x = 0, 0.25, 0.5, 1) biomedical alloys with low elastic modulus and excellent tribological performance are designed and vacuum smelted in this work. Phase analysis and microstructural observation indicate that the Zr–4Cu–xNb–xSn alloys consist of two phases, i.e., α-Zr and Zr3Cu. Zr3Cu is mainly concentrated in the grain boundary and the eutectoid structure. With the increase in Nb and Sn contents, content of the grain boundary Zr3Cu changes in a zigzag manner. Compression tests indicate that the alloys have low elastic modulus (25.2–27.45 GPa), high compressive strength (1024–1139 MPa) and elastic energy (7.14 MJ/m3–11.80 kJ/m3). Compressive fracture behaviors have been investigated concerning the mechanism with alloying contents and microstructure. Through the tribological test in artificial saliva, it is indicated that the Zr–4Cu–xNb–xSn alloys have better friction and wear properties than pure titanium. Wear mechanism of the alloys is mainly abrasive wear and fatigue wear.

Similar content being viewed by others

References

Wu, J.; Li, H.; Yuan, B.; Gao, Y.: High recoverable strain tailoring by Zr adjustment of sintered Ti–13Nb–(0–6)Zr biomedical alloys. J. Mech. Behav. Biomed. Mater. 75, 574–580 (2017)

Kim, R.; Kim, H.; Choe, H.; Son, M.; Chung, C.: Microscopic analysis of fractured dental implant surface after clinical user. Procedia Eng. 10, 1955–1960 (2011)

Niinomi, M.: Metallic biomaterials. J. Artif. Organs 11, 105–110 (2008)

Ingham, E.; Fisher, J.: Biological reactions to wear debris in total joint replacement. Proc. Inst. Mech. Eng. Part H 214(1), 21–37 (2000)

Spector, M.: Biomaterial failure. Orthop Clin. N. Am. 23(2), 211–217 (1992)

Mabilleau, G.; Bourdon, S.; Joly-Guillou, M.; Filmon, R.; Basle, M.; Chappard, D.: Influence of fluoride, hydrogen peroxide and lactic acid on the corrosion resistance of commercially pure titanium. Acta Biomater. 2(1), 121–129 (2006)

Hu, X.; Shortall, A.C.; Marquis, P.M.: Wear of three dental composites under different testing conditions. J. Oral Rehabil. 29(8), 756–764 (2002)

Wen, C.; Yamada, Y.; Hodgson, P.: Fabrication of novel TiZr alloy foams for biomedical applications. Mater. Sci. Eng. C 26(8), 1439–1444 (2006)

Niinomi, M.: Fatigue performance and cyto-toxicity of low rigidity titanium alloy, Ti–29Nb–13Ta–4.6Zr. Biomaterials 24(16), 2673–2683 (2003)

Niinomi, M.: Mechanical properties of biomedical titanium alloys. Mater. Sci. Eng. A 243(1–2), 231–236 (1998)

Okamoto, H.: Cu–Zr (Copper–Zirconium). J. Phase Equilib. Diffus. 33(5), 417–418 (2012)

Nie, L.; Zhan, Y.; Liu, H.; Tang, C.: In situ synthesized low modulus biomedical Zr–4Cu–xNb alloys. Mater. Sci. Eng. C 33(8), 5105–5108 (2013)

Kiran Kumar, N.; Szpunar, J.: EBSD studies on microstructure and crystallographic orientation of δ-hydrides in Zircaloy-4, Zr–1% Nb and Zr–2.5% Nb. Mater. Sci. Eng. A 528(21), 6366–6374 (2011)

Cho, G.; Kaneko, L.; Donovan, T.; White, S.: Diametral and compressive strength of dental core materials. J. Prosthet. Dent. 82(3), 272–276 (1999)

Li, Q.; Xu, L.; Yang, Y.; Liang, X.; Peng, J.; Yao, M.; Zhou, B.: Microstructure of Zr alloy containing Nb or Cu element. Rare Met. Mater. Eng. 45(6), 1526–1530 (2016)

Wang, X.; Xu, S.; Zhou, S.; Xu, W.; Leary, M.; Choong, P.; Qian, M.; Brandt, M.; Xie, Y.: Topological design and additive manufacturing of porous metals for bone scaffolds and orthopaedic implants: a review. Biomaterials 83, 127–141 (2016)

Li, C.; Zhan, Y.; Jiang, W.: β-Type Ti–Mo–Si ternary alloys designed for biomedical applications. Mater. Des. 34, 479–482 (2012)

Xiang, Y.; Zhang, Y.; Yan, S.; Fan, S.: Elevated-temperature tribological behavior of Sn–Ag–Cu self-lubricating materials. Lubr. Eng. 41(8), 48–52 (2016)

Acknowledgements

This research work is supported by the Guangxi Natural Science Foundation (2018GXNSFDA050008, 2020GXNSFAA159093), the National Natural Science Foundation of China (51761002), the National Key R&D Program of China (2016YFB0301400), the Training Plan of High-Level Talents of Guangxi University (XMPZ160714) and the research Project of Guangxi Key Laboratory of Processing for Non-ferrous Metallic and Featured Materials (GXYSSF1807).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Gan, X., Zhang, J., Zhang, J. et al. Design and Characterization of Novel Biomedical Zr–4Cu–xNb–xSn Alloys for Hard Tissue Substitution. Arab J Sci Eng 46, 6075–6084 (2021). https://doi.org/10.1007/s13369-021-05356-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-05356-6