Abstract

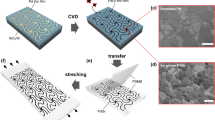

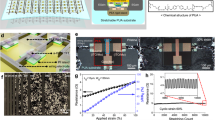

Flexible electrodes that allow electrical conductance to be maintained during mechanical deformation are required for the development of wearable electronics. However, flexible electrodes based on metal thin films on elastomeric substrates can suffer from complete and unexpected electrical disconnection after the onset of mechanical fracture across the metal. Here we show that the strain-resilient electrical performance of thin-film metal electrodes under multimodal deformation can be enhanced by using a two-dimensional interlayer. Insertion of atomically thin interlayers—graphene, molybdenum disulfide or hexagonal boron nitride—induces continuous in-plane crack deflection in thin-film metal electrodes. This leads to unique electrical characteristics (termed electrical ductility) in which electrical resistance gradually increases with strain, creating extended regions of stable resistance. Our two-dimensional interlayer electrodes can maintain a low electrical resistance beyond a strain at which conventional metal electrodes would completely disconnect. We use the approach to create a flexible electroluminescent light-emitting device with an augmented strain-resilient electrical functionality and an early damage diagnosis capability.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the plots within this paper and other findings of this study are available from the corresponding author upon reasonable request.

References

Gao, W., Ota, H., Kiriya, D., Takei, K. & Javey, A. Flexible electronics toward wearable sensing. Acc. Chem. Res. 52, 523–533 (2019).

Akinwande, D., Petrone, N. & Hone, J. Two-dimensional flexible nanoelectronics. Nat. Commun. 5, 5678 (2014).

Hong, G. & Lieber, C. M. Novel electrode technologies for neural recordings. Nat. Rev. Neurosci. 20, 330–345 (2019).

Ray, T. R. et al. Bio-integrated wearable systems: a comprehensive review. Chem. Rev. 119, 5461–5533 (2019).

Pang, C., Lee, C. & Suh, K. Recent advances in flexible sensors for wearable and implantable devices. J. Appl. Polym. Sci. 130, 1429–1441 (2013).

Koh, A. et al. A soft, wearable microfluidic device for the capture, storage and colorimetric sensing of sweat. Sci. Transl. Med. 8, 366ra165 (2016).

Robinson, A. P., Minev, I., Graz, I. M. & Lacour, S. P. Microstructured silicone substrate for printable and stretchable metallic films. Langmuir 27, 4279–4284 (2011).

Nathan, A. et al. Flexible electronics: the next ubiquitous platform. Proc. IEEE 100, 1486–1517 (2012).

Graudejus, O., Go, P. & Wagner, S. Controlling the morphology of gold films on poly(dimethysiloxane). ACS Appl. Mater. Interfaces 2, 1927–1933 (2010).

Gerratt, A. P., Michaud, H. O. & Lacour, S. P. Elastomeric electronic skin for prosthetic tactile sensation. Adv. Funct. Mater. 25, 2287–2295 (2015).

Rogers, J. A., Someya, T. & Huang, Y. Materials and mechanics for stretchable electronics. Science 327, 1603–1607 (2010).

Decataldo, F. et al. Stretchable low impedance electrodes for bioelectronic recording from small peripheral nerves. Sci. Rep. 9, 10598 (2019).

Song, E. et al. Flexible electronic/optoelectronic microsystems with scalable designs for chronic biointegration. Proc. Natl Acad. Sci. USA 116, 15398–15406 (2019).

Lu, N. & Kim, D. Flexible and stretchable electronics paving the way for soft robotics. Soft Robot. 1, 53–62 (2013).

Lacour, S. P., Wagner, S., Huang, Z. & Suo, Z. Stretchable gold conductors on elastomeric substrates. Appl. Phys. Lett. 82, 2404–2406 (2003).

Lu, N., Wang, X., Suo, Z. & Vlassak, J. Metal films on polymer substrates stretched beyond 50%. Appl. Phys. Lett. 91, 221909 (2007).

Baëtens, T., Pallecchi, E., Thomy, V. & Arscott, S. Cracking effects in squashable and stretchable thin metal films on PDMS for flexible microsystems and electronics. Sci. Rep. 8, 9492 (2018).

Beuth, J. L. Cracking of thin bonded films in residual tension. Int. J. Solids Struct. 29, 1657–1675 (1992).

Wang, J., Cheng, Q. & Tang, Z. Layered nanocomposites inspired by the structure and mechanical properties of nacre. Chem. Soc. Rev. 41, 1111–1129 (2012).

Yin, Z., Hannard, F. & Barthelat, F. Impact-resistant nacre-like transparent materials. Science 364, 1260–1263 (2019).

Kim, Y. et al. Strengthening effect of single-atomic-layer graphene in metal–graphene nanolayered composites. Nat. Commun. 4, 2114 (2013).

Oh, S. H., Ryu, S. & Han, S. M. Role of graphene in reducing fatigue damage in Cu/Gr nanolayered composite. Nano Lett. 17, 4740–4745 (2017).

Hutchinson, J. W. & Suo, Z. Mixed mode cracking in layered materials. Adv. Appl. Mech. 29, 63–191 (1991).

Kruzic, J. J., Nalla, R. K., Kinney, J. H. & Ritchie, R. O. Crack blunting, crack bridging and resistance-curve fracture mechanics in dentin: effect of hydration. Biomaterials 24, 5209–5221 (2003).

Chowdhury, P. & Sehitoglu, H. Mechanisms of fatigue crack growth—a critical digest of theoretical developments. Fatigue Fract. Eng. Mater. Struct. 39, 652–674 (2016).

Suh, Y. D. et al. Random nanocrack, assisted metal nanowire-bundled network fabrication for a highly flexible and transparent conductor. RSC Adv. 6, 57434–57440 (2016).

Nam, K. H., Park, I. H. & Ko, S. H. Patterning by controlled cracking. Nature 485, 221–224 (2012).

Leterrier, Y., Pinyol, A., Rougier, L., Waller, J. H. & Mnson, J. A. E. Electrofragmentation modeling of conductive coatings on polymer substrates. J. Appl. Phys. 106, 113508 (2009).

Zhang, S., Ma, T., Erdemir, A. & Li, Q. Tribology of two-dimensional materials: from mechanisms to modulating strategies. Mater. Today 26, 67–86 (2019).

Hess, P. Prediction of mechanical properties of 2D solids with related bonding configuration. RSC Adv. 7, 29786–29793 (2017).

Polikov, V. S., Tresco, P. A. & Reichert, W. M. Response of brain tissue to chronically implanted neural electrodes. J. Neurosci. Methods 148, 1–18 (2005).

Niu, S. et al. A wireless body area sensor network based on stretchable passive tags. Nat. Electron. 2, 361–368 (2019).

Jia, H. et al. Single- and few-layer transfer-printed CVD MoS2 nanomechanical resonators with enhancement by thermal annealing. In Proc. 2016 IEEE International Frequency Control Symposium (IFCS) 1–3 (IEEE, 2016).

Wu, X. et al. Growth of continuous monolayer graphene with millimeter-sized domains using industrially safe conditions. Sci. Rep. 6, 21152 (2016).

Cao, C. et al. Nonlinear fracture toughness measurement and crack propagation resistance of functionalized graphene multilayers. Sci. Adv. 4, eaao7202 (2018).

Zhang, P. et al. Fracture toughness of graphene. Nat. Commun. 5, 3782 (2014).

Stuart, S. J., Tutein, A. B. & Harrison, J. A. A reactive potential for hydrocarbons with intermolecular interactions. J. Chem. Phys. 112, 6472–6486 (2000).

Van Duin, A. C. T., Dasgupta, S., Lorant, F. & Goddard, W. A. ReaxFF: a reactive force field for hydrocarbons. J. Phys. Chem. A 105, 9396–9409 (2001).

Liang, T., Phillpot, S. R. & Sinnott, S. B. Parametrization of a reactive many-body potential for Mo–S systems. Phys. Rev. B Condens. Matter Mater. Phys. 79, 245110 (2009).

Sun, H. COMPASS: an ab initio force-field optimized for condensed-phase applications—overview with details on alkane and benzene compounds. J. Phys. Chem. B 102, 7338–7364 (1998).

Fonseca, A. F. et al. Graphene–titanium interfaces from molecular dynamics simulations. ACS Appl. Mater. Interfaces 9, 33288–33297 (2017).

Xiong, S. & Cao, G. Bending response of single layer MoS2. Nanotechnology 27, 105701 (2016).

Chen, H., Lu, B.-W., Lin, Y. & Feng, X. Interfacial failure in flexible electronic devices. IEEE Electron Device Lett. 35, 132–134 (2014).

Bae, S. et al. Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nat. Nanotechnol. 5, 574–578 (2010).

Acknowledgements

We acknowledge support from NSF (MRSEC DMR-1720633, ECCS-1935775, DMR-1708852 and CMMI-1554019), AFOSR (FA2386-17-1-4071), NASA ECF (NNX16AR56G), ONR YIP (N00014-17-1-2830) and LLNL (B622092). C.C. acknowledges support from a NASA Space Technology Research Fellow grant (80NSSC17K0149). The simulations were performed using the Extreme Science and Engineering Discovery Environment (XSEDE; supported by NSF grant no. OCI1053575), Blue Waters (supported by NSF awards OCI-0725070, ACI-1238993 and the State of Illinois, and, as of December 2019, by the National Geospatial-Intelligence Agency) and Frontera computing project at the Texas Advanced Computing Center (supported by NSF grant no. OAC-1818253). This research was primarily supported by the NSF through the University of Illinois at Urbana-Champaign Materials Research Science and Engineering Center (DMR-1720633). We are grateful for helpful discussions with A. J. Rosakis and J. A. Rogers.

Author information

Authors and Affiliations

Contributions

C.C., P.K. and S.N. conceived the idea, designed experiments and contributed to the discussion and analysis of the results. C.C. performed fabrication and characterization, and wrote the manuscript. A.T., Y.J. and N.R.A. contributed to the analytical and computational analysis. K.Y. worked on the growth of 2D materials and assisted with twist and fatigue tests. J.M.K. worked on fracture monitor videos. M.F.H. performed atomic force microscopy characterizations.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature Electronics thanks Seung Hwan Ko and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–23, Table 1, video captions 1–3 and Notes.

Supplementary Video 1

Crack development in a bare Au electrode under bending deformation.

Supplementary Video 2

Crack development in an Au/1LG electrode under bending deformation.

Supplementary Video 3

Practical functionality demonstration of flexible light-emitting devices integrated with a conventional thin-metal-film-based interconnector and a metal–2D-based interconnector.

Rights and permissions

About this article

Cite this article

Cho, C., Kang, P., Taqieddin, A. et al. Strain-resilient electrical functionality in thin-film metal electrodes using two-dimensional interlayers. Nat Electron 4, 126–133 (2021). https://doi.org/10.1038/s41928-021-00538-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41928-021-00538-4