Abstract

Herein, copper oxide/copper sulfide (CuO/CuxS) composites have been prepared by treating CuO with thiourea by an aqueous hydrothermal route and their thermoelectric properties are studied. The electrical conductivity is improved with the increase in thiourea content, as a result, thermoelectric power factor increased from 10–4 to 101 µW m−1 K−2, and thermal conductivity of the CuO is also found to decrease with thiourea treatment. A detailed analysis indicated that these changes are due to the formation of copper sulfide (CuxS) in the CuO compound; a small fraction of electrically good conducting CuxS in the bulk CuO has produced composites with better electrical conductivity. These low-cost and non-toxic materials can be useful in thermoelectric energy conversion applications.

Similar content being viewed by others

Introduction

Thermoelectric materials are the group of electronic materials capable of converting thermal gradients into electric power [1,2,3]. The present commercial thermoelectric materials invariably include elements like Pb, Bi, Te, etc. which cause a vast concern of environmental pollution [4]. Therefore, less-toxic and earth-abundant materials are essential for the development of thermoelectric generators and for wider applications [5,6,7,8,9,10,11,12,13].

Some of the transition metal oxides are quite abundant in nature and can be easily synthesized cost-effectively for different applications [14,15,16,17,18]. These materials have attracted different applications due to their non-toxicity, easy availability, and low cost. One such metal oxides is a cupric oxide (CuO), intrinsically a p-type semiconductor [19]. It is an interesting candidate for gas sensors, solar energy devices, superconducting devices, etc [19]. But, it is not considered to be suitable for thermoelectric applications as it has very low electrical conductivity and possesses a high thermal conductivity, both of which are drawbacks for thermoelectric applications. However, a couple of studies have been made to check its thermoelectric properties [20], 21,22,23. For illustration, Hartung et al. have fabricated a series of CuxO (with x ranging from 1 to 2) using the rf-sputtering process by controlling the oxygen flux [20]. Doping of Li atoms has shown to be promising for CuO by Yoshida et al. [21]. Similarly, Andrei et al. have investigated the thermoelectric properties of copper oxide-graphite-polymer composite pastes [24]. By compositional variation, they have observed systematic changes in the Seebeck coefficient and the electrical conductivity.

In addition, researchers have utilized conductive impurity phases to largely enhance the electrical conductivity and power factor of less conducting compounds [25, 26]. For illustration, Salah et al. have achieved enhanced properties in CuO by adding single-walled carbon nanotubes (SWCNT) into it to form CuO/SWCNT composites [27]. Enhancements in thermoelectric performance have also been observed in polymer composites [28, 29]. Similarly, many chaclogenide compounds are promising for thermoelectric applications [30,31,32,33,34].

Here, copper oxide powder has been treated with thiourea via a hydrothermal treatment using an aqueous solution. After treatment, a significant enhancement was observed in the electrical conductivity that results in an improved thermoelectric power factor despite the fall in the Seebeck coefficient. The present approach can also be extended for other thermoelectric materials to investigate the changes in their properties.

Experimental details

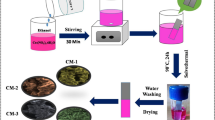

Commercial copper (II) oxide (CuO) powder was purchased from sd-Fine Chemicals, India. Thiourea (CH4N2S) was used as a source of sulfur, obtained from Himedia Chemicals, India. Deionized water was used in the entire synthesis process. The chemicals were used as received without any further purification. In a reaction, the desired amount of dopant precursor, thiourea was weighed and dissolved in water (30 ml) and then a known amount of CuO powder was dispersed into it and stirred for few minutes. Here, the quantity of CuO was kept constant (1 gm) for each reaction and the thiourea content was varied to get a series of samples with different doping levels. The amounts of thiourea chosen to dope are 1, 2, 5, 8, and 10 wt% of CuO. After stirring for 10 min, the reactants were transferred to a Teflon cup of volume 50 ml sealed inside a stainless steel autoclave which was then transferred to an oven (180 °C for 2 h). Upon completion of the reaction, the autoclave was naturally cooled down to room temperature. The final product was taken out and washed with de-ionized water for a couple of times to remove any unreacted ions. Finally, the washed product was dried under open-air conditions at 60 °C.

X-ray diffraction studies were done by using the Rigaku Miniflex-600 diffractometer. Surface morphological studies were made using FEI-ESEM Quanta-200 model. The surface chemistry of the compound was studied using PHI 5000 Versa Prob-II the XPS system with a monochromatic Al Kα X-ray source (hν = 1486.6 eV). For the thermoelectric measurements, the powder was pelletized (under a pressure of 100 kg cm−2) with a pellet diameter of 10 mm. The Seebeck coefficient measurements were done using a homemade setup, the details of which are given elsewhere [35]. A temperature gradient (ΔT) of about 2 to 8 K was established and the resulting Seebeck voltage (ΔV) was measured. Several data points have been taken by varying the temperature difference to take the average value of the Seebeck coefficient (S) using the following expression [36].

Electrical resistivity (ρ) measurements were done using a standard four-probe method and thermoelectric power factors (PF) were estimated using the expression:

Thermal conductivity measurements were carried out using a setup that works on the principle of parallel thermal conductance technique reported by Zawilski et al.[37] All these electrical measurements were repeated 3–4 times and average values from the obtained data have been used in the plots.

Results and discussion

The idea of thiourea treatment to the CuO was experimentally studied to see the changes in the electrical properties of CuO, expecting either sulfur doping or secondary sulfur-based phase formation in it. Various samples of CuO, doped with sulfur were characterized by XRD and the patterns are shown in Fig. 1. The bottom curve shows the XRD pattern of the commercial copper oxide used in the work which can be well-indexed to the standard pattern of CuO (JCPDS File No. 05–0661). The XRD patterns for 1, 2, 5, and 10 wt% thiourea treated CuO are also given in the same figure from which it can be observed that the CuO pattern is well preserved in all the doped samples. The effect of sulfur doping into CuO was not clear but, a minor new peak appeared in the highest thiourea (10%) treated sample could be indicating that there is a small fraction of secondary phase formation. The appeared small peak can be indexed with a prominent peak of one of the copper sulfide (CuxS) compounds and so, looking at the comparative intensity of this new peak with host CuO peaks it can be predicted that there can be a very small amount of secondary phase formation in the CuO in the form of copper sulfide.

The surface morphological pictures shown in Fig. 2 are the images corresponding to the pure CuO (a–b) and thiourea treated CuO (c–f) with low and high magnification. The particles are spherical shaped and rigid and having sizes of about 5–10 µm. Figures (c) and (d) correspond to the 2 wt% thiourea treated sample where most of the particles have lost their rigid and spherical nature to some extent which is the same in the case of 10 wt% treated sample [Figures (e) and (f)]. It is predicted that the damage in the particle shapes is mainly due to the hydrothermal treatment where a sufficient temperature of 180 °C is used which creates high pressure in the reaction media. Further, there is a formation of smaller particles that are broken out from the rigid spherical particles during the hydrothermal treatment which can be seen by comparing the SEM images of pure and hydrothermal treated CuO powders.

To get an analysis of the chemistry of the samples, the XPS measurements are carried out and their XPS survey scan spectra are given in Fig. 3. The peaks in the spectrum of pure CuO are clearly showing the presence of Cu, O, and C peaks consistent with the literature. where the peaks of C are usually associated with adsorbed carbon on the samples. Similarly, the XPS spectra of samples treated with 2 wt% and 10 wt% thiourea are also having similar peaks along with that there are minor appearance of S peaks around 160 eV with no other changes in their spectra in comparison to the pure CuO. This gives an idea about the possible sulfur incorporation/doping into the CuO. Further, to observe the changes in chemical states of the constituents in the CuO after thiourea treatment, the core level scanning of the elements was recorded, as shown in Fig. 4. The high-resolution XPS spectra of Cu 2p for the pure and thiourea treated have prominent peaks between 933.4 eV and 953.5 eV; attributed to Cu 2p3/2 and 2p1/2, respectively [38]. Further, the spectrum has characteristic “shake-up” satellite peaks in the energy range 940–945 eV, which are evident for the presence Cu2+ state in CuO. Similarly, the high-resolution spectra of O 1 s is shown to contain a major peak at 529.3 eV and a shoulder peak at 531.2 eV. The major peak at 529.3 eV is ascribed to the lattice oxygen of CuO which is usually considered while characterizing CuO and the shoulder peak at 531.2 eV is associated with Cu (OH)2 or chemi-adsorbed oxygen in the form of C–O [38]. This shoulder peak at 531.2 eV is improved in intensity with doping which could be due to the formation of sulfate (SxOy2−) containing moieties on the particles [39,40,41]. A noticeable change in the Cu 2p spectrum of the 10% thiourea treated sample can be observed where Cu2p3/2 and Cu 2p1/2 peaks widths have been broadened. In these peaks, clearly two components can be accommodated where the new component can be assigned to Cu 2p of copper sulfide (CuxS) compound, hence there is a possible formation of CuxS on CuO particles. To further investigate the presence of sulfur, its chemical nature, and also to confirm the formation of CuO/CuxS composite, the high-resolution spectrum of S 2p was obtained for the pure and thiourea treated samples, the spectra of which are given as an inset of Fig. 3. Obviously, there is no sulfur signal in pure CuO whereas in the case of thiourea treated samples well-pronounced peaks can be observed. The S 2p spectra of 2% and 10% thiourea treated CuO have two broad peaks at binding energy regions at ~ 162.2 eV and ~ 168.5 eV. The estimated sulfur content in 10% doped sample (using CasaXPS software) is found to be 2.1 at%. The peak at lower binding energy (162.2 eV) is well reported and studied and is related to the metal sulfide or in this case related to copper sulfide [40, 42]. Further, the broad peak at higher binding energy is attributed to SxOy2− related groups [42].

Though the contribution of CuxS appears to be more from the area of the Cu 2p and clearly pronounced S 2p peaks, the technique is surface-based analysis where only about ~ 10 nm thickness of the sample typically contributes to the XPS signals, and thus XPS is more of surface chemistry rather than the bulk chemistry of the samples. As there is a clear distinction between the electrical conductivity of CuO which is very low of the order of 10–4 S m−1 whereas CuxS is a very good conductor whose conductivity is about 103 to 105 S m−1.[24, 43, 44] For illustration, Cu7S4 compound has an electrical conductivity of ~ 3 × 105 S m−1.[45] Therefore, such conducting phase incorporation into CuO helps in the modification of electrical properties. To observe these expected changes from the thiourea treated samples, thermoelectric measurements were carried out which are presented in Fig. 5. The room temperature Seebeck coefficients of the samples are plotted in Fig. 5a; undoped CuO had a Seebeck coefficient of about ~ 630 ± 10 μVK−1 which is consistent with previous works on CuO [24]. When it is doped with sulfur, there is a large fall in the values. The Seebeck coefficients of the 1, 2, 5, 8, and 10 wt% thiourea treated CuO samples have produced 580, 455, 228, 107, and 54 μVK−1. The decrease in thermopower is actually due to the significantly enhanced electrical conductivity of the CuO with doping which was realized by the electrical resistivity measurements, the data of which is shown in Fig. 5b. As the Seebeck coefficient is inversely proportional to the number of free carriers, such decrease in Seeveck coefficient with an increase in electrical conductivity can be predicted according to Mott’s relation [46],

where kB, h, e, m* and T are the Boltzmann constant, Planck’s constant, charge, effective mass of free carriers, and temperature, respectively.

The undoped CuO has shown a high resistivity of about 7 × 104 Ω cm, this value was found to be decreasing with an increase in thiourea doping. The observed values of resistivity are 9.9 × 103, 1.8 × 103, 5.04, 0.40, and 0.11 Ω cm for 1, 2, 5, 8, and 10 wt% thiourea treated CuO, almost there is six orders of magnitude decrease. The power factor was estimated using the above data of S and ρ and presented in Fig. 5c. Although there was a significant reduction in the S, it has been overcome by the enhanced electrical conductivity and hence improvements in the power factors of the CuO after doping. The pure CuO sample has a very low power factor of the order of 10–4 µW m−1 K−2 and after doping it has improved to 3.4 × 10–3, 1.1 × 10–2, 1.02, 2.86, and 2.65 µW m−1 K−2 for 1, 2, 5, 8, and 10 wt% thiourea treated CuO, respectively. These power factor values of the doped CuO are slightly better and comparable to previous efforts of doping effects on CuO, alongside providing a simple aqueous-based doping process compared to earlier reports [21].

Further, the thermal conductivity data of the undoped CuO shown by Fig. 5d is found to be 5.2 Wm−1 K−1 which is less than the reported values which are about 6–9 W m−1 K−1 [20]. This deviation in the value could be associated with the density of the cylindrical pellets used in the present work which is about 88% of the standard density of CuO. The presence of pores or porous nature of the pellets used in the present measurements has a role in the low value of the measured thermal conductivity compared reported values. Alongside, interestingly, a linear decrease in the thermal conductivity is observed with doping even though there is an increase in electrical conductivity which generally indicates an increase in the number of charge carriers. This peculiar behaviour of reverse change in thermal and electrical conductivity of the CuO samples can be explained by the fact that the presence of secondary compound CuxS whose thermal conductivity is significantly smaller (~ 0.5 to 2 W m−1 K−1) than CuO [4]. Further, the presence of non-homogeneous media or interfaces between CuO and CuxS can scatter more phonons and result in lower thermal conductivity. This decrease in thermal conductivity markedly changed with thiourea content used for the doping process and hence it is predicted that CuxS formation makes the compound thermally less conducting, which is evident from the data. In addition, there could also be a small contribution from the broken particles into smaller ones due to the hydrothermal process.

The thermoelectric figure of merit (zT) of CuO samples shown in Fig. 6 have been estimated for room temperature using the above three parameters. The improved power factors and decreased thermal conductivity have made significant changes in the zT values after doping. The undoped CuO has a very low zT of 3.2 × 10–8 and which is changed to 2.08 × 10–7, 7.26 × 10–7, 8.08 × 10–5, 2.38 × 10–4, and 2.27 × 10–4 after doping it with 1, 2, 5, 8, and 10 wt% thiourea. However, these zT values are quite low for real applications; the strategy of changing the electrical properties of such metal oxides can be extended to other materials. Overall improvements have been observed in the thermoelectric properties of copper oxide with a simple hydrothermal doping treatment.

Conclusions

A simple, aqueous-based protocol for sulfur doping has been tried for CuO via the hydrothermal method and a series of CuO/CuxS composites are prepared by varying thiourea content. Significant improvement in the electrical conductivity is observed which produced a better power factor values in spite of a large fall in the Seebeck coefficient. Further, the thermal conductivity of the doped samples is also found to decrease to some extent due to the doping effect, morphological changes of the CuO particles. All these electronic and physical changes have helped in the improvement of the zT value of the CuO and more than four orders of magnitude change has been observed. The approach can be extended to other materials to investigate and achieve possible improvements in their electrical properties.

Data availability

Available from the authors.

References

Bell, L.E.: Cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science 321, 1457–1461 (2008)

Petsagkourakis, I., Tybrandt, K., Crispin, X., Ohkubo, I., Satoh, N., Mori, T.: Thermoelectric materials and applications for energy harvesting power generation. Sci Technol Adv Mater 19, 836–862 (2018)

Du, Y., Chen, J., Meng, Q., Dou, Y., Xu, J., Shen, S.Z.: Thermoelectric materials and devices fabricated by additive manufacturing. Vacuum 178, 109384 (2020)

Mulla, R., Rabinal, M.H.K.: Copper sulfides: earth-abundant and low-cost thermoelectric materials. Energy Technol 7, 1800850 (2019)

N. Tsujii, T. Mori, Stability and thermoelectric property of Cu9Fe9S16: Sulfide mineral as a promising thermoelectric material, MRS Proceedings, 1680 (2014) mrss14–1680-p1606–1608.

Mulla, R., Rabinal, M.K.: Defect-controlled copper iodide: a promising and ecofriendly thermoelectric material. Energy Technol 6, 1178–1185 (2018)

Dou, Y., Zhu, Q., Du, Y., Xu, J., Li, D.: Enhanced thermoelectric performance of Cu3SbSe4 doped with alkali-Ion (Na and K). Electron Mater Lett 16, 99–105 (2020)

Prasoetsopha, N., Pinitsoontorn, S., Amornkitbamrung, V.: Synthesis and thermoelectric properties of Ca3Co4O9 prepared by a simple thermal hydro-decomposition method. Electron Mater Lett 8, 305–308 (2012)

Du, Y., Tian, T., Meng, Q., Dou, Y., Xu, J., Shen, S.Z.: Thermoelectric properties of flexible composite fabrics prepared by a gas polymerization combining solution coating process. Synth Met 260, 116254 (2020)

Du, Y., Xu, J., Paul, B., Eklund, P.: Flexible thermoelectric materials and devices. Appl Mater Today 12, 366–388 (2018)

R. Amirabad, A. Ramazani Saadatabadi, M.H. Siadati (2020) Preparation of polyaniline/graphene coated wearable thermoelectric fabric using ultrasonic-assisted dip-coating method. Mater Renew Sustain Energy 9 21

Ang, R., Khan, A.U., Tsujii, N., Takai, K., Nakamura, R., Mori, T.: Thermoelectricity generation and electron-magnon scattering in a natural chalcopyrite mineral from a deep-sea hydrothermal vent. Angew Chem Int Ed 54, 12909–12913 (2015)

Khan, A.U., Orabi, R.A.R.A., Pakdel, A., Vaney, J.-B., Fontaine, B., Gautier, R., Halet, J.-F., Mitani, S., Mori, T.: Chem Mater 29, 2988–2996 (2017)

Walia, S., Balendhran, S., Nili, H., Zhuiykov, S., Rosengarten, G., Wang, Q.H., Bhaskaran, M., Sriram, S., Strano, M.S., Kalantar-zadeh, K.: Transition metal oxides—thermoelectric properties. Prog Mater Sci 58, 1443–1489 (2013)

RaymondVirtudazo, V.R., Guo, Q., Wu, R., Takei, T., Mori, T.: An alternative, faster and simpler method for the formation of hierarchically porous ZnO particles and their thermoelectric performance. RSC Advances 7, 31960–31968 (2017)

Hirose, Y., Tsuchii, M., Shigematsu, K., Kakefuda, Y., Mori, T., Hasegawa, T.: Thermoelectric properties of amorphous ZnOxNy thin films at room temperature. Appl Phys Lett 114, 193903 (2019)

Zheng, Z.-H., Fan, P., Luo, J.-T., Liang, G.-X., Zhang, D.-P.: Enhanced room-temperature thermoelectric performance of In-doped ZnO: al thin films through prefabricated layer doping method. Electron Mater Lett 11, 429–434 (2015)

Prasad, R., Bhame, S.D.: Review on texturization effects in thermoelectric oxides. Mater Renew Sustain Energy 9, 3 (2020)

Murali, D.S., Kumar, S., Choudhary, R.J., Wadikar, A.D., Jain, M.K., Subrahmanyam, A.: Synthesis of Cu2O from CuO thin films: optical and electrical properties. AIP Adv 5, 047143 (2015)

Hartung, D., Gather, F., Hering, P., Kandzia, C., Reppin, D., Polity, A., Meyer, B.K., Klar, P.J.: Assessing the thermoelectric properties of CuxO (x = 1 to 2) thin films as a function of composition. Appl Phys Lett 106, 253901 (2015)

Yoshida, N., Naito, T., Fujishiro, H.: Thermoelectric properties of Li-Doped CuO. Jpn J Appl Phys 52, 031102 (2013)

Abinaya, C., Bethke, K., Andrei, V., Baumann, J., Pollakowski-Herrmann, B., Kanngießer, B., Beckhoff, B., Vásquez, G.C., Mayandi, J., Finstad, T.G., Rademann, K.: The effect of post-deposition annealing conditions on structural and thermoelectric properties of sputtered copper oxide films. RSC Advanc 10, 29394–29401 (2020)

Linnera, J., Sansone, G., Maschio, L., Karttunen, A.J.: Thermoelectric properties of p-Type Cu2O, CuO, and NiO from hybrid density functional theory. J Phys Chem C 122, 15180–15189 (2018)

Andrei, V., Bethke, K., Rademann, K.: Adjusting the thermoelectric properties of copper(i) oxide–graphite–polymer pastes and the applications of such flexible composites. Phys Chem Chem Phys 18, 10700–10707 (2016)

Mori, T., Hara, T.: Hybrid effect to possibly overcome the trade-off between Seebeck coefficient and electrical conductivity. Scripta Mater 111, 44–48 (2016)

Son, H.-W., Guo, Q., Suzuki, Y., Kim, B.-N., Mori, T.: Thermoelectric properties of MgTi2O5/TiN conductive composites prepared via reactive spark plasma sintering for high temperature functional applications. Scripta Mater 178, 44–50 (2020)

Salah, N., Baghdadi, N., Alshahrie, A., Saeed, A., Ansari, A.R., Memic, A., Koumoto, K.: Nanocomposites of CuO/SWCNT: promising thermoelectric materials for mid-temperature thermoelectric generators. J Eur Ceram Soc 39, 3307–3314 (2019)

Nandihalli, N., Liu, C.-J., Mori, T.: Polymer based thermoelectric nanocomposite materials and devices: fabrication and characteristics. Nano Energy 78, 105186 (2020)

Abad, B., Alda, I., Díaz-Chao, P., Kawakami, H., Almarza, A., Amantia, D., Gutierrez, D., Aubouy, L., Martín-González, M.: Improved power factor of polyaniline nanocomposites with exfoliated graphene nanoplatelets (GNPs). J Mater Chem A 1, 10450–10457 (2013)

Dennler, G., Chmielowski, R., Jacob, S., Capet, F., Roussel, P., Zastrow, S., Nielsch, K., Opahle, I., Madsen, G.K.H.: Are binary copper sulfides/selenides really new and promising thermoelectric materials? Advanc Energy Mater 4, 1301581 (2014)

Qu, S., Wang, Y., Xiao, Y., Yuan, Y., Li, S., Chen, J., Zhao, L., Xia, Z., Zhao, J.: Temperature-driven n–p conduction type switching without structural transition in a Cu-rich chalcogenide, NaCu5S3. Chem Commun 56, 4882–4885 (2020)

Liu, H., Chen, Z., Tang, J., Zhong, Y., Guo, X., Zhang, F., Ang, R.: High quality factor enabled by multiscale phonon scattering for enhancing thermoelectrics in low-solubility n-Type PbTe–Cu2Te alloys. ACS Appl Mater Interfaces 12, 52952–52958 (2020)

Chen, Z., Guo, X., Tang, J., Xiong, F., Li, W., Chen, Y., Ang, R.: Extraordinary role of Bi for improving thermoelectrics in low-solubility SnTe–CdTe alloys. ACS Appl Mater Interfaces 11, 26093–26099 (2019)

Tang, J., Gao, B., Lin, S., Li, J., Chen, Z., Xiong, F., Li, W., Chen, Y., Pei, Y.: Manipulation of band structure and interstitial defects for improving thermoelectric SnTe. Adv Func Mater 28, 1803586 (2018)

Mulla, R., Rabinal, M.K.: A tweezer as a thermoelectric tester. Phys Educ 54, 055032 (2019)

Mulla, R., Rabinal, M.K.: A simple and portable setup for thermopower measurements. ACS combinator Sci 18, 177–181 (2016)

Zawilski, B.M., Littleton, R.T., Tritt, T.M.: Description of the parallel thermal conductance technique for the measurement of the thermal conductivity of small diameter samples. Rev Sci Instrum 72, 1770 (2001)

Vasquez, R.P.: CuO by XPS. Surf Sci Spectra 5, 262–266 (1998)

Zhao, S., Peng, Y.: The oxidation of copper sulfide minerals during grinding and their interactions with clay particles. Powder Technol 230, 112–117 (2012)

Figueira, J., Loureiro, J., Marques, J., Bianchi, C., Duarte, P., Ruoho, M., Tittonen, I., Ferreira, I.: Optimization of cuprous oxides thin films to be used as thermoelectric touch detectors. ACS Appl Mater Interfaces 9, 6520–6529 (2017)

S. Åsbrink, L. J. Norrby (1970) A refinement of the crystal structure of copper(II) oxide with a discussion of some exceptional e.s.d.'s, Acta Crystallographica section B structural crystallography and crystal chemistry 26 8–15

Shinagawa, T., Larrazábal, G.O., Martín, A.J., Krumeich, F., Pérez-Ramírez, J.: Sulfur-modified copper catalysts for the electrochemical reduction of carbon dioxide to formate. ACS Catalysis 8, 837–844 (2018)

Mulla, R., Rabinal, M.K.: Large-scale synthesis of copper sulfide by using elemental sources via simple chemical route. Ultrason Sonochem 39, 528–533 (2017)

Mulla, R., Rabinal, M.K.: Ambient growth of highly oriented Cu_2S dendrites of superior thermoelectric behaviour. Appl Surface Sci (2017). https://doi.org/10.1016/japsusc201611106

Ge, Z.-H., Zhang, B.-P., Chen, Y.-X., Yu, Z.-X., Liua, Y., Lib, J.-F.: Synthesis and transport property of Cu1.8S as a promising thermoelectric compound. Chem Commun 47, 12697–12699 (2011)

Suwardi, A., Bash, D., Ng, H.K., Gomez, J.R., Repaka, D.V.M., Kumar, P., Hippalgaonkar, K.: Inertial effective mass as an effective descriptor for thermoelectrics via data-driven evaluation. J Mate Chem A 7, 23762–23769 (2019)

Funding

None.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mulla, R., Rabinal, M.K. CuO/CuxS composites fabrication and their thermoelectric properties. Mater Renew Sustain Energy 10, 3 (2021). https://doi.org/10.1007/s40243-021-00189-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40243-021-00189-7