Abstract

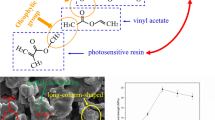

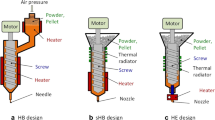

In this work, PDC SiOC porous structures were fabricated using the stereolithography (SLA) 3D printing method with preceramic resin methylsiloxane. The printed structures were then sintered at 1000 °C for 1 h. Water treatment can help prevent the shrinkage and remove the unreacted resin. From the XRD and FT-IR results, the sintered ceramic is amorphous SiOC. The microstructures show that the printed structures have high geometric accuracy. The water reinforcement process produces smoother surfaces on the printed structures.

Similar content being viewed by others

References

K.V. Wong, A. Hernandez, A review of additive manufacturing. International Scholarly Research Notices 1, 10 (2012)

F.P. Melchels, J. Feijen, D.W. Grijpma, A review on stereolithography and its applications in biomedical engineering. Biomaterials 31(24), 6121–6130 (2010)

L. Brigo et al., 3D nanofabrication of SiOC ceramic structures. Adv Sci 5(12), 1800937 (2018)

A. Zocca et al., SiOC ceramics with ordered porosity by 3D-printing of a preceramic polymer. J Mater Res 28(17), 2243–2252 (2013)

L. Zoli et al., Additive manufacturing of ceramics enabled by flash pyrolysis of polymer precursors with nanoscale layers. J Am Ceram Soc 99(1), 57–63 (2016)

P. Colombo et al., Polymer-derived ceramics: 40 years of research and innovation in advanced ceramics. J Am Ceram Soc 93(7), 1805–1837 (2010)

P. Colombo et al., Additive manufacturing techniques for fabricating complex ceramic components from preceramic polymers. Am Ceram Soc Bull 96(3), 16–23 (2017)

Z.C. Eckel et al., Additive manufacturing of polymer-derived ceramics. Science 351(6268), 58–62 (2016)

R. Riedel et al., A silicoboron carbonitride ceramic stable to 2,000 C. Nature 382(6594), 796–798 (1996)

E. Ionescu et al., Polymer-derived SiOC/ZrO2 ceramic nanocomposites with excellent high-temperature stability. J Am Ceram Soc 93(1), 241–250 (2010)

Y. Wang et al., Polymer-derived SiAlCN ceramics resist oxidation at 1400 C. Scripta Mater 55(4), 295–297 (2006)

C. Bentivoglio Ruiz et al., Oxygen inhibition and coating thickness effects on UV radiation curing of weatherfast clearcoats studied by photo-DSC. J Therm Anal Calorim 75(2), 507–512 (2004)

K. Studer et al., Overcoming oxygen inhibition in UV-curing of acrylate coatings by carbon dioxide inerting Part I. Prog Org Coat 48(1), 92–100 (2003)

J. Alvankarian, B. Majlis, Exploiting the oxygen inhibitory effect on UV curing in microfabrication: a modified lithography technique. PLoS ONE 10, e0119658 (2015)

G. Mera et al., Polymer-derived SiCN and SiOC ceramics–structure and energetics at the nanoscale. J Mater Chem A 1(12), 3826–3836 (2013)

Y. Fu et al., Multiple metals doped polymer-derived SiOC ceramics for 3D printing. Ceram Int 44(10), 11030–11038 (2018)

D. Erb, K. Lu, Additive and pyrolysis atmosphere effects on polysiloxane-derived porous SiOC ceramics. J Eur Ceram Soc 37(15), 4547–4557 (2017)

N. Wu et al., Conversion of hydrophilic SiOC nanofibrous membrane to robust hydrophobic materials by introducing palladium. Appl Surf Sci 425, 750–757 (2017)

S. Sen et al., Carbon substitution for oxygen in silicates in planetary interiors. Proc Natl Acad Sci 110(40), 15904–15907 (2013)

V. Jousseaume et al., Comparison between e-beam and ultraviolet curing to perform porous a-SiOC: H. J Electrochem Soc 154(5), G103 (2007)

T. Oh, Correlation between potential barrier and FTIR spectra in SiOC Film with the CO bond Of Sp 3 structure. Bull Korean Chem Soc 30(2), 467–470 (2009)

T. Oh, C.K. Choi, Comparison between SiOC thin films fabricated by using plasma enhance chemical vapor deposition and SiO2 thin films by using fourier transform infrared spectroscopy. J Korean Phys Soc 56(4), 1150–1155 (2010)

S.A. Brinckmann et al., Stereolithography of SiOC polymer-derived ceramics filled with SiC micronwhiskers. Adv Eng Mater 20(11), 1800593 (2018)

Acknowledgements

This work is partially supported by the “Human Resources Program in Energy Technology (No. 20194030202450)” and “Power Generation & Electricity Delivery grant (No. 20193310100030)” of the Korea Institute of Energy Technology Evaluation and Planning (KETEP). Xuehui Yang is supported by the Research Foundation doctoral thesis research award provided by Indiana University – Purdue University Indianapolis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, X., Zhang, J., Park, HY. et al. Water surface reinforcement effect in 3D printed polymer derived SiOC ceramics. Appl. Phys. A 127, 151 (2021). https://doi.org/10.1007/s00339-021-04305-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-04305-2