Abstract

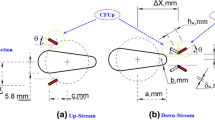

The thermal enhancement and pressure drop in a circular tube with radially-arrayed winglet vortex generator (VG) mounted inside at different orientations were experimentally studied. A series of four winglet rings containing VGs were on the inner surface of the tube at different sections. The effects of winglet attack angles β (0–45°), pitch ratios PR (1.6–4.8), porosity ratio γ (0–20%), winglet length L (10–20 mm), and inclination angle α (0–30°) on heat transfer and pressure drop characteristics were carefully examined. The study was carried out at Reynolds numbers (Re) ranging from 6 × 103 to 2.7 × 104 nestling in the turbulent flow regime. Results showed a significant effect of the winglets on the heat transfer enhancement and pressure penalty compared to the smooth tube. Experiments further revealed that as the length or attack angle of winglets increased, both Nusselt number (Nu) and friction factor (f) were intensified. When it turned to pitch ratio and inclination angle of winglets, the trend became adverse. By comparing the contribution of different winglet parameters, it is preferable to optimize the pitch ratio (PR) other than length, inclination angle (α) nor attack angle (β) for a higher thermal enhancement. The case of small porosity ratio (γ = 10%) at a low Re yields the maximum thermal enhancement of 1.26. Empirical correlations for Nu and f were generated for the winglets based on experimental data.

Similar content being viewed by others

Abbreviations

- A [m2]:

-

Lateral area of the duct

- Cp [Jkg-1K-1)]:

-

Capacity

- D [m]:

-

Diameter of the duct

- f [-]:

-

Friction factor

- H [m]:

-

Height of winglet vortex generator

- h [Wm-2K-1]:

-

Convective heat transfer coefficient

- I [A]:

-

Current

- k [Wm-1K-1]:

-

Thermal conductivity

- L [m]:

-

Length of vortex generator

- l [m]:

-

Length of test section

- \( \dot{m} \) [kgs-1]:

-

Mass flow rate

- Nu [-]:

-

Nusselt number

- P [m]:

-

Pitch

- PR [-]:

-

Pitch ratio

- ∆P [Pascal]:

-

Pressure drop

- Pr [-]:

-

Prandtl number

- Q [J]:

-

Heat

- R :

-

Result function

- δR :

-

Error of result

- Re [-]:

-

Reynolds number

- T [K]:

-

Temperature

- t [m]:

-

Tube thickness

- U [ms-1]:

-

Velocity

- V [volt]:

-

Voltage

- \( \dot{V} \) [m3s-1]:

-

Volumetric flow rate

- X :

-

Independent variable

- δX :

-

Error of independent variable

- \( \overline{X} \) :

-

Averaged variable

- α [°]:

-

Inclination angle

- β [°]:

-

Attack angle

- γ [-]:

-

Porosity ratio

- ρ [kgm-3]:

-

Density

- υ [m2s-1]:

-

Kinematic viscosity

- b :

-

bulk

- conv :

-

Convective

- D :

-

Duct

- i :

-

index

- in :

-

Inlet

- loss :

-

Heat loss

- out :

-

Outlet

- O :

-

Smoothduct

- pp :

-

Pump power

- s :

-

Surface

References

Ligrani PM, Oliveira MM, Blaskovich T (2003) Comparison of heat transfer augmentation techniques. AIAA J 41:337–362. https://doi.org/10.2514/2.1964

Ghanem A, Habchi C, Lemenand T et al (2013) Energy efficiency in process industry - high-efficiency vortex (HEV) multifunctional heat exchanger. Renew Energy 56:96–104. https://doi.org/10.1016/j.renene.2012.09.024

Anxionnaz Z, Cabassud M, Gourdon C, Tochon P (2008) Heat exchanger/reactors (HEX reactors): concepts, technologies: state-of-the-art. Chem Eng Process Process Intensif 47:2029–2050. https://doi.org/10.1016/j.cep.2008.06.012

Thakur RK, Vial C, Nigam KDP et al (2003) Static mixers in the process industries - a review. Chem Eng Res Des 81:787–826. https://doi.org/10.1205/026387603322302968

Oneissi M, Habchi C, Russeil S et al (2016) Novel design of delta winglet pair vortex generator for heat transfer enhancement. Int J Therm Sci 109:1–9. https://doi.org/10.1016/j.ijthermalsci.2016.05.025

Khanjian A, Habchi C, Russeil S et al (2017) Effect of rectangular winglet pair roll angle on the heat transfer enhancement in laminar channel flow. Int J Therm Sci 114:1–14. https://doi.org/10.1016/j.ijthermalsci.2016.12.010

Biswas G, Torii K, Nishino K (1996) Numerical and experimental determination of flow structure and heat transfer effects of longitudinal vortices in a channel flow. Int J Heat Mass Transf 39:3441–3451. https://doi.org/10.1016/0017-9310(95)00398-3

Jedsadaratanachai W, Jayranaiwachira N, Promvonge P (2015) 3D numerical study on flow structure and heat transfer in a circular tube with V-baffles. Chinese J Chem Eng 23:342–349. https://doi.org/10.1016/j.cjche.2014.11.006

Yakut K, Sahin B, Celik C et al (2005) Effects of tapes with double-sided delta-winglets on heat and vortex characteristics. Appl Energy 80:77–95. https://doi.org/10.1016/j.apenergy.2004.03.003

Zhou G, Ye Q (2012) Experimental investigations of thermal and flow characteristics of curved trapezoidal winglet type vortex generators. Appl Therm Eng 37:241–248. https://doi.org/10.1016/j.applthermaleng.2011.11.024

Promvonge P, Tamna S, Pimsarn M, Thianpong C (2015) Thermal characterization in a circular tube fitted with inclined horseshoe baffles. Appl Therm Eng 75:1147–1155. https://doi.org/10.1016/j.applthermaleng.2014.10.045

Noothong W, Suwannapan S, Thianpong C, Promvonge P (2015) Enhanced heat transfer in a heat exchanger square-duct with discrete V-finned tape inserts. Chinese J Chem Eng 23:490–498. https://doi.org/10.1016/j.cjche.2014.05.018

Islam MD, Oyakawa K, Yaga M, Kubo I (2009) The influence of channel height on heat transfer enhancement of a co-angular type rectangular finned surface in narrow channel. Int J Therm Sci 48:1639–1648

Islam MD, Oyakawa K, Yaga M, Kubo I (2009) The effects of duct height on heat transfer enhancement of a co-rotating type rectangular finned surface in duct. Exp Thermal Fluid Sci 33:348–356. https://doi.org/10.1016/j.expthermflusci.2008.10.005

Didarul IM, Kenyu O, Minoru Y, Izuru S (2007) Study on heat transfer and fluid flow characteristics with short rectangular plate fin of different pattern. Exp Thermal Fluid Sci 31:367–379. https://doi.org/10.1016/j.expthermflusci.2006.05.009

Islam MD, Oyakawa K, Yaga M (2008) Heat transfer enhancement from a surface affixed with rectangular fins of different patterns and arrangement in duct flow. J Enhanc Heat Transf:15

Islam MD, Oyakawa K, Kubo I (2009) Visualization of flow pattern and thermal image analysis of enhanced heat transfer surface. Heat Mass Transf 45:511–517

Oyakawa K, Didarul IM, Yaga M (2006) Fluid flow and infrared image analyses on endwall fitted with short rectangular plate fin. J Therm Sci 15:145

Habchi C, Lemenand T, Della D et al (2011) Entropy production and field synergy principle in turbulent vortical flows. Int J Therm Sci 50:2365–2376. https://doi.org/10.1016/j.ijthermalsci.2011.07.012

Tiggelbeck S, Mitra N, Fiebig M (1992) Flow structure and heat transfer in a channel with multiple longitudinal vortex generators. Exp Thermal Fluid Sci 5:425–436. https://doi.org/10.1016/0894-1777(92)90029-5

Tang LH, Tan SC, Gao PZ, Zeng M (2016) Parameters optimization of fin-and-tube heat exchanger with a novel vortex generator fin by Taguchi method. Heat Transf Eng 37:369–381. https://doi.org/10.1080/01457632.2015.1052715

Sanders PA, Thole KA (2006) Effects of winglets to augment tube wall heat transfer in louvered fin heat exchangers. 49:4058–4069. https://doi.org/10.1016/j.ijheatmasstransfer.2006.03.036

Skullong S, Promvonge P, Thianpong C, Pimsarn M (2016) Thermal performance in solar air heater channel with combined wavy-groove and perforated-delta wing vortex generators. Appl Therm Eng 100:611–620. https://doi.org/10.1016/j.applthermaleng.2016.01.107

Webb RL (1981) Performance evaluation criteria for use of enhanced heat transfer surfaces in heat exchanger design. Int J Heat Mass Transf 24:715–726. https://doi.org/10.1016/0017-9310(81)90015-6

Moffat RJ (1988) Describing the uncertainties in experimental results. Exp Thermal Fluid Sci 1:3–17. https://doi.org/10.1016/0894-1777(88)90043-X

Bergman TL, Incropera FP, DeWitt DP, Lavine AS (2011) Fundamentals of heat and mass transfer. John Wiley & Sons

Habchi C, Harion JL (2014) Residence time distribution and heat transfer in circular pipe fitted with longitudinal rectangular wings. Int J Heat Mass Transf 74:13–24. https://doi.org/10.1016/j.ijheatmasstransfer.2014.03.007

Joshi P, Nigam KDP, Nauman EB (1995) The Kenics static mixer: new data and proposed correlations. Chem Eng J Biochem Eng J 59:265–271. https://doi.org/10.1016/0923-0467(94)02948-2

Chompookham T, Thianpong C, Kwankaomeng S, Promvonge P (2010) Heat transfer augmentation in a wedge-ribbed channel using winglet vortex generators. Int Commun Heat Mass Transf 37:163–169. https://doi.org/10.1016/j.icheatmasstransfer.2009.09.012

Rahimi M, Shabanian SR, Alsairafi AA (2009) Experimental and CFD studies on heat transfer and friction factor characteristics of a tube equipped with modified twisted tape inserts. Chem Eng Process Process Intensif 48:762–770. https://doi.org/10.1016/j.cep.2008.09.007

Eiamsa-ard S, Promvonge P (2006) Experimental investigation of heat transfer and friction characteristics in a circular tube fitted with V-nozzle turbulators. Int Commun Heat Mass Transf 33:591–600. https://doi.org/10.1016/j.icheatmasstransfer.2006.02.022

Li HZ, Fasol C, Choplin L (1997) Pressure drop of newtonian and non-newtonian fluids across a sulzer SMX static mixer. Chem Eng Res Des 75:792–796. https://doi.org/10.1205/026387697524461

Eiamsa-ard S, Thianpong C, Eiamsa-ard P, Promvonge P (2010) Thermal characteristics in a heat exchanger tube fitted with dual twisted tape elements in tandem. Int Commun Heat Mass Transf 37:39–46. https://doi.org/10.1016/j.icheatmasstransfer.2009.08.010

Promvonge P, Thianpong C (2008) Thermal performance assessment of turbulent channel flows over different shaped ribs. Int Commun Heat Mass Transf 35:1327–1334. https://doi.org/10.1016/j.icheatmasstransfer.2008.07.016

Acknowledgements

We gratefully acknowledge the support of the Khalifa University of Science and Technology, Abu Dhabi, UAE and the Petroleum Institute, Abu Dhabi (Research Grant: RIFP 15322-2015) for the completion of this research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liang, G., Islam, M., Alam, M.M. et al. An experimental study of heat transfer enhancement with winglets inside a tube. Heat Mass Transfer 57, 1223–1234 (2021). https://doi.org/10.1007/s00231-021-03021-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-021-03021-0