Abstract

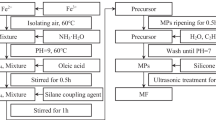

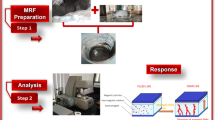

Magnetorheological fluids have a viscosity which can be controlled by the application of magnetic field. Usually they have dispersions of magnetic particles with size micrometric in a carrier liquid. After purification process, extracted material from mining waste allowed us to obtain the magnetite that was used as the magnetic component of a magnetorheological fluid. The carrier continuous medium for such fluid was 2.5 and 20 W oils. These oils are used for damping systems in high-performance motorcycles and are readily available. The magnetics particle’s size ranged from 2 to 100 µm. Magnetic fields from 50 to 1200 gauss, as well as structural, morphological, and rheological studies were performed to the analyzed fluids. We observed that the model that best fits the stress vs. shear rate curves was the Herschel–Bulkley model.

Similar content being viewed by others

References

W.M. Winslow, Induced Fibration of Suspensions. J. Appl. Phys. 20, 1137 (1949)

J. Rabinow, The magnetic fluid Clutch. J. AIEE Trans. 67, 1308 (1948)

J.D. Carlson, in Proceedings of the 7th International Conference on ER fluids and MR suspensions, 2000, ed. by R. Tao (World Scientific Singapore), pp. 621–628

H.J. Choi, M.S. Jhon, Electrorheology of polymers and nanocomposites. Soft Matter 5, 1562 (2009)

Q. Cheng, V. Pavlinek, Y. He, A. Lengalova, C. Li, P. Saha, Structural and eletrorheological properties of mesoporous silica modified with triethanolamine. Colloids Surf. A: Physicochem. Eng. Aspects 318, 169 (2008)

P. Hiamtup, A. Sirivat, A.M. Jamieson, Hysteresis and strain hardening in the creep response of a polyaniline ER fluid. J. Colloid Interf. Sci. 325, 122 (2008)

F.F. Fang, B.M. Lee, H.J. Choi, Electrorheologically intelligent polyaniline and its composites. Macromol. Res. 18, 99 (2010)

H.J. Choi, J.W. Kim, K. To, Synthesis and electrorheological behavior of semiconducting poly(aniline-co-o-ethoxyaniline). Synth. Met. 101, 697 (1999)

J.L. Carrillo, F. Donado, M.E. Mendoza, Fractal patterns, cluster dynamics, and elastic properties of magnetorheological suspensions. Phys. Rev. E 68, 061509 (2003)

J.L. Carrillo, M.E. Mendoza, F. Donado, Fractal patterns and aggregation processes in rheological dispersions. J. Stat. Mech. 2005(06), P06001 (2005)

T. Ukai, T. Maekawa, Patterns formed by paramagnetic particles in a horizontal layer of a magnetorheological fluid subjected to a dc magnetic field. Phys. Rev. E 69, 032501 (2004)

E.M. Furst, A.P. Gast, Micromechanics of magnetorheological suspensions. Phys. Rev. E 61 (2000) 6732. Dynamics and lateral interactions of dipolar chains. Phys. Rev. E. 62, 6916 (2000)

Y. Nagaoka, H. Morimoto, T. Maekawa, Dynamics of disklike clusters formed in a magnetorheological fluid under a rotational magnetic field. Phys. Rev. E 71, 032502 (2005)

R. Tao, Super-strong magnetorheological fluids. J. Phys.: Condens. Matter 13, R979 (2001)

F. Donado, J.L. Carrillo, M.E. Mendoza, Sound propagation in magneto-rheological suspensions. J. Phys. Condens. Matter 14(9), 2153–2157 (2002)

B.O. Park, K.H. Song, B.J. Park, H.J. Choi, Miniemulsion fabricated Fe3O4/poly (methyl methacrylate) composite particles and their magnetorheological characteristics. J. Appl. Phys. 107, 09A506 (2010)

X. Tang, X. Zhang, R. Tao, Y. Rong, Structure-enhanced yield stress of magnetorheological fluids. J. Appl. Phys. 87, 2634 (2000)

I.B. Jang, H.B. Kim, J.Y. Lee, J.L. You, H.J. Choi, M.S. Jhon, Role of organic coating on carbonyl iron suspended particles in magnetorheological fluids. J. Appl. Phys. 97, 10Q912 (2005)

J. De Vicente, M.T. López-López, J.D.G. Durán, F. González-Caballero, Shear flow behaviour of confined magnetorheological fluids at low magnetic field strengths. Rheol. Acta 44, 94 (2004)

X.Z. Zhang, X.L. Gong, P.Q. Zhang, Q.M. Wang, Study on the mechanism of the squeeze-strengthen effect in magnetorheological fluids. J. Appl. Phys. 96, 2359 (2004)

M.S. Cho, S.T. Lim, I.B. Jang, H.J. Choi, M.S. John, Encapsulation of spherical iron particle with PMMA and by its magnetorheological particles. IEEE Trans. Magn. 40, 3036 (2004)

F.F. Fang, H.J. Choi, Polymeric nanobead coated carbonyl iron particles and their magnetic property. Phys. Stat. Sol. (a) 204, 4190 (2007)

F.F. Fang, H.J. Choi, Noncovalent self-assembly of carbon nanotube wrapped carbonyl iron particles and their magnetorheology. J. Appl. Phys. 103, 07A301 (2008)

Pradeep P Phulé, Magnetorheological (MR) fluids: Principles and applications Smart Materials. Bulletin Feb/ 2001.

J.M. Ginder, L.C. Davis, L.D. Elie, Rheology of magnetorheological fluids: Models and measurements. Int. J. Mod. Phys. B 10, 3293 (1996)

S. Genc, B. Derin, Synthesis and rheology of ferrofluids: a review. Curr. Opin. Chem. Eng. 3, 118–124 (2014). https://doi.org/10.1016/j.coche.2013.12.006

M.T. López-López, P. Kuzhir, G. Bossis, P. Mingalyov, Preparation of well-dispersed magnetorheological fluids and effect of dispersion on their magnetorheological properties. Rheol. Acta 47(7), 787–796 (2008)

M. Jessica, P. Tomáš, K. Pavel, Iron–sepiolite magnetorheological fluids with improved performances. J. Rheol. 63(1), 125–139 (2019)

F. Imaduddin, S.A. Mazlan, H. Zamzuri, A design and modelling review of rotary magnetorheological damper. Mater. Des. 51, 575–591 (2013)

R. Stanway, J.L. Sproston, N.G. Stevens, Non-linear modeling of an electro-rheological vibration damper. J. Electrostatics 20, 167–184 (1987)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A

Appendix A

See Table 4

Rights and permissions

About this article

Cite this article

Quitian, G., Saldarriaga, W. & Rojas, N. Steady rheological properties of a magnetorheological fluid from mining waste. Appl. Phys. A 127, 149 (2021). https://doi.org/10.1007/s00339-020-04221-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-020-04221-x