Abstract

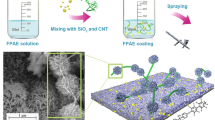

Superhydrophobic coatings with high flexibility and mechanical durability can well address many practical application problems. To this end, we proposed and fabricated a kind of bio-based superhydrophobic (multi-walled carbon nanotubes) CNT@PU (polyurethane) coatings. It was demonstrated that the CNT@PU coatings with 64% soft segment content possessed the preferable bonding strength (5B) with metal substrates. The multi-walled carbon nanotubes, as additive materials, were used to construct the microscopic structures of the coating surfaces, which made polyurethane surface superhydrophobic (water contact angle being 156.9°, and water sliding angle being 4.3°). Furthermore, the high bonding strength between CNT and coating matrix led to robust mechanical durability of superhydrophobic CNT@PU coatings, and the coatings remained superhydrophobicity after 10 cycles of abrasion under 100 g load pressure. Also, the superhydrophobic coatings could well resist 5 cycles of tape-peeling action, and presented outstanding flexibility. The superhydrophobic CNT@PU coatings with high flexibility and mechanical durability could be applied to various substrates suggesting their big potential in future real-world application.

Similar content being viewed by others

References

Sun T, Feng L, Gao X, Jiang L. Bioinspired surfaces with special wettability. Accounts of Chemical Research, 2005, 38, 644–652.

Barthlott W, Neinhuis C. Purity of the sacred lotus, or escape from contamination in bio-based surfaces. Planta, 1997, 202, 1–8.

Long J, Fan P, Gong D, Jiang D F, Zhang H J, Li L, Zhong M L. Superhydrophobic surfaces fabricated by femtosecond laser with tunable water adhesion: From lotus leaf to rose petal. ACS Applied Materials & Interfaces, 2015, 7, 9858–9865.

Cheng Q Y, Liu M C, Li Y D, Zhu J, Du A K, Zeng J B. Biobased superhydrophobic coating on cotton fabric fabricated by spray-coating for efficient oil/water separation. Polymer Testing, 2018, 66, 41–17.

Li Z, Sun Z, Duan Z, Li R, Yang Y L, Wang J Y, Lv X X, Qi W, Wang H. Superhydrophobic silver-doped TiO2@ polycarbonate coatings created on various material substrates with visible-light photocatalysis for self-cleaning contaminant degradation. Scientific Reports, 2017, 7, 42932.

Shen Y, Xie Y, Tao J, Chen H F, Zhu C L, Jin M M, Lu Y. Rationally designed nanostructure features on superhydrophobic surfaces for enhancing self-propelling dynamics of condensed droplets. ACS Sustainable Chemistry & Engineering, 2018, 7, 2702–2708.

Xiang T, Han Y, Guo Z, Wang R, Zheng S L, Li S, Li C, Dai X M. Fabrication of inherent anticorrosion superhydrophobic surfaces on metals. ACS Sustainable Chemistry & Engineering, 2018, 6, 5598–5606.

Zhu T, Li S, Huang J Y, Mihailiasa M, Lai Y K. Rational design of multi-layered superhydrophobic coating on cotton fabrics for UV shielding, self-cleaning and oil-water separation. Materials & Design, 2017, 134, 342–351.

Li Y, He L, Zhang X, Zhang N, Tian D L. External-field-induced gradient wetting for controllable liquid transport: From movement on the surface to penetration into the surface. Advanced Materials, 2017, 29, 1703802.

Verho T, Bower C, Andrew P, Franssila S, Ikkala O, Robin H A. Mechanically durable superhydrophobic surface. Advanced Materials, 2010, 23, 673–678.

Feng L, Li S, Li Y, Li H, Zhang L, Zhai J, Song Y, Liu B, Jiang L, Zhu D. Superhydrophobic surfaces: From natural to artificial. Advanced Materials, 2002, 14, 1857–1860.

Ma M, Hill R M. Superhydrophobic surfaces. Current Opinion in Colloid & Interface Science, 2006, 11, 193–202.

Ebert D, Bhushan B. Transparent, superhydrophobic, and wear-resistant surfaces using deep reactive ion etching on PDMS substrates. Journal of Colloid and Interface Science, 2016, 481, 82–90.

Kim S, Hwang H J, Cho H, Choi D, Hwang W. Repeatable replication method with liquid infiltration to fabricate robust, flexible, and transparent, anti-reflective superhydrophobic polymer films on a large scale. Chemical Engineering Journal, 2018, 350, 225–232.

Wu X, Fu Q, Kumar D, Ho JWC, Kanhere P, Zhou H F, Chen Z. Mechanically robust superhydrophobic and superoleophobic coatings derived by sol-gel method. Materials & Design, 2016, 89, 1302–1309.

Liu S, Liu X, Latthe S, Latthe, Gao L, An S, Yoon S S, Liu B, Xing R M. Self-cleaning transparent superhydrophobic coatings through simple sol-gel processing of fluoroalkylsilane. Applied Surface Science, 2015, 351, 897–903.

Golovin K, Boban M, Mabry J M, Tuteja A. Designing self-healing superhydrophobic surfaces with exceptional mechanical durability. ACS Applied Materials & Interfaces, 2017, 9, 11212–11223.

Pi P, Mu W, Fei G, Deng Y L. Superhydrophobic film fabricated by controlled microphase separation of PEO-PLA mixture and its transparence property. Applied Surface Science, 2013, 273, 184–191.

Jin M, Shen Y, Luo X, Tao J, Xie Y H, Chen H F, Wu Y. A combination structure of microblock and nanohair fabricated by chemical etching for excellent water repellency and icephobicity. Applied Surface Science, 2018, 455, 883–890.

Lu Y, Song J, Liu X, Xu W J, Xing Y J, Wei Z F. Preparation of superoleophobic and superhydrophobic titanium surfaces via an environmentally friendly electrochemical etching method. ACS Sustainable Chemistry & Engineering, 2012, 1, 102–109.

Zhang F, Shi Z, Chen L, Jiang Y J, Xu C Y, Wu Z H, Wang Y Y, Peng C S. Porous superhydrophobic and superoleophilic surfaces prepared by template assisted chemical vapor deposition. Surface and Coatings Technology, 2017, 315, 385–390.

Cai J, Huang J, Wang S, Iocozzia J, Sun Z T, Sun J Y, Yang Y K, Lai Y K, Lin Z Q. Crafting mussel-inspired metal nano-particle-decorated ultrathin graphitic carbon nitride for the degradation of chemical pollutants and production of chemical resources. Advanced Materials, 2019, 31, 1806314.

Zeng M, Wang P, Luo J, Peng B, Ding B, Zhang L, Wang L, Huang D, Echols I, Deep E A, Bordovsky E, Choi C, Ybanez C, Meras P, Situ E, Mannan M. Cheng Z. Hierarchical, self-Healing and superhydrophobic zirconium phosphate hybrid membrane based on the interfacial crystal growth of lyotropic two-dimensional nanoplatelets. ACS Applied Materials & Interfaces, 2018, 10, 22793–22800.

Genzer J, Efimenko K. Creating long-lived superhydrophobic polymer surface through mechanically assembled monolayer. Science, 2000, 290, 2130–2133.

Shen Y, Wu Y, Tao J, Zhu C L, Chen H F, Xie Y H. Spraying fabrication of durable and transparent coatings for anti-icing application: Dynamic water repellency, icing delay, and ice adhesion. ACS Applied Materials & Interfaces, 2018, 11, 3590–3598.

Zheng H, Pan M, Wen J, Yuan J F, Zhu L, Yu H F. Robust, transparent and superhydrophobic coating fabricated with waterborne polyurethane and inorganic nanoparticle composites. Industrial & Engineering Chemistry Research, 2019, 351, 897–903.

Yamauchi Y, Tenjimbayashi M, Samitsu S, Naito M. Durable and flexible superhydrophobic materials: Abrasion/scratching/slicing/droplet impacting/bending/twisting-tolerant composite with porcupinefish-like structure. ACS Applied Materials & Interfaces, 2019, 11, 32381–32389.

Panahi-Sarmad M, Abrisham M, Noroozi M, Goodarzi V, Arjmand M, Sadri M, Dehghan P, Amirkiai A, Khonakdar H A. Programing polyurethane with rational surface-modified graphene platelets for shape memory actuators and dielectric elastomer generators. European Polymer Journal, 2020, 133, 109745.

Panahi-Sarmad M, Goodarzi V, Amirkiai A, Noroozi M, Abrisham M, Dehghan P, Shakeri Y, Karimpour-Motlagh N, Poudineh Hajipoor F, Ali Khonakdar H, Asefnejad A. Programing polyurethane with systematic presence of graphene-oxide(go) and reduced graphene-oxide(rgo) platelets for adjusting of heat-actuated shape memory properties. European Polymer Journal, 2019, 118, 619–632.

Javadi S, Panahi-Sarmad M, Razzaghi-Kashani M. Interfacial and dielectric behavior of polymer nano-composites: Effects of chain stiffness and cohesive energy density. Polymer, 2018, 145, 31–10.

Lau K K S, Bico J, Teo K B K, Chhowalla M, Amaratunga G A J, Milne W I, McKinley G H, Gleason K K. Superhydrophobic carbon nanotube forests. Nano Letters, 2003, 3, 1701–1705.

Varga M, Izak T, Vretenar V, Kozak H, Holovsky J, Artemenko A, Hulman M, Skakalova V, SuLee D, Kromka A. Diamond/carbon nanotube composites: Raman, FTIR and XPS spectroscopic studies. Carbon, 2017, 111, 54–61.

Qu M, Ma X, He J, Feng J, Liu S S, Yao Y L, Hou L G, Liu X G. Facile selective and diverse fabrication of superhydrophobic, superoleophobic-superhydrophilic and superamphiphobic materials from kaolin. ACS Applied Materials & Interfaces, 2016, 9, 1011–1020.

Chen L, Guo Z, Liu W. Biomimetic multi-functional superamphiphobic FOTS-TiO2 particles beyond lotus leaf. ACS Applied Materials & Interfaces, 2016, 8, 27188–27198.

Schondelmaier D, Cramm S, Klingeler R, Morenzin J, Zilkens C, Eberhardt W. Orientation and self-assembly of hydrophobic fluoroalkylsilanes. Langmuir, 2002, 18, 6242–6245.

Lei H, Xiao J, Zheng L, Xiong M N, Zhu Y R, Qian J, Zhuang Q X, Han Z W. Superhydrophobic coatings based on colloid silica and fluorocopolymer. Polymer, 2016, 86, 22–31.

Hejazi I, Sadeghi G M M, Jafari S H, AliKhonakdar H, Seyfi J, Holzschuh M, Simon F. Transforming an intrinsically hydrophilic polymer to a robust self-cleaning superhydrophobic coating via carbon nanotube surface embedding. Materials & Design, 2015, 86, 338–346.

Cao C, Ge M, Huang J, Li S H, Deng S, Zhang S N, Chen Z, Zhang K Q, Al-Deyab S S, Lai Y K. Robust fluorine-free superhydrophobic PDMS-ormosil@ fabrics for highly effective self-cleaning and efficient oil-water separation. Journal of Materials Chemistry A, 2016, 4, 12179–12187.

Hwang G B, Patir A, Page K, Lu Y, Allan E, Parkin I P. Buoyancy increase and drag-reduction through a simple superhydrophobic coating. Nanoscale, 2017, 9, 7588–7594.

Peng C, Chen Z, Tiwari M K. All-organic superhydrophobic coatings with mechanochemical robustness and liquid impalement resistance. Nature Materials, 2018, 17, 355–360.

Shen Y, Liu S, Zhu C, Tao J, Wang G Y. Facile fabrication of hierarchical structured superhydrophobic surface and its ultra dynamic water repellency. Chemical Engineering Journal, 2017, 313, 47–55.

Mittal N, Deva D, Kumar R. Exceptionally robust and conductive superhydrophobic free-standing films of mesoporous carbon nanocapsule/polymer composite for multifunctional application. Carbon, 2015, 93, 492–501.

Das G, Kalita R D, Deka H, Buragohain A K, Karak N. Biodegradation, cytocompatability and performance studies of vegetable oil based hyperbranched polyurethane modified biocompatible sulfonated epoxy resin/clay nanocomposites. Progress in Organic Coatings, 2013, 76, 1103–1111.

Deka H, Karak N. Bio-based hyperbranched polyurethanes for surface coating applications. Progress in Organic Coatings, 2009, 66, 192–198.

Kong X, Liu G, Qi H, Curtis J M. Preparation and characterization of high-solid polyurethane coating systems based on vegetable oil derived polyols. Progress in Organic Coatings, 2013, 76, 1151–1160.

Fang Z, Yang Z, Ji D, Zhu N, Li X, Wan L, Zhang K, Guo K. Novel synthesis of a soy-based polyol for a polyurethane rigid foam. RSC Advances, 2016, 6, 90771–90776.

Choi W M, Park O O. A soft-imprint technique for direct fabrication of submicron scale patterns using a surface-modified PDMS mold. Microelectronic Engineering, 2003, 70, 131–136.

Rengasamy S, Mannari V. Hydrophobic and oil-resistant coatings based on advanced green polyurethane dispersions. Journal of Applied Polymer Science, 2013, 130, 3874–3884.

Mathew A, Kurmvanshi S, Mohanty S, Nayark S K. Sustainable production of polyurethane from castor oil, functionalized with epoxy and hydroxyl-terminated poly (dimethyl siloxane) for biomedical applications. Journal of Materials Science, 2018, 53, 3119–3130.

Nishino T, Meguro M, Nakamae K, Matsushita M, Ueda Y. The lowest surface free energy based on -CF3 alignment. Langmuir, 1999, 15, 4321–4323.

Chalker P R, Bull S J, Rickerby D S. A review of the methods for the evaluation of coating-substrate adhesion. Materials Science and Engineering A, 1991, 140, 583–592.

Xiang D, Liu L, Liang Y. Effect of hard segment content on structure, dielectric and mechanical properties of hydroxyl-terminated butadiene-acrylonitrile copolymer-based polyurethane elastomers. Polymer, 2017, 132, 180–187.

Hu X, Vatankhah-Varnoosfaderani M, Zhou J, Li Q X, Sheiko S S. Weak hydrogen bonding enables hard, strong, tough, and elastic hydrogels. Advanced Materials, 2015, 27, 6899–6905.

Panahi-Sarmad M, Chehrazi E, Noroozi M, Raef M, Razzaghi-Kashani M, Haghighat Baian M A. Tuning the surface chemistry of graphene oxide for enhanced dielectric and actuated performance of silicone rubber composites. ACS Applied Electronic Materials, 2019, 1, 198–209.

Panahi-Sarmad M, Zahiri B, Noroozi M. Graphene-based composite for dielectric elastomer actuator: A comprehensive review. Sensors and Actuators A: Physical, 2019, 293, 222–241.

Acknowledgment

This work was supported by the National Natural Science Foundation of China (Nos. 52075246, 51671105, 51705244, and U1937206), the Natural Science Foundation of Jiangsu Province (No. BK20170790), the Project Funded by China Postdoctoral Science Foundation (No. 2019M661826), Open Fund of Key Laboratory of Icing and Anti/De-icing (No. IADL20190202), the Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions, and the NUAA Innovation Program for Graduate Education (No. kfjj20190617).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wu, Z., Shen, Y., Tao, J. et al. Green Synthesis of Mechanical Robust Superhydrophobic CNT@PU Coatings with High Flexibility for Extensive Applications. J Bionic Eng 18, 40–54 (2021). https://doi.org/10.1007/s42235-021-0016-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42235-021-0016-0