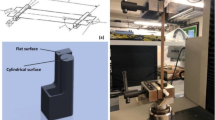

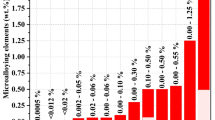

The article presents the results of an experimental study into the distribution of contact stresses (pressures) along the length of a milling roll barrel and external longitudinal stresses measured by a magnetic anisotropy sensor (MAD) with an accuracy of ±1 MPa over a width of 250 mm of a steel (08kp) strip with a thickness of about 1 mm during cold rolling at the exit from a four-roller mill 205/360 × 500. A quantitative analysis shows the influence of longitudinal stresses in the outer parts of the steel strip on the metal pressure in the deformation zone. An equation is proposed for calculating the coefficient of the influence of unevenness and distribution of longitudinal stresses along the strip width at the exit from the mill on the pressure of the metal on the rolls. A computer-aided design (CAD) system was used to model and calculate the deformation and strength indicators of rolling thin strips, taking into account the influence of the characteristics of the rigid ends on the deformation zone. The graphs of the distribution of normal and tangential stresses along the length of the deformation zone are calculated depending on the longitudinal stresses.

I. M. Pavlov’s theory about the significant influence of the external “hard” parts of the strip on the pressure of the metal on the rolls is empirically demonstrated. Based on the results of the experiments, an equation is proposed that takes into account the effect of the uneven longitudinal stresses in the outer parts and the stiffness of the strip on the pressure. The equation for determining the average metal pressure on the rolls is refined, taking into account the influence of the outer parts of the strip on the deformation zone during thin-sheet rolling.

Similar content being viewed by others

Notes

The program was improved in collaboration with A. S. Lukash.

References

I. M. Pavlov, “Rolling, drawing and extrusion of metals in relation to cracks formation,” Zh. Ros. Met. Ob., No. 1, part 1, 253–313 (1927).

I. M. Pavlov, Theory of Rolling and the Foundations of Plastic Deformation of Metals [in Russian], GONTI, Leningrad-Moscow (1938).

I. M. Pavlov and I. K. Suvorov, “Characteristic of the action of the trailing end of the strip during rolling,” in: Pressure Processing of Metals (Collection of Articles), No. 1, Metallurgizdat, Moscow (1952), pp.76–83.

I. M. Pavlov, “To the theory of rigid ends,” Stal’, No. 1, 45–52 (1952).

I. M. Pavlov and I. K. Suvorov, “Influence of the outer parts of the strip on the conditions of metal deformation during rolling,” in: Steel Production and Processing Technology (MISiS, collection No. 31) [in Russian], Metallurgizdat, Moscow (1953), pp. 177–211.

I. M. Pavlov, “To the theory of rigid ends,” in: Materials on Rolling Theory, Part, 5, Metallurgizdat, Moscow (1960), pp. 200–209.

I. M. Pavlov and I. K. Suvorov, “Influence of the outer ends of the strip on the rolling pressure,” in: Materials on Rolling Theory, Part 5 [in Russian], Metallurgizdat, Moscow (1960), pp. 232–236.

I. M. Pavlov, Yu. D. Zheleznov, and P. Yargstorf, “Unevenness of compression along the width of cold-rolled strips and internal stresses,” Izv. Vuz. Cher. Met., No. 9, 95–100 (1968).

I. M. Pavlov and Yu. D. Zheleznov et al., “Influence of the external parts on deformation in width during thin-sheet rolling,” Izv. Vuz. Cher. Met., No. 11, 81–85 (1970).

Yu. D. Zheleznov, Rolling Flat Sheets and Strips [in Russian], Metallurgiya, Moscow (1971).

G. G. Grigoryan, Yu. D. Zheleznov, V. A. Cherny et al., Adjustment, Stabilization and Control of the Sheet Rolling Process [in Russian], Metallurgiya, Moscow (1975).

Yu. D. Zheleznov, G. G. Grigoryan, R. L. Shatalov, and A. S. Gurov, “Differences in the conditions of rolling thin strips before and after the loss of flat shape,” Teor. Tekh. Obr. Met. Dav. Nauch. Tr. MISiS [in Russian], No. 81, 157–160, Metallurgiya, Moscow (1975).

R. L. Shatalov, T. A. Koynov, and N. N. Litvinova, Automation of Technological Processes for Rolling and Heat Treatment of Metals and Alloys [in Russian], Metallurgizdat, Moscow (2010).

R. L. Shatalov, “Investigation of conditions of metal deformation at the stages of rolling “rigid” and “soft” ends of the strip,” Proizv. Prok., No. 8, 14–17 (2011).

R. L. Shatalov and E. A. Maksimov, “Refinement of the method for calculating critical stresses and flatness index for thin-sheet rolling,” Stal’, No. 4, 26–30 (2016).

R. L. Shatalov, “Rigid and soft ends in metal rolling,” in: Proc. of the 2nd “Pavlovsky Readings” [in Russian], IMET RAN, (2010), pp. 131–134.

A. I. Tselikov, Fundamentals of Rolling Theory, Metallurgiya, Moscow (1965).

M. Ya. Brovman, Power Parameters and Improvement of Rolling Technology [in Russian], Metallurgiya, Moscow (1995).

A. I. Tselikov, G. S. Nikitin, and S. E. Rokotyan, Theory of Longitudinal Rolling [in Russian], Metallurgiya, Moscow (1980).

M. A. Zaykov, V. P. Polukhin, A. M. Zaykov, and L. N. Smirnov, Rolling Process [in Russian], MISiS, Moscow (2004).

N. D. Lukashkin, L. S. Kokhan, and N. N. Lebedev, Stresses and Deformations in Metal Pressure Processing [in Russian], Akademkniga, Moscow (2004).

G. S. Nikitin, Theory of Continuous Longitudinal Rolling [in Russian], BMSTU, Moscow (2009).

R. L. Shatalov, Theory of Rolling and Drawing Processes [in Russian], MRSU, Moscow (1993).

V. P. Polukhin, V. T. Torshin, and E. N. Kosarimov, “Distribution of contact stresses along the strip width under the influence of tension and lubrication,” Izv. Vuz. Cher. Met., No. 7, 71–74 (1973).

A. N. Shkarin and S. M. Belsky, “Influence of the cross-sectional profile shape of a hot rolled strip on the construction of a diagram of specific tensions of cold-rolled strips,” Metallurg., No. 7, 85–90 (2020).

R. L. Shatalov and M. A. Kulikov, “Influence of the outer parts of the strip on deformation and power parameters during thin-sheet rolling,” Metallurg., No. 7, 77–84 (2020).

R. L. Shatalov, “Automated system for calculating and designing technology and equipment for rolling sheets,” in: Plastic Deformation of Steels and Alloys: a Collection of Scientific Works [in Russian], MISIS, Moscow (1996), pp. 374–378.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 64, No. 10, pp. 48–53, October, 2020.

(On the occasion of the 120th anniversary of Igor Mikhaylovich Pavlov, Corresponding Member of the Academy of Sciences of the USSR)

Rights and permissions

About this article

Cite this article

Shatalov, R.L., Maksimov, E.A. Development and Application of the Theory of Rigid Ends in Thin-Sheet Rolling. Metallurgist 64, 1035–1042 (2021). https://doi.org/10.1007/s11015-021-01084-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-021-01084-2