Abstract

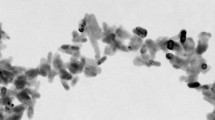

Yttrium silicate is one of the promising environmental barrier coating materials used to protect ceramic matrix composites (CMCs) under specific operating conditions. In this paper, yttrium monosilicate (Y2SiO5, YMS) nanoparticles were synthesized using a molten salt method with a low synthesis temperature. To find the optimal experimental parameters, YMS nanoparticles were synthesized under different conditions using the molten salt method. The experimental parameters, such as different precursor/salt ratios, precipitants, calcination temperatures, and holding times, were studied. The samples were systematically characterized using X-ray diffraction (XRD), scanning electron microscopy (SEM), and BET method. The results showed that all the parameters we mentioned have effects on the synthesis of Y2SiO5 nanoparticles, especially the calcination temperature, the precipitant, and holding time.

Similar content being viewed by others

References

Kumar, P., Srivastava, V.: Tribological behaviour of C/C–SiC composites—a review. J Adv Ceram. 5(1), 1–12 (2016)

Naslain, R.: Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: an overview. Compos Sci Technol. 64(2), 155–170 (2004)

Du, J., Zhang, H., Geng, Y., Ming, W., He, W., Ma, J., Cao, Y., Li, X., Liu, K.: A review on machining of carbon fiber reinforced ceramic matrix composites. Ceram Int. 45, 18155–18166 (2019)

Yin, X., Cheng, L., Zhang, L., Travitzky, N., Greil, P.: Fibre-reinforced multifunctional SiC matrix composite materials. Int Mater Rev. 62(3), 117–172 (2017)

Arai, Y., Inoue, R., Goto, K., Kogo, Y.: Carbon fiber reinforced ultra-high temperature ceramic matrix composites: a review. Ceram Int. 45, 14481–14489 (2019)

Grathwohl, G., Hähnel, A., Meier, B., Pippel, E., Richter, G., Woltersdorf, J.: Fibre-reinforced SiC-matrix composites: microstructure, interfaces and mechanical properties. J Eur Ceram Soc. 10(1), 1–12 (1992)

Lamon, J.: Creep of fibre-reinforced ceramic matrix composites. Int. Mater. Rev. 65(1), 28–62 (2020)

Richards, B.T., Young, K.A., de Francqueville, F., Sehr, S., Begley, M.R., Wadley, H.N.: Response of ytterbium disilicate–silicon environmental barrier coatings to thermal cycling in water vapor. Acta Mater. 106, 1–14 (2016)

Kousaalya, A.B., Kumar, R., Packirisamy, S.: Characterization of free carbon in the as-thermolyzed Si-BCN ceramic from a polyorganoborosilazane precursor. J. Adv. Ceram. 2(4), 325–332 (2013)

Lodhe, M., Babu, N., Selvam, A., Balasubramanian, M.: Synthesis and characterization of high ceramic yield polycarbosilane precursor for SiC. J. Adv. Ceram. 4(4), 307–311 (2015)

Krenkel, W., Berndt, F.: C/C–SiC composites for space applications and advanced friction systems. Mater Sci Eng A. 412(1–2), 177–181 (2005)

Jie, X., Qiaomu, L., Jingchen, L., Hongbo, G., Huibin, X.: Microstructure and high-temperature oxidation behavior of plasma-sprayed Si/Yb2SiO5 environmental barrier coatings. Chin J Aeronaut. 32(8), 1994–1999 (2019)

Ryu, H., Lee, S.M., Han, Y.S., Choi, K., An, G.S., Nahm, S., Oh, Y.S.: Preparation of crystalline ytterbium disilicate environmental barrier coatings using suspension plasma spray. Ceram. Int. 45(5), 5801–5807 (2019)

Yang, M.-Y., Wang, J.-W., Li, L., Dong, B.-B., Xin, X., Agathopoulos, S.: Fabrication of low thermal conductivity yttrium silicate ceramic flat membrane for membrane distillation. J Eur Ceram Soc. 39(2–3), 442–448 (2019)

Summers, W.D., Poerschke, D.L., Taylor, A.A., Ericks, A.R., Levi, C.G., Zok, F.W.: Reactions of molten silicate deposits with yttrium monosilicate. J Am Ceram Soc. 103(4), 2919–2932 (2020)

Stokes, J.L., Harder, B.J., Wiesner, V.L., Wolfe, D.E.: High-temperature thermochemical interactions of molten silicates with Yb2Si2O7 and Y2Si2O7 environmental barrier coating materials. J Eur Ceram Soc. 39(15), 5059–5067 (2019)

Ogura, Y., Kondo, M., Morimoto, T., Notomi, A., Sekigawa, T.: Oxygen permeability of Y2SiO5. Mater Trans. 42(6), 1124–1130 (2001)

Sun, Z., Li, M., Zhou, Y.: Thermal properties of single-phase Y2SiO5. J Eur Ceram Soc. 29(4), 551–557 (2009)

Rakov, N., Maciel, G.S.: Broadband light emission induced by laser absorption and optimized by thermal injection in Nd3+: Y2SiO5 ceramic powder. J Am Ceram Soc. 103(3), 1782–1788 (2020)

Haile, H., Dejene, F.: Effect of substrate temperature on the material properties of the Y2SiO5: Ce3+ thin film by pulsed laser deposition (PLD) method. Optik. 184, 508–517 (2019)

Ramakrishna, G., Nagabhushana, H., Basavaraj, R., Prashantha, S., Sharma, S., Naik, R., Anantharaju, K.: Green synthesis, structural characterization and photoluminescence properties of Sm3+ co-doped Y2SiO5: Ce3+ nanophosphors for wLEDs. Optik. 127(13), 5310–5315 (2016)

Flores, D.-L., Gutierrez, E., Cervantes, D., Chacon, M., Hirata, G.: White-light emission from Y2SiO5: Ce3+, Tb3+ and Sr2Si5N8: Eu2+ phosphor blends: a predictive model. Micro Nano Lett. 12(7), 500–504 (2017)

Ishiwada, N., Fujii, E., Yokomori, T.: Evaluation of Dy-doped phosphors (YAG: Dy, Al2O3: Dy, and Y2SiO5: Dy) as thermographic phosphors. J Lumin. 196, 492–497 (2018)

Dhanalakshmi, K., Reddy, A.J., Monika, D., Krishna, R.H., Parashuram, L.: Concentration dependent luminescence spectral investigation of Sm3+ doped Y2SiO5 nanophosphor. J Non-Cryst Solids. 471, 195–201 (2017)

Zhang, R., Li, S., Ye, C.: Fabrication and properties of machinable porous ZrO2f/Y2SiO5 nanocomposites prepared by a simple method. J Alloys Compd. 712, 445–450 (2017)

Raghunandan, S., Kumar, R.S., Kamaraj, M., Gandhi, A.S.: Role of water in the sol-gel synthesis of yttrium monosilicate. Ceram Int. 45(4), 4487–4492 (2019)

Kumar, S., Drummond, C.H.: Crystallization of various compositions in the Y2O3–SiO2 system. Int J Mater Res. 7(4), 997–1003 (1992)

Zhang, R., Fang, D., Chen, X., Pei, Y., Wang, Z., Wang, Y.: Microstructure and properties of highly porous Y2SiO5 ceramics produced by a new water-based freeze casting. Mater Des. 46, 746–750 (2013)

Zhang, R., Han, B., Fang, D., Wang, Y.: Porous Y2SiO5 ceramics with a centrosymmetric structure produced by freeze casting. Ceram Int. 41(9), 11517–11522 (2015)

Chen, H., Gao, Y., Liu, Y., Luo, H.: Hydrothermal synthesis of ytterbium silicate nanoparticles. Inorg Chem. 49(4), 1942–1946 (2010)

Sun, Z., Li, M., Li, Z., Zhou, Y.: Hot corrosion of γ-Y2Si2O7 in strongly basic Na2CO3 molten salt environment. J Eur Ceram Soc. 28(1), 259–265 (2008)

Reddy, M., Kenrick, K., Wei, T.Y., Chong, G.Y., Leong, G.H., Chowdari, B.: Nano-ZnCo2O4 material preparation by molten salt method and its electrochemical properties for lithium batteries. J Electrochem Soc. 158(12), A1423–A1430 (2011)

Huang, Z., Li, F., Jiao, C., Liu, J., Huang, J., Lu, L., Zhang, H., Zhang, S.: Molten salt synthesis of La2Zr2O7 ultrafine powders. Ceram Int. 42(5), 6221–6227 (2016)

Safaei-Naeini, Y., Golestani-Fard, F., Khorasanizadeh, F., Aminzare, M., Zhang, S.: Low temperature molten salt synthesis of nano crystalline MgAl2O4 powder. Iran J Mater Sci Eng. 8(3), 23–28 (2011)

Funding

This work was jointly supported by the National Natural Science Foundation (NSFC) (No. 51671208), NSAF Joint Fund (No. U1730139), University Nursing Program for Young Scholars with Creative Talents in Heilongjiang Province (No. 2018103), Fundamental Research Funds in Heilongjiang Provincial Universities (No. 135309110), Basic scientific project of Heilongjiang Provincial Department of Education (No. 135309512), and National Science and Technology Major Project (2017-VI-0020-0093) of the Ministry of Science and Technology of China.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, G., Wang, C., Wang, L. et al. Effects of preparing conditions on the synthesis of Y2SiO5 nanoparticles by low-temperature molten salt method. J Aust Ceram Soc 57, 29–36 (2021). https://doi.org/10.1007/s41779-020-00507-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-020-00507-8