Abstract

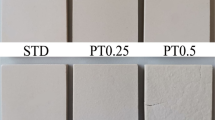

Previously, a way to process phosphogypsum (PG) into non-fired ceramic tile by an intermittent loading hydration process was proposed; however, its mechanical strength and especially waterproof property are unsatisfactory. Herein, PG non-fired ceramic with a porosity reduced was prepared and used as a matrix, which was then impregnated with MMA together with azobisisobutyronitrile (AIBN) and benzoyl peroxide (BPO) as initiators. After polymerization, a novel 3-3 type PMMA/PG non-fired ceramic composite with highly improved mechanical and waterproof properties was obtained. The bending strength, softening coefficient, and contact angle of the PMMA/PG composite are 21.5 MPa, 0.78, and 75.1°, which are 1.43, 1.77, and 1.68 times those of the matrix, respectively. It is found that PMMA completely covers the matrix surface and well fills the interparticle pores of dihydrate gypsum crystals inside the matrix, forming an interpenetrating and dense composite structure. This work can guide not only the utilization of waste PG but also the development of polymer/gypsum composite product.

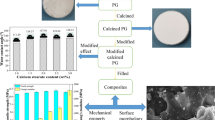

Graphical abstract

We designed a facile process to prepare a novel 3-3 type PMMA/PG non-fired ceramic composite with highly improved mechanical and waterproof properties. The bending strength, softening coefficient, and contact angle of the final PMMA/PG composite are 21.5 MPa, 0.78, and 75.1°, which are 1.43, 1.77, and 1.68 times those of the matrix, respectively. The improvements originate from the delicate structure that PMMA completely covers the outside surface of the PG matrix and well fills the pores inside the PG matrix. PMMA tightly combines with dihydrate gypsum crystals and forms a relatively dense 3-3 type three-dimensional composite.

Similar content being viewed by others

References

Holanda, F.d.C., Schmidt, H., Quarcioni, V.A.: Influence of phosphorus from phosphogypsum on the initial hydration of Portland cement in the presence of superplasticizers. Cem Concr Compos. 83, 384–393 (2017). https://doi.org/10.1016/j.cemconcomp.2017.07.029

Taher, M.A.: Influence of thermally treated phosphogypsum on the properties of Portland slag cement. Resour Conserv Recycl. 52, 28–38 (2007). https://doi.org/10.1016/j.resconrec.2007.01.008

Zemni, S., Hajji, M., Triki, M., M’Nif, A., Hamzaoui, A.H.: Study of phosphogypsum transformation into calcium silicate and sodium sulfate and their physicochemical characterization. J Clean Prod. 198, 874–881 (2018). https://doi.org/10.1016/j.jclepro.2018.07.099

Garg, M., Minocha, A.K., Jain, N.: Environment hazard mitigation of waste gypsum and chalk: use in construction materials. Constr Build Mater. 25, 944–949 (2011). https://doi.org/10.1016/j.conbuildmat.2010.06.088

Singh, M.: Treating waste phosphogypsum for cement and plaster manufacture. Cem Concr Res. 32, 1033–1038 (2002). https://doi.org/10.1016/S0008-8846(02)00723-8

Değirmenci, N.: Utilization of phosphogypsum as raw and calcined material in manufacturing of building products. Constr Build Mater. 22, 1857–1862 (2008). https://doi.org/10.1016/j.conbuildmat.2007.04.024

Shen, Y., Qian, J., Chai, J., Fan, Y.: Calcium sulphoaluminate cements made with phosphogypsum: production issues and material properties. Cem Concr Compos. 48, 67–74 (2014). https://doi.org/10.1016/j.cemconcomp.2014.01.009

Li, Y., Chen, B.: Factors that affect the properties of magnesium phosphate cement. Constr Build Mater. 47, 977–983 (2013). https://doi.org/10.1016/j.conbuildmat.2013.05.103

Formosa, J., Chimenos, J.M., Lacasta, A.M., Niubó, M.: Interaction between low-grade magnesium oxide and boric acid in chemically bonded phosphate ceramics formulation. Ceram Int. 38, 2483–2493 (2012). https://doi.org/10.1016/j.ceramint.2011.11.017

Banno, T., Yamada, Y., Nagae, H.: Fabrication of porous alumina ceramics by simultaneous thermal gas generating and thermal slurry solidification. J Ceram Soc Jpn. 117, 713–716 (2009). https://doi.org/10.2109/jcersj2.117.713

Hien, T.T.T., Shirai, T., Fuji, M.: Mechanical modification of silica powders. J Ceram Soc Jpn. 120, 429–435 (2012). https://doi.org/10.2109/jcersj2.120.429

Guo, J., Zhao, X., Herisson De Beauvoir, T., Seo, J.-H., Berbano, S.S., Baker, A.L., Azina, C., Randall, C.A.: Recent progress in applications of the cold sintering process for ceramic-polymer composites. Adv Funct Mater. 28, 1801724 (2018). https://doi.org/10.1002/adfm.201801724

Zhou, J., Sheng, Z., Li, T., Shu, Z., Chen, Y., Wang, Y.: Preparation of hardened tiles from waste phosphogypsum by a new intermittent pressing hydration. Ceram Int. 42, (2016). https://doi.org/10.1016/j.ceramint.2016.01.117

Zhou, J., Zhang, Y., Shu, Z., Wang, Y., Yakubu, Y., Zhao, Y., Li, X.: Enhancing waterproof performance of phosphogypsum non-fired ceramics by coating silane-coupled unsaturated polyester resin. Mater Lett. 252, (2019). https://doi.org/10.1016/j.matlet.2019.05.105

Kowalska, B., Wielgosz, Z.: The use of phosphogypsum as a filler for thermoplastics, Part I: the use of phosphogypsum as a filler for polyolefine compositions. J Reinf Plast Compos. 21, 1013–1026 (2002). https://doi.org/10.1106/073168402025787

Kowalska, B., Kawinska, B.: The use of phosphogypsum as a filler for thermoplastics, Part II: phosphogypsum as a filler for polyamide 6 and for PVC. J Reinf Plast Compos. 21, 1043–1052 (2002). https://doi.org/10.1106/073168402025789

Sormunen, P., Kärki, T.: Compression molded thermoplastic composites entirely made of recycled materials. Sustainability. 11, 631 (2019). https://doi.org/10.3390/su11030631

Deng, Y., Xuan, L., Feng, Q.: Effect of a waterproof agent on gypsum particleboard properties. Holzforschung. 60, (2006). https://doi.org/10.1515/hf.2006.051

Fowler, D.W.: Polymers in concrete: a vision for the 21st century. Cem Concr Compos. 21, 449–452 (1999). https://doi.org/10.1016/S0958-9465(99)00032-3

Amianti, M., Botaro, V.R.: Recycling of EPS: a new methodology for production of concrete impregnated with polystyrene (CIP). Cem Concr Compos. 30, 23–28 (2008). https://doi.org/10.1016/j.cemconcomp.2007.05.014

Ghorbani, M., Nikkhah Shahmirzadi, A., Amininasab, S.M.: Physical and morphological properties of combined treated wood polymer composites by maleic anhydride and methyl methacrylate. J Wood Chem Technol. 37, 443–450 (2017). https://doi.org/10.1080/02773813.2017.1310902

Ansong, O.E., Jansen, S., Wei, Y., Pomrink, G., Lu, H., Patel, A., Li, S.: Accelerated controlled radical polymerization of methacrylates. Polym Int. 58, 54–65 (2009). https://doi.org/10.1002/pi.2492

Daraboina, N., Madras, G.: Kinetics of the ultrasonic degradation of poly (alkyl methacrylates). Ultrason Sonochem. 16, 273–279 (2009). https://doi.org/10.1016/j.ultsonch.2008.08.007

Sheng, Z., Zhou, J., Shu, Z., Yakubu, Y., Chen, Y., Wang, W., Wang, Y.: Calcium sulfate whisker reinforced non-fired ceramic tiles prepared from phosphogypsum. Bol Soc Esp Cerámica Vidr. 57, 73–78 (2018). https://doi.org/10.1016/j.bsecv.2017.09.005

Schafföner, S., Fruhstorfer, J., Ludwig, S., Aneziris, C.G.: Cyclic cold isostatic pressing and improved particle packing of coarse grained oxide ceramics for refractory applications. Ceram Int. 44, 9027–9036 (2018). https://doi.org/10.1016/j.ceramint.2018.02.106

Santos, P.R., Stochero, N.P., Marangon, E., Tier, M.D.: Mechanical and thermal behavior of kaolin/rice-husk ash matrix composites reinforced with corrugated steel fibers. Ceram Int. 44, 14291–14296 (2018). https://doi.org/10.1016/j.ceramint.2018.05.034

Bonnard, B., Causse, P., Trochu, F.: Experimental characterization of the pore size distribution in fibrous reinforcements of composite materials. J Compos Mater. 51, 3807–3818 (2017). https://doi.org/10.1177/0021998317694424

Hanna, A.A., Akarish, A.I.M., Ahmed, S.M.: Phosphogypsum: Part I: mineralogical, thermogravimetric, chemical and infrared characterization. J Mater Sci Technol. 15, 431–432 (1999). https://doi.org/10.1111/j.1749-6632.1969.tb12913.x

Ma, B., Xing, P., Wang, C., Chen, Y., Shao, S.: A novel way to synthesize calcium sulfate whiskers with high aspect ratios from concentrated calcium nitrate solution. Mater Lett. 219, 1–3 (2018). https://doi.org/10.1016/j.matlet.2018.02.025

Han-Cheol, C., Hori, M., Yoshida, T., Yamada, N., Komada, Y., Tamaki, Y., Miyazaki, T.: Tri-calcium phosphate (ß-TCP) can be artificially synthesized by recycling dihydrate gypsum hardened. Dent Mater J. 33, 845–851 (2014). https://doi.org/10.4012/dmj.2014-040

Chen, C.-H., Huang, R., Wu, J.K., Chen, C.-H.: Influence of soaking and polymerization conditions on the properties of polymer concrete. Constr Build Mater. 20, 706–712 (2006). https://doi.org/10.1016/j.conbuildmat.2005.02.003

Cho, H., Jung, M.J., Jeon, J., Lee, H., Nayab, S.: Synthesis, structural characterization and MMA polymerization studies of dimeric 5-coordinate copper(II), cadmium(II), and monomeric 4-coordinate zinc(II) complexes supported by N-methyl-N-((pyridine-2-yl)methyl)benzeneamine. Inorg Chim Acta. 487, 221–227 (2019). https://doi.org/10.1016/j.ica.2018.12.020

Wang, C., Wang, S., Zhang, Y., Wang, Z., Liu, J., Zhang, M.: Self-polymerization and co-polymerization kinetics of gadolinium methacrylate. J Rare Earths. 36, 298–303 (2018). https://doi.org/10.1016/j.jre.2017.09.015

CLARKE, D.R.: Interpenetrating phase composites. J Am Ceram Soc. 75, 739–759 (1992). https://doi.org/10.1111/j.1151-2916.1992.tb04138.x

Chang, H., Binner, J., Higginson, R., Myers, P., Webb, P., King, G.: High strain rate characteristics of 3-3 metal–ceramic interpenetrating composites. Mater Sci Eng A. 528, 2239–2245 (2011). https://doi.org/10.1016/j.msea.2010.12.016

Khan, K.A., Khan, M.A.: 3-3 piezoelectric metamaterial with negative and zero Poisson’s ratio for hydrophones applications. Mater Res Bull. 112, 194–204 (2019). https://doi.org/10.1016/j.materresbull.2018.12.016

Chen, Y., Cai, J., Boyd, J.G., Kennedy, W.J., Naraghi, M.: Mechanics of emulsion electrospun porous carbon fibers as building blocks of multifunctional materials. ACS Appl Mater Interfaces. 10, 38310–38318 (2018). https://doi.org/10.1021/acsami.8b10499

Chen, M., Mao, P., Qin, Y., Wang, J., Xie, B., Wang, X., Han, D., Wang, G.H., Song, F., Han, M., Liu, J.M., Wang, G.: Response characteristics of hydrogen sensors based on PMMA-membrane-coated palladium nanoparticle films. ACS Appl Mater Interfaces. 9, 27193–27201 (2017). https://doi.org/10.1021/acsami.7b07641

Liu, H., Ye, H., Lin, T., Zhou, T.: Synthesis and characterization of PMMA/Al2O3 composite particles by in situ emulsion polymerization. Particuology. 6, 207–213 (2008). https://doi.org/10.1016/j.partic.2008.01.003

Bhadrakumari, S., Predeep, P.: Elaboration and variable properties of polymer-impregnated superconducting ceramic composite. J Supercond Nov Magn. 23, 233–236 (2009). https://doi.org/10.1007/s10948-009-0520-7

Funding

This work was supported by the Science and Technology Department of Hubei Province of China (2017ACA091), the National Natural Science Foundation of China (41502030), the Hubei Environmental Protection Bureau (2013HB10), the Zhejiang Provincial Natural Science Foundation of China (LQY18D020001), and the Fundamental Research Funds for the Central Universities, China University of Geosciences (Wuhan) (CUGL180405).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• A non-fired ceramic-based composite was prepared from waste phosphogypsum (PG).

• The highest proportion of PG in the polymer/gypsum composite materials with polymer well-filled inside gypsum matrix can reach 94.2%, and it is beneficial to recycle PG.

• The composite has favorable mechanical strength and waterproof properties.

• This composite may be an alternative to conventional building ceramics as a decorative material.

Rights and permissions

About this article

Cite this article

Zhao, Y., Zhou, J., Shu, Z. et al. Fabrication of PMMA/phosphogypsum non-fired ceramic composites with improved mechanical and waterproof properties. J Aust Ceram Soc 57, 81–90 (2021). https://doi.org/10.1007/s41779-020-00510-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41779-020-00510-z