Abstract

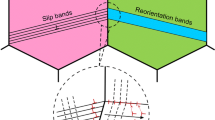

Microstructure evolution and texture development during cold rolling of a Ti15333 alloy were systematically investigated in the present work. Texture was simulated using mean-field [Visco-Plastic Self-Consistent (VPSC) and Taylor] models. Evolution of crystallographic texture was also simulated using the Visco-Plastic Fast Fourier Transform (VPFFT) model. The as-received samples (in the hot-forged and hot-rolled condition) were cold rolled unidirectionally up to 20, 40, 60 and 80 pct thickness reductions. Increase in the cold-rolling reduction resulted in changes in the crystallographic texture as well as grain morphology. The initial hot-rolled sample consisted of in-grain shear bands that were aligned approximately ± 35 to 40 ° with respect to the sample rolling direction. Shear band density gradually increased with the increase in cold-rolling reduction, and these bands usually represent narrow zones of intense strain. α (RD//〈110〉) and γ (ND//〈111〉) fibers were observed in all the cold-rolled samples. The volume fraction of both these fibers was found to be highest for the 80 pct deformed sample. For mean-field simulations, the normalized difference of the texture index (normalized TIdiff) was found to be a good criterion to represent the match between the simulated and experimental texture. The affine model (VPSC) was found to give a good match with the experimental texture compared to the Taylor models. The γ-fiber and α-fiber were always overestimated in mean-field VPSC simulations. Extensive shear band formation could be the possible reason for mismatch between the simulated and experimental texture. For VPFFT simulations, the general texture evolution involved the intensification of the γ-fiber and α-fiber texture. Simulated texture was reasonably well predicted quantitatively with VPFFT, analyzed based on the volume fraction of the different texture fibers/components.

Similar content being viewed by others

References

G. Lütjering and J.C. Williams: Titanium, 2nd edn., Springer-Verlag Berlin Heidelberg, Hamburg, 2007.

I. Weiss and S.L. Semiatin: Mater. Sci. Eng. A, 1998, vol. 243, pp. 46–65.

R.R. Boyer: Mater. Sci. Eng. A, 1996, vol. 213, pp. 103–14.

A. Gupta, R.K. Khatirkar, A. Kumar, and M.S. Parihar: J. Mater. Res., 2018, vol. 33, pp. 946–57.

O.P. Karasevskaya, O.M. Ivasishin, S.L. Semiatin, and Y. V. Matviychuk: Mater. Sci. Eng. A, 2003, vol. 354, pp. 121–32.

A. Gupta, R.K. Khatirkar, T. Dandekar, J.S. Jha, and S. Mishra: J. Mater. Res., 2019, vol. 34, pp. 1–11.

R. Khatirkar, B. Vadavadagi, S.K. Shekhawat, A. Haldar, and I. Samajdar: ISIJ Int., 2012, vol. 52, pp. 884–93.

S. Suwas and R.K. Ray: Crystallographic Texture of Materials, Springers, Manchester, UK, 2014.

R. Khatirkar, L. Kestens, R. Petrov, and I. Samajdar: ISIJ Int., 2009, vol. 49, pp. 78–85.

G. Alireza, P.D. Hodgson, and M.R. Barnett: Key Eng. Mater., 2013, vol. 551, pp. 210–16.

N.P. Gurao, A. Ali, and S. Suwas: Mater. Sci. Eng. A, 2009, vol. 504, pp. 24–35.

H. Inoue, S. Fukushima, and N. Inakazu: Mater. Trans., 1992, vol. 33, pp. 129–37.

B.K. Sokolov, V. V. Gubernatorov, I. V. Gervasyeva, A.K. Sbitnev, and L.R. Vladimirov: Textures Microstruct., 1999, vol. 32, pp. 21–39.

W.B. Lee and K.C. Chan: Acta Metall. Mater., 1991, vol. 39, pp. 411–7.

I.L. Dillamore, J.G. Roberts, and A.C. Bush: Met. Sci., 1979, vol. 13, pp. 73–7.

M. Hatherly and F.J. Humphreys: Recrystallization and Related Annealing Phenomena, Pergamon: Elsevier, 2012.

K. Murakami, M. Sugiyama, and K. Ushioda: IOP Conf. Ser. Mater. Sci. Eng., 2015, 89: 89.

P. Bate: Philos. Trans. R. Soc. Lond. Ser. A 1999, vol. 357, pp. 1589– 1601.

P.V. Houtte: Acta Metall., 1978, vol. 26, pp. 591–604.

A. Molinari, G.R. Canova, and S. Ahzi: Acta Metall., 1987, vol. 35, pp. 2983–94.

R.A. Lebensohn and C.N. Tomé: Acta Metall. Mater., 1993, vol. 41, pp. 2611–24.

P. Van Houtte: Mater. Sci. Eng., 1982, vol. 55, pp. 69–77.

F. Wagner, G. Canova, P. Van Houtte, and A. Molinari: Textures Microstruct., 1991, vol. 14, pp. 1135–40.

D. Raabe: Phys. Status Solidi, 1995, vol. 149, pp. 575–81.

S. M’Guil, W. Wen, S. Ahzi, and J.J. Gracio: Mater. Sci. Eng. A, 2011, vol. 528, pp. 5840–53.

B. Hutchinson: Philos. Trans. R. Soc. London. Ser. A, 1999, vol. 357, pp. 1471–85.

D. Raabe: Mater. Sci. Technol., 1995, vol. 11, pp. 455–60.

F. Royer, A. Nadari, F. Yala, and P. Lipinski: Textures Microstruct., 1991, vol. 14–18, pp. 1129–34.

C. Adam, U. Lin, H. Thomas, and A.D. Rollet: Integr. Mater. Manuf. Innov., 2014, vol. 3, pp. 1–19.

H. Moulinec and P. Suquet: Comput. Methods Appl. Mech. Eng., 1998, vol. 157, pp. 69–94.

R.A. Lebensohn, M. Zecevic, M. Knezevic, and R.J. McCabe: Acta Mater., 2016, vol. 104, pp. 228–36.

R.A. Lebensohn, Y. Liu, and P.P. Castañeda: Acta Mater., 2004, vol. 52, pp. 5347–61.

R.A. Lebensohn: Acta Mater., 2001, vol. 49, pp. 2723–37.

C. Paramatmuni and A.K. Kanjarla: Int. J. Plast., 2019, vol. 113, pp. 269–90.

S. Sinha, A. Ghosh, and N.P. Gurao: Philos. Mag., 2016, vol. 96, pp. 1485–4508.

RK Sabat, MVSSDSS Pavan, DS Aakash, M Kumar, SK Sahoo (2018) Philos. Mag. 98, 2562–81.

A.S.M. Handbook: Metallography and Microstructures, ASM International, Materials Park, 2004.

OIM: Anal. Version 7.2. User Manual, TexSEM Lab. Inc., Draper, 2013.

P. Van Houtte: The ‘MTM-FHM’ Software System, Version 2 Manual .

S. Ghosh, S. Keshavarz, and G. Weber: in Inelastic Behavior of Materials and Structures Under Monotonic and Cyclic Loading, H. Altenbach and M. Brünig, eds., Springer International Publishing, Cham, 2015, pp. 67–96.

ASTM: ASTM E112-10, 2012, pp. 1–27.

A. Gupta, R.K. Khatirkar, A. Kumar, K. Thool, N. Bibhanshu, and S. Suwas: Mater. Charact., 2019, vol. 156, p. 109884.

V.D. Mote, Y. Purushotham, and B.N. Dole: J. Theor. Appl. Phys., 2012, 6: pp. 2–9.

C.G. Oertel, I. Huensche, W. Skrotzki, W. Knabl, A. Lorich, and J. Resch: Mater. Sci. Eng. A, 2008, vol. 483–484, pp. 79–83.

A. Bhattacharyya, M. Knezevic, and M. Abouaf: Metall. Mater. Trans. A, 2014, vol. 46A, pp. 1085–96.

I.L. Dillamore, C.J.E. Smith, and T.W. Watson: Met. Sci. J., 1967, vol. 1, pp. 49–54.

R.K. Ray, J.J. Jonas, and R.E. Hook: Int. Mater. Rev., 1994, vol. 39, pp. 129–72.

W.B. Hutchinson: Int. Met. Rev., 1984, vol. 29, pp. 25–42.

P.P. Date, S.K. Yerra, H. V Vankudre, and I. Samajdar: J. Eng. Mater. Technol., 2018, vol. 126, pp. 53–61.

B. Verlinden, J. Driver, I. Samajdar, and R.D. Doherty: Thermo-Mechanical Processing of Metallic Materials, Elsevier, New York, NY, 2007.

W.G. Guo: Key Eng. Mater., 2007, vol. 340–341, pp. 823–8.

.R. Barnett: ISIJ Int., 1998, vol. 38, pp. 78–85.

N.P. Gurao and S. Suwas: Mater. Lett., 2013, vol. 99, pp. 81–5.

S.N. Nasser, W.G. Guo, and J.Y. Cheng: Acta matter, 1999, vol. 47, pp. 3705–20.

S.N. Nasser, W.G. Guo, V.F. Nesterenko, S.S. Indrakanti, and Y.B. Gu: Mech. Mater., 2001, vol. 33, pp. 425–39.

S. Cicalè, I. Samajdar, B. Verlinden, G. Abbruzzese, and P. Van Houtte: ISIJ Int., 2002, vol. 42, pp. 770–8.

M.R. Barnett and J.J. Jonas: ISIJ Int., 1997, vol. 37, pp. 706–14.

M.R. Barnett and L. Kestens: ISIJ Int., 1999, vol. 39, pp. 923–9.

A. Kumar, R.K. Khatirkar, D. Chalapathi, N. Bibhanshu, and S. Suwas: Philos. Mag., 2017, vol. 97, pp. 1939–62.

H. Inagaki: ISIJ Int., 1994, vol. 34, pp. 313–21.

V. Tari, A.D. Rollett, H. El Kadiri, H. Beladi, A.L. Oppedal, and R.L. King: Model. Simul. Mater. Sci. Eng., 2015, vol. 23, pp. 1–23.

R. Pokharel, J. Lind, A.K. Kanjarla, R.A. Lebensohn, S.F. Li, P. Kenesei, R.M. Suter, and A.D. Rollett: Annu. Rev. Condens. Matter Phys., 2014, vol. 5, pp. 317–46.

O. Diard, S. Leclercq, G. Rousselier, and G. Cailletaud: Int. J. Plast., 2005, vol. 21, pp. 691–722.

P. Van Houtte, J. Gawad, P. Eyckens, B. Van Bael, G. Samaey, and D. Roose: JOM, 2011, vol. 63, pp. 37–43.

Acknowledgments

The authors thank the Director, VNIT Nagpur, for providing the necessary facilities and constant encouragement to publish this paper. Thanks are also due to Prof. I. Samajdar, Convener, ‘National Facility of Texture & OIM’ (a DST-IRPHA facility), IIT Bombay, for EBSD and bulk texture measurements. One of the authors, RKK, wishes to acknowledge the Science and Engineering Research Board (SERB) for financial assistance to carry out this work (grant no. EEQ/2016/000408). The authors also thank Dr. Anand Kanjarla (IIT Madras) for providing facilities for VPFFT simulations.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted July 8, 2020; accepted November 24, 2020.

Rights and permissions

About this article

Cite this article

Gupta, A., Khatirkar, R.K., Kumar, A. et al. Texture Development During Cold Rolling of a β-Ti Alloy: Experiments and Simulations. Metall Mater Trans A 52, 1031–1043 (2021). https://doi.org/10.1007/s11661-020-06117-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-06117-0