Abstract

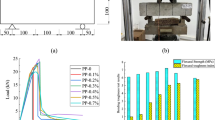

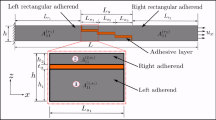

To obtain the tensile mechanics of the arrow combination structure with carbon fiber–epoxy resin composite, the quasi-static experiments were carried out in this paper. Firstly, the concave hexagon single-cell structure and star single-cell structure were designed, and the tensile force–displacement characteristics of the two structures were obtained by cyclic loading and single loading experiments. The mechanism of the “step effect” on the force–displacement curve was analyzed, and the failure mode of the two structure was emphatically investigated. Then, the stress–strain relationship of the structures was drawn, and the constitutive model of representative elements was established. The energy absorption and specific energy absorption of the two structures were calculated, too. The results show that the concave hexagonal single-cell structure has a higher stiffness (about 2.2 times of the star single-cell structure), but the star single-cell structure has a better plastic deformation range (about 2.2 times of the concave hexagonal single-cell). On the whole, the concave hexagonal single-cell structure has the linear elastic characteristics, but the star single-cell structure has the elastic–plastic characteristics and the strengthening stage is obvious. The specific energy absorption of concave hexagonal single-cell structure is 5/8 of the star single-cell structure.

Similar content being viewed by others

References

Ren, X.; Das, R.; Tran, P.; et al.: Auxetic metamaterials and structures: a review. Smart Mater. Struct. 27, 023001 (2018). https://doi.org/10.1088/1361-665x/aaa61c

Huang, C.W.; Chen, L.: Negative Poisson’s ratio in modern functional materials. Adv. Mater. 28(37), 8079–8096 (2016). https://doi.org/10.1002/adma.201601363

Yu, J.J.; Xie, Y.; Pei, X.: State-of-art of metamaterials with negative Poisson’s ratio. J Mech Eng 054(013), 1–14 (2018). https://doi.org/10.3901/JME.2018.13.001

Alderson, A.; Rasburn, J.; Ameer-Beg, S.; et al.: An auxetic filter: a tuneable filter displaying enhanced size selectivity or defouling properties. Ind. Eng. Chem. Res. 39(3), 654–665 (2000). https://doi.org/10.1021/ie990572w

Ren, X.; Zhang, X.Y.; Xie, Y.M.: Research progress in auxetic materials and structures. Chin J Theor App Mech 51(03), 656–687 (2019). https://doi.org/10.1002/adma.201601363

Shi, W.; Shi, W.; Li, Z.M.; et al.: Advances in negative Poisson’s ratio materials. Polym. Bull. 5(4), 293–296 (2003). https://doi.org/10.1002/adma.19930050416

Yang, Z.C.; Deng, Q.T.: Mechanical property and application of materials and structure with negative Poisson’s ratio. Adv Mech 41(03), 335–350 (2011)

Gibson, L.J.A.A.; Ashby, M.F.: Cellular Solids: Structure and Properties, pp. 1–13. Cambridge University Press, Cambridge (1997). https://doi.org/10.1017/CBO9781139878326

Evans, K.E.; Nkansah, M.A.; Hutchinson, I.J.: Auxetic foams: modelling negative Poisson’s ratios. Acta Metall. Mater. 42(4), 1289–1294 (1994). https://doi.org/10.1016/0956-7151(94)90145-7

Wan, H.; Ohtaki, H.; Kotosaka, S.; et al.: A study of negative Poisson’s ratios in auxetic honeycombs based on a large deflection model. Eur. J. Mech. A. Solids 23(1), 95–106 (2004). https://doi.org/10.1016/j.euromechsol.2003.10.006

Zhang, G.L.; Yang, D.Q.: Optimization design of an auxetic honeycomb isolator in a ship. J. Vib. Shock 32(22), 68–72+78 (2013)

Hiller, Jonathan; Lipson, Hod: Tunable digital material properties for 3D voxel printers. Rapid Prototyping J (2010). https://doi.org/10.1108/13552541011049252

Nkansah, M.A.; Evans, K.E.; Hutchinson, I.J.: Modelling the effects of negative Poisson’s ratios in continuous-fibre composites. J. Mater. Sci. 28(10), 2687–2692 (1993). https://doi.org/10.1007/bf00356204

Zhao, C.; Zhou, Z.; Liu, X.; et al.: The in-plane stretching and compression mechanics of negative Poisson’s ratio structures: concave hexagon, star shape, and their combination. J Alloys Compd (2020). https://doi.org/10.1016/j.jallcom.2020.157840

Bhardwaj, Preetam; Grace, Andrews Nirmala: Antistatic and microwave shielding performance of polythiophene-graphene grafted 3-dimensional carbon fibre composite. Diam. Relat. Mater. 106, 107871 (2020). https://doi.org/10.1016/j.diamond.2020.107871

Singh, B.P.; Bharadwaj, P.; Choudhary, V.; et al.: Enhanced microwave shielding and mechanical properties of multiwall carbon nanotubes anchored carbon fiber felt reinforced epoxy multiscale composites. Appl Nanosci 4(4), 421–428 (2014). https://doi.org/10.1007/s13204-013-0214-0

Zhao, C.F.; Zhou, Z.T.; Zhao, C.X.; et al.: Research on compression properties of unidirectional carbon fiber reinforced epoxy resin composite (UCFREP). J. Compos. Mater. (2020). https://doi.org/10.1177/0021998320972176

Du, X.; Zhou, H.; Sun, W.; et al.: Graphene/epoxy interleaves for delamination toughening and monitoring of crack damage in carbon fibre/epoxy composite laminates. Compos Sci Technol 140, 123–133 (2017). https://doi.org/10.1016/j.compscitech.2016.12.028

Sprenger, Stephan: Epoxy resin composites with surface-modified silicon dioxide nanoparticles: a review. J. Appl. Polym. Sci. 130(3), 1421–1428 (2013). https://doi.org/10.1002/app.39208

Tan, H.L.; He, Z.C.; Li, K.X.; et al.: In-plane crashworthiness of re-entrant hierarchical honeycombs with negative Poisson’s ratio. Compos. Struct. 229, 111415 (2019). https://doi.org/10.1016/j.compstruct.2019.111415

Li, J.J.; Tao, M.; Ye, H.F.: Anti-shock performance of honeycomb claddings with negative Poisson’s ratio subjected to UNDEX. J. Vib. Shock 38(21), 126–132 (2019). https://doi.org/10.13465/j.cnki.jvs.2019.21.018

Carneiro, V.H.; Puga, H.; Meireles, J.: Positive, zero and negative Poisson’s ratio non-stochastic metallic cellular solids: dependence between static and dynamic mechanical properties. Compos. Struct. 226, 111239 (2019). https://doi.org/10.1016/j.compstruct.2019.111239

Acknowledgements

The authors gratefully acknowledged the financial supports from the National Natural Science Foundation of China (No. 12002169), China Scholarship Council (No. 201906845017), Natural Science Foundation of Jiangsu Province of China (No. BK20170837) and Postgraduate Research & Practice Innovation Program of Jiangsu Province of China (No. KYCX19_0327, No. KYCX20_0306, No. KYCX20_0318).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Zhao, C., Zhou, Z., Zhang, K. et al. Experimental Study on Tensile Mechanics of Arrow Combination Structure with Carbon Fiber–Epoxy Resin Composite. Arab J Sci Eng 46, 2891–2900 (2021). https://doi.org/10.1007/s13369-020-05202-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-05202-1