Abstract

In the present era of Industry 4.0, organizations are transforming from traditional production systems to digital production systems. This transformation is in terms of additional deployment of technologies that lead to digitization and integration of products and services, business processes and customers, etc. A high volume of unstructured data is being created across different processes due to digitization. The digitization captures the data that includes text, images, multimedia, etc., due to multiplicity of platforms, e.g., machine-to-machine communications, sensors networks, cyber-physical systems, and Internet of Things. Managing this huge data generated from different sources has become a challenging task. Big data analytics (BDA) may be helpful in managing this unstructured data for effective decision making and sustainable operations. Many organizations are struggling to integrate BDA with their manufacturing processes for sustainable operations. The application of BDA from a sustainability perspective is not extensively researched in the current literature. Therefore, firstly this study explores the contribution of BDA in sustainable manufacturing operations. It further identifies strategic factors for the successful application of BDA in manufacturing for sustainable operations. For a detailed analysis of strategic factors in manufacturing, a hybrid approach comprising the analytic hierarchy process, fuzzy TOPSIS and DEMATEL is used. Results revealed that development of contract agreement among all stakeholders, engagement of top management, capability to handle big data, availability of quality and reliable data, developing team of knowledgeable, and capable decision-makers have emerged as major strategic factors for the application of BDA in the manufacturing sector for sustainable operations. Major contribution of this study is in analyzing BDA benefits for manufacturing sector, identifying major strategic factors in implementation and categorization of these factors into cause and effect group. These findings may be used by managers as guidelines for successful implementation of BDA across different functions in their respective organization to achieve sustainable operations goal. The results of this study will also motivate industry professionals to integrate BDA with their manufacturing functions for effective decision making and sustainable operations.

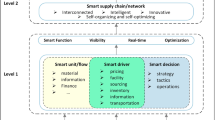

Graphic abstract

Similar content being viewed by others

Data availability

The data that support the findings of this study are collected through the expert’s opinion and available in Appendix.

References

Agrawal S, Singh RK, Murtaza Q (2016) Prioritizing critical success factors for reverse logistics implementation using fuzzy-TOPSIS methodology. J Ind Eng Int 12:15–27. https://doi.org/10.1007/s40092-015-0124-8

Altuntas S, Dereli T (2015) A novel approach based on DEMATEL method and patent citation analysis for prioritizing a portfolio of investment projects. Expert Syst Appl 42:1003–1012. https://doi.org/10.1016/j.eswa.2014.09.018

Amui LBL, Jabbour CJC, de Sousa Jabbour ABL, Kannan D (2017) Sustainability as a dynamic organizational capability: a systematic review and a future agenda toward a sustainable transition. J Clean Prod 142:308–322. https://doi.org/10.1016/j.jclepro.2016.07.103

Bag S, Wood LC, Xu L et al (2020) Big data analytics as an operational excellence approach to enhance sustainable supply chain performance. Resour Conserv Recycl 153:104559. https://doi.org/10.1016/j.resconrec.2019.104559

Barlow M (2013) Real-time big data analytics: emerging architecture. O’Reilly Media, Sebastopol, USA

Belhadi A, Zkik K, Cherrafi A et al (2019) Understanding Big Data Analytics for manufacturing processes: insights from literature review and multiple case studies. Comput Ind Eng 137:106099. https://doi.org/10.1016/j.cie.2019.106099

Bi Z, Cochran D (2014) Big data analytics with applications. J Manag Anal 1:249–265. https://doi.org/10.1080/23270012.2014.992985

Braganza A, Brooks L, Nepelski D et al (2017) Resource management in big data initiatives: Processes and dynamic capabilities. J Bus Res 70:328–337. https://doi.org/10.1016/j.jbusres.2016.08.006

Brinch M, Stentoft J, Jensen JK (2017) Big data and its applications in supply chain management: findings from a delphi study. Hawaii Int Conf Syst Sci. https://doi.org/10.24251/HICSS.2017.161

Chen M, Mao S, Liu Y (2014) Big data: a survey. Mob Networks Appl 19:171–209. https://doi.org/10.1007/s11036-013-0489-0

Cui Y, Kara S, Chan KC (2020) Manufacturing big data ecosystem: a systematic literature review. Robot Comput Integr Manuf 62:101861. https://doi.org/10.1016/j.rcim.2019.101861

Das R, Shaw K, Irfan M (2020) Supply chain network design considering carbon footprint, water footprint, supplier’s social risk, solid waste, and service level under the uncertain condition. Clean Technol Environ Policy 22:337–370. https://doi.org/10.1007/s10098-019-01785-y

de Camargo FP, Roman Pais Seles BM, Chiappetta Jabbour CJ et al (2018) Management theory and big data literature: from a review to a research agenda. Int J Inf Manage 43:112–129. https://doi.org/10.1016/j.ijinfomgt.2018.07.005

Del Fabbro E, Santarossa D (2016) Ergonomic Analysis in Manufacturing Process A real time approach. Procedia CIRP 41:957–962. https://doi.org/10.1016/j.procir.2015.12.056

Demirkan H, Delen D (2013) Leveraging the capabilities of service-oriented decision support systems: Putting analytics and big data in cloud. Decis Support Syst 55:412–421. https://doi.org/10.1016/j.dss.2012.05.048

Doolun IS, Ponnambalam SG, Subramanian N, G K, (2018) Data driven hybrid evolutionary analytical approach for multi objective location allocation decisions: automotive green supply chain empirical evidence. Comput Oper Res 98:265–283. https://doi.org/10.1016/j.cor.2018.01.008

Duan Y, Edwards JS, Dwivedi YK (2019) Artificial intelligence for decision making in the era of big data–evolution, challenges and research agenda. Int J Inf Manage 48:63–71. https://doi.org/10.1016/j.ijinfomgt.2019.01.021

Dubey R, Gunasekaran A, Childe SJ et al (2016) The impact of big data on world-class sustainable manufacturing. Int J Adv Manuf Technol 84:631–645. https://doi.org/10.1007/s00170-015-7674-1

Dubey R, Gunasekaran A, Childe SJ et al (2019a) Big data analytics and organizational culture as complements to swift trust and collaborative performance in the humanitarian supply chain. Int J Prod Econ 210:120–136. https://doi.org/10.1016/j.ijpe.2019.01.023

Dubey R, Gunasekaran A, Childe SJ et al (2019b) Empirical investigation of data analytics capability and organizational flexibility as complements to supply chain resilience. Int J Prod Res. https://doi.org/10.1080/00207543.2019.1582820

Elgendy N, Elragal A (2014) Big data analytics: a literature review paper. pp 214–227

ElMaraghy HA, Youssef AMA, Marzouk AM, ElMaraghy WH (2017) Energy use analysis and local benchmarking of manufacturing lines. J Clean Prod 163:36–48. https://doi.org/10.1016/j.jclepro.2015.12.026

Fercoq A, Lamouri S, Carbone V (2016) Lean/green integration focused on waste reduction techniques. J Clean Prod 137:567–578. https://doi.org/10.1016/j.jclepro.2016.07.107

Gandhi S, Mangla SK, Kumar P, Kumar D (2015) Evaluating factors in implementation of successful green supply chain management using DEMATEL: a case study. Int Strateg Manag Rev 3:96–109. https://doi.org/10.1016/j.ism.2015.05.001

Gandomi A, Haider M (2015) Beyond the hype: big data concepts, methods, and analytics. Int J Inf Manage 35:137–144. https://doi.org/10.1016/j.ijinfomgt.2014.10.007

Gawankar SA, Gunasekaran A, Kamble S (2020) A study on investments in the big data-driven supply chain, performance measures and organisational performance in Indian retail 4.0 context. Int J Prod Res 58:1574–1593. https://doi.org/10.1080/00207543.2019.1668070

Gong M, Simpson A, Koh L, Tan KH (2018) Inside out: The interrelationships of sustainable performance metrics and its effect on business decision making: Theory and practice. Resour Conserv Recycl 128:155–166. https://doi.org/10.1016/j.resconrec.2016.11.001

Gunasekaran A, Papadopoulos T, Dubey R et al (2017) Big data and predictive analytics for supply chain and organizational performance. J Bus Res 70:308–317. https://doi.org/10.1016/j.jbusres.2016.08.004

Gupta A, Singh RK, Suri PK (2018) Prioritizing critical success factors for sustainable service quality management by logistics service providers. Vis J Bus Perspect 22:295–305. https://doi.org/10.1177/0972262918786102

Gupta S, Modgil S, Gunasekaran A (2020) Big data in lean six sigma: a review and further research directions. Int J Prod Res 58:947–969. https://doi.org/10.1080/00207543.2019.1598599

Hazen BT, Skipper JB, Ezell JD, Boone CA (2016) Big data and predictive analytics for supply chain sustainability: a theory-driven research agenda. Comput Ind Eng 101:592–598. https://doi.org/10.1016/j.cie.2016.06.030

Hidayanto AN, Abednego N, Aminah S, Sucahyo YG (2015) Analysis of cloud adoption determinants by using BOCR analysis and DEMATEL. Int J Bus Inf Syst 18:221. https://doi.org/10.1504/IJBIS.2015.067265

Ivanov D, Dolgui A, Sokolov B (2019) The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. Int J Prod Res 57:829–846. https://doi.org/10.1080/00207543.2018.1488086

Janssen M, van der Voort H, Wahyudi A (2017) Factors influencing big data decision-making quality. J Bus Res 70:338–345. https://doi.org/10.1016/j.jbusres.2016.08.007

Ji-fan Ren S, Fosso Wamba S, Akter S et al (2017) Modelling quality dynamics, business value and firm performance in a big data analytics environment. Int J Prod Res 55:5011–5026. https://doi.org/10.1080/00207543.2016.1154209

Kalema BM, Mokgadi M (2017) Developing countries organizations readiness for big data analytics. Probl Perspect Manag 15:260–270. https://doi.org/10.21511/ppm.15(1-1).2017.13

Kim G, Park CS, Yoon KP (1997) Identifying investment opportunities for advanced manufacturing systems with comparative-integrated performance measurement. Int J Prod Econ 50:23–33. https://doi.org/10.1016/S0925-5273(97)00014-5

Kumar P, Singh RK (2012) A fuzzy AHP and TOPSIS methodology to evaluate 3PL in a supply chain. J Model Manag 7:287–303. https://doi.org/10.1108/17465661211283287

Lavalle S, Lesser E, Shockley R, Hopkins MS, Kruschwitz N (2011) Big data, analytics and the path from insights to value. MIT Sloan Manag Review 52:21–32

Lee I (2017) Big data: dimensions, evolution, impacts, and challenges. Bus Horiz 60:293–303. https://doi.org/10.1016/j.bushor.2017.01.004

Lee J, Lapira E, Bagheri B, Kao H (2013) Recent advances and trends in predictive manufacturing systems in big data environment. Manuf Lett 1:38–41. https://doi.org/10.1016/j.mfglet.2013.09.005

Lee J, Ardakani HD, Yang S, Bagheri B (2015) Industrial big data analytics and cyber-physical systems for future maintenance and service innovation. Procedia CIRP 38:3–7. https://doi.org/10.1016/j.procir.2015.08.026

Li J, Tao F, Cheng Y, Zhao L (2015) Big data in product lifecycle management. Int J Adv Manuf Technol 81:667–684. https://doi.org/10.1007/s00170-015-7151-x

Lima Junior FR, Osiro L, Carpinetti LCR (2014) A comparison between fuzzy AHP and fuzzy TOPSIS methods to supplier selection. Appl Soft Comput 21:194–209. https://doi.org/10.1016/j.asoc.2014.03.014

Lin R-J (2013) Using fuzzy DEMATEL to evaluate the green supply chain management practices. J Clean Prod 40:32–39. https://doi.org/10.1016/j.jclepro.2011.06.010

Lin K-P, Tseng M-L, Pai P-F (2018) Sustainable supply chain management using approximate fuzzy DEMATEL method. Resour Conserv Recycl 128:134–142. https://doi.org/10.1016/j.resconrec.2016.11.017

Luthra S, Govindan K, Kharb RK, Mangla SK (2016) Evaluating the enablers in solar power developments in the current scenario using fuzzy DEMATEL: an Indian perspective. Renew Sustain Energy Rev 63:379–397. https://doi.org/10.1016/j.rser.2016.04.041

Manavalan E, Jayakrishna K (2019) A review of Internet of Things (IoT) embedded sustainable supply chain for industry 4.0 requirements. Comput Ind Eng 127:925–953. https://doi.org/10.1016/j.cie.2018.11.030

Mangla SK, Luthra S, Rich N et al (2018) Enablers to implement sustainable initiatives in agri-food supply chains. Int J Prod Econ 203:379–393. https://doi.org/10.1016/j.ijpe.2018.07.012

Munirathinam S, Ramadoss B (2014) Big data predictive analytics for proactive semiconductor equipment maintenance. In: 2014 IEEE international conference on big data (big data). IEEE, pp 893–902

Mustapha MA, Manan ZA, Wan Alwi SR (2017) Sustainable Green Management System (SGMS)–an integrated approach towards organisational sustainability. J Clean Prod 146:158–172. https://doi.org/10.1016/j.jclepro.2016.06.033

Piyathanavong V, Garza-Reyes JA, Kumar V et al (2019) The adoption of operational environmental sustainability approaches in the Thai manufacturing sector. J Clean Prod 220:507–528. https://doi.org/10.1016/j.jclepro.2019.02.093

Popovič A, Hackney R, Tassabehji R, Castelli M (2018) The impact of big data analytics on firms’ high value business performance. Inf Syst Front 20:209–222. https://doi.org/10.1007/s10796-016-9720-4

Raut RD, Mangla SK, Narwane VS et al (2019) Linking big data analytics and operational sustainability practices for sustainable business management. J Clean Prod 224:10–24. https://doi.org/10.1016/j.jclepro.2019.03.181

Saaty TL (1980) The analytic hierarchy process. McGraw-Hill, New York, p 324

Saaty TL (2000) Fundamentals of decision making and priority theory with the analytic hierarchy process. Vol. 6 RWS publications

Samaie F, Javadi S, Meyar-Naimi H, Feshki-Farahani H (2020) Environmental sustainability policy on plug-in hybrid electric vehicle penetration utilizing fuzzy TOPSIS and game theory. Clean Technol Environ Policy. https://doi.org/10.1007/s10098-020-01821-2

Sanders NR (2016) How to use big data to drive your supply chain. Calif Manage Rev 58:26–48. https://doi.org/10.1525/cmr.2016.58.3.26

Singh RK (2012) Justification of coordinated supply chain in small and medium enterprises using analytic hierarchy process. Int J Serv Sci 4:277. https://doi.org/10.1504/IJSSCI.2012.051062

Singh RK (2013) Prioritizing the factors for coordinated supply chain using analytic hierarchy process (AHP). Meas Bus Excell 17:80–97. https://doi.org/10.1108/13683041311311383

Singh RK, Agrawal S (2018) Analyzing disposition strategies in reverse supply chains: fuzzy TOPSIS approach. Manag Environ Qual An Int J 29:427–443. https://doi.org/10.1108/MEQ-12-2017-0177

Singh SK, El-Kassar A-N (2019) Role of big data analytics in developing sustainable capabilities. J Clean Prod 213:1264–1273. https://doi.org/10.1016/j.jclepro.2018.12.199

Singh RK, Luthra S, Mangla SK, Uniyal S (2019) Applications of information and communication technology for sustainable growth of SMEs in India food industry. Resour Conserv Recycl 147:10–18. https://doi.org/10.1016/j.resconrec.2019.04.014

Song M, Fisher R, Kwoh Y (2019) Technological challenges of green innovation and sustainable resource management with large scale data. Technol Forecast Soc Change 144:361–368. https://doi.org/10.1016/j.techfore.2018.07.055

Tan J, Tan RR, Aviso KB et al (2017) Study of microalgae cultivation systems based on integrated analytic hierarchy process–life cycle optimization. Clean Technol Environ Policy 19:2075–2088. https://doi.org/10.1007/s10098-017-1390-5

Tao F, Cheng J, Qi Q et al (2018) Digital twin-driven product design, manufacturing and service with big data. Int J Adv Manuf Technol 94:3563–3576. https://doi.org/10.1007/s00170-017-0233-1

Telukdarie A, Buhulaiga E, Bag S et al (2018) Industry 4.0 implementation for multinationals. Process Saf Environ Prot 118:316–329. https://doi.org/10.1016/j.psep.2018.06.030

Tseng M-L, Lim MK, Wu K-J (2019) Improving the benefits and costs on sustainable supply chain finance under uncertainty. Int J Prod Econ 218:308–321. https://doi.org/10.1016/j.ijpe.2019.06.017

Wamba SF, Dubey R, Gunasekaran A, Akter S (2020) The performance effects of big data analytics and supply chain ambidexterity: the moderating effect of environmental dynamism. Int J Prod Econ 222:107498. https://doi.org/10.1016/j.ijpe.2019.09.019

Wang Z, Xue M, Wang Y et al (2019) Big data: new tend to sustainable consumption research. J Clean Prod 236:117499. https://doi.org/10.1016/j.jclepro.2019.06.330

Weerakkody V, Kapoor K, Balta ME et al (2017) Factors influencing user acceptance of public sector big open data. Prod Plan Control 28:891–905. https://doi.org/10.1080/09537287.2017.1336802

Wilcox T, Jin N, Flach P, Thumim J (2019) A big data platform for smart meter data analytics. Comput Ind 105:250–259. https://doi.org/10.1016/j.compind.2018.12.010

Wood LC, Wang C, Abdul-Rahman H, Jamal Abdul-Nasir NS (2016) Green hospital design: integrating quality function deployment and end-user demands. J Clean Prod 112:903–913. https://doi.org/10.1016/j.jclepro.2015.08.101

Yaqoob I, Hashem IAT, Gani A et al (2016) Big data: from beginning to future. Int J Inf Manage 36:1231–1247. https://doi.org/10.1016/j.ijinfomgt.2016.07.009

Zhong RY, Huang GQ, Lan S et al (2015) A big data approach for logistics trajectory discovery from RFID-enabled production data. Int J Prod Econ 165:260–272. https://doi.org/10.1016/j.ijpe.2015.02.014

Zhong RY, Newman ST, Huang GQ, Lan S (2016) Big Data for supply chain management in the service and manufacturing sectors: Challenges, opportunities, and future perspectives. Comput Ind Eng 101:572–591. https://doi.org/10.1016/j.cie.2016.07.013

Zimmermann H-J (1985) Applications of fuzzy set theory to mathematical programming. Inf Sci (Ny) 36:29–58. https://doi.org/10.1016/0020-0255(85)90025-8

Funding

There has been no financial support for this work that could have influenced its outcome.

Author information

Authors and Affiliations

Contributions

All authors contributed extensively to the work presented in this paper.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

See Table

12.

Appendix 2

See Table

13.

Appendix 3

Let P1 be the pairwise comparison matrix and P2 principal vector matrix.

\(\lambda \max ,\) Average of the element of P4 = 7.7481.

Now, consistency Index (CI) = \(\frac{\lambda \max - n}{{n - 1}}\) = (7.7481–7)/(7–1) = 0.12468.

And, consistency ratio (CR) = CI/RCI = (n Appendix 2).

CR = 0.12468/1.35 0.0923, i.e., CR < 0.1. So, result is consistent.

Appendix 4

See Table

14.

Appendix 5

See Table

15.

Appendix 6

See Table

16.

Appendix 7

See Table

17.

Appendix 8

See Table

18.

Appendix 9

Variable used in the article.

AHP Methodology

P1 = Pairwise comparison matrix

P2 = Principal matrix

λmax = Average of the elements of P4.

CI = Consistency index.

CR = Consistency Ratio.

RCI = random consistency Index.

n = Number of elements.

PV = priority Vector.

Fuzzy TOPSIS Methodology

A+ = Fuzzy ideal solution.

A− = Fuzzy negative ideal solution.

Yij = (dij, eij, and fij) = Triangular fuzzy number for the linguistic term.

\(c_{{j^{*} }}^{*}\) and \(d_{j}^{ - }\) = Benefit criteria and cost criteria respectively.

W = Weight of criteria.

V* and V− = Values considered for the ideal and negative ideal solution.

g, h, and i = aThe real numbers.

D+ = Distance between to fuzzy numbers.

D− = Distance of rating.

C = Closeness the ideal solution.

DEMATEL Methodology

Z = Average matrix.

xij = Elements of average matrix.

N = Normalized initial direct-relation matrix.

nij = Elements of normalized initial direct-relation matrix.

Y = Total relation matrix.

I = Identity matrix.

Rights and permissions

About this article

Cite this article

Kumar, N., Kumar, G. & Singh, R.K. Big data analytics application for sustainable manufacturing operations: analysis of strategic factors. Clean Techn Environ Policy 23, 965–989 (2021). https://doi.org/10.1007/s10098-020-02008-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-020-02008-5